Picture this: your car's paint is encased in a flexible, glass-like shield. It’s a surface so slick that water, dirt, and road grime just slide right off. This isn't science fiction; it's what modern sprayable ceramic coatings deliver, and it's a world away from old-school waxes. These coatings create a semi-permanent bond with your clear coat, locking in a deep, candy-like gloss that lasts for years.

The Future of Shine Beyond Traditional Wax

For years, car guys like Mark were stuck in the same exhausting loop. Every weekend was the same ritual: wash, clay, polish, and then spend hours lovingly applying a layer of carnauba wax. The shine was incredible, but it never lasted. A couple of good rainstorms or one drive down a dusty road, and that brilliant gloss was gone. He was right back where he started.

If you've ever relied on traditional waxes, you know this frustration. They just sit on top of the paint, offering almost no real chemical resistance and breaking down fast under the sun and weather. Reapplying it constantly isn't just a chore; it's a battle you can't win. Mark knew there had to be a better way to protect his ride without giving up his entire weekend.

A New Era of Paint Protection

Mark’s hunt for a real solution led him to sprayable ceramic coatings, where the science has completely changed the game. Unlike wax, these coatings actually form a molecular bond with the vehicle's clear coat. You’re not just polishing the surface; you're creating a hardened, semi-permanent layer of protection. This is a functional shield, not just a temporary shine.

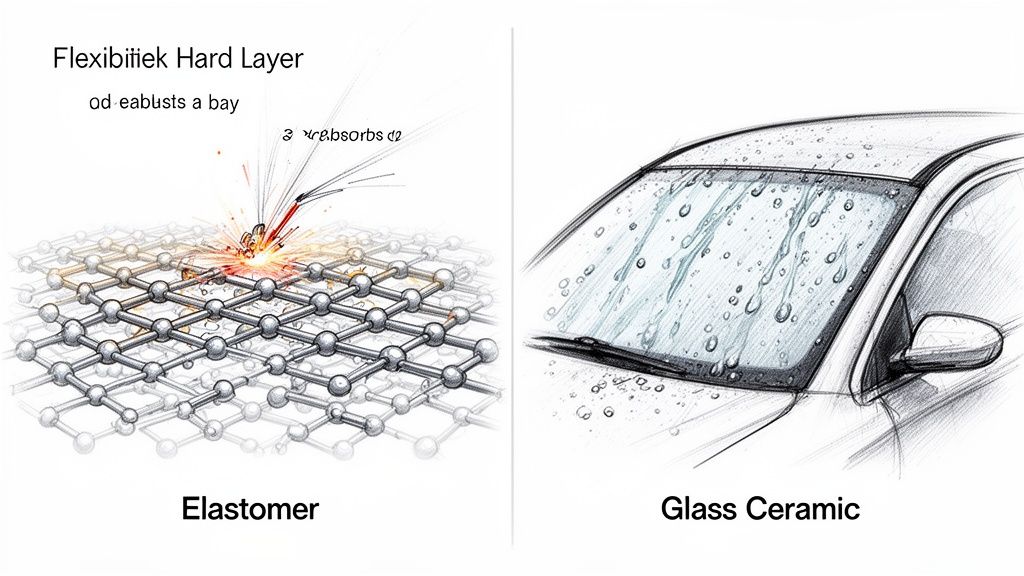

This is where technology from innovators like Titan Coatings really shines. Titan was the first to bring elastomer coatings to the market, and it was a massive step forward. They solved a huge problem that plagued older, more rigid ceramic formulas by introducing nano tubes and their proprietary Dark Matter Tech.

Think about it: traditional ceramic coatings are hard, but they can also be brittle. That stiffness makes them prone to micro-cracking when body panels expand and contract with wild temperature swings—from a freezing winter night to a scorching summer afternoon.

The Power of Flexibility and Strength

The genius in Titan's approach is their unique blend of nano tubes and proprietary Dark Matter Tech. This technology allows them to engineer coatings that are both incredibly hard and remarkably flexible. It's like creating armor that can bend without breaking. That elasticity is the secret to real-world longevity.

Take a pro-grade product like Titan's Alpha Quartz. It perfectly embodies this principle. It's designed to be glass-hard for serious scratch resistance, but it has a unique flexibility built right in.

