Imagine this: You’ve just spent your Saturday washing and detailing your car. You step back, and it’s gleaming—a shine so deep it looks like wet paint. It’s a moment of pure pride. But then, life happens. A few weeks of rain, sun, and road grime, and that perfect finish starts to fade, sending you right back to the garage for another round of waxing and polishing.

It’s an aggravating cycle, and it’s exactly what the modern automotive ceramic coating was created to break. This isn’t just another wax or sealant; it’s a semi-permanent, microscopic shield that forms a chemical bond with your car’s paint, offering years of serious protection.

Your Guide to Modern Automotive Ceramic Coating

In this guide, we’re going to pull back the curtain on how this incredible technology works, with a special focus on the breakthroughs coming from Titan Coatings. We’ll dig into their game-changing elastomer technology, which is rewriting the rules for durability and performance in the world of vehicle protection.

A Story of Innovation

For decades, the goal was pretty straightforward: make a car shine. But the real question that drove one team of innovators was, “What if protection could be smarter? More resilient?” That was the challenge that sparked the creation of Titan Coatings. It all started with a vision to get away from the old-school, brittle, glass-like layers of traditional ceramic coatings that were prone to cracking under real-world stress.

The result? The market’s very first elastomer coating, a product born from sophisticated nanotube technology and our proprietary Dark Matter Tech™.

This wasn’t just a small step forward; it was a complete pivot in how we think about surface protection. We engineered a coating that delivers the hardness of glass but with incredible flexibility. That elasticity is the secret sauce behind its remarkable longevity.

Think of it this way: a rigid shield might crack under pressure, but a flexible one bends, absorbs the impact, and snaps right back to its original form. That’s the core idea behind our advanced automotive ceramic coating.

Hardness Meets Flexibility

So, why does flexibility matter so much? Your vehicle’s body panels are in constant motion, expanding in the summer heat and contracting in the winter cold. A completely rigid coating simply can’t keep up with that movement, which eventually leads to micro-cracks that let dirt and moisture in, compromising the entire layer.

Titan’s elastic coatings solve this problem head-on. They’re built to handle unbelievable temperature swings, from freezing winters to blistering summers, without cracking or giving up. This means the protective shield stays solid and unbroken, safeguarding your paint all year long. It’s the kind of performance that gives you real peace of mind.

This unique blend of hardness and flexibility also does a much better job of absorbing impacts from bugs and road debris. Instead of chipping away, the coating flexes, preserving that flawless finish underneath. It’s this kind of smart engineering that truly defines the next generation of surface protection.

The Science Behind a Flawless and Flexible Finish

Let’s get straight to the science behind a truly great ceramic coating, but without the confusing jargon. Think of it like giving your car a microscopic, flexible suit of armor. This isn’t just about a pretty shine; it’s about creating a tough, resilient barrier that becomes one with your vehicle’s paint.

