Protecting the finish on a black car isn't just a good idea—it's essential. Anyone who has owned one knows the struggle. A professional-grade ceramic coating is hands down the best way to shield that notoriously delicate paint, locking in a deep, liquid-like gloss and making maintenance a whole lot easier. It forms a tough, slick barrier that fights off contaminants and, most importantly, resists the fine scratches and swirl marks that are the bane of every black car owner's existence.

Why Black Cars Are a Special Case

There’s a unique pride that comes with owning a perfectly clean black car, but it's often matched by an equal amount of frustration. When it's clean, nothing beats the depth and elegance. It’s like a flawless mirror. But that same stunning reflectivity is also its biggest weakness, highlighting every single speck of dust, water spot, and tiny micro-scratch.

This isn't just in your head; it's basic physics. Lighter colors diffuse light, which helps hide minor imperfections. Black paint does the opposite. It absorbs most light and reflects a crisp, clear image, meaning any break in that smooth surface—like a swirl mark—sticks out like a sore thumb.

The Endless Fight for a Flawless Finish

Sure, traditional waxes can help. They fill in minor swirls and add a nice gloss, but their protection is temporary at best. We're talking weeks, not years. They break down under the sun and wash away with a few car washes, leaving that delicate black paint vulnerable all over again.

This cycle of detailing, enjoying a few days of perfection, and then watching the flaws creep back in is exhausting. It's a constant battle. This is exactly why the demand for more advanced, long-term solutions is exploding. The global Black Coatings Market, driven heavily by automotive needs, is projected to jump from USD 183.1 million in 2025 to USD 242.44 million by 2033. The market knows what detailers and owners have known for years: temporary fixes just don't cut it.

Here's the bottom line: a black car's beauty is completely dependent on the perfection of its surface. Without a durable, long-term shield, keeping it perfect is a constant, uphill fight against everything from the weather to simple human error.

To illustrate just how much of a leap forward a modern coating is, let's compare it directly to old-school wax.

Traditional Wax vs Titan Elastomer Coating on Black Paint

The difference between a traditional carnauba wax and an advanced elastomer coating is night and day, especially on the unforgiving canvas of black paint. While wax provides a temporary shine, it offers little in terms of real-world, long-lasting protection.

| Feature | Traditional Carnauba Wax | Titan Elastomer Ceramic Coating |

|---|---|---|

| Durability | Lasts weeks | Lasts 3-7+ years |

| Chemical Resistance | Poor; strips easily | Excellent; resists bird droppings, acid rain |

| Hardness (Scratch Resistance) | Very low; offers almost no protection | 9H+ Hardness; resists swirls and micro-scratches |

| UV Protection | Minimal; breaks down quickly | High; prevents oxidation and paint fade |

| Flexibility | Brittle; can crack or haze | Elastic; flexes with paint to prevent cracking |

| Gloss & Depth | Good, but short-lived and attracts dust | Extreme, long-lasting "wet look" |

| Self-Cleaning Properties | None | Strong hydrophobic effect; water and dirt slide off |

| Maintenance | Frequent reapplication needed | Simple maintenance washes are all that's required |

As you can see, there's really no contest. For a black car, the investment in a high-quality elastomer coating pays for itself through superior protection, a lasting finish, and a massive reduction in maintenance headaches.

A Modern Solution for a Classic Problem

This is where paint protection science really shines. Imagine a shield that isn’t just a temporary film on your paint, but a semi-permanent, chemically-bonded part of the clear coat itself. That’s the promise of ceramic coatings, but let’s be clear: not all coatings are built the same.

The real challenge has always been creating a protective layer that’s both incredibly hard to resist scratches but also flexible enough to handle the real world. This is where Titan Coatings’ work with elastomer technology completely changed the game. By integrating nano tubes and our proprietary Dark Matter Tech, we were the first to create truly elastic coatings.

This breakthrough solves a huge failure point in older, more rigid ceramic coatings. Standard coatings, while hard, can be brittle. Think about how a car's body panels expand and contract with temperature swings—from freezing winters to blistering summers. A rigid coating can't move with the paint, which can lead to micro-cracking over time, killing its protective ability.

Our elastic coatings are different. They're engineered to be hard as glass yet flexible enough to move with the vehicle's body. This prevents cracking, ensuring the protection is more durable and performs better for far longer. It’s the ultimate defense for that perfect black finish you work so hard to achieve.

