Imagine driving your brand-new car off the lot. The paint is a flawless, liquid mirror reflecting the sky. Now, picture a high-tech, invisible suit of armor wrapping itself around every curve, bonding with the paint to protect that perfection. That’s an automotive paint protection coating. It's a transparent, sacrificial layer that chemically bonds to the paint, taking all the hits—from environmental hazards, chemical stains, and light scratches—so your original factory finish doesn't have to. It's the ultimate defense for keeping your car looking incredible and protecting its resale value.

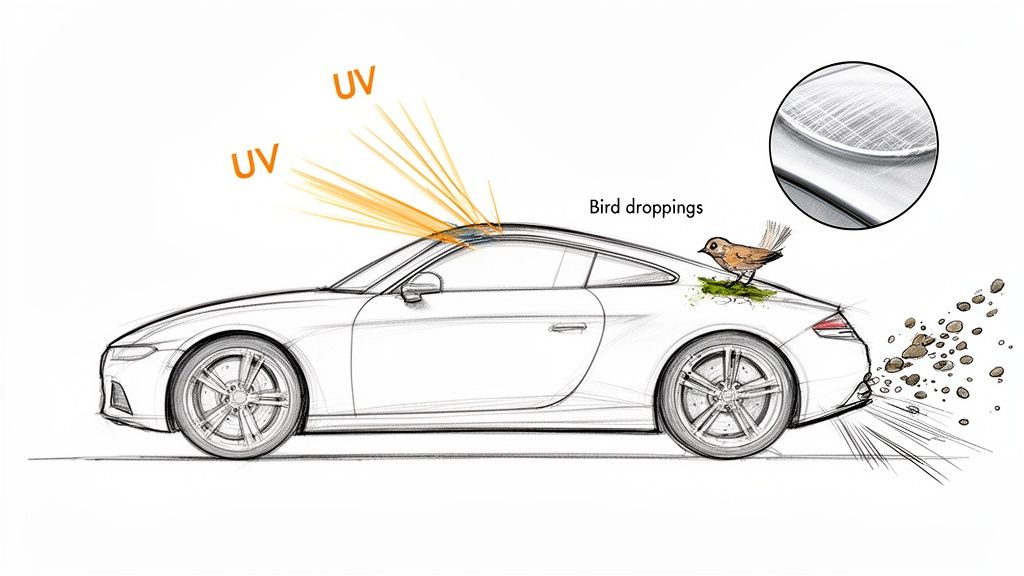

Your Car's Finish Is Under Constant Attack

Every single time you pull out of the driveway, your car’s paint is heading into a warzone. It doesn't matter if it's a quick run to the grocery store or a cross-country road trip; the battle is on.

Remember that day you brought it home? That deep, flawless, mirror-like shine was perfect. But from that moment on, a relentless barrage of environmental enemies has been working overtime to dull that luster and chip away at that perfection. This isn't a once-in-a-while problem. It’s a constant, day-in, day-out assault.

Picture the slow, heartbreaking reality. The first few months are great—careful hand washes, admiring glances from neighbors. But slowly, the finish starts to show its battle scars. You notice tiny scratches from road debris kicked up on the highway. The sun’s harsh UV rays begin to bleach the life out of that vibrant color, leaving it looking tired and faded. And bird droppings, if not wiped away instantly, bake into the clear coat, leaving permanent, ugly etchings.

The Unseen Enemies of Your Paintwork

The biggest threats aren't always the obvious ones. Much of the damage is subtle, accumulating over weeks and months until it's impossible to ignore. Whether you're navigating daily traffic or looking at the extreme conditions in professional racing like the British Touring Car Championship (BTCC), a vehicle's paint is constantly under siege.

Here are the usual suspects we see in the shop all the time:

- Environmental Fallout: Things like acid rain, tree sap, and industrial pollution contain nasty corrosive compounds. They settle on your car and literally eat away at the clear coat, creating imperfections and dull spots.

- UV Radiation: Your car's paint gets sunburned, just like your skin. Constant exposure to UV rays causes oxidation, which is just a technical term for your paint losing its gloss, fading, and looking chalky.

