The best ceramic wheel coatings strike a critical balance between extreme hardness and flexibility. They need to be tough enough to resist contaminants but flexible enough to avoid cracking under intense heat cycles, all while making cleanup almost effortless. For those in the know, elastomer-based coatings are the pinnacle of this technology, offering a level of durable, long-lasting protection against brake dust and road grime that old-school waxes just can’t touch.

Why Your Wheels Demand Elite Protection

We all know someone like Alex. He’s a true performance car enthusiast who pours his heart and soul into maintaining his ride. Every panel is polished, the interior is immaculate, but his custom alloy wheels are a constant source of pain. No matter how thoroughly he scrubs them, the frustrating cycle always repeats itself.

Within a few days, a fine layer of corrosive brake dust blankets the intricate spokes, baking itself onto the surface. Road grime, tar, and other chemical nasties join the party, quickly turning his brilliant wheels into a dull, filthy mess. Alex has tried it all—carnauba waxes, polymer sealants, and every so-called “miracle” spray cleaner on the shelf. They all fail the same way, washing away after a couple of weeks and leaving his expensive wheels exposed.

This endless loop of aggressive cleaning for temporary results is a battle every car lover wages. But the problem isn’t a lack of effort; it’s the punishing environment your wheels live in.

The Harshest Environment on Your Vehicle

Your wheels endure the most brutal conditions of any part of your car, period. They are on the front lines, facing a relentless assault that conventional products are simply not designed to withstand.

- Extreme Heat: Hard braking generates incredible temperatures, literally cooking microscopic iron particles from your brake pads directly onto the wheel’s finish. Once baked on, this dust is a nightmare to remove without resorting to harsh chemicals.

- Chemical Assault: From acidic wheel cleaners to road salt and grime, your wheels are constantly bombarded with corrosive elements that degrade clear coats and painted finishes. Proper prep for any real protection requires a dedicated product, and you can learn more about how a quality iron fallout remover is non-negotiable.

- Abrasive Debris: Think about it—small rocks, sand, and other road debris are constantly pelting your wheels at high speed. This creates a network of micro-scratches that dull the finish and give dirt a perfect place to anchor itself.

Traditional waxes and sealants just melt away under this kind of thermal and chemical abuse. They might offer a fleeting shine, but they provide zero meaningful, long-term protection. This is precisely where modern ceramic coatings change the game, offering a solution that’s in a different league.

But not all ceramic coatings are created equal. A new breed of protection—elastomer coatings—is delivering the holy grail: extreme hardness combined with essential flexibility. It’s a combination that finally promises to end the constant cleaning cycle for good. This guide will take a hard look at what makes the best ceramic wheel coating and help you choose the right protection that actually lasts.

When you’re looking for the best ceramic wheel coating, you have to cut through the marketing noise and get down to what really matters. What separates a truly high-performance product from the rest? It boils down to a specific set of characteristics that deliver real, measurable protection in the harshest environment your vehicle faces.

This isn’t just about a nice shine that lasts a few weeks. We’re talking about creating a durable, functional barrier engineered to survive the daily onslaught of heat, chemicals, and grime that your wheels endure.

The Core Pillars of Performance

Forget the hype. Three key benchmarks truly define an elite wheel coating. Each one is a direct response to a specific threat your wheels are constantly up against.

- Chemical Resistance: Your wheels get hit with everything. Aggressive, acidic wheel cleaners, corrosive road salt, and grime can eat away at the finish. A top-tier coating needs to be a chemically inert shield that prevents etching, staining, or degrading, no matter what it comes in contact with.

- Thermal Resistance: Hard braking, especially on a performance car, generates an incredible amount of heat—often spiking to several hundred degrees. That kind of thermal stress will cause lesser products to simply break down and fail. A high-performance coating has to remain stable and fully bonded even when things get incredibly hot.

- Hydrophobicity: This is the “self-cleaning” magic everyone talks about. A truly hydrophobic surface repels water aggressively, forcing it to bead up and sheet off the wheel. As the water rolls away, it takes brake dust and dirt with it, making cleanup drastically easier and keeping your wheels looking cleaner for longer.

These three pillars are the foundation. But real innovation in coating technology has pushed durability to a whole new level.

