Want to know the real secret to waxing a car? It has almost nothing to do with the wax itself. The magic happens before that can of wax is even opened. You can have the most expensive, exotic wax in the world, but if you slap it on a dirty surface, you're just putting lipstick on a pig. A flawlessly clean and decontaminated surface is the only way to get that deep, durable shine we're all after.

Your Foundation for a Flawless Finish

I see it all the time. Let’s call him Alex, a weekend enthusiast who was constantly frustrated. He’d spend his Saturday laying down a coat of premium carnauba, stand back and admire the gloss, and then watch it all wash away after a couple of rainstorms. His hard work just vanished, leaving a dull finish that felt gritty to the touch. It was a vicious cycle.

His big breakthrough wasn't finding a "better" wax. It was realizing he was trying to paint on a dirty canvas. There’s a world of difference between a car that looks clean and one that is truly clean, down to the microscopic level. This is the #1 mistake that causes a wax job to fail, and getting this foundational prep right is what separates a quick shine from a professional-grade finish.

The Two-Bucket Wash Method

It all starts with a good wash, but I’m not talking about a quick once-over. The two-bucket method is your absolute best defense against adding new swirls and scratches to your paint.

- Bucket One: This is your "clean" bucket, filled with fresh water and a quality car shampoo.

- Bucket Two: This is your "dirty" bucket, filled with plain water to rinse your mitt.

The process is brilliant in its simplicity. Dunk your wash mitt in the soap bucket, wash a small section of the car (always start at the top and work your way down), and then rinse the now-dirty mitt in the plain water bucket before you ever put it back in your soapy water. This one little habit keeps all the grit and grime you just removed from getting dragged right back across your paint.

Think about it: you wouldn't mop your kitchen floor with a dirty mop head. The two-bucket system ensures only clean, sudsy water touches your car's delicate finish.

Going Deeper: Chemical Decontamination

Even after the perfect wash, your car's paint is still hiding embedded contaminants that have bonded to the clear coat. We're talking about things like industrial fallout, rail dust, and those tiny orange specks of iron from brake dust. You can't see most of it, but you can definitely feel it—run your hand over the paint and it will feel slightly rough or gritty.

This is where chemical decontamination becomes a game-changer. An iron remover, for example, is a spray that chemically reacts with those iron particles. You'll literally see it working as the product turns a deep purple and "bleeds" down the paint, dissolving the contamination. A good tar remover does the same for stubborn road tar and gunk without any harsh scrubbing. If you're serious about your wax lasting, this step is non-negotiable. It creates a truly pure surface for the wax to bond with. Finding the right products is a huge part of this, and knowing the best soaps for cars can make a massive difference right from the start.

The Final Touch: Mechanical Decontamination

The last hurdle to a perfectly smooth canvas is mechanical decontamination, usually with a clay bar or a clay mitt. After you’ve washed and chemically treated the paint, you'll glide the lubricated clay over every panel. The clay acts like a gentle razor, shearing off any stubborn bonded contaminants that the chemicals couldn't dissolve.

If you've never done this, prepare to be amazed. The paint will go from feeling slightly rough to being as smooth as a sheet of glass. That perfectly pristine surface is now finally ready to accept a coat of wax, allowing it to bond directly to the clear coat for incredible gloss, beading, and longevity. Our friend Alex learned this lesson the hard way, but once he adopted this three-stage prep, his wax jobs started lasting for months, not just a few weeks.