- Road Grime and Debris: Think of road salt, tar, and tiny pebbles as a fine-grit sandpaper constantly blasting your car's surface. This is what creates that frustrating web of swirl marks and light scratches you see in the sun.

- Chemical Stains: Bug guts and bird droppings are surprisingly acidic. When the sun heats them up, they can chemically burn right into the paint, leaving a permanent blemish that even aggressive polishing sometimes can't remove.

More Than Just a Cosmetic Issue

This slow-motion destruction is about more than just looks; it's a direct hit to your wallet. A car with a dull, scratched, and faded finish is worth significantly less when it's time to sell or trade it in. And the cost to fix it? A quality repaint can easily run into the thousands of dollars.

An automotive paint protection coating isn't just a fancy add-on. It is essential armor in this ongoing battle, acting as a crucial investment in preserving your car's beauty, integrity, and financial worth.

This is why modern protection is so critical. Old-school waxes give you a temporary shine but offer almost no real, durable defense. To truly shield your investment, you need something engineered to withstand this constant attack. This is where advanced coatings become a necessity, not a luxury.

If your car is already showing signs of this assault, understanding how to use a quality iron fallout remover is a critical first step before you can even think about applying protection. You can find more info on that process here: https://titancoatings.us/iron-fallout-remover/

Understanding Modern Automotive Paint Protection

So, what exactly is an automotive paint protection coating? The simplest way I explain it to people is to think of it as a transparent, high-tech suit of armor that chemically bonds right to your car's factory paint. This isn't your grandfather's carnauba wax that just sits on top for a few weeks; this is a semi-permanent shield that actually becomes one with the surface.

Think of it like a quality screen protector for your smartphone. You apply it once, and it fuses with the glass, creating a tough, sacrificial layer that takes the daily abuse of keys, drops, and scuffs. A modern coating does the exact same thing for your vehicle's far more expensive and delicate paintwork—it takes the hit so the original finish doesn't have to.