Of course, before you can protect the paint, you have to perfect it. That’s why you need to understand what paint correction is and why it's a non-negotiable first step for a truly flawless result.

Mastering the Prep Work for a Mirror Finish

The real secret to that unbelievable, liquid-like finish on a ceramic coated black car? It has nothing to do with the bottle of coating itself. The magic is forged in the hours of meticulous, often tedious, preparation that comes before the first drop of ceramic ever touches the paint.

Think of it this way: a ceramic coating doesn't create perfection. It simply locks in whatever finish you give it. On black paint, this means every shortcut, every missed spot, every tiny flaw will be magnified and sealed in for years to come.

Let's imagine a common scenario. A client brings in their three-year-old black sedan. Under the shop lights, it looks okay. But once you hit it with a proper inspection light, the truth is revealed: a chaotic web of swirl marks, faint scratches from drive-thru car washes, and bonded gunk that makes the paint feel like sandpaper. Slapping a coating on this mess would be a disaster—you'd just have a shiny, flawed finish permanently on display. The only path to that deep, mirror-like gloss is to meticulously erase every single imperfection first.

The Two-Stage Decontamination Process

Before you can even dream of polishing, the surface has to be surgically clean. This goes way beyond a simple wash.

First up is chemical decontamination. This part targets the grime you can't even see. I always start by spraying the entire car with a good iron remover, paying extra attention to the lower panels and the rear end. You’ll see it work almost instantly. That clear liquid turns a deep, dramatic purple as it dissolves the tiny, embedded iron particles from brake dust and industrial fallout. If you skip this, those little metal shards will just get dragged across the paint during the next step, ruining your polishing pads and creating new scratches.

Next, we move to mechanical decontamination. Even after the iron remover does its job, you've still got microscopic contaminants like tree sap, tar, and stubborn road film clinging to the clear coat. This is where a clay bar or a quality clay mitt becomes essential. With plenty of clay lubricant to protect the surface, you'll glide the clay over every single panel. The difference is night and day; you can literally feel the surface change from rough and gritty to perfectly smooth as glass. This step is non-negotiable if you want the strongest possible bond between the coating and the paint. If you want to get this part perfect, it’s worth learning how to properly clay bar your car, as it's a true cornerstone of professional detailing.

Erasing Imperfections with Paint Correction

With the paint finally, truly clean, the most critical phase begins: paint correction. This is where you physically remove the swirl marks, holograms, and scratches. On notoriously soft black paint, this is less of a process and more of an art form that demands patience and the right combination of tools.

Rushing this or using a compound that’s too aggressive will just trade one problem for another. You'll end up with buffer trails or holograms—those hazy, rainbow-like patterns that look absolutely horrendous on black paint in the sunlight. To avoid that nightmare, a two-step correction is the only way to go.

- The Compounding Stage: I start with a medium-cut compound on a microfiber or foam cutting pad with my dual-action polisher. The key is to work in small, manageable 2×2 foot sections, using slow, overlapping passes. Your lighting is your best friend here. Use multiple light sources and check your work from every angle to make sure you've removed all the deeper defects.

- The Polishing Stage: Once the compounding is done, I'll switch to a fine-finishing polish and a soft foam finishing pad. This is the step that refines the surface, clearing up any micro-marring left from the cutting stage. It’s what really burnishes the paint to an intense, deep gloss and creates that flawless, mirror-like foundation we're chasing.

