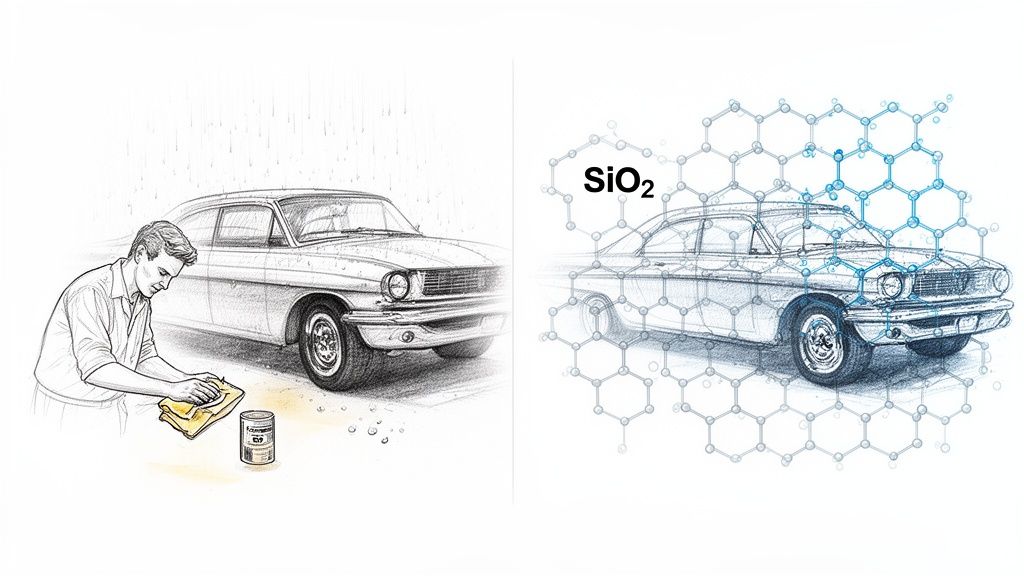

For ages, the go-to for protecting your car’s paint was a good old-fashioned wax.But let’s be honest, traditional waxes are a temporary fix. They form a weak, sacrificial layer that sits on top of the paint, offering a decent shine but very little in the way of real, lasting protection. It’s a bit like applying lotion—it feels good for a bit, but it washes away and needs constant reapplication.

Ceramic coatings are a whole different ball game. Instead of a temporary layer, they create a semi-permanent, chemical bond with your vehicle’s clear coat. This isn’t just a surface treatment; it’s a molecular-level fusion that becomes a functional part of the paintwork. The result is a hard, slick, and incredibly resilient shield that guards against everything from bird droppings and UV rays to light scratches, all while delivering an unbelievable, water-beading gloss that makes washing a breeze.

From Wax-On, Wax-Off to a Molecular Shield

We’ve all been there. Spending hours on a sunny Saturday carefully applying and buffing a coat of carnauba wax, only to watch that mirror-like finish get washed away by the first downpour. For decades, this was the ritual for car enthusiasts—a constant cycle of wash, polish, wax, repeat. It was a labor of love, for sure, but the results were always fleeting.

Even modern synthetic sealants, which last longer than natural waxes, suffer from the same fundamental weakness: they just don’t bond strongly enough. They sit on the surface, ready to be broken down by detergents, road grime, and the elements.

The Shift to Nanotechnology

This is where nanotechnology completely changed the detailing world. The development of ceramic coatings represented a move away from temporary surface films and toward genuine, long-term molecular protection. These advanced liquid polymers are designed to seep into the microscopic pores of your car’s clear coat.

A ceramic coating doesn’t just sit on the paint; it becomes one with it. It forms a semi-permanent, glass-like shield that solves the very problems waxes and sealants could never touch.

Through a chemical process called cross-linking, the coating forms an incredibly strong covalent bond with the surface. This bond is far tougher and more durable than anything a wax could ever achieve. What you get is a sacrificial layer that’s actually harder, slicker, and more chemically resistant than the factory paint it’s protecting. If you want a deep dive into this, check out our full comparison of wax versus ceramic coatings.