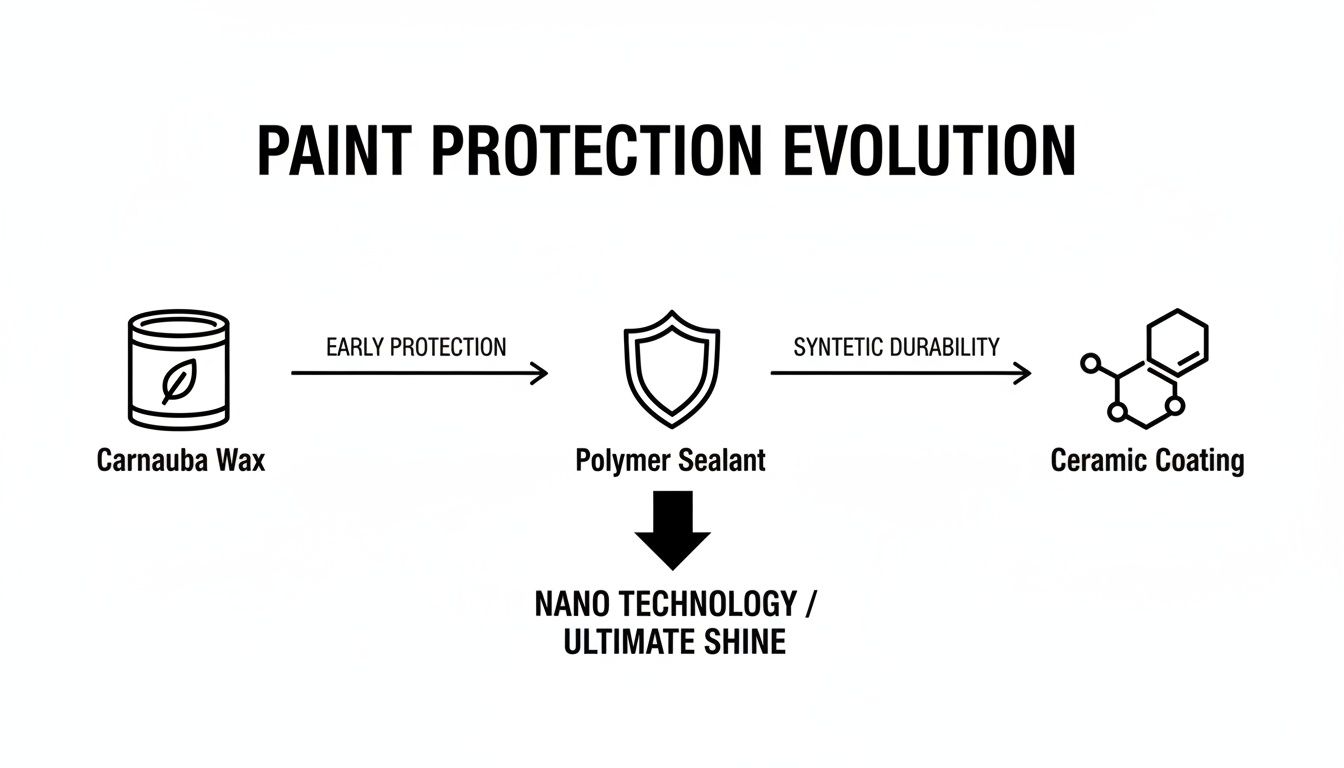

The whole concept has come a long way. For decades, carnauba waxes were the best you could get, offering a beautiful warm glow that, unfortunately, faded after a few washes. Polymer sealants came next, giving us better longevity but still lacking the serious defense needed against chemical attacks and physical wear. The real breakthrough was the arrival of ceramic (SiO₂) coatings, which brought a new level of hardness and resilience. But the evolution didn't stop there.

The Leap from Rigid to Resilient

One of the biggest headaches with many early-generation ceramic coatings was their sheer rigidity. They cured into a hard, glass-like shell. While that sounds great on paper, in the real world, it was also brittle. Picture a thin pane of glass: it's hard, but under stress from a rock chip or a sudden temperature swing—like pulling a car from a frigid garage into the hot sun—it's prone to developing microscopic cracks.

This is where the next major step in paint protection science had to happen. The real challenge became creating a coating that offered the hardness of glass but with enough flexibility to handle the abuse of daily driving. It’s one thing for a car to look great sitting in a pristine garage; it’s a whole different ball game for it to survive a bug striking the bumper at 70 mph or the constant expansion and contraction from freezing winters to scorching summers.

At Titan Coatings, we saw this critical flaw in the market and focused all our energy on pioneering the solution. By engineering and introducing the first-ever elastomer-based coatings to the automotive world, we fundamentally changed the core property of paint protection from rigid to resilient.

Introducing the Power of Flexibility

Our groundbreaking work in elastomer coatings, powered by advanced nano-tube structures and our proprietary Dark Matter Tech, completely solved the cracking problem. Instead of being hard and brittle, our coatings are hard and flexible. This built-in elasticity means the protective layer can absorb impacts and flex with temperature changes without failing.

This single property is a game-changer, dramatically extending the lifespan and real-world performance of the protection. Our Alpha Quartz elastomer coating, for example, doesn't just form a simple shield; it forms a flexible one. A stone chip that might shatter a purely rigid coating is instead absorbed and its energy dissipated by the elastic surface of Alpha Quartz.

This resilience is what ensures the protection remains intact and effective for years, not just a few months. To truly grasp the difference this technology makes, you can learn more about the specifics of ceramic coating technology in our detailed guide. It’s this crucial leap—from a simple hard layer to an intelligent, flexible barrier—that truly defines the pinnacle of automotive paint protection today.

The Titan Coatings Elastomer Revolution

For years, the paint protection world was stuck with a big trade-off. You could have a hard, durable shield, but that shield was also rigid and brittle. This has always been the Achilles' heel of traditional ceramic coatings. At Titan Coatings, we saw more than just a problem—we saw a chance to completely change the game.

Our story didn't start in a detailing shop. It began in a lab, with a singular mission: to create a coating that behaved as dynamically as the vehicles it was designed to protect. We saw detailers apply coatings that looked spectacular on day one, only to hear stories of them failing prematurely under real-world stress.