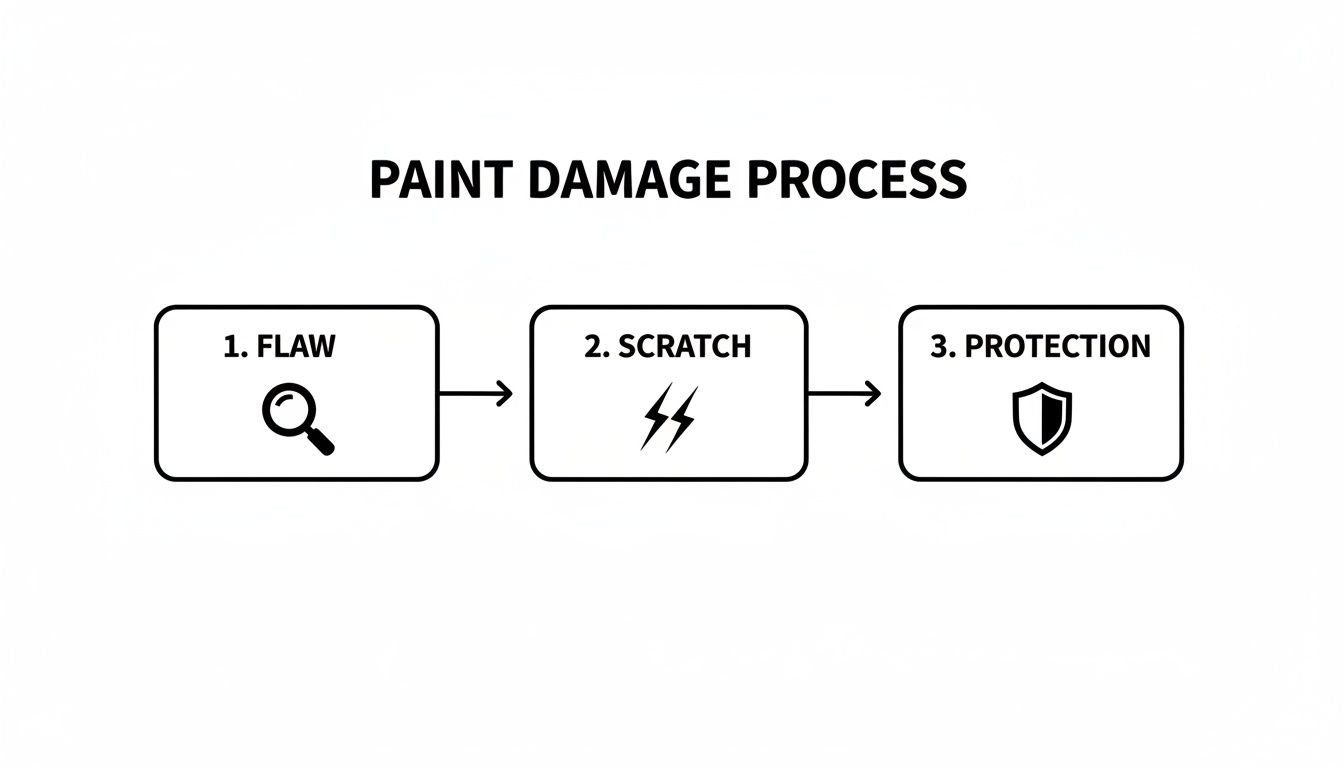

This visual shows exactly why this process is so important—it's about stopping damage in its tracks and then laying down a protective shield.

The flowchart perfectly illustrates that protection is the final, essential step after you've identified and corrected all the surface damage.

The Final Wipe Down for a Perfect Bond

Okay, you've spent hours decontaminating and polishing the paint to absolute perfection. This last step, right before you open the coating bottle, is arguably the most critical for its long-term survival. You have to get every last trace of polishing oils, residue, and fingerprints off the surface.

The tool for the job is an IPA (isopropyl alcohol) solution or a dedicated panel prep spray. Lightly mist the solution onto a clean, high-quality microfiber towel and gently wipe a panel. Immediately follow up with a second, completely dry microfiber towel to buff away any remaining residue.

Key Takeaway: This final wipe makes the surface completely sterile. It's what allows the nanoparticles in the ceramic coating to form a direct, powerful covalent bond with the car's clear coat. If you skip this, the bond will be weak, and the coating will fail much sooner than it should.

Once that final wipe is done, the car is officially ready. The surface is now a flawless, decontaminated, and sterile canvas. Every bit of effort you just poured into this prep work is about to pay off in a big way, allowing the ceramic coating to perform at its peak and lock in that perfect, jaw-dropping finish that makes owning a black car so rewarding.

Applying Your Ceramic Coating Like a Pro

Alright, the long hours of prep work are behind you. The paint is flawless. Now for the moment of truth—applying the armor that transforms that perfect finish into a hyper-glossy, protected work of art.

This is where finesse and patience take over. Applying a coating, especially on the unforgiving mirror of black paint, is a delicate dance. It’s all about understanding how the product behaves and trusting the process.

Imagine standing next to that perfectly corrected black car, the shop lights creating a deep, liquid pool of color on the hood. You've got your bottle of Titan's Alpha Quartz in hand. This isn't just another ceramic coating. It's an elastomer—a completely different breed of protection that flexes and endures in ways traditional, brittle coatings just can't.