The difference between a best-in-class ceramic wheel coating and an old-school wax or sealant isn’t just marketing—it’s backed by data. A conventional wheel wax might last you 4–8 weeks before brake dust and road grime completely break it down. In contrast, a professionally installed nano-ceramic can be validated for 3–5 years or even more. Industry analysis shows that advanced oxide-based formulas now make up around 59% of the global ceramic coating market, dominating older organic films thanks to their superior hardness and high-temperature stability. You can dive deeper into the ceramic coatings market trends on fortunebusinessinsights.com.

The Titan Coatings Difference: Elastomer Technology

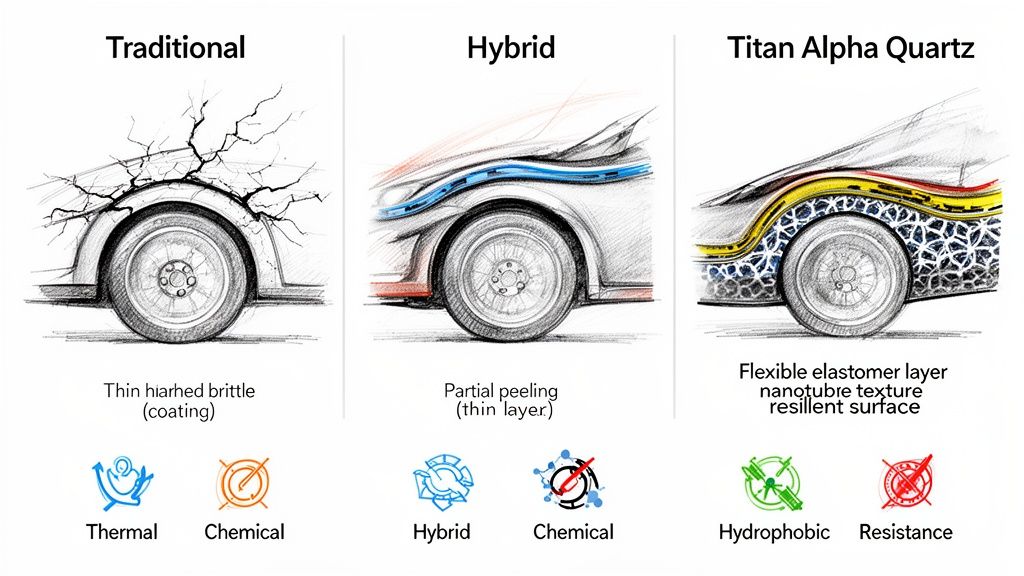

For years, traditional ceramic coatings have offered a hard, glass-like shell. But that hardness comes with a hidden weakness: it’s brittle. This rigidity makes them vulnerable to micro-fracturing from the constant thermal expansion and contraction of the wheel, not to mention impacts from road debris. This is where Titan Coatings completely changed the game.

We were the first to bring Elastomer coatings to the market, a revolutionary formula driven by nano tubes and our own Dark Matter Tech. This isn’t just a minor tweak to an old formula; it’s a fundamental leap forward in surface protection. Our elastomer technology creates a shield that is as hard as glass but has a remarkable degree of flexibility.

That flexibility is the key differentiator.

Think about it: a coating that can absorb the energy from a small stone impact instead of chipping. A protective layer that can actually flex with the metal of your wheel as it goes from blistering hot on a track day to freezing cold overnight.

This elastic property is what prevents the micro-cracking that plagues and ultimately causes traditional, rigid coatings to fail. The coating won’t crack down due to extreme temperature changes between frozen and hot environments. It means the bond stays stronger for far longer, ensuring the chemical, thermal, and hydrophobic protection never develops a weak point. This is why our elastic coatings have such incredible longevity—they’re built to survive the violent, dynamic reality of the road. It’s a type of resilience that goes far beyond the simple 9H hardness rating that so many brands fixate on. By combining that hardness with flexibility, we’ve created a truly robust shield for your wheels.

Comparing the Top Contenders in Wheel Protection

Choosing the right wheel coating isn’t about grabbing the shiniest bottle. It’s about matching advanced chemistry to the real-world abuse your wheels endure every single day. They face a brutal combination of extreme heat, corrosive chemicals, and physical abrasion that demands a highly specialized defense. To figure out what actually works, we have to look past the simple wax-versus-ceramic debate and judge these technologies by how they handle genuine, punishing conditions.

