For years, the gold standard for protecting a car’s paint was a good old-fashioned coat of wax. It worked, sure, but it was a temporary fix. A few weeks of rain, sun, and road grime, and that deep, glossy shine would start to fade, sending you right back to the garage for another round of buffing and polishing.

But what if you could lock in that “just detailed” look for years, not weeks? That’s the promise of a ceramic car coating. This isn’t just a beefed-up wax; it’s a completely different approach to paint protection. It forms a hard, glass-like shield that chemically bonds to your car’s clear coat, creating a sacrificial layer that stands up to the worst the environment can throw at it.

Moving Beyond Wax: The New Era of Paint Protection

Think about that familiar cycle. You spend a whole Sunday afternoon washing, polishing, and waxing your car to perfection. It looks incredible—a deep, wet shine that turns heads. Then a few storms roll through, and suddenly, it’s back to looking dull and unprotected. That’s the frustrating reality for countless car lovers who just want their ride to stay looking its best without constant upkeep.

The search for a better way led detailers and enthusiasts away from traditional waxes, which just sit on the paint’s surface, and into the world of ceramic car coatings. A ceramic coating doesn’t just sit there; it forms a semi-permanent, molecular bond directly with the clear coat. It’s not just another layer on your car; it effectively becomes a new, harder, more resilient top layer of your car. This is the fundamental leap forward in automotive paint care. If you want a deep dive, you can explore the differences between wax and ceramic coatings to see just how far the technology has come.

The Evolution of Vehicle Armor

Durable paint protection isn’t a new idea, but the technology has evolved at a dizzying pace. From their niche beginnings in the early 2000s, ceramic coatings have exploded into a global phenomenon. Projections show it becoming a $13.47 billion industry by 2025, a boom fueled by car owners demanding more than just a fleeting shine.

This explosive growth paved the way for the next big breakthrough. First-generation coatings were all about hardness, but that often came at the cost of flexibility. We at Titan Coatings identified this as a critical flaw. We pioneered the first-ever elastomer-infused coatings, using our proprietary Dark Matter Tech and nano tubes technology to create a product that was both incredibly hard and remarkably flexible.

This elasticity is a true game-changer. It allows the coating to expand and contract with the vehicle’s body panels as they react to temperature swings—from freezing winters to scorching summers. A purely rigid coating can develop micro-cracks under that kind of stress, compromising the entire protective barrier. Our elastic coatings, however, flex with the vehicle, ensuring the shield remains intact and lasts for years. This is the new benchmark for professional paint protection.

The Science of a Flawless Finish

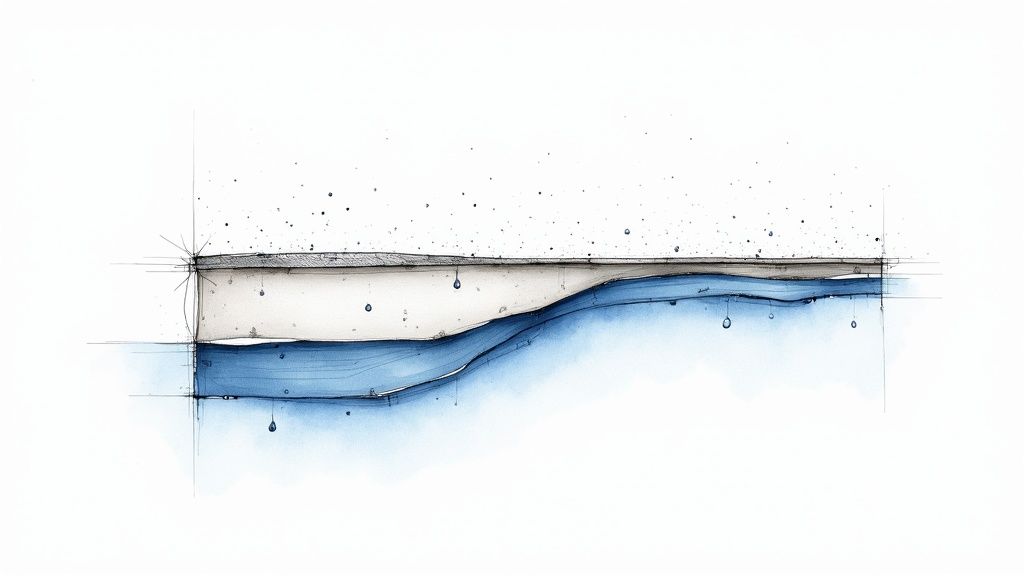

How does a clear liquid transform into an invisible, glass-like shield for your car? It all comes down to nanotechnology. To the naked eye, your car’s clear coat looks perfectly smooth, but on a microscopic level, it’s a rugged landscape of pores and valleys. Traditional waxes and sealants just sit on top, a temporary layer of shine that rain and car washes quickly strip away.