The Application Process: A Step-by-Step Feel

When you open the bottle, you'll start by priming your suede applicator block. Just a few drops to create a line down the center is all you need. For that first panel—let's say the hood—add a couple more drops. The goal here isn't to flood the surface; you're aiming for a thin, even layer.

On black paint, a systematic approach is your best friend. I never tackle more than a small, 2×2 foot section at a time. I like to outline the section with the applicator first, then fill it in using a crisp cross-hatch pattern. Go side-to-side, then top-to-bottom. This is the only way to guarantee you’ve got complete, even coverage with zero missed spots.

Now, you wait and watch for the magic. The coating will begin to "flash" as the carrier solvents evaporate, leaving the protective solids behind. You'll see this as a subtle rainbowing or "sweating" effect on the surface. Timing is everything here, and it's heavily influenced by the temperature and humidity in your garage.

Pro Tip: Your lighting is your most critical tool during application. Have a powerful, diffused primary light overhead, but keep a handheld inspection light nearby. By sweeping the handheld light at a low angle across the panel, you can instantly spot "high spots"—any excess coating that hasn't been leveled—before they cure into a nightmare.

Once the coating has flashed (usually 1-3 minutes), it’s time to level it. Take a clean, short-nap microfiber towel and perform an initial, gentle wipe to remove about 80% of the residue. Immediately follow up with a second, plush microfiber towel to buff the area to a perfect, streak-free shine. That feeling when the towel glides effortlessly over the now impossibly slick surface? That’s one of the most satisfying parts of the job.

There’s a reason the market for this level of protection is exploding—the High Performance Ceramic Coatings Market is on track to hit USD 15.8 billion by 2032. For black cars, the value is undeniable. These coatings offer superior UV protection against the oxidation that fades black paint faster than any other color. Owners consistently see 20-30% better gloss retention after three years compared to waxed finishes, and the unbelievable water-beading can slash cleaning time by up to 50%.

Why Titan's Elastomer Technology Is a Game-Changer

As you move from one panel to the next, remember you're not just laying down a sheet of glass. Alpha Quartz is an elastomer, and this is the key difference that sets Titan Coatings apart. While traditional ceramic coatings are incredibly hard, that hardness can also make them brittle.

Think about a car's life. It sits in the hot sun, and the metal panels expand. In the freezing cold, they contract. A rigid, glass-like coating can't handle that constant movement, leading to microscopic stress cracks over time that completely undermine the protection.

Titan’s elastomer technology, born from our work with nano tubes and Dark Matter tech, creates a coating that is both hard and flexible. It literally moves with your car's paint, preventing those stress fractures and ensuring the bond stays strong through scorching summers and icy winters. This elasticity also gives it a better ability to absorb impacts from things like rock chips and bug splatters without cracking.

A Powerful, Easy-to-Install Alternative

Let's be real—not everyone has the time or dedicated space for a full multi-year coating application. But that doesn't mean you have to settle for weak, short-lived protection.

Titan's Ultra Ceramic Spray is the perfect solution for this. This is not just another detail spray with some ceramic in it. It's a true spray-and-wipe ceramic coating that delivers mind-blowing hydrophobicity, slickness, and gloss.

- As a Standalone: For someone who wants 6-12 months of serious protection without the intensive process, Ultra is an incredible choice. The application is as simple as misting it onto a panel, spreading with one microfiber, and buffing to a shine with another.

- As a Topper: For cars already wearing Alpha Quartz, using Ultra every few months as a maintenance topper is the secret to keeping that "just coated" look. It recharges the hydrophobic properties and adds a fresh sacrificial layer of protection.

The simplicity of products like Ultra makes next-level ceramic protection accessible to everyone, ensuring even a daily-driven black car can stay looking its absolute best without a weekend-long commitment.

Whether you go for the professional-grade endurance of Alpha Quartz or the amazing convenience of Ultra, the core principles are the same. Applying a ceramic coating on black cars is about working smart, being patient, and choosing a product truly engineered to handle the unique challenges of dark paint. Once you step back and see that final result—a deep, flawless, brilliantly protected finish—you'll know every second of effort was worth it.

Don't Forget the Details: Protecting Your Glass, Wheels, and Trim

After hours spent perfecting that mirror-like black paint, it's easy to call it a day. But a truly protected vehicle means giving that same obsessive level of care to every surface. The glass, wheels, and trim are the supporting cast, and if they're neglected, they’ll drag down the whole look. It’s like putting a masterpiece in a cheap, dirty frame.