Think about a harsh northern winter, where your wheels are constantly soaked in a slushy mix of road salt and de-icing agents. Or picture a track day, where brake calipers are glowing red, superheating the wheel and baking corrosive dust right into the finish. These are the moments that separate a true protective shield from a short-lived cosmetic treatment.

The Three Tiers of Wheel Defense

Let’s break down the main players in the wheel protection game, from old-school sealants to the most advanced elastomer coatings available today.

1. Traditional Waxes and Hybrid Sealants

These are the classics, the entry point for most people. Based on carnauba wax or synthetic polymers, they create a temporary barrier that adds a bit of gloss and minimal water beading. While certainly better than leaving your wheels bare, their low melting point and weak chemical resistance make them fundamentally unfit for the job. Road salt and aggressive wheel cleaners strip them away in no time, and the intense heat from braking renders them useless almost instantly.

2. Standard Ceramic Coatings

This is where things get serious. These silica-based (SiO2) coatings form a hard, glass-like layer that chemically bonds to the wheel’s surface, becoming a semi-permanent part of it. They offer excellent hardness, far better chemical resistance than any sealant, and impressive durability, often lasting a year or more. Their main weakness, however, is their rigidity. This brittleness makes them prone to micro-cracking when hit with the thermal shock of rapid heating and cooling or impacts from road debris.

3. Titan Coatings Elastomer Technology

This is where the science takes a massive leap forward. As the first company to introduce elastomer coatings using nanotubes and our proprietary Dark Matter Tech, we engineered a solution that directly addresses the core weakness of traditional ceramics. Our formulas, like Titan Alpha Quartz, create a protective layer that is as hard as glass but also incredibly flexible.

This elasticity is the game-changer. It allows the coating to absorb impacts and flex with the wheel’s metal during extreme temperature swings—from freezing cold to scorching hot—preventing the microscopic cracks that lead to premature failure. This also means it won’t crack when bugs hit the car’s surface.

Wheel Coating Technology Head-to-Head Comparison

To truly grasp the differences, let’s compare these technologies side-by-side on the metrics that matter most.

| Feature | Traditional Wax/Sealant | Standard Ceramic Coating | Titan Alpha Quartz (Elastomer) |

|---|---|---|---|

| Durability | Weeks | 1-2+ years | 2-3+ years |

| Heat Resistance | Very Low (< 150°F) | High (~1,000°F) | Extremely High (>1,800°F) |

| Chemical Resistance | Low (strips easily) | Good (pH 2-11) | Excellent (pH 1-13) |

| Flexibility | None (melts off) | Low (rigid & brittle) | High (absorbs impacts & thermal shock) |

| Primary Weakness | Melts and washes away | Prone to micro-cracking | Higher initial investment |

This table makes it clear: while standard ceramics were a huge step up, the flexible, resilient nature of elastomer technology provides a level of protection that simply wasn’t possible before.

Real-World Scenarios Head-to-Head

So, how do these technologies stack up when the rubber meets the road?

- The Winter Salt Test: A sealant might last a few washes before salt eats through it. A standard ceramic holds up much better but can be compromised if micro-cracks form and let contaminants in. The flexible elastomer coating maintains its integrity, providing a continuous, impenetrable barrier against corrosion all winter.

- The Track Day Torture Test: Under intense braking heat, a sealant is gone in minutes. A standard ceramic may survive, but the repeated heat cycles stress its rigid structure. An elastomer coating, built for these extremes, remains stable and bonded, ensuring brake dust can’t bake itself into the finish.

- The Harsh Cleaner Challenge: Using a strong wheel cleaner on a sealant is a surefire way to strip it completely. Standard ceramics offer good resistance but can be worn down by repeated exposure. Our elastomer coatings are engineered with superior chemical resilience, shrugging off even potent cleaners without degrading.

Our commitment to a higher standard of performance is validated by our ISO 9001 certification. This isn’t just a badge; it’s a rigorous, third-party audited process ensuring that our products, from development to delivery, meet the highest possible quality standards. When you choose Titan, you’re choosing a product backed by military-grade polymer science and an unwavering dedication to excellence.

Total Vehicle Protection Beyond Wheels

This philosophy of durable, functional protection extends to every part of your vehicle. The same principles of clarity and resilience are just as crucial for your windshield. Driving in a downpour can be incredibly stressful, slashing visibility and increasing driver fatigue.