A true ceramic car coating plays an entirely different game. When this liquid polymer—often packed with at least 80% silica dioxide (SiO2)—is applied, it doesn’t just sit on the surface; it flows into every last imperfection. Through a chemical reaction, it forms a covalent bond directly with the paint, essentially becoming a permanent, new top layer. This process, called cross-linking, creates a hardened, seamless layer of what we often call “liquid glass.”

This new surface is incredibly slick and non-porous. This is the secret behind its most famous trick: the hydrophobic effect. Water simply can’t get a grip. Instead, it forms tight, perfect beads that roll right off, taking dirt, dust, and grime along for the ride. It’s this self-cleaning property that keeps a coated car looking pristine for so much longer.

Hardness Meets a New Dimension of Flexibility

For years, the gold standard for measuring a coating’s strength has been the “pencil hardness test,” with 9H representing the pinnacle of scratch resistance. This rating tells you a coating can stand up to fine scratches and swirl marks, acting as a tough, sacrificial barrier that protects the precious paint underneath. While this hardness is a huge selling point, it also concealed a critical flaw.

A detailer I know put it perfectly. He’d apply a top-tier, rigid 9H coating to a client’s black muscle car, and it looked incredible. But after a year of brutal summer heat and freezing winter nights, he started seeing tiny, spiderweb-thin cracks in the coating. The car’s metal panels were naturally expanding and contracting with the temperature swings, but the rock-hard coating couldn’t flex with them. The shield was slowly shattering under the stress.

That exact problem is what drove us at Titan Coatings to innovate. We knew pure, rigid hardness wasn’t the whole story for real-world durability. That’s why we pioneered the first elastomer-based coatings, integrating our proprietary Dark Matter Tech and nano tubes technology.

The Titan Coatings Advantage: A Story of Innovation

This was never about just making another hard coating; it was about engineering a smarter one. Think of the difference between a standard pane of glass and a sheet of shatterproof laminate. The glass is incredibly hard, but it shatters on impact. The laminate is just as clear and hard but has an inner flexibility that lets it absorb impacts and stress without failing.

Our elastic coatings work on that very principle. They deliver that glass-like hardness but are engineered to be flexible enough to move with the vehicle’s body. This resilience means dramatic temperature shifts no longer compromise the coating’s integrity. It won’t crack down under the pressure of going from a frozen morning to a sun-baked afternoon.

Our Titan T1 coating, for example, embodies this philosophy. It provides the brilliant gloss and hardness professionals demand, but with that crucial added dimension of elasticity. This ensures the protection doesn’t just look good on day one—it continues to perform for years, standing up to the real-world challenges your vehicle faces every single day. This is the next evolution of surface science, built to deliver a truly enduring, flawless finish.

Why Flexibility Is the Future of Paint Protection

For years, the ceramic coating industry was obsessed with one thing: hardness. Everyone chased higher numbers on the pencil hardness scale, convinced that pure, unyielding rigidity was the pinnacle of paint protection. But what if that very strength was also its biggest weakness?

Think about it like this. A pane of glass is incredibly hard and scratch-resistant, but what happens when it takes a hit or experiences a sudden temperature change? It shatters. Now, picture a sheet of shatterproof laminate. It’s just as clear and tough, but it has the built-in ability to flex and absorb energy without breaking. That’s the fundamental difference between old-school coatings and the next generation of surface protection.

A car’s body panels are constantly moving. They expand in the summer sun and contract on a cold winter night. A completely rigid coating bonded to that surface is put under enormous stress with every temperature swing. Over thousands of these cycles, microscopic cracks start to form, and the very shield you applied begins to compromise itself from within.

The Story of a Smarter Solution

We saw this flaw firsthand at Titan Coatings. We watched talented detailers apply perfectly good coatings, only to see them fail prematurely—not because they weren’t hard, but because they couldn’t adapt. That’s what pushed us to become the first company to bring elastomer coatings to the market, built from the ground up with our proprietary Dark Matter Tech and nano tubes technology.