Making Rainy Drives Stress-Free

We’ve all been there—driving through a downpour at night, a white-knuckle experience where the wipers can't keep up. Water sheets across the windshield, smearing and blurring your vision to dangerously low levels. This is where a dedicated glass coating isn't just a cosmetic choice; it's a legitimate safety upgrade.

Picture this: you're on the highway when the sky opens up. Instead of a solid wall of water, you see tiny beads form and then simply fly off the glass as you cruise. Your wipers become almost optional. That's the real-world difference that Apex Glass Ceramic Coating from Titan makes.

The hydrophobic properties are so effective that water has no chance to cling to the surface. It’s forced to bead up and roll away, which massively improves visibility and makes driving in bad weather a far less tense, much safer experience.

Getting it on is simple:

- Clean the glass thoroughly with a high-quality glass cleaner.

- Decontaminate with a clay bar to pull out any bonded grit.

- Wipe it all down with an IPA solution or a panel prep spray.

- Apply Apex Glass in small, manageable sections, buffing it off right after it flashes.

What you're left with is a slick, invisible shield that doesn't just repel water. It also fights back against ice, sleet, and bug guts, making your glass easier to clean all year round.

Defending Your Wheels from Brake Dust

Nothing looks more menacing than a set of clean black wheels. But they're absolute magnets for the nastiest, most corrosive stuff on your car: brake dust. These are tiny, hot, metallic particles that bake themselves into the wheel’s finish, causing permanent pitting and damage if left unchecked. Cleaning them often requires harsh, foul-smelling chemicals and a ton of scrubbing.

A ceramic coating creates a slick, non-stick barrier on your wheels. Instead of brake dust baking into the finish, it sits on top of the coating. This transforms cleaning from a heavy-duty scrubbing session into a simple rinse with a pressure washer in many cases.

This is a game-changer, especially with the intricate designs of modern wheels where it's nearly impossible to get a brush into every nook and cranny. Coating them preserves that deep black finish and slashes your maintenance time. If you want to get really deep into the process, our guide on ceramic coating for rims has all the details you’ll need.

By protecting the glass, wheels, and trim, you complete the circle of protection. You ensure every single part of your black car not only looks its absolute best but is also shielded from the elements. It’s that final step that takes a great detail and makes it exceptional.

Keeping Your Coated Masterpiece Looking Flawless

Let's be real: that ceramic coating is an incredible shield for your black paint, but it's not a magic force field. The secret to that unbelievable, multi-year gloss and mind-blowing water beading isn't a one-and-done application—it's consistent, smart maintenance. I have to bust the biggest myth right now: a coated car is not a “no-wash” car. In fact, washing it the right way is what keeps the coating working at its peak.

Think of it like a high-end non-stick pan. It repels almost everything, but over time, a thin layer of traffic film, dust, and pollen will inevitably settle on the surface. If you let that gunk sit, it starts to clog the coating, killing its hydrophobic properties and dulling that deep, wet shine. A proper wash clears all that away, bringing back the slick, self-cleaning surface you invested in.

The Right Way to Wash a Coated Car

First things first: stay far away from automated car washes. Those giant, spinning brushes are the sworn enemy of a perfect finish, whether it’s coated or not. The absolute foundation of safe maintenance is the two-bucket wash method.

It's a simple setup, but it’s non-negotiable for black paint.

- You'll have one bucket for your pH-neutral car soap solution.

- The second bucket is just for clean rinse water.

- Make sure you have grit guards in the bottom of both. These little plastic grates are critical for trapping dirt and keeping it from getting back on your wash mitt.

Here’s the part that saves your paint: after washing a single panel, you dunk and scrub your mitt in the clean rinse water bucket before you ever put it back in the soap bucket. This one simple habit is a total game-changer for preventing the swirl marks that haunt every black car owner.

Drying Without Doing Damage

How you dry the car is just as crucial as how you wash it. Dragging an old, crusty towel across the paint can easily inflict micro-scratches, undoing all the careful work you just did. The goal is to get the car dry with the least amount of friction possible.

Your best friends here are a massive, plush microfiber drying towel (we're talking 1000+ GSM thick) or a filtered air blower. Honestly, the air blower is the ultimate touchless solution. It blasts water out of every nook, cranny, and panel gap where towels can't even dream of reaching. If you're using a towel, don't scrub. Just gently lay it on the surface to blot the water up, or slowly pull it across the panel with zero pressure.