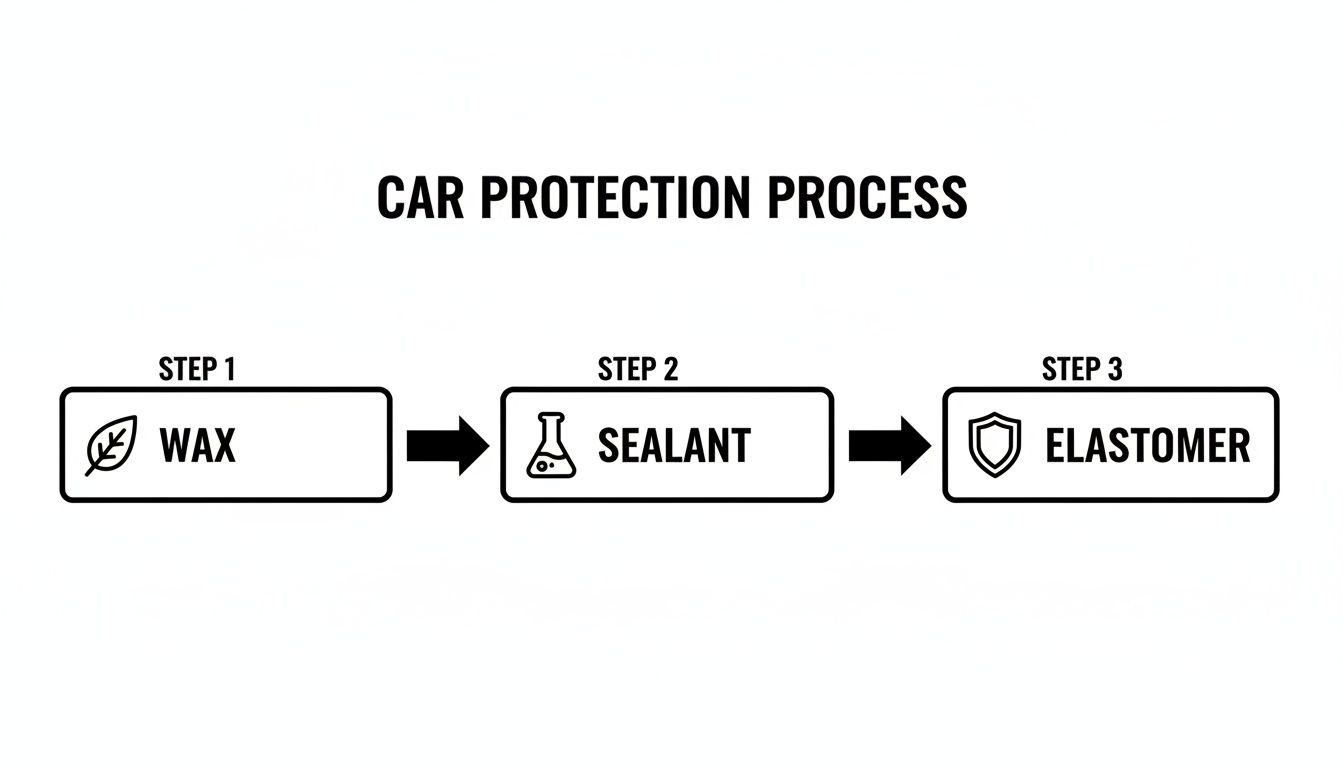

Choosing Your Protection: Wax, Sealant, or Elastomer Coating

Alright, your car’s paint is perfectly prepped and pristine. Now comes the moment of truth: what are you going to protect it with? This decision is a big one. It's what separates a shine that lasts a few weeks from a finish that stands up to the elements for years.

It’s easy to get lost in the world of paint protection. Do you go for the classic, warm glow of a natural carnauba wax? Or maybe the slick, modern durability of a synthetic sealant? Each has its place, but honestly, the real innovation in protection lies beyond these traditional choices.

The Old Guard: Waxes and Sealants

For decades, the choice was pretty straightforward: wax or sealant.

- Carnauba Wax: This is the old-school favorite for a reason. Derived from a palm tree, it gives the paint a deep, wet, organic look that purists absolutely love. The downside? It’s short-lived, typically giving you just 4-6 weeks of protection before it fades away.

- Synthetic Sealant: These are the lab-created cousins of wax. They're polymers engineered for better durability, offering a sharper, more reflective shine. You’ll get a solid 3-6 months of protection and better resistance to chemicals.

Both are respectable options, but they are temporary. Think of them as sacrificial layers that sit on top of the paint, wearing away with every wash and rainstorm. They demand constant reapplication. If you want to dive deeper into how these classics stack up against modern tech, check out this guide on the difference between wax and ceramic coatings.

The New Frontier: Elastomer Coatings

I was chatting with a professional detailer the other day—let’s call him Mike. For years, Mike’s entire business model was built on maintenance washes and applying a sealant every few months. He was good at it, but he felt like he was constantly fighting a losing battle against time and the elements. He was stuck in a cycle of reapplication.

Then he discovered the next evolution in paint protection: elastomer coatings. This is where the game completely changes. Titan was the first company to introduce these revolutionary coatings to the market, pioneering a new level of durability.