Beyond Hardness: A New Evolution

For years, the industry was obsessed with hardness, often marketed with the “9H” pencil hardness rating. While hardness is definitely a piece of the puzzle, it’s not the whole story. The problem with being extremely hard is that it often leads to brittleness. Think about it—glass is very hard, but it cracks under stress. A super-rigid coating can develop micro-fractures when your car’s body panels expand and contract with temperature changes, from a freezing winter night to a scorching summer day.

This is where Titan’s work with Elastic Coatings set a new benchmark. We figured out that true durability requires both hardness and flexibility. By weaving flexible elastomer polymers into our formulas using proprietary nanotube technology, we created a shield that is hard like glass yet flexible.

This unique ability allows our coatings to move with your vehicle’s panels, absorbing the stresses of thermal expansion and contraction. It’s this elasticity that prevents the micro-cracking that plagues older, more rigid ceramic technologies, ensuring the protective shield stays fully intact and lasts longer, year after year, no matter what the climate throws at it.

The Science Behind That “Freshly Detailed” Look

Ever wonder how a professional ceramic coating makes water dance off a car’s paint? It’s not magic—it’s some seriously cool chemistry happening at a microscopic level.

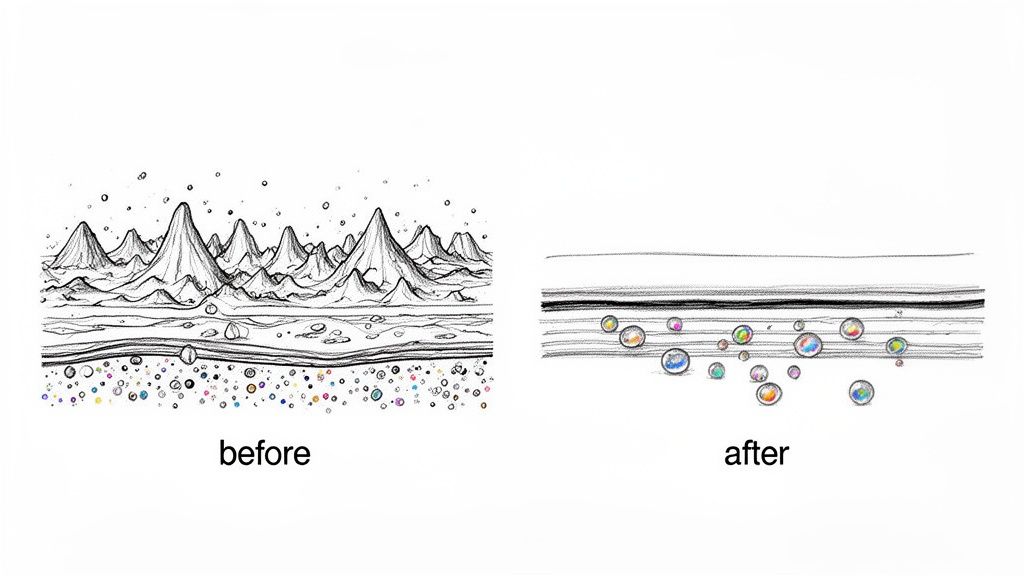

Let’s get right down to the surface. To your eye, your car’s clear coat looks as smooth as glass. But put it under a microscope, and you’d see a rugged landscape full of tiny peaks and valleys.

Those imperfections are magnets for dirt, grime, and water, which is what dulls your finish and makes the car a pain to keep clean. A liquid ceramic coating, which is packed with Silicon Dioxide (SiO₂), is engineered to seep into every last one of those pores.

As the coating cures, the liquid polymerizes, hardening into a perfectly smooth, transparent layer of protection. This process, known as cross-linking, forms a powerful covalent bond. It’s not just sitting on top of your paint; it’s chemically fused to it.

The “Lotus Effect” in Action

The result of creating that ultra-smooth, perfectly level surface is a powerful phenomenon we call the hydrophobic effect. “Hydrophobic” literally means “water-fearing,” and for good reason.

By leveling out the microscopic texture of the clear coat, the coating drastically changes how water behaves on the surface. Instead of spreading out and clinging on, water beads up into tight little spheres and rolls right off, taking dirt and other gunk along for the ride.

This is the exact same principle that keeps a lotus leaf clean and dry in a murky pond. It’s a “self-cleaning” property, and it’s one of the most sought-after benefits of a true professional-grade ceramic coating.