We understood that a car's surface is constantly moving. It expands under the summer sun, contracts in the freezing cold, and gets hammered by road debris. A rigid, glass-like coating just can't keep up. Over time, that stress leads to micro-fractures, which compromise the protective layer and let the bad stuff get to the paint. We knew we could build something better—something smarter.

This infographic really shows the evolution of paint protection, leading right up to the point where this fundamental shift was desperately needed.

This progression from temporary waxes to harder ceramics shows how the industry was always searching for more durability. That search led directly to our breakthrough.

The Birth of Elastic Coatings

As the first company to introduce Elastomer coatings to the market, our solution was born from revolutionary thinking. Using advanced nano-tube technology and our proprietary Dark Matter Tech, we didn't just make an incremental improvement; we created a whole new category of protection: the Elastic Coating.

Think about the difference between a thin pane of glass and a sheet of high-tech ballistic plexiglass. Both are hard and clear, but one shatters on impact. The other absorbs and dissipates the force. That’s the simple idea behind our elastomer technology.

Our coatings give you the hardness of a ceramic with a flexibility that was unheard of before. This combination means the protective layer can shrug off impacts from road debris and handle extreme temperature swings—from freezing cold to blistering heat—without cracking.

This directly solves the biggest failure point of older ceramic formulas, giving detailers and car owners a level of real-world durability that just wasn't possible before. It's a critical innovation in a market that just keeps growing, with projections showing the global automotive coatings industry is set to expand from USD 30.97 billion in 2026 to USD 38.82 billion by 2031, according to insights from The Business Research Company.

How Titan Elastomer Stacks Up

To see just how different our approach is, let's compare our elastomer technology side-by-side with the traditional ceramic coatings that have dominated the market until now. You can also see a full breakdown on our product comparison page.

Titan Elastomer Coatings vs Traditional Ceramic Coatings

| Feature | Traditional Ceramic Coating | Titan Elastomer Coating (e.g., Alpha Quartz) |

|---|---|---|

| Flexibility | Rigid and brittle; prone to micro-fracturing under stress. | Highly flexible and elastic; absorbs impacts and adapts to temperature changes. |

| Impact Resistance | Limited. Can chip or crack from small stone chips or debris. | Superior. Dissipates impact energy, preventing cracks and preserving the layer. |

| Self-Healing | None. Scratches and swirls are permanent until polished. | Offers some self-healing properties, especially with heat, reducing fine swirls. |

| Longevity | Lifespan is often reduced by environmental stress and micro-fractures. | Enhanced durability and longer lifespan due to its resilience against cracking. |

| Application | Can be unforgiving, with short flash times and potential for high spots. | Designed for a more user-friendly application with better workability for detailers. |

The table makes it clear: this isn't just a minor upgrade. It's a fundamental shift in how we think about protecting a vehicle's finish.

Alpha Quartz: The Resilient Shield in Action

The flagship of our elastomer technology is Alpha Quartz. This professional-grade coating is the ultimate proof of what happens when you focus on resilience instead of just rigidity. For a detailer, it's a dream to install. For a car owner, the performance is where it truly shines.

Imagine a bug hitting the front bumper at 70 mph. A brittle ceramic might develop a tiny micro-fracture at the point of impact, creating a weak spot. With Alpha Quartz, the elastic surface flexes, absorbs the energy, and bounces right back, leaving the shield completely intact. That elasticity is the secret to its long life, preventing it from cracking under temperature changes from frozen to hot.

This is the power of our elastomer revolution—an automotive paint protection coating that works with a vehicle's dynamics, not against them. By solving the brittleness problem, we’ve created a shield that lasts longer, protects better, and gives everyone true peace of mind. You can learn more about our elastomer technology and see how it’s changing the industry.

Choosing the Right Shield from Titan Coatings

Alright, so you understand the science behind our elastomer technology. Now comes the fun part: picking the right shield for your vehicle. I know the world of paint protection can feel a bit crowded, but we’ve designed our products to offer clear-cut solutions, whether you're a seasoned pro or a weekend car care fanatic.