Mike made the switch to Titan Coatings' Alpha Quartz Elastomer Coating. He admitted he was skeptical at first. In his area, the temperature swings are wild, and he’d seen countless rigid ceramic coatings fail. A freezing winter night followed by a warm, sunny afternoon would cause those glass-like coatings to develop microscopic cracks, killing their effectiveness.

"The flexibility is the key," Mike told me. "Traditional ceramics are hard, but they're brittle. The first time a rock hits them or the temperature plummets, they can fracture. With Alpha Quartz, the coating flexes. It absorbs the impact."

That’s the power of Titan’s pioneering elastomer technology. It uses advanced nano tubes technology and Dark Matter tech to create a protective layer that’s hard like glass but remains flexible. This unique property makes it incredibly resilient. It doesn’t just sit there and take damage; it adapts.

Bugs splattering on the bumper at 70 mph, minor road debris, even those dramatic temperature shifts from frozen to hot no longer cause the coating to crack down. Its elastic nature allows it to absorb these stresses, keeping the protection intact for the long haul. For Mike, this meant his clients went from needing a new sealant every quarter to enjoying robust, multi-year protection. His business transformed from temporary maintenance to long-term preservation.

Protection Showdown: Wax vs. Sealant vs. Elastomer Coating

So, when it comes down to it, what’s the right call for your vehicle? Seeing the options side-by-side makes the decision much clearer. You can even see a detailed comparison on our site to find the perfect fit.

Here's a breakdown of how these three protection types truly compare in the real world.

| Attribute | Traditional Carnauba Wax | Synthetic Sealant | Titan Alpha Quartz Elastomer Coating |

|---|---|---|---|

| Durability | 4-6 Weeks | 3-6 Months | Multi-Year Protection |

| Shine | Deep, warm glow | Sharp, reflective shine | Intense gloss and depth |

| Protection | Basic UV protection | Good UV & chemical resistance | Superior impact, chemical, and UV resistance |

| Key Feature | Natural, organic look | Slickness and durability | Elasticity and flexibility prevents cracking |

| Maintenance | High (frequent reapplication) | Moderate (seasonal reapplication) | Low (proper washing is key) |

While waxes and sealants have served car enthusiasts well for years, they represent a past era of technology. They're just temporary films that demand constant upkeep.

If you are truly searching for the best way to wax a car, the modern answer is to evolve beyond wax altogether. Investing in an advanced elastomer coating like Alpha Quartz is the smartest move for anyone seeking the highest level of gloss, resilience, and genuine long-term protection. It's not just another coating; it’s a flexible shield engineered to endure the real world, saving you countless hours of work while delivering a finish that traditional products simply can't touch.

Mastering Hand and Machine Application: The Art of the Perfect Finish

Alright, you've done the hard work. The surface is clean, smooth, and ready for that final layer of protection. Now comes the fun part, but it's also where your technique really matters. Whether you're a traditionalist who loves the feel of applying wax by hand or you prefer the speed and precision of a machine, getting this step right is what separates a good finish from a great one.

It’s no surprise that most people are looking for an easier way to get professional results. The market data tells the same story. Liquid waxes now dominate, holding a whopping 45% market share because they're just so easy to work with and deliver a killer shine. They've pulled way ahead of old-school paste waxes (30%) and the quick-fix sprays (25%). This shift shows what people really want: products that work brilliantly without being a pain to use. With the car care market expected to hit nearly USD 975 million by 2032, simple yet effective is clearly the future.

This chart really puts the evolution of car protection into perspective, showing how we've moved from basic waxes to advanced, durable coatings.

You can see the journey from temporary shine to the kind of long-term, rugged protection that modern elastomers provide.

The Feel of Hand Application

There’s something deeply satisfying about applying wax by hand. You get a real connection to the curves and lines of your car. But if you're going this route, you need to burn one rule into your brain: less is more. I can't tell you how many times I've seen people slather on wax thinking more equals better protection. It doesn't. All it does is make buffing it off a nightmare and waste a ton of product.

You're aiming for a super-thin, even coat. Here’s how you get there:

- Grab a good foam applicator: Don't use an old rag. A quality foam pad will make all the difference. Dab a few small, pea-sized drops onto the pad itself, never directly on the car.