But this isn’t just for show. That effect is a sign of a durable, semi-permanent barrier that’s fighting off chemical etching, blocking damaging UV rays, and shrugging off environmental contaminants in a way no wax or sealant ever could. It’s this robust science that’s fueling a booming market, projected to more than double from USD 12.15 billion to USD 25.60 billion by 2034.

Hardness is Good. Flexible Hardness is Better.

For years, the industry was obsessed with one thing: hardness. A “9H” rating was the gold standard. But a few years back, a detailer friend of mine, Mark, ran into a problem. He’d applied a top-tier 9H coating to a client’s black sports car, and living in an area with brutal temperature swings, the car saw it all.

Six months later, the client came back. Under magnification, Mark discovered the coating was riddled with microscopic fractures. The super-rigid coating, like a thin sheet of glass, couldn’t handle the metal panels expanding in the summer heat and contracting in the winter cold. It was cracking under the pressure.

This is where the story of modern coatings takes a turn. True, long-lasting protection isn’t just about being hard; it’s about being resilient. Hardness without flexibility is just brittleness waiting to happen.

This is the exact problem we at Titan Coatings set out to solve. We were the first company that introduced Elastomer coatings to the market, using our own nano tube technology and Dark Matter tech to build a better shield.

Our formulas create a surface that’s hard like glass and flexible, a combination that makes them last longer. This elasticity allows the coating to move with your vehicle’s body panels, preventing the micro-cracking that plagued Mark’s client. Because the coating won’t crack down, temperature changes between frozen and hot conditions won’t affect it. It’s this ability to withstand thermal expansion that ensures a Titan coating maintains its integrity and hydrophobic pop for years, not just a few months.

This is the science at the core of our advanced products, and it’s what separates a good coating from a great one. If you want to dive deeper into how this tech stacks up against other formulas, check out our guide on Graphene Coating vs. Ceramic Coating.

Why We Threw Out The Old Rulebook On Protection

Traditional ceramic coatings were a game-changer, no doubt. But they had a hidden weakness, one that we saw as a critical flaw. Think of them like a sheet of tempered glass. They’re incredibly hard, which is great for fighting off scratches. The problem? That same hardness makes them brittle.

Your car’s body panels are constantly expanding and contracting with temperature changes—baking in the summer sun, freezing in the winter cold. A rigid, glass-like coating can’t keep up. Over time, that stress creates microscopic cracks, and once those appear, the protection starts to break down from the inside out.

That’s where our story really starts. We saw the problem immediately: the issue wasn’t the hardness; it was the total lack of flexibility. This insight led us to become the first company to introduce Elastomer technology to the automotive market.

Hard Like Glass, Flexible Like Carbon Fiber

Here’s a simple way to picture the difference. Try bending a glass rod. It’s strong, but it will eventually snap under pressure. Now, imagine bending a carbon fiber fishing rod. It’s just as strong, but it flexes, absorbs the stress, and bounces right back to its original shape. Our Elastic Coatings were engineered to do the exact same thing for your car’s paint.

We created a unique formula using our proprietary nano tube technology and Dark Matter tech. These ingredients build an intermolecular structure that gives you the slick, glass-like hardness every detailer wants, but with a level of flexibility that was previously unheard of.

This ability to flex is the secret to true longevity. An elastic coating moves with the vehicle’s panels as they expand and contract. This simple but critical feature prevents the micro-cracking that causes so many traditional coatings to fail long before their time.

This isn’t just some small tweak or marketing gimmick; it’s a completely different way of thinking about paint protection. We built a shield that bends instead of breaking. You can dive deeper into the science behind our groundbreaking Elastomer technology on our website.

Pushing The Boundaries With Vulcan TX155

This entire philosophy of durable, flexible protection is perfectly captured in one of our flagship products for professional detailers.

This screenshot from our shop shows some of the advanced solutions available to certified installers.

Every single product we make, especially a standout like Vulcan TX155, is designed to solve real-world problems for detailers and their customers. You can see our full range of products in our online shop.

Our Graphene-infused elastomer coating, Vulcan TX155, is the absolute pinnacle of this research. We took our flexible elastomer base and integrated Graphene to crank its performance up to a whole new level. Vulcan TX155 doesn’t just give you that signature Titan flexibility; it adds unbelievable chemical resistance that shrugs off the nastiest environmental junk out there.

