Let’s be honest, that feeling of driving a brand-new car off the lot is electric. The paint is perfect—impossibly deep, glossy, and just flawless. But give it a year. That showroom shine often becomes a distant memory, dulled by sun, scarred by tiny scratches, and worn down by the daily grind. This isn’t just you; it’s the tough reality for modern automotive paint.

Why Your Car’s Paint Needs a Modern Shield

Today’s vehicle finishes look incredible, but they’re surprisingly fragile. They’re constantly under attack from UV rays that cause fading, acidic rain that etches the surface, bird droppings, and all sorts of road grime. For decades, the go-to answer was a good coat of wax. But waxing is a temporary solution at best.

Think of it as a fleeting moment of gloss that washes away in a few weeks, leaving your paint completely exposed all over again.

The Old Way Just Doesn’t Cut It

This endless cycle of applying wax, watching it fade, and reapplying it is frustrating, time-consuming, and ultimately, not a real long-term defense. Waxes and traditional sealants just sit on top of the paint. They provide a weak sacrificial layer that breaks down incredibly fast, forcing car owners into a constant battle to protect their investment with products that deliver short-lived results.

This is exactly the problem that modern ceramic coatings were engineered to solve.

A truly modern shield shouldn’t just offer a temporary gloss; it must create a durable, resilient barrier that becomes part of the vehicle itself. This is where the leap from waxing to coating technology becomes a game-changer for car care.

A New Era of Paint Preservation

So, what exactly is a ceramic coating? Forget everything you know about wax. Imagine giving your car a flexible, ultra-hard, glass-like shield that doesn’t just sit on the paint but chemically fuses with it, becoming one. That’s what a high-quality coating delivers. It’s not just another product you apply; it’s a genuine, semi-permanent upgrade to your vehicle’s exterior.

Here at Titan Coatings, we looked at the first generation of rigid, brittle coatings and knew there had to be a better way. We pioneered a new path, becoming the first company to introduce Elastomer coatings to the market, powered by our groundbreaking Dark Matter Tech® using nano tubes technology. This isn’t your average coating; it creates a shield that is not only tough as nails but also incredibly flexible.

That flexibility is the secret sauce. Your car’s metal panels are always expanding in the heat and contracting in the cold. Traditional, rigid coatings can’t handle that stress and develop micro-cracks, compromising the protection. Titan’s elastic technology moves with the vehicle, ensuring the protective layer stays intact for years, not months. The coating won’t crack down due to temperature changes between frozen winters and hot summers because it is hard like glass and flexible, a quality that makes it last much longer.

Protecting your car’s finish is one of the smartest ways to maintain its value. While a quality coating is a huge part of preserving its appearance, it’s also good to know that after an accident, you may need to understand what a diminished value claim is to handle any potential loss in resale value. For a deeper dive into safeguarding your vehicle’s exterior, you can learn more about how to protect car paint in our complete guide.

How Do Automotive Ceramic Coatings Actually Work?