Our Apex Glass Ceramic Coating is engineered to make that stress disappear. Its powerful hydrophobic properties create an ultra-slick surface that water simply can’t cling to. Rain beads up into perfect spheres and is whisked away by the wind, often making wipers unnecessary at highway speeds. This drastically improves visibility and makes driving under rain stress-free and significantly safer. Just like our wheel coatings, it’s remarkably easy to use, delivering a professional-grade safety upgrade for any driver.

Applying Titan Alpha Quartz for Lasting Results

After getting a handle on Titan’s elastomer technology, Alex was sold. This was his answer to the endless war against brake dust, and he was ready to apply Alpha Quartz. He wasn’t a pro detailer, but he was patient and knew that a spectacular, durable finish starts long before the coating ever touches the wheel. It all comes down to the prep work.

Alex began by giving his wheels a deep clean, starting with a quality soap and then hitting them with an iron remover to break down the embedded metallic grit. The final, and most critical, step was a panel wipe with an isopropyl alcohol (IPA) solution. This strips away any lingering oils or polish residues, creating a completely sterile surface. You simply can’t skip this; a clean slate is what allows the coating to forge its strongest possible chemical bond.

With the wheels prepped and spotless, Alex shook the bottle of Alpha Quartz and dripped a few drops onto his applicator. Time to get to work.

The Application Journey

He tackled one small section at a time, using a deliberate cross-hatch pattern to guarantee full, even coverage. The coating glided on effortlessly—a hallmark of a premium formula. He kept a close eye on the surface, waiting for it to “flash.” That’s the detailer’s term for the moment the carrier solvents evaporate, leaving the pure protective layer behind.

This visual cue signaled it was time to level the high spots with a clean microfiber towel. A quick follow-up with a second, plusher towel brought out an incredible, candy-like gloss. It was a simple, methodical process that felt almost relaxing.

Alex repeated these steps for all four wheels, watching each one transform from merely clean to a deep, wet-looking shine. He learned that getting professional-level protection isn’t about some guarded industry secret. It’s about following a proven process with a product that’s engineered to perform. For a full breakdown, our guide on applying ceramic coating to a car offers more tips that apply to any part of your vehicle.

The sense of accomplishment Alex felt is exactly why the ceramic coating market is booming. This isn’t just a niche service for supercars anymore. In fact, dedicated wheel coatings alone were estimated to be a USD 578 million global market in 2024. That demand sends a clear message: enthusiasts want real, long-term protection, and the industry is stepping up.

The Moment of Truth

A few weeks went by. Alex drove through spring downpours and kicked up dust on back roads. The real test came at the next car wash. Instead of spending ages scrubbing, he just pointed a pressure washer at the wheels. The brake dust and grime literally sheeted off, revealing the pristine, high-gloss finish beneath. It was almost hard to believe.

Water beaded up and shot off the surface, carrying the last bits of dirt away with it. All it took was a light wash with a pH-neutral soap to get the wheels looking brand new again. The cycle of scrubbing was finally broken. The ease of maintenance was stunning, but the protection was what truly impressed him. Alex wasn’t just cleaning his wheels anymore; he was witnessing advanced elastomer science in action.

Achieving Total Vehicle Clarity with Glass Coatings

Alex couldn’t get over how easily brake dust and road grime rinsed off his Alpha Quartz-protected wheels. It was a game-changer. That got him thinking: why stop there? The same clarity, durability, and safety he now had on his wheels were even more critical for his windshield.

Driving through a sudden downpour was always a tense, white-knuckle affair. Smearing wipers, poor visibility, and constant stress—he dreaded it. Could Titan’s technology solve that problem, too?

From Wheel Protection to Windshield Safety

The logic felt simple. If a coating was tough enough to create a slick barrier against corrosive brake dust, it could definitely handle rain. He quickly learned that the best ceramic wheel coatings share their core DNA with high-performance glass coatings. Both are engineered to form a super-slick surface that prevents contaminants from getting a grip, whether it’s iron fallout or water droplets.

He decided to go for it, treating his windshield with Titan’s Apex Glass Ceramic Coating. The application was surprisingly simple, and the result was an invisible shield that he hoped would completely change his experience driving in the rain.

A few days later, he got his chance. Driving home from work, the sky opened up. But this time was different. As the first drops hit the glass, they didn’t flatten out and smear. Instead, they beaded into perfect little spheres. The moment he picked up speed, the airflow alone just whisked them away.