- Temperature Resilience: The coating moves with your car's metal and plastic panels, preventing the stress fractures that destroy lesser products. From frozen winters to hot summers, the coating won't crack.

- Impact Absorption: Its elastic nature helps absorb the energy from small impacts, like bugs splattering on the bumper at 70 mph, which reduces chipping.

- Enhanced Durability: This powerful combo of hardness and flexibility means the coating keeps protecting your paint for years, not just a few months.

Moving from wax to advanced elastomer coatings isn't just an upgrade; it’s a total reinvention of paint protection. For enthusiasts like Mark, it meant finally breaking free from the endless waxing cycle. He got a deeper, tougher shine that actually lasted, which gave him his time back and the confidence that his car was protected by the best tech out there. The difference is night and day, which you can see for yourself in our guide on the difference between wax and ceramic coating. You can also check out a direct product comparison to see how our elastic coatings stack up.

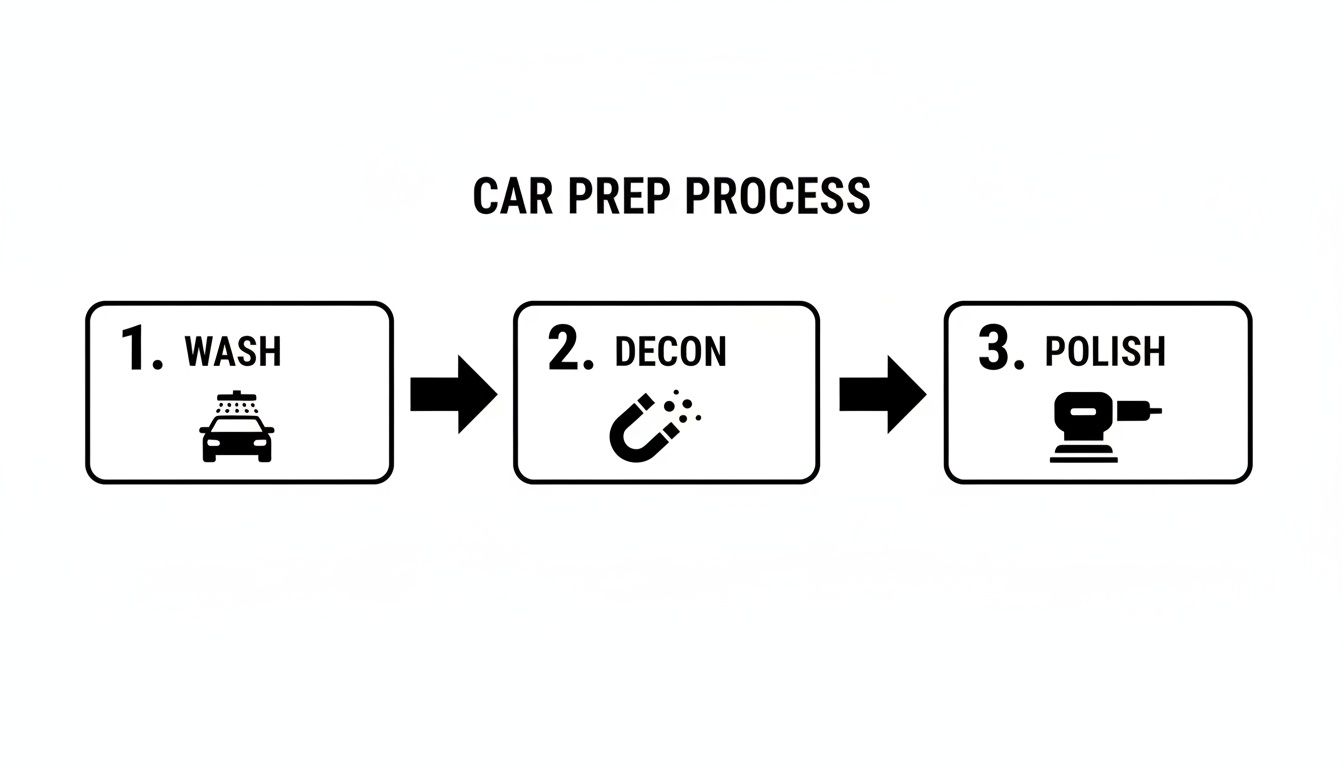

Preparing Your Vehicle for a Perfect Finish

Let's be clear about one thing: the final shine, slickness, and unbelievable water-beading you’re after is 90% dependent on the prep work. Think of it like this—you wouldn't paint a masterpiece on a dirty canvas, right? The same logic applies here, tenfold.