This wasn’t just about tweaking a formula. It was a complete shift in thinking. Our goal was to create something that had the hardness of glass but the elasticity of rubber. This unique combination allows the protective layer to move right along with the vehicle’s paint, absorbing the stress from temperature changes instead of fighting against it.

The result is a coating that doesn’t crack down under pressure. It survives the punishing cycle of frozen winters and blistering summers, holding its structural integrity and its bond to the paint far longer than any rigid alternative could.

This built-in flexibility is also a game-changer for preventing corrosion—a massive global issue costing an estimated $2.2 trillion annually, or about 3% of the world’s GDP. By forming a resilient, unbroken barrier that won’t fracture, our flexible coatings can slash rust formation by up to 70%. That’s a huge factor in extending a vehicle’s life.

How Our Coatings Deliver Unmatched Durability

A perfect example of this “hard-but-flexible” philosophy in action can be seen in our product line, especially when you compare our coatings. Take our Titan Vulcan TX155, a professional-grade coating that gives detailers everything they expect—unbelievable gloss, slickness, and chemical resistance—but with a crucial advantage engineered right into its molecular structure.

Here’s what sets our products apart:

- Elastomer-Based Core: Unlike purely SiO2-based products, our coatings are built on an elastic polymer backbone that allows them to flex without failing.

- Dark Matter Tech Integration: This proprietary tech enhances the cross-linking process, creating a denser protective matrix that’s still incredibly pliable.

- Superior Thermal Resistance: The coating is engineered to handle extreme temperature swings, which stops the micro-fractures that degrade lesser coatings over time.

This isn’t a small improvement; it’s a genuine leap forward in real-world performance. While other coatings might look good in a controlled lab, Titan’s elastic coatings are built for the messy, unpredictable world that cars actually live in. You can dive deeper into the science behind our pioneering use of elastomer technology in ceramic coatings on our website. It’s this focus on dynamic, real-world durability that truly defines the future of paint protection.

Choosing the Right Coating for Your Car

Navigating the world of ceramic car coatings can feel like you need a chemistry degree. With terms like SiO2, graphene, and elastomers being thrown around, it’s easy to get lost in the science. But getting a handle on the core differences is the secret to picking a shield that actually meets your vehicle’s needs and your long-term expectations.

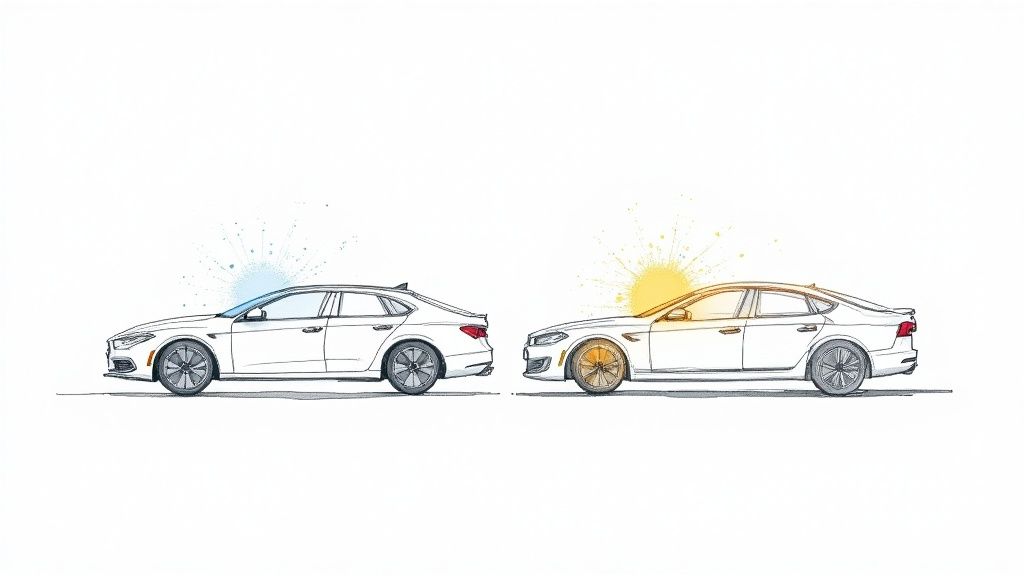

At the end of the day, the choice boils down to one critical idea: rigid protection versus flexible defense.