The desire for real protection isn't just a niche obsession anymore. The global automotive coatings market was a USD 23.2 billion industry in 2023, and it's on track to hit USD 33.4 billion by 2030. That's a huge jump, and it tells us one thing: people see their cars as serious investments worth protecting. You can see the full breakdown in this detailed industry analysis from Grand View Research. It's this growing community of passionate owners that we develop our coatings for.

For the Enthusiast: Ultra Ceramic Spray

If you're a DIYer, you shouldn't need a professional setup to get professional results. That’s the entire idea behind our Ultra Ceramic Spray. We made this for the person who loves taking care of their car but doesn't want to dedicate a whole weekend to a complex coating application.

Ultra Ceramic Spray is unbelievably easy to use. Just spray it on and wipe it off. That’s it. But don't let the simplicity fool you—the results are stunning. You get that deep, dripping-wet gloss and serious water-beading action with great durability. It makes washing your car faster and helps it look cleaner, longer. It’s the perfect entry point into advanced protection without the headache.

For Ultimate Resilience: Alpha Quartz

When you're looking for the absolute best—the toughest, most flexible, long-term defense for your paint—Alpha Quartz is the only choice. This is our flagship elastomer coating, the embodiment of everything we've talked about. It's the "set it and forget it" shield for owners who want to know their vehicle is armed against whatever the road throws at it.

Alpha Quartz uses our signature elastomer tech to be hard as glass but flexible enough to handle the real world. It won't crack under drastic temperature swings, and it can absorb the impact from rock chips or bug splatters that would shatter a traditional ceramic. This unique formula creates a durable barrier that lasts for years, not just a few months. For a closer look at how this compares to other options, we break it down in our guide on Paint Protection Film vs. Ceramic Coating.

I always think of a client we have in Phoenix, Arizona. He had a traditional hard ceramic on his black muscle car. After just one brutal summer, he found tiny stress cracks all over the hood from the intense heat cycles. He switched to Alpha Quartz, and the problem completely disappeared. The coating’s flexibility allowed it to expand and contract with the metal, even in one of the most punishing climates in the country.

For Safer Driving: Apex Glass Coating

Finally, let’s talk about an area that's too often ignored: your glass. Clear visibility is everything, and anyone who’s had a white-knuckle drive through a downpour knows it. We engineered our Apex Glass Ceramic Coating to take that stress away for good.

This specialized coating creates an intensely hydrophobic, slick surface on your windshield. Rain doesn't stand a chance; it beads up and zips right off the glass as you drive, to the point where you barely need your wipers. The difference in visibility and confidence during a storm is night and day, making driving under rain stress-free. It’s a simple application, but the payoff in safety and peace of mind is huge.