This is the stage that separates a professional job from an amateur one. A sprayable ceramic coating is an amplifier; it will magnify whatever is underneath it. If you have swirls, fine scratches, or embedded grime, the coating will just lock them in under a beautiful, glossy shell. You have to put in the work upfront to get that jaw-dropping result.

The Foundation: A Meticulous Wash

Everything starts with a proper wash. I'm not talking about a quick Saturday morning rinse-down. We need to get the surface totally clean without inflicting any new damage. This is where the two-bucket wash method isn't just a suggestion—it's standard operating procedure.

- Bucket One: Your suds bucket, filled with a quality, pH-neutral car soap.

- Bucket Two: Your rinse bucket, filled with clean water and a grit guard at the bottom.

Here's the rhythm: wash one panel, then dunk and scrub your mitt in the rinse bucket. The grit guard traps all the abrasive junk at the bottom. Only after it’s clean do you reload with fresh suds. This simple process is your best defense against creating the very swirl marks you’ll be trying to remove later.

Deep Cleaning: Chemical and Mechanical Decontamination

Even after the perfect wash, your paint is still contaminated. On a microscopic level, it’s covered in bonded junk your wash mitt slides right over—things like iron fallout from brake dust, road tar, and tree sap. You need to get this stuff off.

This is a two-front attack. First, you go in with chemicals. An iron remover is a must. You'll spray it on and see it "bleed" purple as it chemically dissolves all the embedded iron particles. Follow that up with a good tar remover to tackle any stubborn road film. This chemical assault gets rid of the worst offenders without aggressive scrubbing.

Next, you go mechanical with a clay bar or a clay mitt. This step physically pulls out anything that's left, leaving the paint feeling as smooth as glass. If you run your hand over the paint (in a plastic baggie) and it feels gritty, this step is absolutely non-negotiable. For a deep dive, check out this complete guide on how to decontaminate car paint to get the surface truly sterile.

Correcting the Canvas: Paint Polishing

Now that the surface is perfectly clean and smooth, you can finally see the true state of your paint. This is the paint correction phase. We’re hunting down and eliminating every swirl mark, light scratch, and bit of oxidation we can find. The goal is a flawless, mirror-like surface for that coating to bond to.

For a newer car or one in great shape, you might get away with a one-step polish. A good dual-action (DA) polisher paired with a finishing polish can work wonders, refining the clear coat and massively boosting gloss in a single go.

But for a vehicle that’s seen some life, you'll need to roll up your sleeves for a multi-stage correction. This means starting with a heavier cutting compound to level out deeper defects, then following up with a finer polish to refine the finish and bring out that deep, wet shine.

Pro Tip: Real paint correction is what makes the difference between "that looks nice" and "wow, that looks unbelievable." It creates a perfectly uniform surface for the nano-particles in a product like Titan's Ultra Ceramic Spray to grab onto, which directly impacts the gloss, depth, and longevity of the coating.

Don't even think about skipping this. It's like building a house on a shaky foundation—it’s just not going to last. The hours you invest here will pay you back every single time you look at the car.

Below is a checklist to keep you on track. Follow it religiously.

Your Essential Surface Preparation Checklist

Follow these steps methodically to guarantee your vehicle is perfectly prepared for a sprayable ceramic coating.

| Phase | Action Required | Pro Tip for Success |

|---|---|---|

| 1. Wash | Perform a two-bucket method wash with a pH-neutral soap and high-quality wash mitts. | Always wash in the shade on a cool surface to prevent water spots and soap from drying prematurely. |

| 2. Dry | Use a plush microfiber drying towel or a filtered air blower to dry the vehicle completely. | An air blower is ideal for blasting water out of panel gaps, mirrors, and trim where it can drip out later. |

| 3. Chemical Decon | Apply an iron remover to all painted surfaces, wheels, and glass. Let it dwell and rinse thoroughly. | Look for the "bleeding" purple effect. If you don't see much, your paint is relatively clean of iron. |