For a professional detailer, this is the ultimate weapon. You can offer your clients a coating that delivers an incredibly deep, liquid gloss while providing a tough, resilient shield built to last for years, not just months. We found a core weakness in the market and engineered a superior solution. That’s what sets Titan apart.

Choosing Your Armor: Ceramic Coatings vs. Waxes and PPF

Deciding how to protect your vehicle’s paint can feel a lot like choosing the right armor before heading into battle. You’ve got a few different options on the table, and each one promises to be the ultimate defense. But to make the right call, you need to understand their real-world strengths and weaknesses, because your choice directly impacts your car’s look, your cleaning routine, and its value down the road.

Let’s kick things off with the old standby: traditional waxes. Think of wax as a temporary, cosmetic touch-up. It’s cheap and can give you a nice, warm gloss, but that protection is gone in a flash. Carnauba waxes and synthetic sealants just sit on top of the paint, creating a flimsy barrier that washes away after a few weeks of sun, rain, and soap. They demand constant reapplication, which makes them a high-effort, low-reward option.

The Heavy-Duty Physical Shield: Paint Protection Film

Next up is Paint Protection Film (PPF), what a lot of people call a “clear bra.” When it comes to stopping physical damage, PPF is the undisputed heavyweight champ. It’s a thick, clear urethane film that acts as a genuine shield against rock chips, deep scratches, and other nasty impacts.

Picture a thin, invisible layer of armor wrapped around your car’s most vulnerable spots. That’s PPF in a nutshell. But this level of brute-force protection comes with some trade-offs:

- Premium Cost: A professional PPF job is a serious investment, often running into the thousands of dollars.

- Limited Properties: While it’s a beast against impacts, PPF doesn’t naturally have that slick, water-beading magic you get from a top-tier ceramic coating.

- Potential for Damage: Cheaper films can turn yellow or start to peel over time, and they just don’t offer the same kind of chemical or UV resistance as a dedicated coating.

The Smart, Balanced Defender: Ceramic Coatings

This is where ceramic coatings come in. A quality ceramic coating strikes an incredible balance between toughness, looks, and everyday convenience. It creates a semi-permanent, chemically-resistant shield that actually bonds with your paint. While it won’t stop a flying rock like PPF can, it’s a master at defending against the daily grind of environmental hazards.

We’re talking about serious protection from chemical etching caused by bird droppings, resistance to the UV rays that make your paint look old and faded, and that amazing hydrophobic effect that makes water (and dirt) fly right off. Washing your car becomes ridiculously fast and easy. It’s the smart, modern way to lock in that deep gloss and protect your investment for years.

Paint Protection Options: A Head-to-Head Comparison

Choosing the right paint protection can be tough. Each option offers a different balance of durability, cost, and aesthetics. This table breaks down the key differences between traditional waxes, Paint Protection Film (PPF), and our advanced Elastomer Ceramic Coatings to help you see where each one shines.

| Attribute | Traditional Wax / Sealant | Paint Protection Film (PPF) | Titan Elastomer Ceramic Coating |

|---|---|---|---|

| Primary Function | Enhances gloss, minimal protection | Physical impact protection | Chemical, UV, and environmental protection |

| Durability | Weeks to a few months | 5-10+ years | 3-7+ years |

| Rock Chip Defense | None | Excellent | Minimal |

| Chemical Resistance | Poor | Good | Excellent |

| UV Protection | Minimal | Good | Excellent |

| Hydrophobics | Good (initially) | Fair to Good | Exceptional |

| Self-Cleaning | Minimal | Poor | Excellent |

| Cost | $ (Low) | $$$ (High) | $$ (Moderate) |

As you can see, there’s no single “best” option for everyone—it’s about matching the protection to the owner’s needs and budget. But for those seeking the ultimate, comprehensive defense, the answer isn’t choosing just one.