It was incredible. At highway speeds, the water was clearing so fast he barely needed his wipers. His visibility was crystal clear, turning a drive that used to be a nightmare into something calm and safe. This wasn’t just a convenience product; it was a fundamental safety upgrade.

This holistic approach to car care is what separates the casual enthusiast from someone who demands peak performance and protection in every situation. The market for these solutions is exploding, proving there’s a real demand for products that deliver tangible results. The automotive wheel coating segment alone is projected to grow from USD 761.3 million in 2024 to USD 1.105 billion by 2034. For pro detailers, partnering with brands that offer proven, multi-surface solutions is becoming a major advantage. You can read more about the automotive wheel coating market on market.us.

Extending your vehicle’s protection from the wheels to the glass creates a complete shield against the elements, boosting both its look and your safety on the road. You can dive deeper into the science and benefits by reading our in-depth look at ceramic coating for glass.

So, Which Titan Coating Is Right For You?

Choosing the right protection for your wheels is a big decision. You’ve seen the science, you understand the application process, and you’ve looked at the real-world results. It’s pretty clear that Titan Coatings is in a league of its own, and that’s because our search for the best wheel coating led us to create something entirely new: our groundbreaking elastomer technology.

This isn’t just another hard, candy-like shell. We engineered a flexible, resilient shield built to withstand the brutal reality your wheels face every single day.

Traditional ceramic coatings talk a big game about hardness, but that rigidity is their fatal flaw. They’re fragile. The constant stress from braking heat and cool-downs, not to mention impacts from road debris, causes them to micro-crack and fail. Our coatings, supercharged with nano tubes and Dark Matter Tech, completely solve this problem. You get that same incredible glass-like hardness but with the game-changing ability to flex. This prevents cracks and ensures the protective barrier stays intact, whether you’re navigating a frozen winter commute or a blistering hot track day.

Your Guide to Ultimate Protection

Finding the right product in our lineup is straightforward. We’ve designed specific solutions for specific jobs, so you can get the perfect match for your car and how you drive it.

- For the Die-Hard Enthusiast: Titan Alpha Quartz

If you’re looking for absolute, no-compromise durability and wheels that are ridiculously easy to clean, Titan Alpha Quartz is the only choice. It offers our highest level of thermal, chemical, and abrasion resistance, all while leaving behind a fantastic gloss. Its easy-to-install formula and flexible structure mean it simply outlasts and outperforms brittle, old-school ceramics, delivering great results every time. - For Complete Vehicle Safety: Apex Glass Ceramic Coating

Why stop at the wheels? Apex Glass Ceramic Coating is a massive safety upgrade for driving in bad weather. It creates an intensely hydrophobic surface on your windshield, causing rain to fly right off. This drastically improves your visibility in a downpour, making the drive safer and a lot less white-knuckle. It’s a must-have for any daily driver.

The real secret sauce is our elastomer formula. It gives our coatings a level of resilience that rigid products just can’t touch. This flexibility is what lets our coatings take years of punishment without chipping, cracking, or breaking down. To really get into the weeds on this, you can explore our detailed breakdown of Titan Coatings’ elastomer technology.

When you choose Titan, you’re choosing not to settle. If you want to see exactly how our different products measure up against each other, our comparison page gives you all the details you need to make the right call. It’s time to step up to the next generation of surface protection and give your vehicle the defense it truly deserves.

Still Have Questions? Let’s Talk Wheels.

It’s normal to have a few lingering questions before committing to a coating. After all, you want the best for your car. We’ve been there. Let’s tackle some of the most common things people ask.