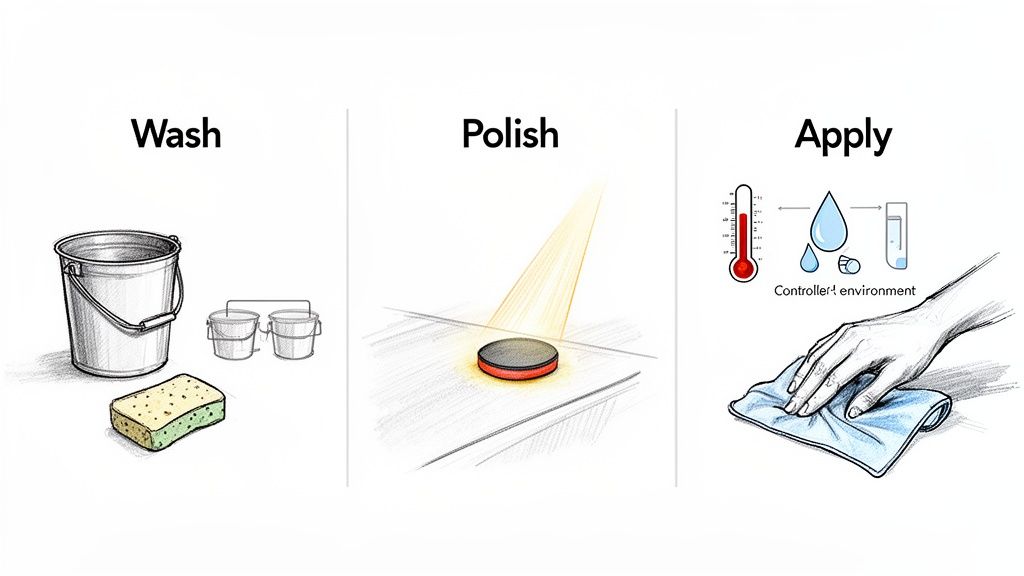

Application Best Practices for Flawless Results

Let's be honest: a world-class coating is only as good as the hands that apply it. Achieving that unbelievable, liquid-gloss finish isn't just about the product in the bottle. It's about the disciplined, meticulous process you follow before that bottle is even opened. Think of it this way: you wouldn't commission a masterpiece and then hand the artist a dirty, pre-used canvas. The exact same principle applies to your vehicle's paint.

This preparation stage is completely non-negotiable. Seriously. Every single swirl mark, speck of iron fallout, or bit of road tar left on the surface gets permanently entombed under the coating. It's the one thing that separates a truly stunning, head-turning result from a job that just looks "okay."

The Art of Surface Preparation

Before a drop of coating touches the paint, you have to create the perfect foundation. This isn't just about cleaning; it's about creating an atomically smooth, bare surface that allows the coating to form the strongest possible chemical bond with the clear coat. That bond is everything—it dictates both how good the car looks and how long the protection will actually last.

Here are the mission-critical steps you simply can't afford to skip:

- Thorough Decontamination Wash: This goes way beyond a Saturday morning bucket wash. We're talking a multi-stage process using iron removers to dissolve brake dust and tar solvents to break down road grime. You need to pull all those embedded nasties out of the paint's pores.

- Clay Bar Treatment: Even after a deep clean, the paint might feel gritty. A clay bar is your best friend here, safely lifting away bonded contaminants and leaving the surface feeling as smooth as glass.

- Paint Correction: This is the make-or-break step for that flawless look. Using a machine polisher, you must meticulously remove imperfections like swirl marks, minor scratches, and oxidation. This is what creates that pristine, mirror-like canvas the coating deserves.

Mastering the Application Environment

Once the surface is perfect, your surroundings become the next critical variable. Applying a professional-grade coating requires a controlled setting. Trust me, fighting with wind, dust, and unpredictable weather outdoors is a recipe for disaster.

Your ideal workspace should have a stable temperature and humidity. I always aim for a temperature between 60-80°F (15-27°C) and keep humidity below 70%. A clean, well-lit garage is your best bet for controlling these factors and stopping dust from landing on the tacky coating.

Good lighting is just as important as any tool in your kit. You need bright, diffused light from multiple angles to spot "high spots"—those sneaky areas where excess coating hasn't been fully wiped away. If you miss them, you'll be left with dark, streaky blotches that are a nightmare to fix once the coating starts to cure.

Getting this process right is the secret to a professional-grade finish every time. If you want a more detailed walkthrough, our complete guide on how to apply a ceramic coating breaks down every single technique. It’s packed with the kind of hands-on advice that will give you the confidence to get stunning, durable results.

Keeping Your Investment Protected: Long-Term Care

Putting a high-quality paint protection coating on a vehicle is a huge first step, but the work isn't over. Think of it this way: just because you’ve installed the best armor doesn't mean you stop cleaning it. Proper, consistent maintenance is what truly determines the lifespan and performance of your investment.

Let's get one thing straight: a coated car isn't invincible. But the great news is, maintaining one is far easier than caring for an unprotected finish. A smart, simple routine is all it takes to keep your Titan coating delivering that unbelievable gloss and wild water-beading for years to come. Skipping this part is like buying a race engine and never bothering with an oil change—it just doesn't make sense.

Simple Rules for a Lasting Finish

The goal is simple: clean the surface gently. You want to avoid aggressive chemicals or abrasive tools that could compromise the coating. The absolute worst offenders are those automated car washes with their brutal brushes and recycled, gritty water—they are the sworn enemy of a perfect finish and must be avoided at all costs.

