A top-tier rain repellent ceramic coating is more than just a car care product—it’s a fundamental upgrade for safer driving. It completely transforms your windshield and paint into super-slick, water-hating surfaces that force rain to simply get out of the way. This technology forms an invisible, durable shield that dramatically boosts visibility and helps your vehicle stay cleaner, longer.

Why Your Vehicle Struggles in Wet Weather

We’ve all been there. You’re driving along, and a sudden downpour hits. Your world instantly shrinks to the frantic sweep of your wiper blades. Instead of clearing the view, they seem to just smear the water around, turning oncoming headlights into a blinding glare. It’s not just annoying; it’s a genuine safety hazard every driver knows too well.

This is the constant battle your vehicle fights against the elements. Water naturally wants to stick to surfaces. On untreated glass and paint, this simple fact creates a cascade of problems that extend far beyond just not being able to see clearly.

The Hidden Damage of Rain

When raindrops just sit on your car, they do more than block your view. They become tiny magnets for road grime, dust, and airborne pollutants. Once the water evaporates, it leaves behind a nasty, concentrated residue of minerals that form stubborn water spots. Over time, these spots can actually etch into your clear coat, permanently dulling your vehicle’s finish.

And the fight doesn’t stop there. Wet roads kick up a nasty cocktail of dirt, oil, and road salt that cements itself to your car’s lower panels. This grimy film is a pain to wash off and can even speed up corrosion if you’re not careful. Every rainy day is a fresh assault on both your safety and your car’s condition.

A Modern Solution for a Timeless Problem

For decades, the only real defense was constant washing and applying waxes that offered a little protection for a short time. But what if your car could actively repel the rain on its own? This is exactly where a rain repellant ceramic coating changes everything.

Imagine a surface so incredibly slick that water has no choice but to form tight beads and roll right off, carrying dirt and grime away with it. This isn’t a futuristic concept; it’s the reality of today’s advanced coating technology.

At Titan Coatings, we’ve engineered a solution to make this a reality for every driver. Products like our powerful Titan APEX Glass Ceramic Coating are designed to turn a stressful drive in the rain into a non-event. By creating an intensely hydrophobic barrier, the airflow over your car at speed is enough to whisk water away, often making wipers almost redundant.

This technology delivers more than just a cleaner car—it provides a fundamentally safer, more confident driving experience, no matter what the weather throws at you. It’s the shield your vehicle needs to finally win the battle against the elements.