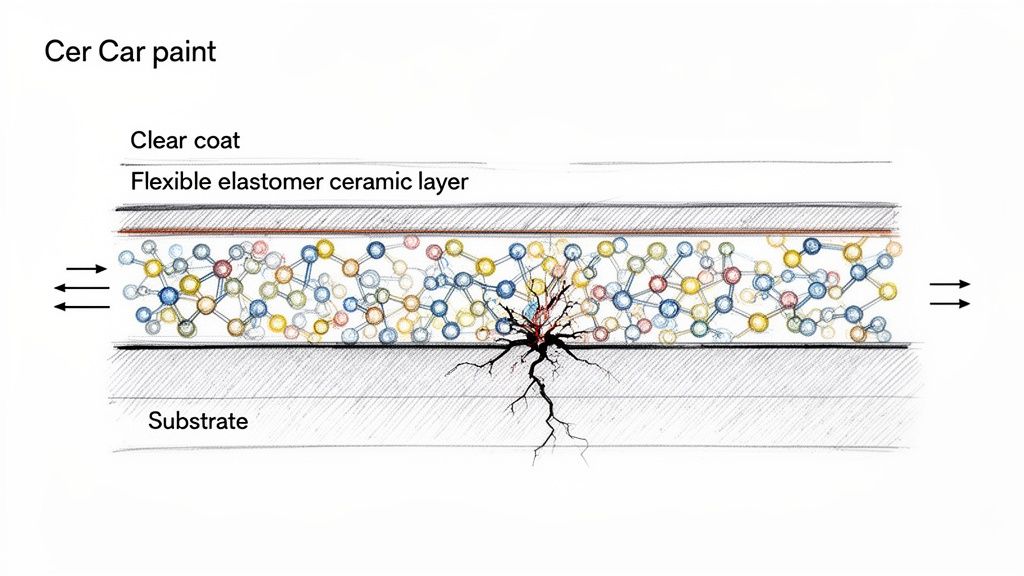

Many traditional ceramic coatings, the ones based on simple silicon dioxide (SiO2), create a layer that’s hard like glass. While that sounds great for scratch resistance, it hides a serious flaw: it’s brittle. That rigidity becomes a major problem when your car’s body panels start doing what they naturally do.

The Problem With Rigidity

Think about what your car goes through every single day. The metal panels expand under the hot summer sun and shrink back down in the bitter cold. A rigid, glass-like coating simply can’t keep up with that movement.

This constant stress eventually leads to micro-cracks. You won’t see them at first, but these tiny fractures are a breach in the armor. They let moisture, dirt, and chemicals sneak underneath, attacking the very paint you paid to protect.

This is where Titan’s innovation completely changes the game. We identified this core weakness in older technologies and engineered a far better solution from the ground up.

By pioneering elastomer technology powered by our proprietary Dark Matter Tech™ and advanced nanotubes, Titan created the market’s first coating that is both hard like glass and remarkably flexible. This isn’t just an improvement; it’s a new category of protection.

Elasticity: The Key to Longevity

Our breakthrough was simple in concept but complex in execution: create a coating that acts less like brittle glass and more like resilient rubber. This elasticity is what allows the protective layer to expand and contract right alongside your vehicle’s paint, stopping those destructive micro-cracks before they ever form.

This flexibility is the secret to genuine, long-term durability, no matter the climate. Whether your car is baking in the Arizona sun or surviving a Canadian winter, the coating remains fully intact and ready to protect.

Imagine this real-world scenario: a piece of gravel gets kicked up and smacks your fender. A rigid coating might chip or form a stress fracture at the point of impact. But an elastic coating like Titan’s Alpha Quartz flexes, absorbs that energy, and bounces right back, dramatically reducing or even preventing any damage.

- Temperature Stability: Our coatings stay stable and effective from freezing cold to blistering heat, eliminating the risk of thermal-induced cracking.

- Impact Absorption: The flexible surface helps dissipate the force from bug splatters and minor road debris, safeguarding the finish underneath.

- Superior Chemical Bond: Our advanced formula creates a powerful chemical bond with the paint, ensuring the coating won’t delaminate or peel away over time.

This sophisticated approach to chemistry is what separates a standard coating from a truly durable one. While the market is flooded with options, it’s critical to understand these scientific differences. For a deeper look, you can explore our detailed comparison of graphene coating vs. ceramic coating to see exactly how different technologies perform.

Beyond the Paint: Protection for Every Surface

We’ve applied this same principle of flexible, resilient protection to other parts of your vehicle. Glass, for example, presents its own unique set of problems. Driving in a heavy downpour can be a tense, white-knuckle experience as your wipers struggle to clear your view.

So, we applied our hydrophobic science to solve this with our APEX Glass Ceramic Coating. It creates an incredibly slick surface that water just can’t stick to. Instead of smearing, rain instantly beads up into tiny spheres and gets whisked away by the airflow over your car. At highway speeds, you often won’t even need to turn your wipers on.