- Think small: Work in manageable sections, maybe 2×2 feet at a time. This keeps the wax from drying out before you can spread it properly.

- Be consistent: Whether you prefer straight lines or small, overlapping circles, just stick with it. The goal is complete, uniform coverage across the panel.

So, how do you know when it's ready to come off? Forget timing it. Use the "swipe test." After a few minutes, just lightly swipe your finger across the waxed area. If it smears, give it more time to haze up. If your swipe leaves a clean, glossy line, you're good to go. It’s that simple.

The Speed and Precision of Machine Application

If you want a flawless, even finish and want to get it done in a fraction of the time, a dual-action (DA) polisher is your best friend. Don't be intimidated; using a machine isn't about being aggressive, it's about pure consistency. A DA polisher spreads the product thinner and more evenly than you could ever achieve by hand, which also makes taking it off a breeze.

A DA polisher on a low-speed setting with a soft finishing pad is the absolute best way to lay down a sealant or liquid wax. The machine's orbital motion creates a perfectly uniform, microscopic layer of protection that’s just impossible to do manually.

Just like with hand application, work in small sections and overlap your passes by about 50% to ensure you don’t leave any gaps. The key is to let the machine do the work. Don't push down on it; just guide it gently and let it glide across the paint.

For those chasing perfection, leveling up your prep game before waxing can make a world of difference. If you want to get rid of any minor swirls or scratches for the ultimate base, you should learn how to polish car paint first.

Don't Forget Your Glass

It’s easy to get so focused on the paint that you completely forget about your windows. But clear, protected glass isn't just about looks—it's a massive safety feature. And no, you can't just use your car wax on it. That will only lead to a greasy, smeared mess.

This is where a product made specifically for glass is essential. A great example is Titan's Apex Glass Ceramic Coating. It's incredibly easy to use and creates a super-hydrophobic surface. What that means in the real world is that when it rains, water beads up and literally flies off your windshield as you drive.

Suddenly, driving in a heavy downpour is stress-free. Your visibility is drastically enhanced because the glass sheds water on its own, so you're not desperately hammering the windshield wiper switch. It's a small step that adds a huge amount of safety and convenience, and it's a must for any complete vehicle protection plan.

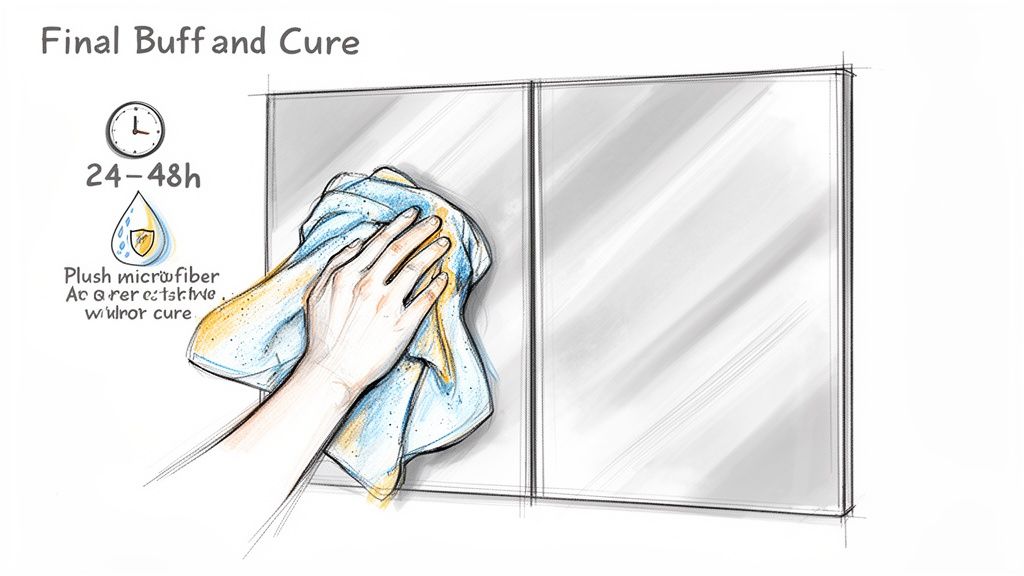

Perfecting the Final Buff and Cure for Maximum Gloss

The job isn't done just because the wax is on the car. Far from it. That final, flawless buff is what truly separates an okay shine from a jaw-dropping, mirror-like finish. This is the part that makes all the prep work worth it, turning a glossy surface into one with deep, liquid reflections.