The Science of Hydrophobic Protection

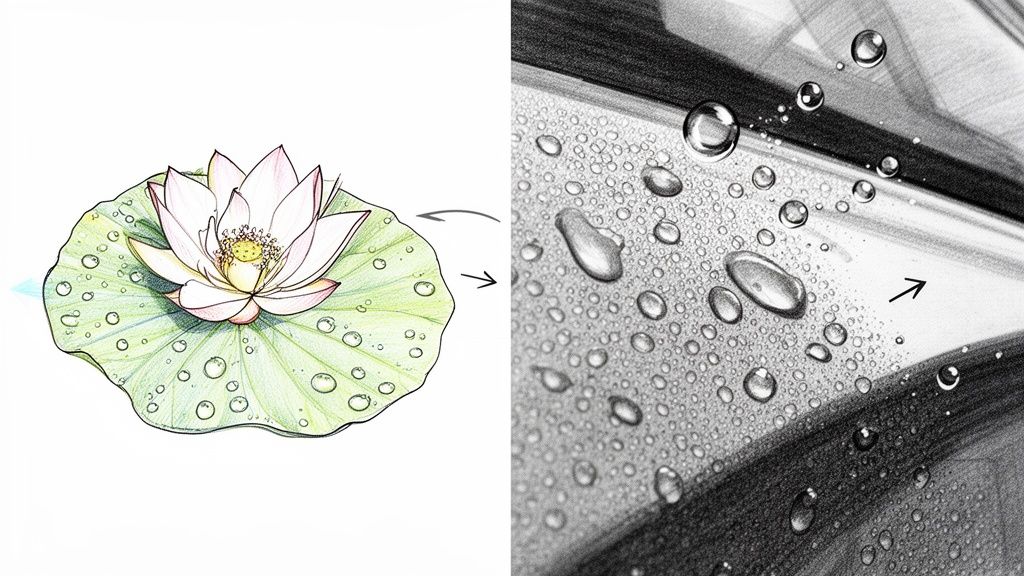

Ever wondered how a surface can shed water so aggressively it seems to defy physics? It’s not magic. The secret is a brilliant principle we borrowed directly from nature and perfected in the lab.

Think about a lotus leaf. It stays pristine and dry even in the murkiest water. That natural phenomenon is the inspiration behind every advanced rain repellant ceramic coating on the market today.

If you could zoom in on that leaf, you’d see it’s anything but smooth. It’s covered in a complex pattern of nano-scale bumps and waxy structures. This texture dramatically reduces the surface area a water droplet can touch, forcing it into a tight, almost perfect sphere. This is called a high water contact angle, and it’s the very essence of hydrophobicity.

Instead of flattening out and wetting the surface, the water beads up, perched on these microscopic peaks. The slightest movement sends those beads rolling off, scooping up dirt and dust along the way. This is nature’s self-cleaning masterpiece, and it’s exactly what we replicate for your vehicle.

From Nature to Nanotechnology

Bringing this effect from a leaf to your car’s paint is where the real engineering comes in. This is where Titan Coatings’ work with Dark Matter Tech® and nano tubes completely changes the game. We’ve found a way to build a similar nanostructure right on your vehicle’s clear coat and glass, creating a molecular barrier that is unbelievably dense and slick.

This isn’t just another layer that sits on top, like a wax. A true ceramic coating, like the ones we’ve developed at Titan, forges a chemical bond with the surface itself, becoming a semi-permanent part of it. This creates a tough, slick shield that gives water and grime nowhere to go but off. You can get a solid primer on the basics in our guide explaining what ceramic coatings are.

This technology fundamentally rewrites the rules of how your vehicle interacts with the elements. It’s a scientifically engineered defense that temporary products just can’t touch.

The Growing Demand for True Hydrophobic Solutions

It’s no surprise that people want this kind of protection. In fact, the global rain repellent coating market hit an impressive USD 1.54 billion in 2024, proving just how much demand there is for real hydrophobic performance. This niche is all about coatings that excel at water beading and sheeting, protecting surfaces from water spots and corrosion while keeping cars looking incredible.

For professional detailers and serious car owners, a top-tier rain repellant ceramic coating is the pinnacle of vehicle care. For a closer look at these market trends, you can explore the full report on growthmarketreports.com.

At Titan Coatings, our journey began by pioneering the first elastomer coatings for the automotive market, using our nano tube and Dark Matter tech. This innovation created a coating that is not only hard like glass but also remarkably flexible, a quality that prevents cracking under stress.

This flexibility is a massive advantage. Traditional, brittle ceramic coatings can develop micro-cracks when temperatures swing from freezing cold to scorching hot. Our elastic coatings, on the other hand, flex and adapt. This resilience keeps the hydrophobic barrier intact and working for years, delivering the kind of dependable, season-after-season performance you expect.