The result is a dramatic improvement in visibility that makes driving under rain stress-free. It turns a tense drive into a safe and comfortable one, and the easy-to-use formula means anyone can get professional-grade water repellency.

Why Modern Coatings Are Better Than Just a Shine

The first thing that grabs your eye on a freshly detailed car is that unbelievable, liquid-like shine. But with a modern automotive ceramic coating, that stunning gloss is just the tip of the iceberg. The real magic isn’t just in how it looks, but in how it performs under the pressures of the real world. Think of it less as a polish and more as a functional upgrade that completely redefines paint protection.

The most obvious benefit you’ll notice right away is its amazing hydrophobic properties. Water doesn’t just sit there; it beads up into tight little spheres and zips right off the surface, taking dirt and grime along for the ride. This self-cleaning effect means your car stays looking sharp for much longer, and when you finally do need to wash it, the job is ridiculously easy.

A Story of Everyday Protection

Imagine you’re driving home after a long road trip. The front of your car is a graveyard of bug splatters and caked-on road grime. With an old-school wax, that mess starts to etch into the finish, forcing you to use harsh chemicals and a lot of elbow grease to get it off—often leaving faint marks behind.

Now, let’s replay that same scenario, but this time your car is shielded by Titan’s Alpha Quartz. This is where the true value of our elastomer technology really comes into its own. The coating’s signature elasticity is engineered to flex and absorb the kinetic energy from those bug impacts. Instead of the force chipping or cracking a rigid surface, the flexible layer dissipates it, stopping damage before it ever reaches your paint.

When you get home, a simple, gentle wash is all it takes to bring back that perfect finish. The bugs and dirt release with almost no effort because they never got a chance to truly bond to the protected surface. That’s the difference between a temporary shine and an active, durable shield.

More Than Just Paint Defense

This level of protection isn’t just for your car’s body panels. Your windshield and windows face a constant assault from rain, sleet, and road spray, which can turn driving in bad weather into a stressful, white-knuckle experience. We took that same hydrophobic science and applied it to solve this exact problem.

Our APEX Glass Ceramic Coating creates an intensely slick surface on your glass. Rainwater can’t spread out and smear; it instantly beads up and gets whisked away by the wind as you drive. Once you hit highway speeds, your visibility is so clear you might not even need your wipers. It transforms a hazardous drive into a safe and confident one, and its straightforward formula delivers professional-grade results.

“A high-quality ceramic coating does more than enhance aesthetics; it provides a sacrificial, semi-permanent layer that preserves the original factory paint. This protection against chemical etching and oxidation is critical for maintaining a vehicle’s long-term value.”

Comparing Old and New School Protection

The jump from traditional waxes to elastomer coatings is a huge one. Waxes give you a short-lived, superficial layer of shine that starts breaking down almost immediately. For a deep dive into how these products stack up in terms of durability, performance, and application, check out our guide on the difference between wax and ceramic coating.

To see just how big the gap is, our comparison page highlights the key differences between our innovative products, but here’s a general overview.

Titan Elastomer Coating vs Traditional Waxes and Sealants

It’s one thing to talk about the benefits, but seeing them laid out side-by-side really drives the point home. Here’s a clear breakdown of how our advanced coatings stack up against the products you’re used to.

| Feature | Traditional Wax/Sealant | Titan Elastomer Ceramic Coating |

|---|---|---|

| Durability | Lasts a few weeks to a few months, requiring frequent reapplication. | Forms a semi-permanent bond lasting for years with proper care. |

| Protection | Offers minimal resistance to chemicals, UV rays, and light scratches. | Provides robust protection against acid rain, bird droppings, UV damage, and oxidation. |

| Flexibility | Brittle and can wear away unevenly; offers no impact absorption. | Elastic properties absorb impacts from bugs and road debris, preventing chips and cracks. |

| Maintenance | Requires frequent washing and re-waxing to maintain its appearance. | Hydrophobic properties make washing easier and less frequent; the vehicle stays cleaner longer. |

| Appearance | Provides a warm gloss that diminishes quickly. | Delivers a deep, candy-like gloss and enhances color depth for years. |

Ultimately, choosing a modern automotive ceramic coating is an investment in your vehicle’s long-term preservation. It’s a commitment to keeping it looking its absolute best not just for a weekend, but for years to come—with a whole lot less effort.