For years, the market was all about traditional ceramic coatings built on a foundation of silicon dioxide (SiO2). These coatings are incredibly hard, creating a glassy shell over your paint that delivers excellent scratch resistance and a deep, wet-looking gloss. They really set the original standard for what durable paint protection could be.

Then came graphene. By lacing coatings with a layer of carbon atoms, manufacturers aimed to improve on the SiO2 formula by reducing water spots and boosting slickness. It was a definite step forward, but these products still operated on the same basic principle: create a purely rigid, rock-hard barrier.

The Weakness of Pure Hardness

So, what’s wrong with being rock-hard? Let me tell you a quick story about a detailer who learned this lesson the hard way.

He applied a top-tier, super-rigid 9H coating to a client’s stunning black sedan. For the first six months, it was flawless. But after a year of enduring brutal Midwest winters and scorching summer heatwaves, the owner noticed something unsettling under direct sunlight—tiny, almost invisible cracks spiderwebbing across the finish. The coating was failing.

What happened? The car’s metal panels had been expanding and contracting with the temperature swings, just like they’re designed to do. The super-hard coating, however, couldn’t flex along with the paint. It was simply too rigid, and the constant stress caused it to develop micro-fractures, destroying the very protection it was meant to provide.

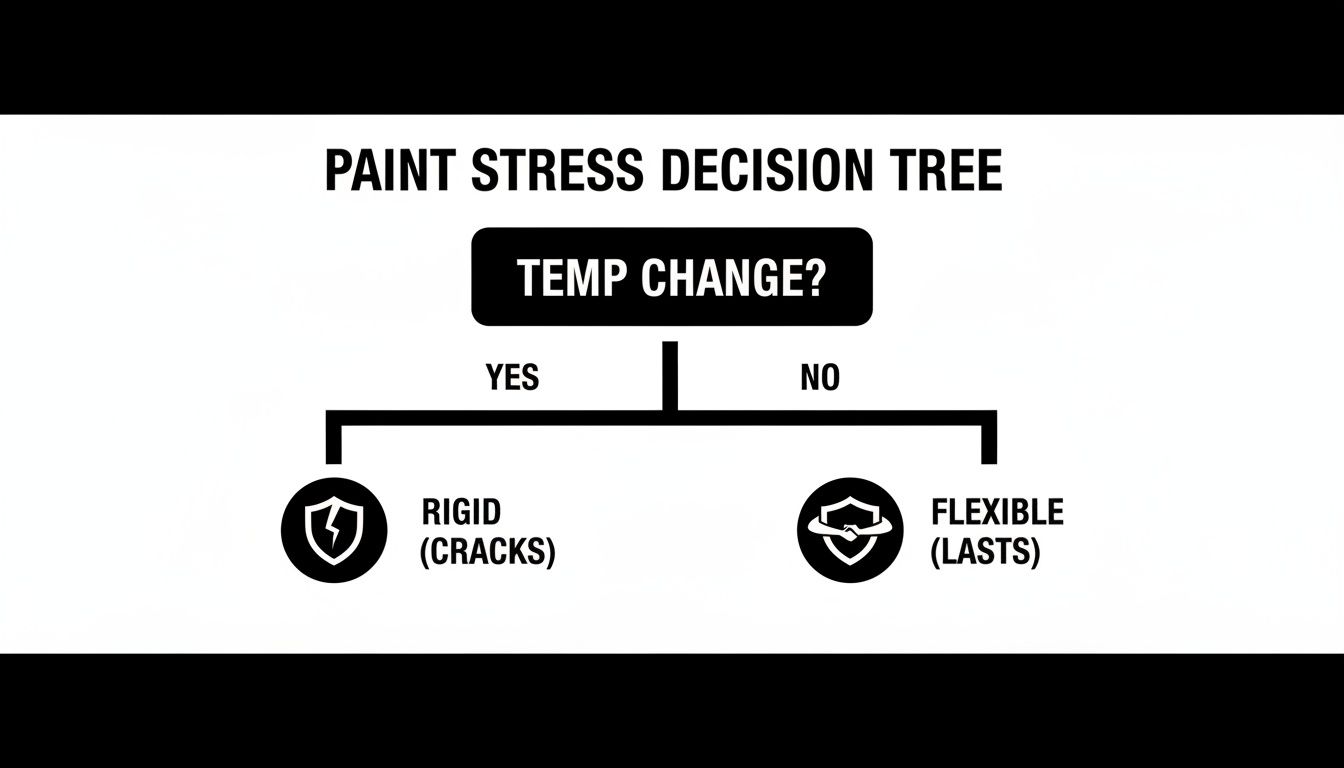

This simple chart breaks down the stress your car’s paint goes through and how different coatings handle it.