The Unmatched Durability of Elastomer Coatings

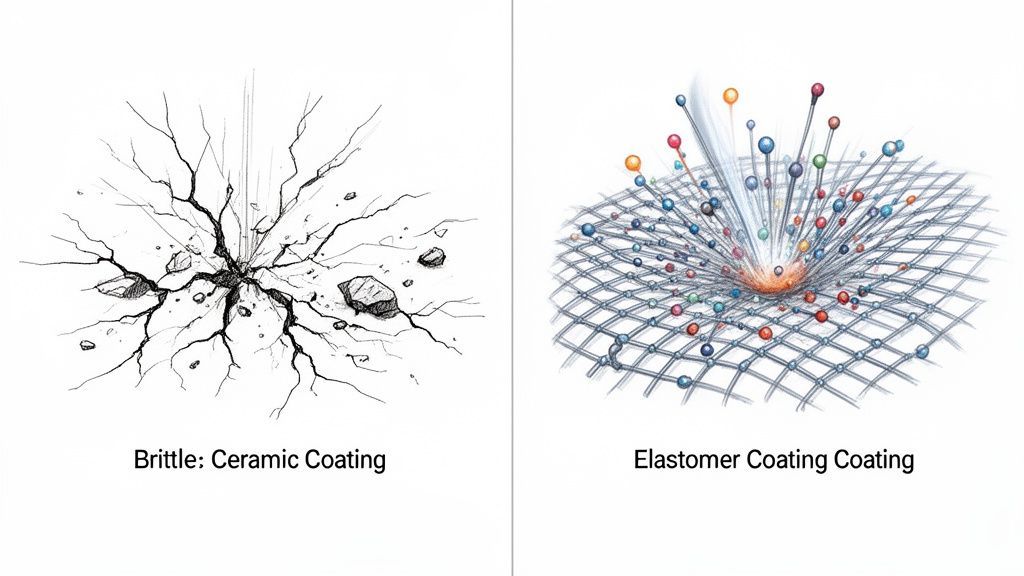

The water-beading magic of a standard ceramic coating is undeniable, but many of them hide a critical weakness. Most traditional coatings cure into a hard, glass-like shell. And while hardness sounds great on paper, that rigidity makes them brittle and vulnerable to the everyday abuse a car faces on the road.

Think about a thin pane of glass. It’s tough, sure, but a single rock chip or the stress from a rapid temperature swing can create tiny fractures. That’s exactly what happens to a lot of ceramic coatings. Over time, these micro-cracks compromise the coating’s integrity, weakening its protective shield and killing its rain-repellent performance.

This very problem was the catalyst for a huge breakthrough here at Titan Coatings. We started asking ourselves, “What if a coating could be as hard as glass but as flexible as rubber?” The pursuit of that answer led us to pioneer the first elastomer-based coatings for the automotive world, creating a whole new category of protection that completely rewrites the rules of durability.

Hardness Meets Flexibility

So, what is an elastomer? It’s basically a polymer that has incredible elasticity. The easiest example is a rubber band—you can stretch it out, and it snaps right back to its original shape. By weaving advanced nano tube technology into our formulas, we developed a rain-repellent ceramic coating that does just that. It cures into a tough, defensive layer that can also flex and absorb impacts without shattering.

This elasticity is the secret to its incredible longevity. Here’s why it’s such a big deal for your car:

- Impact Resistance: When a piece of road debris smacks an elastomer-coated panel, the coating flexes to spread out the force. This dramatically cuts down the risk of chipping or cracking that would plague a brittle coating.

- Thermal Expansion: A vehicle’s body panels are constantly expanding and contracting with temperature changes. An elastomer coating moves right along with the surface, preventing the stress fractures that brittle coatings get from freezing winters and scorching summers.

This built-in resilience means the protective layer doesn’t break down. It just keeps working, delivering that unbelievable hydrophobic performance and protection for years, not just a few months. For a deeper dive into the chemistry, you can learn more about how Titan Coatings’ elastomer technology works.

The Alpha Quartz Advantage

The pinnacle of this technology is our Titan Alpha Quartz. We engineered this product from square one specifically to solve the durability problem. It’s an easy-to-install elastomer coating that lays down an intense, candy-like gloss and provides amazing chemical resistance, all while maintaining that signature flexibility.

A vehicle protected with Alpha Quartz isn’t just shielded; it’s armored with a resilient layer. Bug guts, minor rock pings, and extreme temperatures are no longer a threat to the coating’s structural integrity.