| 4. Mechanical Decon | Use a clay bar or clay mitt with proper lubricant to remove any remaining embedded contaminants. | The "baggie test" is your best friend. Place your hand in a thin plastic bag and feel the paint. If it's not perfectly smooth, keep claying. |

| 5. Polish | Correct the paint using a machine polisher, starting with the least aggressive pad/polish combo necessary. | Use a paint depth gauge on unfamiliar vehicles to avoid burning through the clear coat. Always do a test spot first. |

| 6. Panel Wipe | Wipe down every panel with an IPA (Isopropyl Alcohol) solution or a dedicated panel prep spray. | This final step removes all polishing oils, ensuring a truly bare surface for maximum coating adhesion. Use at least two clean microfiber towels. |

Once you’ve ticked every box on this list, you can be confident that you've created the ideal foundation. Now, and only now, are you ready to apply the coating.

Nailing the Spray Application Technique

You’ve done the hard yards with the prep work, and now it’s time for the payoff. This is the moment where all that painstaking cleaning, decontamination, and polishing comes together to create that jaw-dropping, glass-like finish. The application itself is where the real magic happens, but your technique is what separates a flawless job from one riddled with streaks and high spots.

The great news? Modern formulas have made this process incredibly forgiving. We're long past the days of fussy, temperamental coatings that were a nightmare to work with. Products like Titan's Ultra Ceramic Spray were designed from the ground up for easy application, giving you a pro-level finish without needing a professional's workshop.

Setting the Stage for a Perfect Finish

Before you even think about spraying, take a look around. Your environment plays a massive role in getting a smooth, predictable result.

- Temperature: You're looking for a sweet spot between 50°F and 80°F (10°C to 27°C). If it's too hot, the coating will flash (dry) almost instantly, making it a real battle to level out.

- Humidity: Low to moderate humidity is your best friend. Too much moisture in the air can mess with the curing time and weaken the coating's bond to the paint.

- Location: Always, always work in a well-lit, shaded spot. A garage is perfect. Direct sunlight is your worst enemy here—it heats up the panels, accelerates flashing, and is a surefire recipe for a streaky disaster.

Remember, the application is only as good as the prep work that comes before it.

Think of washing, decontaminating, and polishing as the essential foundation. You simply can't skip these steps and expect a great outcome.

The Art of Application: A Step-by-Step Guide

With your workspace dialed in, it's time to lay down some protection. You'll need your sprayable ceramic coating and a small stack of high-quality, short-pile microfiber towels. I always have at least 6-8 clean towels on hand—some for leveling, some for the final buff. The last thing you want is to reuse a saturated towel and smear product everywhere.

The key is to work in small, manageable sections. A 2 ft. x 2 ft. area is about right. This gives you plenty of time to apply, level, and buff the product before it starts to set up.

- Spray & Spread: Give the panel a light mist of the coating. Alternatively, you can spray directly onto your microfiber applicator. Spread the product evenly over the section using a simple cross-hatch pattern (up-and-down, then side-to-side motions).

- Level the Coating: This is the crucial part. Grab a fresh, dry microfiber and gently wipe over the area, again using a cross-hatch pattern. The goal here is just to knock down any high spots and create a perfectly uniform layer. You're not trying to remove the product, just even it out.

- Final Buff: Immediately follow up with a third clean towel. Buff the section to a brilliant, streak-free shine. Use light pressure and keep flipping your towel to a clean side.

You'll see the coating start to "flash" after a few moments, creating a hazy, rainbow-like effect on the paint. That's your signal to start leveling and buffing. Don't wait too long, or it will become grabby and difficult to remove.

This panel-by-panel rhythm is the secret to a perfect finish. It's a straightforward process, but it requires your full attention. For a deeper dive into the nuances of the process, our guide on applying ceramic coating to your car breaks down every single step. This methodical approach is exactly how professionals get those flawless, dripping-wet results time and time again.

Titan's Groundbreaking Coating Technology

Let's be honest, not all sprayable ceramic coatings are created equal. While most will give you a nice gloss and make water bead up for a while, a few are playing a completely different game on a scientific level. This is where Titan Coatings really shook things up, moving past the standard formulas to engineer something truly unique.

Titan was the very first to bring Elastomer coatings to the detailing world. This wasn't just another incremental update; it was a direct answer to the biggest weakness of traditional, rigid coatings. By weaving in advanced nano tubes technology and their own proprietary Dark Matter Tech, they created a protective layer that redefines what durability means.