As you can see, a rigid coating is a dead end when it comes to long-term durability under real-world conditions. A flexible coating adapts and lasts.

Elasticity: The Smartest Defense

This is exactly where Titan Coatings’ proprietary elastomer technology rewrites the rulebook. We realized that true, lasting durability isn’t just about hardness; it’s about resilient flexibility. Our coatings are engineered to be both hard and elastic.

Think of it like the difference between a normal pane of window glass and the shatterproof safety glass in your car’s windshield. Both are hard, but only one is designed to absorb impact and stress without failing catastrophically.

Our elastic coatings, powered by innovations like Dark Matter Tech and hyper-dense nano tubes, form a shield that actually moves with your vehicle’s paint. This ability to flex prevents those micro-cracks from ever forming, ensuring the protective barrier stays intact year after year, through every season. It’s a smarter, more durable solution built for the real world.

Of course, many car owners also wonder how this type of protection stacks up against other options. You can dive deeper by checking out our guide comparing paint protection film vs. ceramic coatings.

Ceramic Coating Technology Comparison

To make things clearer, let’s put these technologies side-by-side. The table below breaks down the key differences in how each type of coating performs and where it really shines. You can find all of these innovative products in our online shop.

| Coating Type | Key Technology | Durability | Hardness vs Flexibility | Best For | Titan Coatings Advantage |

|---|---|---|---|---|---|

| Traditional SiO2 | Silicon Dioxide (Quartz) | 1-3 years | High hardness, low flexibility (brittle) | Entry-level gloss and basic protection | N/A |

| Graphene-Infused | SiO2 + Graphene Oxide | 3-5 years | Very high hardness, still fundamentally rigid | Reduced water spotting, high gloss | N/A |

| Titan Elastomer Hybrid | Elastomers & Nano Tubes | 5+ years | Engineered Hardness with High Flexibility | Long-term, all-weather paint preservation | Withstands temp changes, self-heals, no cracking |

As the comparison shows, the evolution of coating technology is all about moving beyond simple hardness.

Ultimately, choosing the right coating is an investment in your vehicle’s future. While rigid coatings offer good initial protection, their inflexibility is a built-in point of failure. Titan’s elastomer-based technology provides a superior, longer-lasting defense by embracing flexibility, ensuring your car’s flawless finish endures whatever the road—and the weather—throws at it.