The idea of flexible, waterproof layers isn’t totally new. You can see similar concepts at play by understanding elastomeric roof coating, where a seamless, flexible membrane protects entire buildings from the elements. We’ve just taken that powerful concept, refined it, and adapted it for the very specific demands of automotive paint.

By opting for an elastomer-based rain-repellent ceramic coating, you’re not just getting protection; you’re investing in a smarter, more durable technology. It’s a shield that doesn’t just fight the environment but actually adapts to it, ensuring your vehicle stays protected and looks incredible, no matter what the road throws its way.

Achieving Crystal Clear Vision with Titan APEX

While our elastomer coatings are incredible for protecting your vehicle’s paint, there’s one part of the car where a rain repellant ceramic coating isn’t just a luxury—it’s a critical safety feature. We’ve all been there: driving through a sudden downpour, wipers smearing water across the glass, creating a blinding glare. It’s stressful and downright dangerous. This is precisely where the specialized protection of Titan APEX Glass Ceramic Coating completely changes the game.

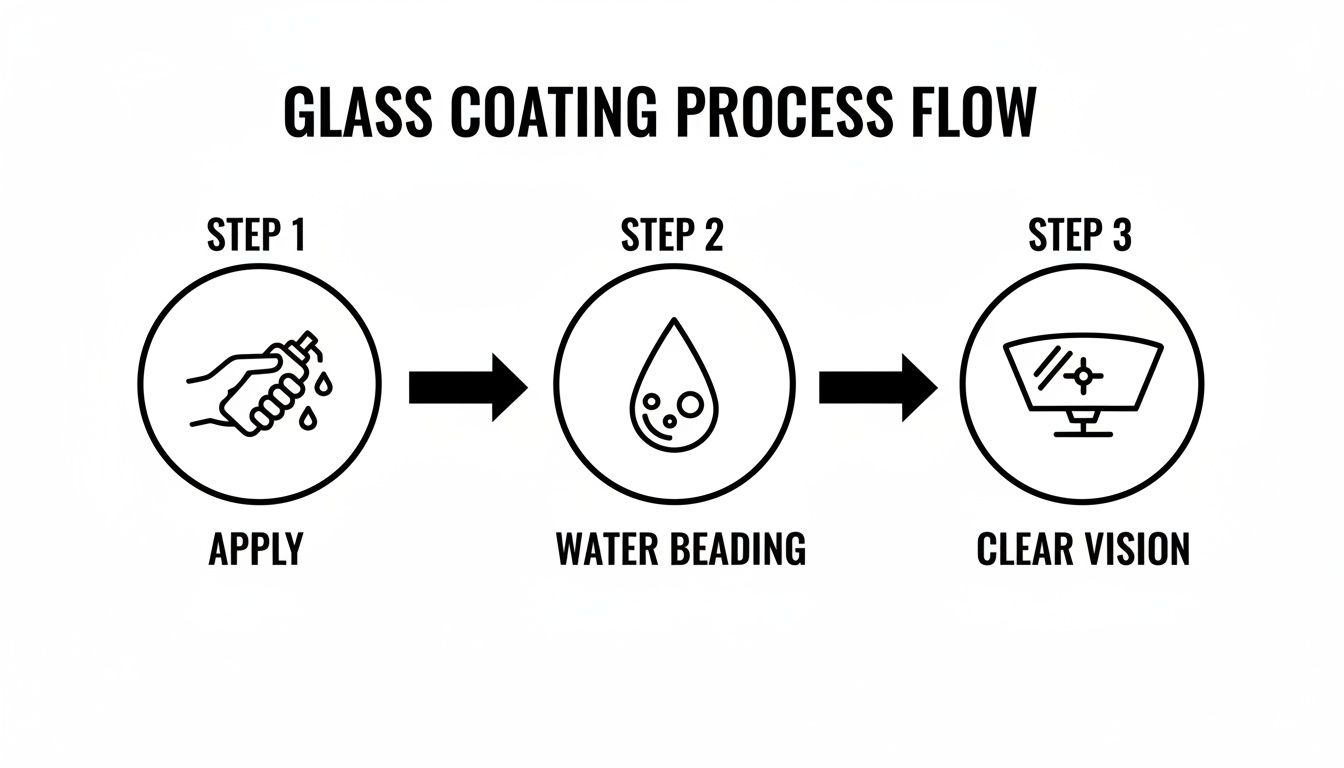

Picture a detailer getting a client’s car ready for the ultimate wet-weather defense. After a meticulous cleaning and prep of the glass, they apply just a few drops of APEX. The application itself is simple and fast, but the results are immediate and profound. The glass becomes incredibly slick, perfectly clear, and ready to take on whatever Mother Nature throws at it.

The real magic happens the moment the first raindrop hits that APEX-treated windshield. Instead of splattering and clinging, the water instantly forms into perfect, tiny spheres. As the car gets up to speed, the airflow alone whisks these beads right off the glass, leaving your line of sight completely clear. In fact, at highway speeds, you often don’t even need to use your wipers, which seriously cuts down on driver fatigue during a heavy storm.

A Transformation in Driving Safety

This isn’t just about making driving more convenient; it’s a fundamental upgrade to your safety. Clear vision is everything on the road, and APEX guarantees you have it when it counts the most. By creating an intensely hydrophobic surface, it gives you an unobstructed view, helping you react faster to hazards and drive with more confidence in bad weather. The anxiety of navigating a storm simply melts away when your windshield is actively clearing itself.