The Art Behind the Professional Application Process

Anyone who thinks a truly professional ceramic coating is just a matter of wiping some liquid on a car is missing the bigger picture. It’s not a product; it’s a process. This is a multi-stage craft where the final, jaw-dropping result is built on a foundation of meticulous preparation.

A certified installer, especially one trained by Titan Coatings, knows that the real work begins long before the coating bottle is even opened. You can’t just slap a coating on a dirty, imperfect surface and expect it to work. That’s why the first step is always a rigorous decontamination wash. This isn’t your average car wash—it’s a deep clean designed to strip away every bit of road grime, tar, and industrial fallout clinging to the paint.

Once the surface grime is gone, it’s time for a clay bar treatment. Think of it like a spa day for your car’s paint. A specialized clay bar is carefully glided across every inch of the vehicle, pulling out microscopic contaminants that washing alone can’t touch. The goal is to get the clear coat flawlessly smooth and pure.

Why Paint Correction is Everything

With a truly clean slate, we get to the most critical part of the entire job: paint correction. This is where the skill of a true professional is on full display. Using a variety of polishers and compounds, the installer painstakingly buffs away swirl marks, light scratches, water spots, and any other blemish in the paint.

Let’s be clear: this step is non-negotiable. Applying a ceramic coating over flawed paint is like putting a sheet of glass over a dusty, scratched photograph. You’re not hiding the imperfections; you’re locking them in and amplifying them for everyone to see. Proper paint correction is what ensures the coating can bond directly to a perfect surface, which is absolutely essential for its gloss, durability, and protective power.

This meticulous process is what unlocks the benefits everyone wants from a coating.

As you can see, a brilliant shine, intense water-beading, and a tough, durable shield are the direct results of doing the prep work right.

The Final Touch: Application and Curing

Only when the paint is absolutely perfect does the ceramic coating finally make its appearance. This isn’t rushed. It’s done with surgical precision in a controlled environment, panel by panel, to keep any dust or moisture from interfering. The installer then carefully levels the coating to create a completely uniform, streak-free layer of protection.

After application comes the waiting game: curing. This is where the magic happens. The nanoparticles in the liquid cross-link with the clear coat, forming an incredibly strong, semi-permanent bond. Without a proper cure, you’ll never get the hardness, hydrophobics, or longevity the coating was engineered to deliver.

This multi-stage process is what separates a professional, long-lasting result from a quick DIY job. It’s a craft, and it’s why Titan ensures our certified installers are trained to deliver a perfect finish, every single time.

The Real-World Difference: A Story of Trust

We once had a client bring his brand-new sports car to a Titan-certified detailer, absolutely beside himself. He’d tried a consumer-grade DIY coating from an auto parts store to save a few bucks. But without the right prep, he had unknowingly sealed in tiny factory blemishes, and his application was a streaky mess. He thought he’d ruined the finish on his dream car.

Our installer calmly walked him through the professional process. After carefully stripping the failed coating, he spent a full day meticulously correcting the paint, bringing it to a level of perfection that even the factory couldn’t match. Only then did he expertly apply Titan’s Alpha Quartz, our signature elastomer coating.

The client was floored. The depth and gloss were beyond anything he thought possible, and the surface was slicker than glass. He learned a valuable lesson that day: the skill of the installer is just as important as the quality of the coating itself. It’s why understanding the details of applying a ceramic coating to a car is so crucial for anyone who truly values their vehicle.

Keeping That Showroom Shine: How to Care for Your Coated Vehicle

One of the best parts about getting a professional ceramic coating is just how ridiculously easy it is to keep your car looking incredible. But let’s be clear: while it’s low-maintenance, it’s not no-maintenance. A few simple habits are all it takes to make sure that investment pays off with years of stunning gloss and protection.