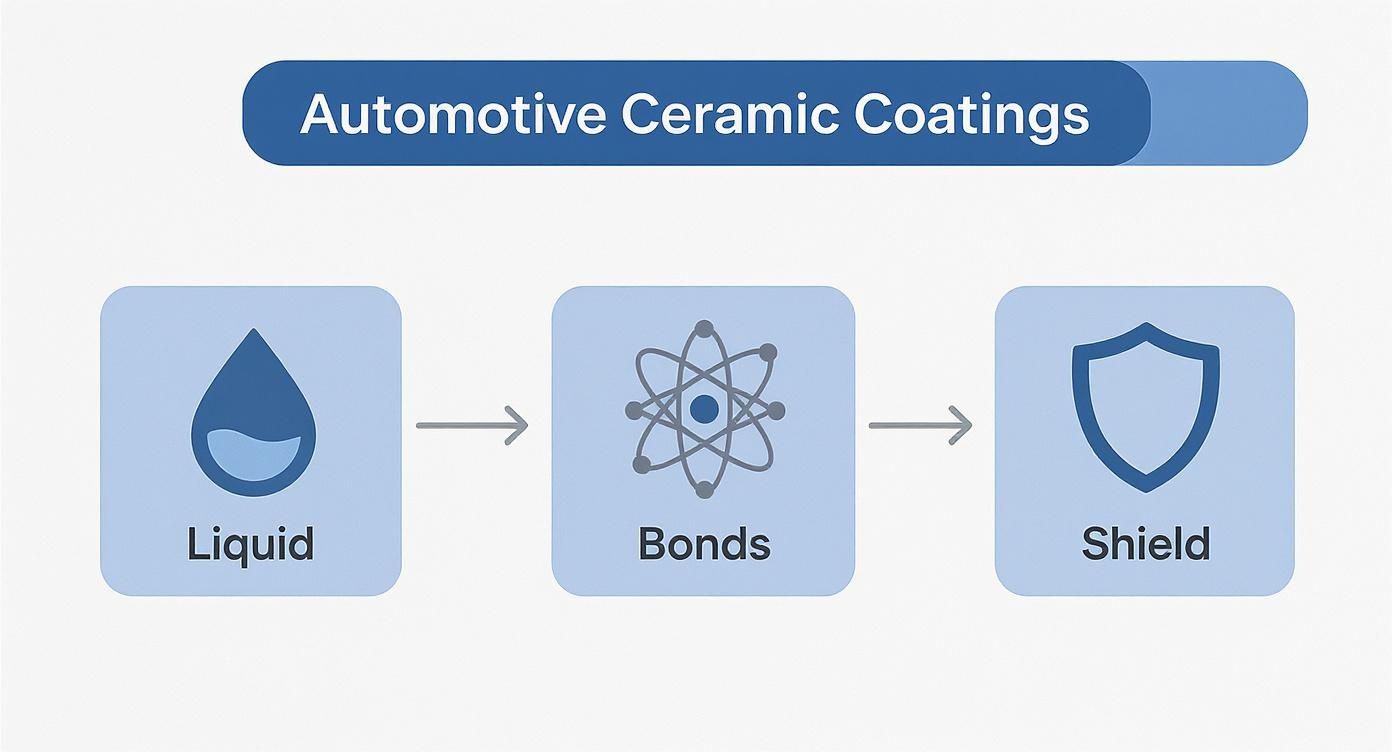

Forget everything you think you know about wax. A true ceramic coating isn’t just a shiny layer that sits on top of your paint—it’s a liquid-polymer that creates a powerful chemical bond with your vehicle’s factory clear coat. The process forms an incredibly durable, completely transparent, and semi-permanent shield.

Imagine you’re laminating your car with a microscopic layer of flexible glass. This new, sacrificial layer becomes the primary barrier against the outside world, taking all the abuse so your original paint doesn’t have to.

The Science Behind the Bond

The secret ingredient in most high-quality ceramic coatings is Silicon Dioxide (SiO2), the same core component found in natural quartz and glass. When the liquid is applied to a perfectly prepped surface, a chemical reaction called covalent bonding takes place. The coating doesn’t just sit there; it physically integrates with the clear coat, filling in every microscopic pore to create a perfectly smooth, uniform surface.

This bond is what makes a ceramic coating so tough and long-lasting. While a traditional wax might wash away after a few weeks, this chemically bonded layer can stand up to harsh detergents, bird droppings, and intense weather for years.

The real magic of a ceramic coating is its ability to turn a porous, vulnerable paint job into a slick, non-porous shield. This fundamental change is what creates that signature deep gloss and relentless protection.

From Hardness to Hydrophobics

All the benefits you see are a direct result of this chemical transformation. The high concentration of SiO2 creates a surface that’s substantially harder than your car’s factory clear coat, giving it impressive resistance to the fine scratches and swirl marks that happen during routine washing.

At the same time, this new ultra-slick surface becomes intensely hydrophobic, which is a fancy way of saying it repels water like you wouldn’t believe. Instead of water clinging and causing spots, it beads up into tight little spheres and rolls right off the panel, taking dirt and dust along for the ride. This self-cleaning property is easily one of the most satisfying What Is Ceramic Coating: A Complete Guide.