The result is a finish that's hard as glass but has this incredible, built-in flexibility. That dual personality is the secret sauce behind its impressive lifespan and real-world performance.

Alpha Quartz and the Power of Elasticity

I see this all the time. A detailer applies a standard ceramic coating to a client’s black sedan. It looks like a mirror, and the client is thrilled. But after a harsh winter followed by a blazing hot summer, they start seeing tiny, web-like cracks spidering across the finish. The coating was simply too brittle to handle the metal expanding and contracting with the temperature swings.

That exact problem is what Titan's Alpha Quartz was built to eliminate. As a top-tier elastomer coating, its molecular structure is engineered to stretch and move with the vehicle's body panels.

- Impact Absorption: When a rock chip or a big June bug smacks the surface, the coating flexes on impact, absorbing and spreading out the force. This makes a huge difference in preventing chips.

- Temperature Stability: It couldn’t care less if it’s freezing cold or scorching hot. The coating remains stable and won’t crack under the stress of thermal cycling.

So what's the bottom line for you and your clients? True peace of mind. The protection you apply today won't give up when the seasons change. The paint stays shielded and glossy for years, not just a few months.

This shift toward more durable solutions isn't just a niche trend. The global high-performance ceramic coatings market was valued at $7.84 billion in 2018 and is on track to hit $12.63 billion by 2026. North America is expected to lead the charge with a 6.5% CAGR, driven almost entirely by the demand for better automotive protection. People are actively seeking out this level of advanced technology.

Driving with Unbelievable Clarity

Titan's thinking goes beyond just the paintwork. We've all been there: driving on the highway when a sudden downpour hits. You crank the wipers to their fastest setting, but visibility is still a mess. It’s a white-knuckle experience nobody enjoys.

Now, imagine that same drive, but with a windshield treated with Titan's Apex Glass Ceramic Coating. The second a raindrop touches the glass, it beads up into a perfect sphere and gets whipped away by the airflow over the car. Your view stays crystal clear. It's almost like it isn't even raining.

This isn’t just about keeping the glass clean—it’s a massive safety upgrade. The super-hydrophobic barrier Apex creates makes water fly off the surface effortlessly, enhancing visibility and making drives in the rain completely stress-free.

And the best part? It's ridiculously easy to apply. Apex is a simple wipe-on, wipe-off process that turns a stressful drive into a relaxed one. It's a small detail that makes a world of difference in the driving experience. By covering both paint and glass, Titan gives you a complete protective system built on next-level science. To see it in action, check out this deep dive into Titan's elastomer technology.

Curing and Long-Term Coating Maintenance

Alright, the final buff is done and the paint looks like glass. It's easy to think the job is over, but what happens next is what makes or breaks the entire application. We're talking about the cure. This is where the liquid you just sprayed on undergoes a complete chemical transformation, cross-linking and hardening into that super-durable, hydrophobic shield your client is paying for.

It's not just about drying. Think of it like pouring concrete—it might be solid enough to touch soon after, but it's not ready to be driven on. Your freshly applied coating is the same. It's touch-dry pretty quickly, but it’s still chemically soft and incredibly vulnerable. The full cure, where it reaches maximum hardness and water-beading prowess, takes time. And that waiting game is non-negotiable for getting the performance you promised.

The Critical Curing Window

For the first 24 to 48 hours, that fresh coating is at its most fragile. You have to treat it like a newborn. The biggest enemy here is water. Rain, sprinklers, even a heavy dew can cause water spots that will literally etch themselves into the semi-cured surface, leaving a permanent mark.

Here's the simple rundown of what to tell your client (or do yourself) for this initial period:

- No Water. Period. The car needs to stay inside and dry. If it gets a few drops on it by accident, don't wipe. Gently blot it dry with a fresh, high-quality microfiber towel.

- No Chemicals. This means no car soaps, no quick detailers, nothing. The solvents and surfactants in those products can get in the way of the cross-linking process and weaken the final bond.

- No Contaminants. Park it away from trees that drop sap or anything else. Bird droppings are basically acid-bombs for a fresh coating and will cause damage almost immediately.

- No Washing. This is the big one. Do not wash the vehicle for a minimum of 7 days. Let it harden. Let it fully cure.