Honestly, a proper wash is usually all you’ll need to bring back that slick, just-detailed look.

The Right Way to Wash Your Coated Car

Washing is the foundation of good coating care, and getting it right is simple. Always, and I mean always, use the two-bucket wash method with grit guards. This isn’t just some old detailer’s tale—it’s the single best way to keep dirt and grit at the bottom of the bucket instead of dragging it across your paint and creating swirl marks.

You’ll also want to use a quality, pH-neutral car soap. Aggressive detergents or degreasers are the enemy here; they can slowly eat away at the coating’s hydrophobic surface, making it less effective. And please, for the love of your car’s finish, steer clear of automatic car washes with those giant, spinning brushes. They’re far too harsh and can easily scratch and damage the protective layer you paid good money for.

We’ve put together a full breakdown on this, so check out our guide on how to maintain your ceramic coating to get it perfect every time.

Good maintenance isn’t just about keeping the shine. It’s about preserving the coating’s incredible hydrophobic power, making sure water, dirt, and grime keep sheeting off effortlessly for years.

The Soaring Demand for Real Protection

This blend of durability and easy maintenance is exactly why ceramic coatings have blown up. A decade ago, they were a niche product for hardcore enthusiasts. Today, they’re a go-to solution for anyone who loves their car. This isn’t just a feeling; the numbers back it up. The global market for these coatings hit USD 11.16 billion in 2023 and is on track to hit USD 19.20 billion by 2030.

And what’s driving that growth? Cars. The automotive sector makes up a massive 32% of that demand. People are catching on that this is the new standard in paint protection.

Looking at the Bigger Picture of Car Care

Of course, a beautiful finish is only part of the equation. Your ceramic coating is doing its job on the outside, but don’t forget the rest of the car. A vehicle that’s well-cared-for mechanically simply runs better, lasts longer, and is worth more when it’s time to sell. To stay on top of everything under the hood, a comprehensive car maintenance by mileage guide is an invaluable resource.

When you pair proper coating care with routine mechanical upkeep, you’re creating a total preservation plan for your vehicle. It’s a strategy that doesn’t just keep your car looking amazing, but also ensures it runs like a dream—protecting your investment from the inside out and making every drive that much better.

Why Settle for Anything Less Than a Proven Leader?

When it comes to protecting your car, you’re not just buying a product; you’re investing in peace of mind. But let’s be honest, the ceramic coating market is flooded with options, and it’s tough to tell what’s real and what’s just clever marketing. The difference between a fleeting shine and genuine, long-term protection boils down to one thing: the science in the bottle.

At Titan Coatings, we don’t just follow industry trends—we create them. We’re not in the business of slapping our label on someone else’s formula. We were the first to bring elastomer coatings to the market, a huge leap forward driven by our proprietary Dark Matter Tech™ and its advanced nanotube structure.

This isn’t just talk. Our commitment to creating flexible, durable, and genuinely superior protection is backed by independent, third-party ISO/ASTM testing and our ISO 9001 certification. That’s your proof that every bottle we produce will perform exactly as promised, even when faced with the harshest conditions on the planet.

The Power of Elastic Protection

Picture this: it’s a frigid winter morning, and your car’s metal panels are contracted from the cold. By afternoon, the sun is beating down, causing those same panels to expand. Most traditional ceramic coatings are rigid, almost glass-like. They can’t handle this constant movement, and over time, that stress causes microscopic cracks, which eventually leads to failure.

This is exactly where our technology changes the game. Our Alpha Quartz elastomer coating was engineered to solve this very problem. It’s incredibly hard, yet it has a built-in flexibility. This allows the coating to expand and contract right along with your vehicle’s paint, completely preventing the micro-cracks that plague older, more brittle formulas.

Choosing Titan means you’re getting more than just a coating. You’re getting a scientifically engineered shield that actively preserves your vehicle’s value and appearance. It’s the confidence that comes from knowing your car is protected by the most advanced technology out there.