The Titan Coatings Evolution: A Story of Flexible Protection

Years ago, a car fanatic named Mike was obsessed with keeping his prized vehicle perfect. He had a top-of-the-line ceramic coating installed, expecting it to last for years. But after a year of brutal winters and blazing hot summers, he started seeing tiny, web-like cracks spidering across the finish. The coating was too rigid—it couldn’t expand and contract with the car’s metal panels, so it simply failed.

This exact problem lit a fire under our team at Titan Coatings. We knew hardness wasn’t the whole story. Real-world durability demanded flexibility. This led us to a genuine breakthrough: we became the first company to pioneer Elastomer coatings, built on our proprietary nano tubes technology and Dark Matter Tech®.

Our coatings are engineered to be hard like glass yet flexible like rubber. This unique elasticity allows them to move with your vehicle’s body as it cycles through extreme temperatures, preventing the micro-cracking that dooms traditional, brittle coatings. This resilience is precisely why our coatings last so much longer, providing a shield that truly endures. This kind of innovation is driving massive growth—the global ceramic coatings market was valued at USD 12.15 billion in 2024 and is projected to hit USD 25.60 billion by 2034, with cars leading the way.

By fusing hardness with flexibility, we’ve set a new standard for paint protection. To see all the advantages this technology brings to the table, take a look at our guide on the primary ceramic coating benefits for your vehicle.

The Evolution to Flexible Elastomer Coatings

For years, the detailing world chased one thing: hardness. Traditional ceramic coatings were all about creating a tough, shell-like layer of protection, and the harder, the better—or so we thought. But this obsession with rigidity ignored a simple, fundamental truth about cars. They move.

A vehicle’s body panels are in a constant state of flux. They swell under the blistering summer sun and shrink in a winter freeze. This constant thermal expansion and contraction puts an incredible amount of stress on whatever is sitting on the paint’s surface. For a standard, rigid ceramic coating, this movement is its kryptonite.

Over time, this repeated stress causes microscopic cracks to form in the coating. You can’t see them at first, but these tiny fissures are a huge problem. They break the seal, allowing water, chemicals, and grime to sneak through and attack the clear coat underneath. It was a frustrating limitation that capped the true long-term potential of paint protection.

A New Approach Inspired by a Common Flaw

The next leap forward started with a simple observation: hardness alone isn’t enough. True, real-world durability demands resilience. This realization became the core of Titan Coatings’ mission to build something better. We looked at the failings of brittle coatings and asked a simple question: what if a coating could be as hard as glass but as flexible as rubber?

That question led our team to create an entirely new category in the industry. We became the first company to introduce Elastomer coatings to the market, a game-changing innovation built on our proprietary nano tubes technology and Dark Matter Tech®. This wasn’t just another incremental improvement; it was a total reimagining of what a ceramic coating could do.

The diagram below shows the basic journey of how a liquid polymer transforms into a protective shield on your car’s paint—a process our elastomer technology takes to a whole new level.

Combining Hardness with Unbelievable Flexibility

Our unique Elastomer coatings are engineered to give you the best of both worlds. They deliver that slick, glossy, hard-as-nails surface everyone wants from a top-tier ceramic coating, but with a crucial difference—they can stretch and move right along with the vehicle.

By infusing a rubber-like elasticity at the molecular level, we created a coating that flexes with the vehicle’s panels. It expands in the heat and contracts in the cold without cracking, ensuring the protective barrier remains completely sealed and uncompromised.

This adaptability is what makes Titan’s technology a true breakthrough. Where rigid coatings crack under pressure, our elastomer-based formulas endure. The result is dramatically longer-lasting protection that maintains that deep gloss and unbelievable water beading for years, not just a few seasons. Whether you’re dealing with a frozen winter morning or a scorching summer afternoon, the coating won’t break down.

You can dive deeper into what makes Titan Coatings’ Elastomer technology unique and see how it completely redefines durability.