By forming a slick, durable bond with the glass, APEX doesn’t just repel rain. It creates a barrier that makes it much harder for other common nuisances like ice, bugs, and road grime to stick.

This year-round value is what makes APEX such a smart upgrade for any driver. The benefits go far beyond just rainy days:

- Effortless Ice Removal: When the temperature drops, ice scrapes off with almost no effort because it can’t get a solid grip on the slick, coated surface.

- Easy Bug and Grime Cleaning: After a long trip, bug splatters and baked-on dirt wipe away easily, no harsh scrubbing needed.

- Reduced Wiper Wear: Since you’ll find yourself using your wipers a lot less, the blades last longer, which saves you money on replacements.

The Clear Choice for Ultimate Protection

APEX delivers a stress-free driving experience by ensuring your most important window to the road stays clear and clean. Its easy-to-use formula makes professional-grade results accessible, offering long-lasting hydrophobic performance you can see and feel every single time it rains. So while a robust coating like Alpha Quartz protects your paint, APEX provides that specialized, essential shield for your glass. To learn more about why specific glass treatments are so important, check out our guide on choosing the best ceramic coating for your windshield.

Of course, perfect clarity is about more than just repelling rain. Keeping your glass in top shape also means dealing with any existing flaws. Beyond preventing rain buildup, maintaining crystal clear vision also involves addressing existing damage; explore this windscreen scratch repair guide for comprehensive care. When you combine a flawless surface with the superior protection of APEX, you create the safest, clearest view possible for every journey.

A Step-By-Step Coating Application Guide

Getting that amazing water-beading action from a rain repellant ceramic coating isn’t just about the bottle you hold in your hand—it’s all about the process. A perfect, rock-solid finish starts with flawless prep work. This guide is for the pros who live and breathe this stuff and the dedicated weekend warriors who won’t settle for anything less than spectacular results.

The demand for this level of protection is exploding. The global ceramic coating market was valued at a staggering USD 11.16 billion in 2023 and is on track to hit USD 25.60 billion by 2034. That’s not just a trend; it’s a movement. Car owners everywhere are investing in the durability, UV blocking, and slick hydrophobic properties that define modern coatings. You can get a closer look at these numbers and discover more insights on the ceramic coating market at Precedence Research.