That same flexibility also helps the coating absorb small impacts from things like bug splatters and road debris without chipping or flaking. The result is a shield that stays intact, keeping that “just detailed” look locked in, month after month, through sun, rain, and everything in between. You can find out more about how we perfected Titan Coatings’ elastomer technology on our website.

Beyond Paint: A Shield for Every Surface

Real vehicle protection is about more than just the paint. Your windshield is your window to the world, and in a sudden downpour, clear visibility is a matter of safety, not just convenience. Let’s face it, driving in heavy rain is stressful, but it doesn’t have to be.

We engineered our APEX Glass Ceramic Coating with this exact scenario in mind. By applying our advanced hydrophobic science, APEX creates a surface so slick that water has nowhere to cling. Raindrops bead up on contact and are whisked away by the airflow over your car, often making your wipers totally unnecessary at highway speeds. It makes driving in a storm feel effortless, and best of all, it’s incredibly easy to apply.

A Smart Investment in Your Vehicle’s Future

Investing in a high-quality ceramic coating is one of the smartest financial decisions you can make for your vehicle. People are holding onto their cars longer than ever before—often for 8 to 12 years—and they’re looking for protection that lasts.

This lines up with a much bigger global issue: corrosion, which costs the world economy an estimated USD 2.2 trillion annually. The automotive industry accounts for about 32% of the demand for ceramic coatings for a reason. These coatings provide incredible resistance to the UV rays, chemicals, and oxidation that cause a vehicle’s finish to break down over time. By choosing a proven leader, you’re making an investment that will pay for itself for years to come.

Got Questions? We’ve Got Answers.

Even after seeing all the benefits, it’s totally normal to have a few questions rolling around in your head. Let’s tackle some of the most common ones we hear from drivers, so you can feel 100% confident about giving your car the best protection out there.

Can I Just Apply a Ceramic Coating Myself?

Look, there are definitely some DIY-friendly products on the market—we even make a great one called Titan Alpha Quartz, which is easy to install with great results. But here’s the honest truth: a truly professional, long-lasting result is all about the prep work.

Getting that perfect bond requires a completely pristine surface. That means a full decontamination and, most importantly, a thorough paint correction to eliminate any existing imperfections. For our top-tier coatings and a finish that’s backed by a solid warranty, we always point people to a Titan Coatings certified installer. They have the right tools, the controlled environment, and the hands-on experience to nail it every single time.

What’s the Big Deal with a Flexible Elastomer Coating?

Most standard ceramic coatings harden into a super-rigid, glass-like shell. It’s great against fine swirl marks, but that very rigidity can be its downfall. Your car’s body panels naturally expand and contract with the heat of the sun and the cold of winter, and over time, a stiff coating can develop tiny micro-cracks.

This is where Titan’s elastomer coatings completely change the game. They deliver that same incredible hardness and jaw-dropping gloss, but they do it with built-in flexibility. This elasticity lets the coating absorb the impact from small road debris and flex with temperature changes, preventing cracks and dramatically boosting its real-world durability.

So, a Ceramic Coating Makes My Car Scratch-Proof, Right?

This is probably the biggest myth out there. Let’s be clear: a high-quality ceramic coating adds an incredibly tough, sacrificial layer of protection. It’s fantastic at resisting the light swirl marks you get from a bad car wash.

But it’s not a suit of armor. It won’t make your paint bulletproof. A sharp key or a serious impact will still get through the coating and into your clear coat. Think of it as a renewable, super-strong shield that takes the hit from all the daily grind, keeping your factory paint looking brand new for years—something no wax or sealant could ever hope to do.

Ready to wrap your vehicle in the most advanced, flexible protection available? Titan Coatings delivers scientifically proven elastomer technology that locks in that flawless, showroom look for years.

Check out our incredibly effective and easy-to-use Alpha Quartz elastomer coating and see the difference for yourself.

0 Comments