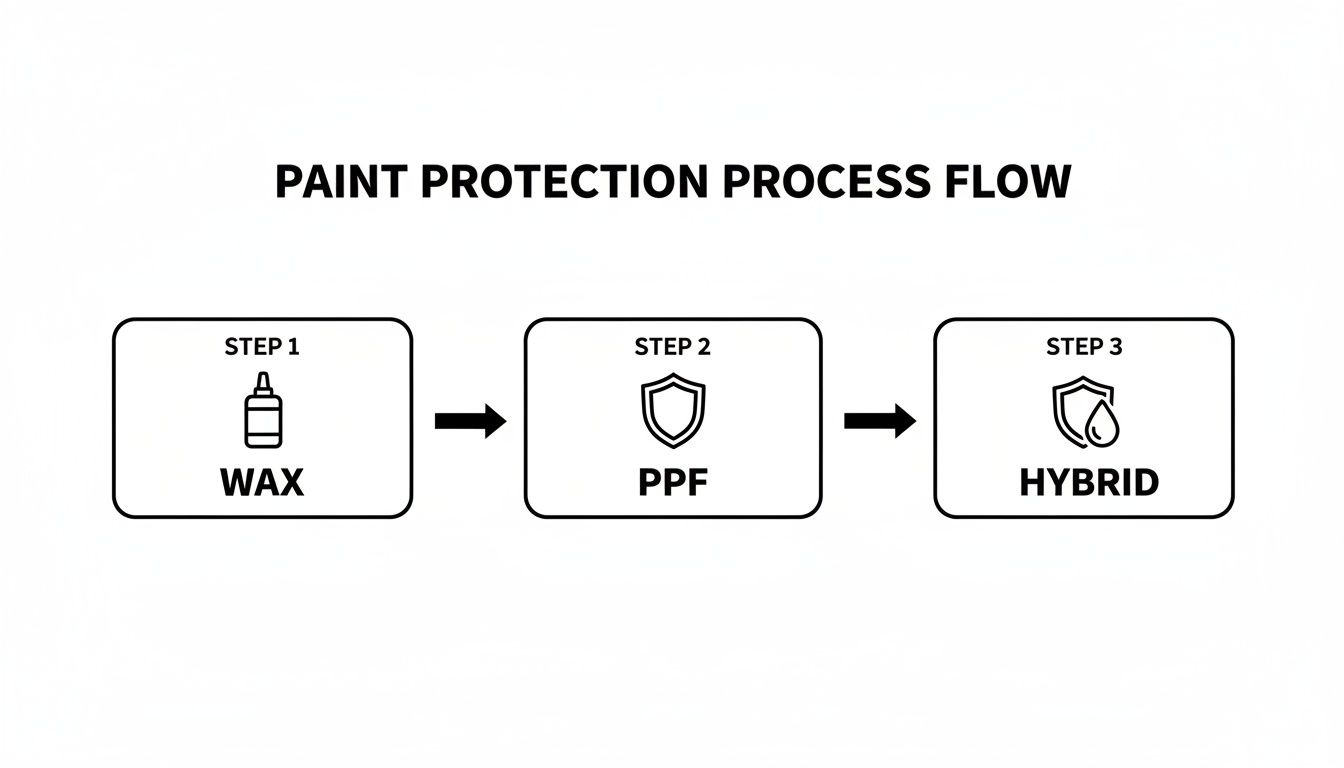

The ultimate strategy isn’t choosing one or the other; it’s combining their strengths. The gold standard in vehicle protection is a hybrid approach—installing PPF on high-impact zones and then applying a high-quality ceramic coating over the entire vehicle.

The Ultimate Combination: A Hybrid Approach

This is where you can truly change the game, whether you’re a professional detailer or a demanding owner. By applying a flexible Titan Elastomer Ceramic Coating over a fresh PPF installation, you create the definitive shield. You get the unbeatable impact resistance of the film combined with the slick, self-cleaning, and glossy properties of our advanced coating.

Our Elastic Coatings are the perfect partner for PPF. They are engineered for flexibility, meaning they won’t crack or delaminate as the film and the body panels beneath it expand and contract with temperature changes. This synergy creates a top-tier, high-value service that answers every client’s needs. To really dig into this powerful combo, check out our detailed breakdown of Paint Protection Film vs. Ceramic Coating.

With this hybrid solution, you’re no longer making a compromise. You’re getting the best of all worlds.

The Pro’s Guide to a Flawless Finish

Let’s get one thing straight: a world-class ceramic coating is only as good as the surface it’s bonded to. Every seasoned detailer knows this in their bones. You could have the most advanced formula known to man, but if you put it on a poorly prepped car, the results will be a massive letdown.

Achieving that unbelievable, liquid-gloss finish is an art, and it’s built on a foundation of meticulous, no-shortcuts-allowed preparation.