Too many people rush this final step. They get impatient, wipe off the hazy residue too aggressively, and end up with streaks or an oily film. The secret is all in the technique and using the right tools—specifically, a couple of high-quality, plush microfiber towels. One for the initial wipe, and a fresh one for the money shot.

The Two-Towel Buffing Method

Once your wax has hazed over and passes the swipe test, it's time to gently remove it. Grab your first microfiber towel and fold it into fourths. This gives you eight clean sides to work with as you go.

With a light touch, wipe away the bulk of the wax residue. You're not trying to polish the paint here; you’re just clearing the panel. Let the towel do the work.

Now, set that towel aside and pick up your second, perfectly clean microfiber. This is your finishing towel. With almost no pressure, gently glide it over the surface. This final pass is what picks up any lingering oily traces and brings out that true, deep gloss. The difference this last buff makes is night and day. If you run into any tricky spots, our guide on how to buff out scratches has some great techniques that can help.

The Curing Process: Why Patience Is Everything

After that final buff, the most important part of the process begins—and all it requires is for you to do nothing at all. This is the "curing" stage, where a chemical reaction takes place, bonding the wax or coating directly to your car’s clear coat.

This is where the protection really locks in. For the coating to achieve its full potential—maximum hardness, water beading, and durability—it absolutely has to stay dry.

A freshly applied wax or coating needs to be protected from rain, sprinklers, and even heavy morning dew for at least 24-48 hours. Getting it wet during this critical window can stop the chemical bonds from forming properly, weakening the protective layer before it even has a chance.

This curing time is especially critical for professional-grade formulas like those from Titan Coatings. Their Dark Matter Technology® relies on this uninterrupted period to allow the elastomer coatings to cross-link, harden, and develop their signature flexible, resilient properties. Rushing this stage is like pulling a cake out of the oven half-baked—it just won’t turn out right.

A little patience here pays huge dividends in the form of a tougher, longer-lasting shine. Give the product the time it needs, and you'll get every bit of performance you paid for.

Keeping That Shine Alive & Knowing When to Reapply

You just spent a solid chunk of your day prepping, polishing, and protecting your car's paint. The last thing you want is to see that deep, wet shine disappear in a few weeks. The real secret to a lasting finish isn't just in the application—it’s in the follow-up care.

The best wax job doesn’t truly end when you put the buffer away. It evolves into a smart, simple maintenance routine that keeps your car looking incredible and, more importantly, protected.

Wash Your Car Without Wrecking Your Wax

Your biggest enemies after waxing are aggressive car soaps and gritty wash mitts. They'll strip that beautiful layer of protection right off. You have to be gentle.

The two-bucket wash method is still the gold standard for a reason; it keeps the dirt you pull off the car from going right back on. Always use a high-quality, pH-neutral car shampoo. These are formulated to clean away grime without chemically attacking the wax or sealant you just applied.

When you're done rinsing, don't just grab any old towel. Using a drying aid or a quality quick detailer provides crucial lubrication. This small step helps prevent swirls and scratches from the drying towel and gives the gloss a nice little boost. A great spray-and-wipe product like Titan's Auto Quick Detailer is perfect for this, helping you lock in that just-waxed look between full washes.

Your Car Will Tell You When It's Time

So, how do you know when you need to re-wax? Easy. Just watch how water behaves on the paint. This is the single best indicator of your protection's health.

A freshly protected car will have tight, tall, almost spherical water beads. It’s a beautiful sight. As that protection starts to wear down over time, you'll see those beads get lazy—they’ll look flatter, more spread out.

The final warning sign is when water stops beading altogether and starts "sheeting," clinging to the paint in large, flat puddles. When you see that, your protective barrier is gone. It’s time to act.

How Often Should You Reapply? It Depends.

The reapplication schedule comes down entirely to what product you're using. And this is where the difference between old-school waxes and modern protection becomes crystal clear.

- Traditional Carnauba Waxes: They produce a gorgeous, warm glow but don't last long. Expect to reapply these every 4-6 weeks.

- Synthetic Sealants: These are a definite step up in staying power, typically giving you 3-6 months of solid protection.