This whole process is about transforming your glass to repel rain, giving you a crystal-clear view of the road ahead.

It’s simple, really. A proper application directly leads to that awesome water-beading effect, which means a safer, clearer drive for you.

Phase 1: The Non-Negotiable Preparation

Let’s be blunt: before a single drop of coating touches the paint, that surface has to be surgically clean. This is the stage where most applications are won or lost. The coating needs a raw, pure surface to bond with chemically. Any old wax, oils, or stubborn grime left behind will kill the bond and cause the coating to fail prematurely.

To do it right, you need a solid three-step attack:

- Deep Decontamination Wash: Forget the quick wash. Start with a quality pH-neutral soap to get the loose stuff off. Then, hit it with an iron remover and a tar remover to dissolve all the nasty, bonded-on contaminants you can’t see.

- Clay Bar Treatment: Even after a good wash, the paint will feel gritty with microscopic junk. A clay bar is your best friend here. It glides over the surface and pulls out everything embedded in the clear coat, leaving it feeling like glass.

- Paint Correction: This is where you create the canvas. Grab your machine polisher and get to work erasing any swirl marks, fine scratches, and oxidation. Not only does this make the paint look incredible, but it creates a perfectly flat, pristine surface for the coating to grab onto for maximum gloss.

Phase 2: The Coating Application

Okay, the paint is perfect. Now you’re ready to lay down the protection. Find a well-lit, clean space where you can control the environment. The sweet spot is usually between 60-75°F (15-24°C) with low humidity. This helps the coating go on smoothly and cure correctly. With a product like Titan Alpha Quartz, the process is pretty user-friendly, but your attention to detail is what makes the difference.

Here’s how you’d tackle a single panel:

- Final Wipe-Down: Mist the panel with an IPA (isopropyl alcohol) solution or a dedicated panel prep spray. This zaps any leftover polishing oils and makes the surface 100% sterile.

- Load the Applicator: Give the coating bottle a good shake. Squeeze a line of the coating onto your suede applicator block.

- Crosshatch Pattern: Pick a small, two-by-two-foot section and apply the coating by wiping side-to-side, then up-and-down. This crosshatch method guarantees you don’t miss a single spot.

- Watch for the “Flash”: In about 30 seconds to a couple of minutes, you’ll see the solvents evaporate. It often looks like a faint rainbow on the surface. That’s your signal that it’s time to wipe.

This is a game of patience. Work panel by panel, take your time, and slightly overlap your sections. Rushing is the fastest way to create an uneven, unprofessional-looking finish.

Phase 3: Leveling and Curing

Once the coating flashes, you’re in the home stretch. All that’s left is to level the residue and let it cure. This is where a lot of people mess up, so stay focused.

- The Initial Wipe (Leveling): Take a clean, plush microfiber towel and gently wipe the section. You’re not scrubbing; you’re just knocking down the excess product and creating a smooth, level layer.

- The Final Buff: Grab a second clean microfiber and give the area a final, light buff. This removes any streaks and ensures you don’t have any “high spots”—those dark, oily-looking patches of uncured coating.

- The Cure: Now, hands off. The vehicle needs to stay dry and out of the elements for at least 12-24 hours for the initial cure. Don’t let it get wet. The coating won’t be fully hardened for up to a week, so hold off on washing it with any soaps during that time.

Follow these steps, and you’ll get a perfect bond every time, unleashing that intense water-repellency and bulletproof durability you’re after. For a more in-depth look with videos, be sure to check out our complete guide on how to apply a ceramic coating to your car.

Your Rain Repellent Coating Questions Answered

Diving into the world of rain repellent ceramic coatings always brings up a few practical questions. Whether you’re a seasoned detailer or a passionate owner, you want to know what you’re really getting into. Let’s break down the most common things people ask us about longevity, application, and the science behind the shine.