Think of yourself as a master painter. Would you lay down priceless oils on a dirty, scratched-up canvas? Of course not. It’s the exact same principle with ceramic coatings. The real work begins long before you even think about cracking open that little glass bottle. It all starts with creating a truly pure surface.

Building the Perfect Foundation

First things first, we have to get the paint surgically clean. This isn’t your average weekend wash; it’s a multi-stage assault designed to strip away every last bit of contamination that doesn’t belong there.

- Chemical Decontamination: This means hitting the paint with specialized iron removers. These products dissolve all the embedded ferrous particles—those tiny, sharp flecks of brake dust and industrial fallout that dig into your clear coat. You’ll know it’s working when the paint starts “bleeding” purple. It’s a satisfying sight, confirming those contaminants are gone for good.

- Physical Decontamination: Once the chemical stage is done, it’s time to break out the clay bar or a quality clay mitt. This step physically pulls off any remaining bonded gunk like tree sap or stubborn road tar. The goal is to get the paint feeling as smooth as a pane of glass.

With the surface finally, truly clean, we move to the most critical stage of all: paint correction. This is where the magic happens. We’re talking about carefully machine polishing away every swirl mark, light scratch, and bit of oxidation. A multi-stage correction ensures the paint is as close to perfect as humanly possible, creating an absolutely flawless base for the coating to lock onto. This is why a professional job is such a smart investment.

The diagram below shows how different protection methods stack on top of each other, from a basic wax all the way to a hybrid strategy.

It’s a great visual for understanding the jump from temporary protection to the more advanced, durable solutions that give you the best of everything.

The Art of the Application

Once your canvas is perfect, applying a Titan coating is a precise, methodical ritual. You work in small, manageable sections, applying the product in a tight cross-hatch pattern—first horizontally, then vertically. This is non-negotiable for getting complete, even coverage.

Then comes the waiting game. We call it “flashing.” This is the crucial window where the carrier solvents evaporate, allowing the active ingredients to start bonding with the clear coat. You’ll see it happening—a sort of rainbow-colored haze will appear on the surface. Timing here is absolutely everything. Wipe too soon, and you pull the coating right off. Wait too long, and you’ll be fighting to remove stubborn high spots.

Finally, you gently “level” the residue, buffing it away with a premium microfiber towel. What’s left behind is nothing but that slick, perfect layer of protection. When you nail the process, the results speak for themselves. We’re talking hydrophobic contact angles that often blast past 90–110 degrees and real-world durability that lasts for years.

One of the biggest mistakes I see is guys trying to apply coatings in direct sun or high humidity. The product will flash way too fast, making it nearly impossible to level correctly. You’ll end up with a streaky, blotchy mess that’s a nightmare to fix.

The entire process demands patience, a controlled environment, and an intimate understanding of the products you’re working with. For a full, step-by-step breakdown, check out our guide on how to properly apply a ceramic coating to your car. It’s this level of craftsmanship that separates a good job from an absolutely unforgettable one.

Protecting Your Investment and Understanding the ROI

Let’s get one of the biggest myths out of the way right now: ceramic coatings are not a “set it and forget it” magic shield. While they make taking care of your car incredibly easy, the secret to getting years of performance is proper maintenance. Don’t worry, this isn’t complicated. It just means leaving behind the harsh, high-effort washing methods of the past.

A simple, smart maintenance routine is all it takes to keep your coating working perfectly. This means adopting gentle wash techniques—like the classic two-bucket method—to avoid putting new swirl marks into your pristine finish. It also means saying goodbye to aggressive, high-pH soaps that can slowly eat away at the coating and kill its hydrophobic magic.

Stick with a quality, pH-neutral car shampoo. This is non-negotiable for preserving the coating’s integrity, letting it do its job of shedding water and grime. If you really want to keep it in peak condition, use a ceramic-infused topper or maintenance spray every few months. A product like Titan Coatings’ Hyper-Seal is built for this; it instantly brings back that slick, just-coated feeling and unbelievable water-beading.

Calculating the Real Return on Investment

For a car owner, a professional ceramic coating isn’t just another expense. It’s a strategic move to protect your vehicle’s value and keep it looking incredible. To really grasp the Return on Investment (ROI), you have to look past the upfront cost and see all the time and money you’ll save down the road.