Pro Tip: Never, ever wash or dry your black car in direct sunlight or when the panels are hot. The heat makes water and soap evaporate way too fast, leaving behind nasty water spots and mineral deposits that can actually etch into your coating. Always work in the shade or during the cooler morning or evening hours.

The explosion in demand for this kind of durable, long-term protection is why the global ceramic coatings market has seen such incredible growth. The market value shot up from USD 1.96 billion in 2018 and is on track to hit a projected USD 3.32 billion by 2026. For us in the trenches, the real magic is that a good coating can cut the risk of wash-induced swirl marks by up to 70%—an absolute lifesaver for black paint that shows every tiny flaw.

Level Up With a Maintenance Topper

Want to keep that "just coated" slickness and off-the-charts water beading? A maintenance topper is your secret weapon. A few times a year, right after a good wash, applying a product like Titan's Ultra Ceramic Spray works wonders.

This isn't just a fancy detail spray. It's a genuine, easy-to-use ceramic formula that adds a fresh sacrificial layer right on top of your primary coating. It instantly rejuvenates the hydrophobic effect, amps up the gloss, and helps your main coating go the distance. The process couldn't be easier: mist it on, gently spread it with one clean microfiber towel, and immediately buff to a streak-free shine with a second one. It’s a 15-minute job that pays you back every time it rains.

For a complete playbook on keeping your investment protected, you should check out our comprehensive guide on ceramic coating maintenance.

Common Questions About Ceramic Coating Black Cars

Thinking about ceramic coating your black car? It's a big step, and it’s smart to have questions. Let's be real—coating a black car is an investment, so you need straight answers before you commit. Here are some of the most common things people ask me before pulling the trigger.

Is It Really Worth the Cost for a Black Car?

One hundred percent, yes. I get it, the upfront cost is more than a bottle of wax, but you're not just buying a shiny finish. You're buying back your time and saving your sanity.

Think about it. A top-tier elastomer coating like Titan Alpha Quartz isn't a six-month solution; it's years of serious protection. This means you can finally break the frustrating cycle of waxing, polishing, and constantly fighting the swirl marks and fine scratches that plague black paint. In the long run, you'll save a ton on detailing products and labor while your car looks like it just rolled off the showroom floor.

Can I Apply a Ceramic Coating Myself?

This really boils down to your own skill set and patience. Let's be honest: some professional-grade coatings are locked down for certified installers only, and for good reason.

That said, the game has changed. Many incredible coatings are now designed for the serious DIY enthusiast. A product like Titan's Alpha Quartz is a great example—it delivers professional-grade durability but is totally manageable for someone who's willing to put in the painstaking prep work. The final result lives or dies by the prep. If you're not confident you can achieve a flawless, corrected surface, handing the keys to a pro is your best bet for a perfect outcome.

Will a Ceramic Coating Hide Existing Scratches?

Absolutely not. This is probably the biggest misconception out there. A ceramic coating is a transparent layer of protection; it doesn't have fillers and won't hide anything. In fact, because it adds such an unbelievable amount of gloss and clarity, it will actually magnify any underlying scratches, swirls, or holograms.

Key Takeaway: Paint correction isn't just a step in the process—it's the most critical stage. Every last imperfection has to be meticulously polished out before a single drop of coating touches the paint. The coating then locks in that perfect, mirror-finish you worked so hard to achieve.

How Do I Wash My Car After It's Coated?

Your washing technique is what will make or break the longevity of your coating. You've got to be gentle. I always tell my clients to stick to the two-bucket wash method, complete with grit guards, a good pH-neutral soap, and a high-quality microfiber wash mitt.

And please, stay away from the automatic car washes. Those spinning brushes are way too aggressive and will inflict damage on your coating over time. For drying, either use a high-GSM, plush microfiber drying towel (the "blot" or "drape" method is best) or, even better, use a filtered air blower to push the water off without ever touching the paint.

Ready to give your black car the kind of flexible, durable protection it deserves? Titan Coatings has developed the next generation of elastomer coatings designed to keep that deep, black finish looking flawless.

Discover the unbeatable gloss and resilience of Alpha Quartz and see for yourself why our technology is the go-to choice for serious car owners and professional detailers around the world.

0 Comments