How Long Does a Rain Repellant Ceramic Coating Really Last?

This is the big one, isn’t it? The honest answer is: it all comes down to the quality of the coating, how well the surface was prepped, and how you take care of it afterward. Those off-the-shelf sprays that promise the world? They might look good for a bit, but most of them are gone after a few weeks of real-world driving.

A professional-grade elastomeric coating like Titan’s Alpha Quartz is playing a completely different game. We engineered it for years, not months, of protection. Its secret weapon is flexibility, a core part of our elastomer technology that prevents the tiny cracks that doom traditional, brittle ceramic coatings. This lets it shrug off everything from blazing heat to freezing cold and even minor impacts from road debris.

With a little common sense care—like using pH-neutral soaps and steering clear of harsh chemicals—you’re looking at years of amazing water beading. For a deeper dive, check out our complete guide on how long you can expect a ceramic coating to last.

Can I Use the Same Ceramic Coating on My Windshield and Paint?

You technically could, but you absolutely shouldn’t. For the best performance and your own safety, you need products designed for the specific job. Alpha Quartz is a masterpiece on paint, creating a brilliant, slick barrier. But a windshield has a whole different set of demands.

This is where a dedicated glass coating like Titan’s APEX Glass Ceramic Coating comes in. APEX is formulated specifically to bond with glass, creating a much slicker and more durable surface. This is what gives you that effortless water-sheeting effect at highway speeds. More importantly, it prevents the dreaded “wiper chatter”—that annoying skipping and shuddering you get when a paint coating gums up your wipers.

It really comes down to using the right tool for the job. APEX for glass, Alpha Quartz for paint. That’s how you guarantee each surface gets the exact protection it was designed for.

What Is the Difference Between Hydrophobic and Super-Hydrophobic?

This isn’t just marketing speak; there’s real science here. The difference boils down to something called the water contact angle, which is just a fancy way of measuring how a single drop of water sits on a surface.

- Hydrophobic: A surface earns this label when the water contact angle is over 90 degrees. Water stops spreading out and starts forming distinct beads.

- Super-Hydrophobic: This is the next level. To be called super-hydrophobic, the contact angle has to be over an incredible 150 degrees. The water forms almost perfect little spheres that just want to roll away.

Our Dark Matter Tech® is engineered to create these extremely high contact angles, pushing our coatings firmly into the super-hydrophobic territory. This is what creates that amazing self-cleaning effect. As those tight water beads roll off your car, they grab dirt and grime, pulling it right off the paint and leaving the surface clean.

Do I Need a Professional to Apply Titan Coatings?

While we’ve designed products like Alpha Quartz to be user-friendly, we’ll always steer you toward a professional application for the absolute best results. A certified detailer brings a level of precision and control to the table that’s just tough to match in a home garage.

Why a Pro Installer Makes a Difference:

- Controlled Environment: Pros work in clean, well-lit bays to keep dust and other junk from ruining the finish. This is non-negotiable for a perfect bond.

- Specialized Tools: They have everything from high-end polishers for flawless prep to infrared lamps that ensure the coating cures perfectly.

- Paint Correction Expertise: This is maybe the most important part. A coating is only as good as the surface it’s on. A pro knows how to correct every swirl and imperfection, creating a perfect canvas.

That said, we make our products available for the dedicated DIY’er who lives and breathes perfection. If you’ve got the skills and patience for obsessive prep work, our detailed instructions will guide you. But the impeccable finish and warranty that come with a pro install are hard to pass up. It all depends on your experience, your setup, and the level of perfection you’re aiming for.

Ready to see what true rain repellency and paint protection look like? Titan Coatings offers a full lineup of advanced elastomer coatings, all engineered for incredible durability and a finish that has to be seen to be believed.

Discover the flexible, long-lasting protection of Alpha Quartz today and find out why it’s the choice for detailers and enthusiasts who refuse to compromise.

0 Comments