This constant cycle of washing and reapplying is a global phenomenon. In fact, the car wax market is booming, with the Asia-Pacific (APAC) region alone accounting for 42% of the market's growth between 2023-2028. In places like India and China, cars face everything from extreme pollution to brutal monsoon seasons, making durable protection a necessity, not a luxury. You can dig into the numbers in this in-depth car wax market analysis.

This is the exact reason why so many of us in the detailing world—both pros and serious enthusiasts—have moved beyond these temporary fixes. A modern elastomer coating isn’t just a product; it’s an investment that gives you back your most precious resource: your time.

Think about it. Instead of dedicating your weekends to waxing your car over and over again, you could get years of relentless protection from just one professional application. Titan Coatings, an ISO 9001 certified company, engineers advanced elastomer coatings that are tested and proven in the world's most brutal climates. Their flexible structure means they won't crack or fail under stress, offering multi-year durability that saves you dozens, if not hundreds, of hours.

That's the real "best way" to wax a car—choosing a solution that works smarter, so you don't have to work harder.

Answering Your Lingering Car Waxing Questions

Even when you've got the process down, a few questions always seem to hang in the air. Nailing down the answers to these common queries is what really separates a good finish from a great one, ensuring you're doing right by your car's paint for the long haul. Let's dig into some of the things people often ask.

Can I Put Wax Over a Ceramic or Elastomer Coating?

I hear this one all the time. The simple answer? You can, but you really, really shouldn't.

Think of a professional-grade coating like Titan's Alpha Quartz as the pinnacle of paint protection. It’s engineered from the ground up to be slick, durable, and incredibly hydrophobic. Slapping a layer of carnauba wax over that is like putting a plastic tarp over a brand-new shingle roof—it completely defeats the purpose.

The wax will just sit on top, masking the coating's amazing self-cleaning abilities. Plus, the wax will break down quickly, leaving you with a blotchy, uneven surface that actually requires more work. The right way to maintain a high-end coating is to stick with a quality pH-neutral car wash and occasionally use a dedicated SiO2-based spray designed to boost, not bury, its performance.

What’s the Single Biggest DIY Car Waxing Mistake?

Hands down, the most common and damaging mistake I see is skipping the prep work. It's so tempting to just wash the car and go straight for the wax, especially when you're short on time. But doing that means you're locking in a layer of bonded contaminants—tiny bits of industrial fallout, rail dust, and road tar—right under your new wax.

This shortcut causes a double-whammy of problems. First, the wax can't properly bond to the clear coat, so its durability tanks. You'll be lucky if it lasts half as long as it should. Second, when you go to buff the wax off, you're essentially grinding those tiny, gritty particles right into your paint. Hello, swirl marks and fine scratches.

Taking the time to decontaminate with an iron remover and a clay bar isn't just an "extra" step—it's the absolute foundation for a durable, flawless shine.

How Do I Get Old Wax Off Before Applying a New Coat?

To get that perfect bond for your new layer of protection, the surface needs to be completely bare. You have to strip every last bit of the old stuff off.

The most straightforward way is to use a dedicated wax-stripping soap during your wash. These are formulated with stronger detergents that safely break down old waxes and sealants.

For a truly pristine surface, follow that up with a panel prep spray. A quick wipe-down of each panel with a clean microfiber towel misted with an isopropyl alcohol (IPA) solution will zap any lingering oils or silicones. This gives you a surgically clean canvas, ready for whatever you're applying next.

Is a Machine Application Better Than Hand Application?

This is a classic "it depends" scenario, and it really comes down to the product you're using.

- For most liquid waxes and synthetic sealants, a dual-action (DA) polisher is your best friend. A machine can lay down a micro-thin, perfectly even coat that’s nearly impossible to achieve by hand. This makes for a cleaner look and makes buffing off the residue a breeze.

- For professional coatings, like Titan's Alpha Quartz Elastomer Coating, a precise hand application is not just preferred, it's required. These advanced formulas are designed to be meticulously applied with a specific applicator block to ensure proper bonding and performance.

So, while a machine brings consistency to traditional products, cutting-edge coatings demand the deliberate, controlled touch of a human hand to unlock their true potential.

Tired of the endless cycle of waxing and re-waxing every few months? Titan Coatings offers a smarter way to protect your investment. See for yourself how the superior durability and flexibility of our Alpha Quartz Elastomer Coating changes the game.

0 Comments