This first week is absolutely crucial. If you want to dive deeper into the specifics, we've broken down the full timeline of how long a ceramic coating takes to cure. Trust me, a little patience here pays off in a huge way down the road.

Long-Term Maintenance for Lasting Brilliance

Once that coating is fully cured, it's a beast. But it's not bulletproof. Proper long-term care is what keeps it looking and performing like new for years. The best part? Maintenance is a breeze compared to old-school waxes. That slick, non-stick surface makes washing faster, easier, and honestly, more enjoyable.

The most important thing you can do is wash it right. Stick to a quality, pH-neutral car soap and always use a two-bucket wash method. This prevents you from grinding new swirls and scratches into the finish you just perfected. Avoid harsh, high-alkaline soaps, especially the kind used in cheap automatic car washes—they will slowly eat away at the coating and kill its hydrophobic properties.

The goal of maintenance isn't just to clean the car; it's to preserve the integrity of the coating. Using dedicated SiO2-infused maintenance sprays every few washes acts as a "top-up," restoring the slickness and water-beading properties while adding another sacrificial layer of protection.

This straightforward, effective approach to protection is why the detailing world is shifting. The global ceramic coatings market was valued at around $1.96 billion in 2018 and is on track to hit $3.32 billion by 2026, growing at a CAGR of 7.1%. You can dig into the numbers about the growth of the ceramic coatings market on fortunebusinessinsights.com. Those figures prove that customers are moving away from temporary solutions and are willing to invest in superior, long-term protection. A simple, consistent maintenance plan is all it takes to make sure that investment pays off with a showroom shine for years to come.

Your Top Questions About Sprayable Coatings, Answered

If you're new to sprayable ceramic coatings, you probably have a few questions. I get it. Moving from old-school waxes or even hand-applied coatings is a big step. Let's clear up some of the most common things people ask.

Spray vs. Paste: What's the Real Difference?

It all comes down to the chemistry and how you get it on the car. Sprayable coatings, like Titan's Ultra Ceramic Spray, are built with specific carrier solvents that let you lay down a perfectly even layer, fast. Think of it as an efficiency upgrade.

Traditional paste coatings often boast a high SiO2 content, and that’s great, but our spray formulas are playing a different game. We use a blend of cutting-edge elastomer and nanotube technologies. The result? You get the tough-as-nails durability you expect, but with way more flexibility and a much more forgiving application process.

Can a DIYer Really Get Pro-Level Results at Home?

Yes, one hundred percent. We specifically designed products like the Ultra Ceramic Spray and our Apex Glass Coating with the serious DIYer in mind. But here's the secret that separates a good job from a great one: it's all about the prep work.

If you nail the prep—washing, decontamination, and maybe a light polish—in a clean, dry spot out of direct sun, you're 90% of the way there. Our sprayable coatings are forgiving enough that even a first-timer can get a slick, professional finish. Just be patient and don't cut corners before you pull the trigger.

What Exactly Is an "Elastomer" Coating?

An elastomer coating like Titan Alpha Quartz is a different beast entirely. It’s where we've blended flexible polymers with incredibly hard nanotube technology. This was a first for the industry, a technology pioneered by Titan.

Think of it like this: instead of a brittle sheet of glass, you get a shield that's both tough and elastic. It can actually absorb the energy from small rock chips and bug impacts. Crucially, it won't crack under the stress of a car's panels expanding and contracting from scorching summers to freezing winters—a common failure point for overly rigid coatings. That resilience is what gives it such impressive longevity.

Seriously, How Long Does This Stuff Last?

Okay, the honest answer is: it depends. How well you prepped the surface, how you maintain the car, and the climate you live in all play a huge role. That said, a properly applied and cared-for coating like Titan Ultra Ceramic Spray will give you a solid 1-2 years of incredible protection.

If you’re looking for the ultimate long-term solution, our professional-grade elastomer coatings like Alpha Quartz are engineered to go the distance, lasting for years. They’re the real deal for "set it and forget it" paint protection, all thanks to that unique flexible structure.

Ready to see what this new level of protection looks like? Titan Coatings has perfected the balance of strength and flexibility. Grab a bottle of our Ultra Ceramic Spray and see for yourself how easy it is to get a durable, professional-grade finish right in your own garage.

0 Comments