A hands-on, gentle approach is the only way to go. Here are the fundamentals of a rock-solid maintenance plan:

- The Two-Bucket Method is Non-Negotiable: Have one bucket for your soapy water and a second one with clean water just for rinsing your wash mitt. This is the single best way to stop yourself from dragging dirt and grit right back onto the paint, which is exactly how swirl marks are born.

- Pick the Right Soap: Always, always use a high-quality, pH-neutral car shampoo. Those cheap, high-alkaline soaps—the kind often used in touchless washes—can actually start to break down the hydrophobic top layer of your coating, killing its performance over time.

- Boost with a Maintenance Spray: This is your secret weapon. Using a product like our Ultra Ceramic Spray every few months as a topper completely rejuvenates the coating. It brings back that slick, water-repelling magic and adds an outrageous layer of gloss.

A well-maintained coating doesn't just look better; it performs better. We see it all the time—regular, gentle washing is the difference between a coating that starts to fade after two years and one that’s still going strong at year five and beyond.

The demand for these kinds of advanced care products is exploding, especially with the rise of electric vehicles and their unique paint systems. EVs are a massive force in the automotive coatings market, which is seeing incredible growth. The market for ceramic coating kits alone was valued at USD 720.0 million in 2026 and is projected to hit USD 1,583.5 million by 2036. You can dig into more of the data behind this trend over at Persistence Market Research.

Sticking to these simple steps ensures you get every ounce of value and protection from your Titan coating. It’s the final piece of the puzzle, locking in that showroom shine and guaranteeing you feel that pride every time you look at your car.

Your Questions, Answered

Let's be honest, the world of paint protection can feel a little overwhelming. With so many terms and technologies flying around, it's easy to get lost. That's why we've put together answers to some of the most common questions we hear, giving you the straight facts you need to make the right choice for your vehicle.

What Makes Titan's Elastomer Coatings So Different?

In a word? Flexibility.

Think of it this way: traditional ceramic coatings are like a sheet of glass. They're incredibly hard, but they're also brittle. When your car's panels expand and contract with the heat of the sun or get hit by road debris, that rigid layer can develop tiny micro-cracks.

Titan's elastomer coatings, like our flagship Alpha Quartz, are a whole different beast. Thanks to advanced nano-tube technology, they're engineered to be both tough and pliable. This means they can absorb impacts and flex with temperature changes without breaking a sweat—or cracking. The end result is a much more durable, resilient shield that keeps your paint safer for longer.

Can I Apply Titan Ultra Ceramic Spray Myself?

You absolutely can. We developed Ultra Ceramic Spray with both pro detailers and weekend warriors in mind.

Its simple spray-on, wipe-off application means you can get that signature deep gloss and amazing water-beading without needing years of experience or complex tools. Just make sure you start with a squeaky-clean, decontaminated surface, and you'll be good to go.

Is a Dedicated Glass Coating Really Worth It?

One hundred percent—it's a massive upgrade for both safety and pure convenience. A purpose-built glass coating like our Apex Glass Ceramic Coating creates such an intensely slick surface that rain simply can't stick to it.

Once you're moving, water beads up and zips right off the windshield, drastically improving your visibility during a downpour. In many cases, you won't even need your wipers. It completely changes the game for driving in bad weather, making it stress-free.

"The first time I drove in a downpour after applying Apex, it was a total game-changer. The rain just vanished from the windshield. My visibility was clearer than I ever thought possible, and I felt so much safer behind the wheel."

How Long Does an Automotive Paint Protection Coating Last?

That’s the million-dollar question, and the answer really depends on the product, your local climate, and your maintenance routine. A basic spray sealant might get you a few months of protection, while a professionally installed elastomer coating can last for years.

This is where the flexible nature of Titan's Alpha Quartz really shines. It’s engineered to fight off the wear-and-tear that causes rigid coatings to break down over time. Stick to a solid wash routine with pH-neutral soaps, and you’ll get the maximum lifespan and performance out of your investment.

Ready to arm your vehicle with the most advanced, resilient protection on the market? The Titan Coatings lineup offers a solution for every need, from easy-to-use sprays to professional-grade elastomer shields. Explore our full range of products and find the perfect armor for your ride.

0 Comments