To push this technology even further, we developed Dark Matter Tech®. Think of it as a reinforcing web woven into the elastomer matrix, massively boosting its structural integrity. This enhances chemical resistance, thermal stability, and overall toughness far beyond what standard SiO₂ formulas can even hope to achieve. This fusion of flexibility and reinforced strength creates a shield so resilient it offers a level of protection we once thought was impossible.

Introducing Titan Vulcan TX155

All that hard work developing flexible, resilient coatings wasn’t just for theory. It led us directly here, to our flagship product: Titan Vulcan TX155. This isn’t just another ceramic coating—it’s the culmination of everything we’ve learned about elastomer chemistry and molecular reinforcement, bottled up and ready to protect your vehicle.

Think of it as a living shield for your paint. We engineered Vulcan TX155 to produce a breathtaking, liquid-like gloss that makes paint look impossibly deep. But its stunning looks are backed by some serious muscle.

The second water hits a panel coated with Vulcan, you’ll witness its extreme hydrophobic power. Water beads up and practically leaps off the surface, meaning your car stays cleaner for longer and washing becomes a breeze.

The Power of Dark Matter Technology

The real magic behind Vulcan TX155 is our proprietary Dark Matter Technology®, infused into its flexible elastomer structure. This isn’t just a fancy name—it’s a nano-scale reinforcement system that creates an incredibly dense, cross-linked bond with your paint. The result is superior resistance to harsh chemicals, UV damage, and everyday grime.

While the elastomer gives the coating its flexibility to expand and contract without cracking, Dark Matter Tech® provides the raw strength to handle the abuse. This one-two punch is what makes Vulcan TX155 such a formidable guardian for any vehicle. As more car owners demand this level of protection, the automotive ceramic coatings market is expected to reach USD 2.5 billion by 2025, growing at a steady 12% each year through 2033. You can dive deeper into the full research about these automotive trends.

A Clear Advantage Over the Competition

When you compare Vulcan TX155 to old-school ceramic coatings, the difference is night and day. Traditional products often chase hardness at the expense of flexibility, which can lead them to become brittle and fail prematurely. Vulcan TX155 simply doesn’t make that compromise.

For a clearer picture, let’s break down how Titan’s elastomer-based technology in Vulcan TX155 stacks up against the rigid ceramics of the past.

Titan Vulcan TX155 vs Traditional Ceramic Coatings

| Feature | Traditional Ceramic Coating | Titan Vulcan TX155 with Elastomer Tech |

|---|---|---|

| Material Structure | Rigid, crystalline structure. Similar to glass. | Flexible, rubber-like polymer matrix. |

| Durability | Prone to micro-fracturing from vibrations and temperature changes. | Absorbs impacts and flexes, preventing cracks and failure. |

| Self-Healing | No inherent self-regenerating ability. Scratches are permanent. | Minor swirls and scratches can self-heal with heat. |

| Chemical Resistance | Good, but can be compromised by stress fractures. | Excellent. The flexible surface seals out contaminants more effectively. |

| Application | Can be unforgiving and prone to high-spotting. | More user-friendly application with a smoother feel. |

| Finish | Hard, candy-like gloss. | Deep, liquid-like gloss with a slick, velvety feel. |

The table makes it obvious: Vulcan TX155 is simply a more advanced, more resilient solution built for the real world.

Vulcan TX155 achieves the perfect balance: the hardness of glass with the flexibility of rubber. It’s built not just to survive the elements, but to thrive in them, offering self-regenerating properties that actively resist fine scratches to keep the finish looking perfect.

For detailers and car owners who refuse to settle for second best, the choice is clear. You can explore our full comparison of our products to see exactly why Vulcan TX155 sits at the top of our shop.

Ready to see for yourself? Discover what makes Titan Vulcan TX155 the definitive choice for those who demand ultimate protection and an unbeatable finish.

Why Professional Application Is Everything

Getting your hands on a top-tier automotive ceramic coating like Titan Vulcan TX155 is only the first step. The second, and frankly more important, step is the application. A product this sophisticated isn’t just wiped on and off; unlocking its true potential demands a level of skill and surface preparation that only a trained professional can deliver.