The Professional’s Playbook for a Flawless Finish

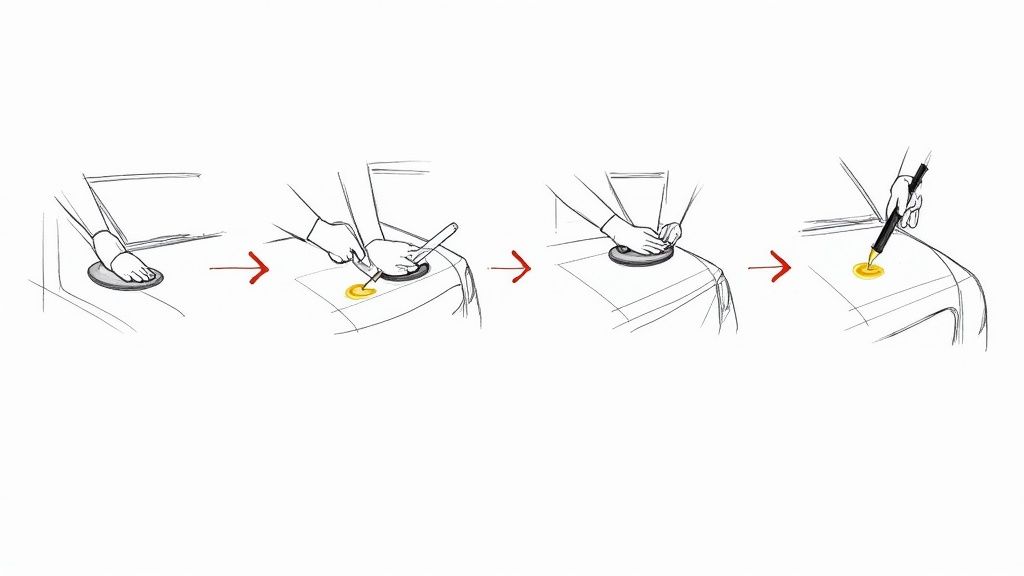

Let’s get one thing straight: a top-tier coating is only as good as the surface it’s applied to. This is the golden rule in the detailing world. It’s why a professional application is the only path to the jaw-dropping, long-lasting results you expect from high-end ceramic car coatings. Think of it like a world-class painter preparing a canvas—they would never dream of starting on a dirty, flawed surface.

The road to that mirror-like shine begins long before a bottle of coating is even uncapped. It’s a painstaking, multi-stage process that certified pros have down to a science, all to create an immaculately clean slate. This is far more than just a car wash; it’s a full-on decontamination mission.

The explosive growth of the professional detailing industry is built on this very need for absolute precision. The automotive ceramic coatings market is proof, projected to hit $2.5 billion by 2025 on the back of a strong 12% compound annual growth rate. That number tells a story: car owners are overwhelmingly choosing the durable, deep protection that only a professionally prepped and applied coating can deliver.

Laying the Groundwork for Perfection

First comes a deep, multi-stage wash to get rid of the obvious dirt. But the real work, the stuff that separates the pros from the amateurs, is in the chemical and mechanical decontamination.

- Iron Decontamination: We start with specialized sprays that literally dissolve tiny, embedded iron particles from brake dust. These are the culprits behind those ugly, rust-colored specks you see on lighter-colored cars.

- Tar Removal: Next, powerful solvents are used to safely break down stubborn tar, road grime, and other gunk that a normal wash simply can’t touch.

- Clay Bar Treatment: Finally, a detailing clay bar is meticulously glided across every square inch of paint. This step physically pulls out any remaining microscopic contaminants, leaving the surface feeling smoother than glass.

This intense cleaning process exposes the paint’s true condition, which brings us to the most critical stage of them all: paint correction.

“Applying a ceramic coating to uncorrected paint is like putting a screen protector on a cracked phone. You’re just permanently locking in all the flaws.” – Professional Detailer Insight

Using a series of machine polishers with progressively finer compounds, a skilled technician carefully erases imperfections—swirl marks, fine scratches, oxidation, you name it. This part alone can take hours, sometimes even days, but it’s non-negotiable. The goal is to restore the paint to a better-than-new condition, creating a flawless, mirror-like foundation for the coating to bond to. To see this in action, check out our in-depth guide on the steps to applying a ceramic coating to a car.

Beyond the Application: Busting the “No Maintenance” Myth

Once the paint is perfected and a Titan coating is skillfully applied, the real protection begins. But let’s bust one of the biggest myths out there: a coated car is not maintenance-free. While it makes cleaning worlds easier and you can say goodbye to waxing, proper care is absolutely essential to get the most out of your investment.

Here are a few simple rules for keeping that shine going for years:

- Stick to pH-Neutral Soaps: Harsh, high-alkaline, or acidic soaps will eat away at the coating over time. Always use a high-quality, pH-neutral car shampoo.

- Wash Smart: Use the two-bucket method with grit guards and plush microfiber mitts. This is your best defense against putting new swirl marks into the finish.

- Boost the Protection: Using a maintenance spray or topper, like Titan Coatings Hyper-Seal, every few washes is a great way to rejuvenate the coating’s hydrophobic punch and add an extra layer of slickness.

Following these simple steps ensures your investment continues to protect and shine, delivering the incredible performance you expect from an advanced ceramic car coating.

Your Ceramic Car Coating Questions Answered

Look, deciding on a ceramic car coating is a big deal. You’ve seen the glossy photos and heard the promises, but you’ve got real questions about the cost, the performance, and what you can truly expect. It’s a serious investment.

Let’s cut through the noise. Here are the straight-up, no-nonsense answers to the questions we hear every single day from car owners just like you.

Are Ceramic Car Coatings Worth the Investment?

Without a doubt, yes. But you have to think about it in the right way. It’s not just another car product; it’s a long-term investment in your vehicle’s health and value.