Think about the old-school routine you get to ditch:

- Constant Waxing: Remember having to apply wax every 4-6 weeks just to keep some shine and basic protection? That’s gone.

- More Frequent Washing: A car without a coating is a dirt magnet and a pain to clean, meaning you’re washing it more often and working harder each time.

- Future Paint Correction: After a few years of improper washing, environmental fallout, and bug guts, your paint ends up a swirled-up, faded mess. Fixing that requires expensive paint correction.

A single, professional application of a durable Titan coating wipes out years of those recurring costs and labor. You stop buying waxes and sealants, you literally cut your wash time in half, and you drastically lower the chances of ever needing a pricey paint correction job.

This changes the entire conversation. The coating isn’t a luxury item; it’s a forward-thinking investment. You’re essentially pre-paying for years of top-tier protection, buying back countless hours of your time, and actively preserving your car’s resale value.

This shift in value has had a massive impact on the professional detailing world. Detailers can now offer high-ticket, long-term protection packages that car owners are happy to invest in, with prices often running from several hundred to thousands of dollars. It has fueled a market where skill and proven results are everything. You can dig into the numbers and see how these services are growing with these ceramic coating market insights.

Ultimately, by choosing a high-quality system, you’re not just buying a product—you’re investing in a proven process that pays for itself over and over again.

Your Ceramic Coating Questions Answered

Look, even after you get the science behind it, deciding to get a professional ceramic coating is a big deal. It’s a real investment in protecting your car, and you should feel 100% confident before you pull the trigger. So let’s jump into the most common questions we hear from car owners and pro detailers alike.

How Long Do Titan’s Elastomer Coatings Really Last?

This is always the first question, and it’s a fair one. We’ve all been there with waxes that barely last a month. Standard ceramic coatings are a huge step up, but they can get brittle over time. This is where Titan’s elastomer coatings really change the game.

The secret sauce is our flexible technology. Think about it: your car’s metal panels are constantly expanding and contracting with temperature changes. A rigid coating can’t handle that stress and eventually develops tiny cracks, which is how it starts to fail. Because our coatings are flexible, they move with your paint.

For a product like our Titan Hyper-Quartz T-6, this means you’re looking at 3-5+ years of solid, reliable protection. The best part? Keeping it looking great is way easier than the endless cycle of waxing.

Can I Apply a Ceramic Coating Myself?

Tempting, I know. There are a ton of DIY products out there, but getting that flawless, glass-like finish and true long-term durability is another story. It really comes down to the prep work, and that’s where the pros earn their keep.

The most critical step by far is paint correction. This isn’t just a quick polish; it’s an intensive process to hunt down and eliminate every single swirl mark, haze, and imperfection. Why? Because once the coating is on, whatever is underneath is locked in for years.

This level of prep takes specialized tools and a ton of experience. That’s why we always recommend having a certified professional install Titan Coatings. You’re not just paying for the product; you’re paying for the peace of mind that it’s done right and will perform exactly as designed.

Will a Ceramic Coating Make My Car Scratch-Proof?

This is a huge misconception we need to clear up. A ceramic coating adds an incredibly hard, sacrificial layer to your paint. It’s fantastic at resisting light scratches, wash-induced swirl marks, and other minor abrasions. However, a ceramic coating will not make your car bulletproof.

Deeper scratches from keys, abrasive automatic car wash brushes, or a nasty rock chip on the highway can still get through.

For people who want the absolute best defense against physical damage, the ultimate setup is a hybrid one. You install Paint Protection Film (PPF) on high-impact zones (like the front bumper and hood), and then you lay down a flexible Titan coating over the entire car. That’s how you get total protection.

“Think of a standard ceramic coating as a thin sheet of glass—it’s very hard, but it’s also rigid and can shatter. An elastomer coating from Titan is more like a sheet of flexible, hardened rubber. You get that same 9H hardness but with the critical ability to flex and absorb impacts.”

This flexibility is what keeps the coating from breaking down, giving you a much more durable shield against whatever the road throws at you. You can see a full breakdown of how our products stack up on our coating comparison page.

Ready to see what this next level of paint protection is all about? The Titan Coatings Hyper-Quartz T-6 strikes the perfect balance of hardness, flexibility, and an unbelievable gloss. It’s our go-to for long-term preservation. Explore the Titan Hyper-Quartz T-6 today and give your vehicle the armor it deserves.

0 Comments