To get that permanent, glass-like bond that makes Titan coatings so legendary, the vehicle’s surface has to be surgically clean and absolutely perfect. We’re talking about a level of prep that goes far beyond a weekend wash. Even a car straight off the showroom floor has hidden flaws in its paint—tiny contaminants, brake dust, and faint swirls that are invisible to the naked eye but will absolutely kill a coating’s ability to bond properly.

The Art of Flawless Surface Prep

A certified professional detailer doesn’t just see paint; they see a canvas that needs to be perfected before the final masterpiece can be applied. This isn’t just cleaning. It’s a deep, multi-stage restoration process that builds the perfect foundation for the coating to fuse with.

This painstaking prep work always includes a few critical stages:

- Decontamination: This is a chemical and mechanical deep clean. Using iron removers and clay bars, a detailer pulls out all the embedded gunk—from industrial fallout to stubborn tar—that has worked its way into the clear coat.

- Paint Correction: Here’s where the magic happens. Through multiple stages of compounding and polishing, every last swirl mark, light scratch, and imperfection is carefully erased from the paint. This is what creates that stunning, liquid-like gloss that ceramic coatings make pop.

Only when the paint is 100% perfect is it ready for the final wipe-down and coating. This obsessive attention to detail is what separates a decent job from a jaw-dropping one.

An Investment in Performance, Not an Expense

Thinking of professional application as just another cost is missing the point entirely—it’s the best insurance policy you can get for your investment. You wouldn’t put a priceless work of art in a flimsy frame, right? The same principle applies here. The flawless canvas created by a professional ensures the automotive ceramic coatings grab on with maximum force, giving you the best possible durability, water beading, and shine.

The demand for this level of quality is exploding. The global automotive ceramics market, which includes these advanced coatings, is expected to jump from USD 2.19 billion in 2025 to USD 2.97 billion by 2030. You can discover more insights about this automotive market growth and see for yourself why premium protection is becoming the new standard.

Trying to save a few bucks by skipping professional prep is a classic mistake. It’s like building a beautiful house on a crumbling foundation—it’s only a matter of time before it fails. A pro installer ensures that foundation is rock-solid.

At the end of the day, trusting your vehicle to a certified installer is the only way to guarantee you get the head-turning results and long-term performance that Titan’s flexible, hard-wearing coatings were designed for. For detailers ready to provide this elite service, checking out our line of professional ceramic coating products is the first step toward becoming a master of perfect, lasting protection.

Keeping Your Ceramic Coating in Top Shape is Easier Than You Think

Let’s clear the air on a common myth: ceramic coatings are not some kind of magical force field that repels all dirt forever. While the tech is seriously impressive, your car will still need a good wash. The real magic is in how ridiculously easy that wash becomes.

Imagine your car’s factory paint is like a rugged, porous surface—a perfect place for dirt and grime to dig in and hold on for dear life. A Titan-coated surface is the complete opposite. It’s so slick and non-porous that contaminants have almost nothing to grab onto. This simple fact changes car washing from a back-breaking chore into a quick, almost effortless task.

A New, Simpler Way to Wash Your Car

The incredible hydrophobicity of a ceramic coating does most of the work for you. Water beads up and sheets off, taking dirt, dust, and road grime along for the ride. This means you can get your car sparkling clean with far less effort, which also dramatically cuts down the risk of accidentally causing swirl marks and light scratches during the wash.

To get the most out of your coating for years to come, a few simple habits make all the difference:

- Stick with pH-Neutral Shampoo: Aggressive soaps with high acid or alkaline levels can slowly eat away at your coating. A good, pH-neutral car wash soap is all you need to lift dirt effectively without harming the protective layer.

- Embrace the Two-Bucket Wash: This is a non-negotiable for pro detailers, and for good reason. One bucket is for your soapy water, the other for clean rinse water. Dunking your wash mitt in the rinse bucket first removes trapped grit, so you aren’t dragging it all over your paint.