Sure, the upfront cost is more than a bottle of wax. But think about the endless cycle of waxing your car every few months. That’s time, money, and effort you’ll never get back, all for temporary shine and minimal protection.

A professional-grade ceramic car coating from Titan flips that script. We’re talking years of protection, not months. You save countless hours of upkeep and stop throwing money away on products that just wash away. More importantly, you’re putting a real shield between your paint and the things that want to destroy it:

- UV Rays: The sun is relentless, but a coating stops it from fading and oxidizing your paint.

- Chemical Etching: Bird droppings, bug guts, and acid rain won’t be able to eat into your clear coat.

- Oxidation: Prevents that dull, chalky look that plagues unprotected cars over time.

This isn’t just about looking good—it’s about preserving your car’s resale value. When it’s time to sell, paint that looks brand new commands a much higher price. Combine that with the unbelievable gloss and how ridiculously easy it makes cleaning, and the return on your investment becomes crystal clear.

How Does a Flexible Coating Actually Last Longer?

This is where the real science comes in, and it’s a game-changer. For years, the industry standard was extremely hard, rigid coatings. The problem? Your car isn’t rigid. Its metal panels are constantly expanding in the heat and contracting in the cold.

When a brittle coating is bonded to a surface that’s always moving, something has to give. That constant stress creates micro-fractures in the coating. You might not see them at first, but these tiny cracks are gateways for moisture and contaminants, compromising the entire protective layer from the inside out.

Titan’s elastomer technology solves this problem at the molecular level. We engineered our coatings to be flexible. This elasticity lets the coating expand and contract right along with your car’s body panels, absorbing the stress instead of cracking under it.

Think of it as the difference between a fragile sheet of glass and a durable, flexible polymer shield. That ability to flex is the secret to true, long-term durability in the real world.

Can I Apply a Professional Coating Myself?

While there are plenty of DIY kits on the market, professional-grade coatings like ours are a completely different animal. They are designed exclusively for certified installers, and for very good reasons. That flawless, liquid-glass finish you want is born from a process that’s nearly impossible to replicate at home.

First, surface preparation is everything. A pro has the right tools, compounds, and thousands of hours of experience to perform multi-stage paint correction. This isn’t a quick polish; it’s an intensive process to eliminate every single swirl, scratch, and imperfection, creating a perfectly sterile canvas. Any defect you leave behind gets locked under the coating forever.

Second, the environment is critical. A professional detailer works in a climate-controlled bay to keep dust, pollen, and humidity from ruining the application. These contaminants can prevent the coating from bonding correctly, leading to failure.

Finally, the application itself is an art. It takes a trained eye and a steady hand to apply the product perfectly evenly, without high spots or streaks, all while managing the product’s specific flashing time. To get the longevity and jaw-dropping finish these coatings are famous for, professional application is non-negotiable.

Do Ceramic Coatings Prevent All Scratches?

This is probably the biggest myth out there. Let’s be clear: a ceramic car coating adds an incredibly hard (often 9H) sacrificial layer that is highly resistant to the light scratches and swirl marks that come from washing and daily driving. It’s like armor for your clear coat.

However, a coating does not make your car scratch-proof or bulletproof. It won’t stop a key from scratching your door, protect against a rock chip on the highway, or prevent damage from a shopping cart. Its main job is to provide unparalleled protection from environmental fallout, lock in a deep, permanent gloss, and make cleaning your car incredibly easy.

The scratch resistance it does provide is huge for preventing the fine, spiderweb-like swirls that accumulate over time and make a car look dull and aged. By fending off that daily wear and tear, a coating keeps your car looking like it just left the showroom, year after year. For a deeper dive on what to expect, check out our guide on how long a ceramic coating lasts.

Ultimately, choosing a ceramic coating is about protecting your investment, preserving its beauty, and making your life easier. When you understand what it can—and can’t—do, you can make a smart decision that pays off in shine and satisfaction for years.

At Titan Coatings, we engineer products to solve the real-world challenges your vehicle faces. Our Titan Pyro TX153, for example, is a pure professional-grade elastomer coating that fuses extreme heat resistance with our signature flexibility. It’s the ultimate shield for the harshest conditions, all while delivering a ridiculous, lasting gloss. It’s time to discover the next generation of paint protection.

0 Comments