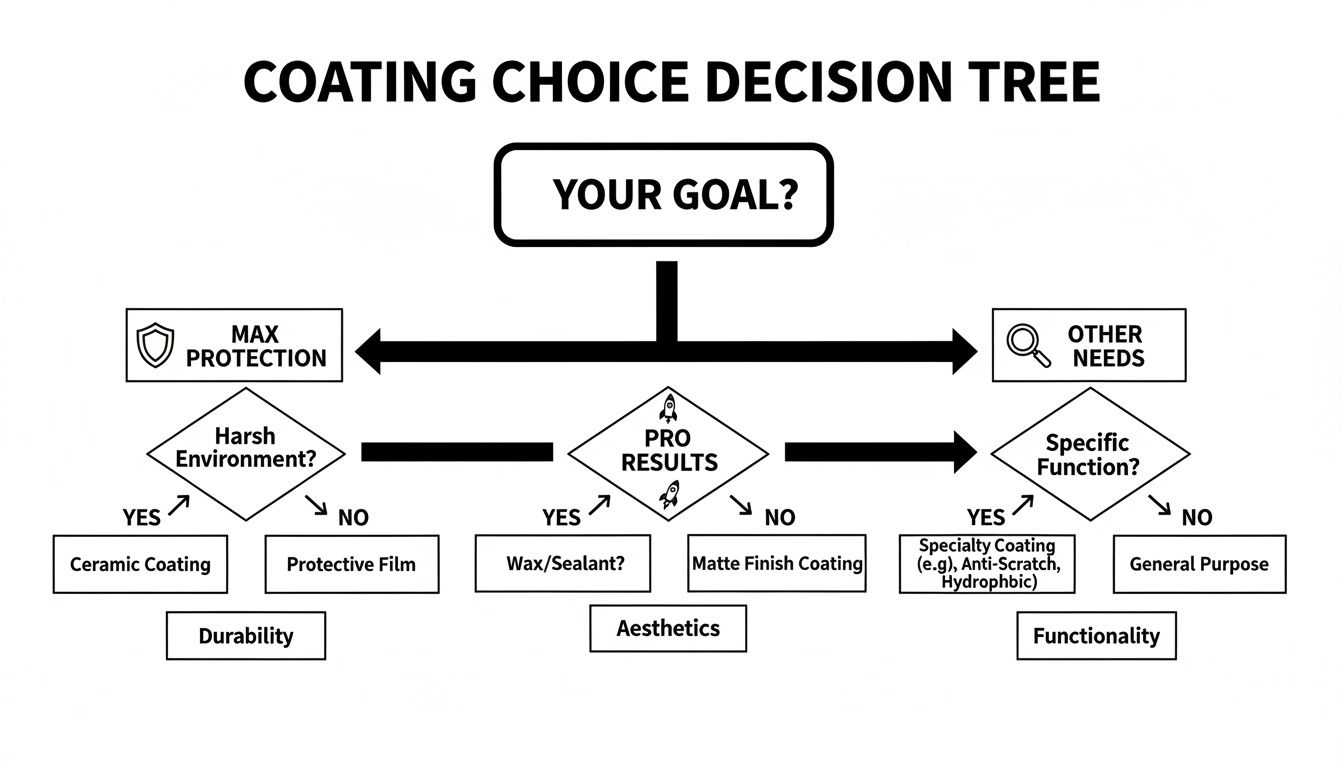

This chart can help you quickly pinpoint what matters most to you—whether it’s bulletproof protection for a track car or just making your daily driver easier to clean.

The biggest takeaway here? Figure out your main goal first. Once you know what you want to achieve, picking the right technology becomes a whole lot easier.

What Makes Elastomer Coatings Last So Much Longer Than Old-School Ceramics?

The magic is in the flexibility. Think of traditional ceramic coatings as a thin sheet of glass—hard, but brittle. When your wheels heat up and cool down, they expand and contract. This “thermal shock” causes micro-fractures in rigid coatings, leading to premature failure.

Titan’s elastomer coatings are different. We engineer them with nano tubes and our Dark Matter Tech to be both hard and pliable. They move with the metal, absorbing impacts and temperature swings without cracking. That’s how they keep the protective layer intact for so much longer.

Can I Use These Coatings on Any Type of Wheel Finish?

You bet. Painted, powder-coated, clear-coated, or even polished alloys—a high-quality coating like Titan Alpha Quartz is formulated to bond with them all.

The type of finish isn’t the most important variable; the prep work is. You need a surgically clean, decontaminated surface to get that strong, lasting chemical bond. Without it, you’re not unlocking the coating’s true potential.

Will I Have to Change My Maintenance Routine After Coating My Wheels?

Yes, and you’re going to love it. Maintenance becomes ridiculously easy. The super-slick surface the coating creates means brake dust and road grime have almost nothing to cling to.

Forget about those harsh, acidic wheel cleaners. Most of the time, a simple wash with a pH-neutral soap and water is all it takes to bring back that deep, glossy shine. It saves you time, effort, and protects your investment.

Ready to give your wheels the protection they deserve? Titan Coatings offers the next generation of durability and performance. Explore our elastomer-based solutions and see the difference for yourself.

0 Comments