- Steer Clear of Abrasive Car Washes: Those giant spinning brushes at automated car washes are a nightmare for your paint. They’re often loaded with grit from hundreds of other cars and can easily inflict scratches. If you must use an automatic wash, stick to touchless options. A gentle hand wash, though, is always best.

A ceramic coating doesn’t mean you never have to wash your car again. It means the process is faster, safer, and more effective. It turns a high-effort scrub into a low-effort rinse, protecting your car from the very act of cleaning it.

Following these simple rules will keep your coating glossy, slick, and hydrophobic for the long haul. A good wash routine is all about removing the stuff you don’t want (contaminants) without adding anything you don’t want (scratches). Your coating just makes that goal easier to achieve than ever before.

Want the full playbook? We’ve laid out the entire process step-by-step. Dive deeper into our comprehensive guide on how to maintain your ceramic coating to keep it performing at its absolute peak. With the right care, your investment will continue to pay dividends with a stunningly clean and protected vehicle, day in and day out.

Your Top Questions About Ceramic Coatings, Answered

Alright, let’s get down to brass tacks. You’ve seen what the technology can do, but you probably have some practical questions about how these coatings hold up in the real world. Let’s tackle the most common ones, especially as they relate to the unique advantages of Titan’s advanced elastomer coatings. My goal is to give you the straight-up answers you need to feel confident about your choice.

How Long Does a Titan Elastomer Coating Really Last?

This is the big one, isn’t it? While many traditional ceramic coatings give you a solid 2-5 years before they start to degrade, Titan’s elastomer coatings are playing a completely different game. The secret is their flexibility.

Think about it: your car’s panels expand and contract with heat. A rigid coating can’t handle that stress and develops micro-cracks, which is where failure begins. Titan coatings, on the other hand, flex with the surface. Stick to a proper maintenance routine after a professional application, and a top-tier coating like Vulcan TX155 can genuinely protect your vehicle for years, blowing past the lifespan of older, more rigid formulas.

Can a Ceramic Coating Stop All Scratches and Rock Chips?

Let’s clear this one up right away, because it’s a huge point of confusion. Ceramic coatings are fantastic for adding a tough, slick layer of protection. They’re brilliant at fending off the light stuff—swirl marks from washing, fine scratches from daily use, and chemical etching from things like bird droppings.

But they are not a suit of armor. A coating won’t stop a deep, intentional key scratch, and it won’t deflect a rock hurtling at you on the highway. For that kind of heavy impact resistance, you need Paint Protection Film (PPF). In fact, the ultimate setup is laying down PPF first and then applying a Titan coating on top for the best of both worlds—physical impact defense and incredible chemical protection and gloss.

Is Professional Application Really Worth the Money?

One hundred percent, yes. The final performance of any ceramic coating is almost entirely down to the prep work. A pro doesn’t just wipe your car down; they perform a meticulous, multi-stage paint correction process to eliminate every single swirl, scratch, and imperfection from the paint.

This creates a perfectly clean and smooth canvas for the coating to bond to. Without that flawless foundation, you’re simply not going to get the durability, shine, or water-beading you paid for. The upfront cost might seem higher than a DIY kit, but professional application is an investment in getting the job done right and unlocking the coating’s true potential.

What’s the Big Deal with Titan’s Dark Matter Technology?

Dark Matter Technology® is our secret sauce. It’s a proprietary element we’ve engineered into our formulas that fundamentally strengthens the coating from the inside out.

Imagine it as a microscopic rebar grid woven throughout the flexible elastomer base. This web dramatically boosts chemical resistance, thermal stability, and overall toughness far beyond what you can get from a standard SiO2-based product.

When you combine this technology with our flexible elastomer and advanced nano-tubes, you get the uniquely resilient, long-lasting, and self-regenerating properties that define Titan Coatings. It’s the powerhouse engine driving the performance that sets our products apart.

Ready to see what the next generation of paint protection looks like on your vehicle? Titan Coatings has a complete range of elastomer-based coatings built for unparalleled durability and shine. To find the perfect shield and compare our technologies head-to-head, check out our product comparison chart and find the right solution for your needs.

0 Comments