Imagine your boat is owned by a seasoned sailor named Captain Eva. For years, she was locked in a frustrating battle with the sea. She’d spend entire weekends waxing and polishing her pride and joy, bringing back that deep, brilliant shine. It looked fantastic… for a little while. But then the elements would get to work. The relentless sun, the corrosive saltwater spray—they’d relentlessly chip away at her hard work, leaving the showroom gloss faded into a dull, chalky haze. Captain Eva was stuck in a baffling cycle of apply, fade, repeat.

This wasn’t just about looks. She knew her boat’s finish was its primary line of defense. A boat clear coating is the ultimate suit of armor for a vessel, a transparent, incredibly tough layer that goes over existing paint or gelcoat. More than just a wax, this is a permanent barrier against the sun’s damaging UV rays, corrosive saltwater, and everyday abrasion. When that protective layer breaks down, the underlying gelcoat and fiberglass become exposed, leaving them vulnerable to serious degradation that hurts a boat’s value and structural health.

Why Your Boat’s Finish Is Under Constant Attack

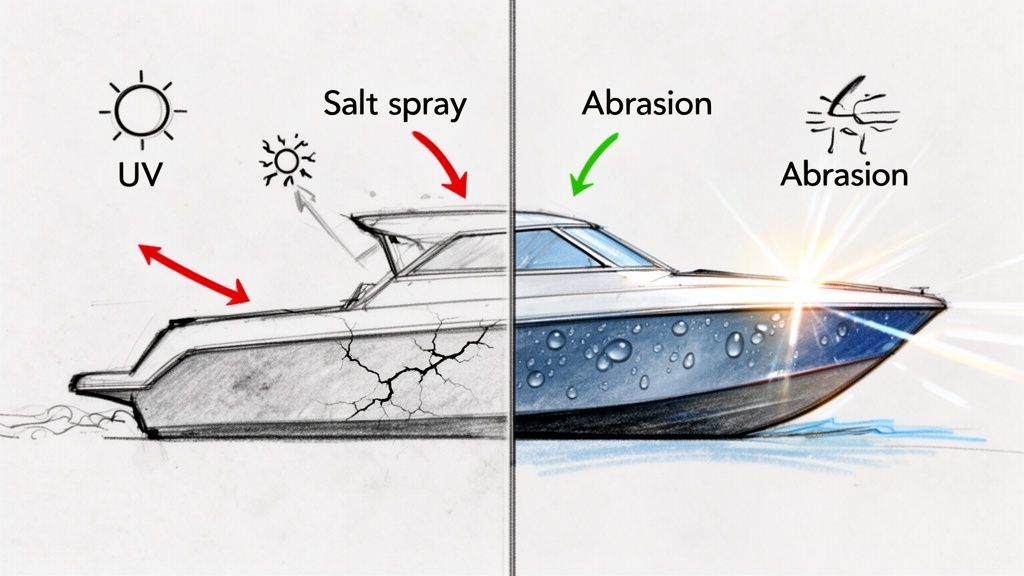

Captain Eva’s struggle is a story every boat owner knows well. The marine environment is brutally tough on surfaces. Traditional waxes and sealants just can’t keep up, offering only a temporary shine before failing. They leave your boat exposed to a handful of major threats.

The Invisible Enemies of Your Boat

- UV Radiation: The sun is public enemy number one for your boat’s finish. It relentlessly breaks down the pigments in paint and gelcoat, causing that faded, oxidized look we all hate.

- Saltwater and Corrosion: Salt crystals don’t just leave ugly spots; they magnify the sun’s UV rays and leave behind corrosive deposits that literally etch into the surface.

- Abrasion and Scuffs: From a slight bump against the dock to dragging a fishing cooler across the deck, small scratches and scuffs create weak points for moisture and contaminants to get in.

- Chemical Contaminants: Acid rain, bird droppings, and the occasional fuel spill can cause permanent stains and damage if your finish isn’t properly shielded.

The truth is, a clear coating isn’t merely an aesthetic choice—it’s a critical investment in your vessel’s longevity. It makes potential issues like moisture penetration more visible, allowing you to address problems before they escalate into serious damage.

This constant assault proves why old-school maintenance products just don’t cut it anymore. They lack the chemical backbone to stand up to the fight. The real solution is a boat clear coating—a modern technology designed to create a lasting, impenetrable shield. Just like your car needs dedicated protection, your boat requires a defense built for the water. Learning about the best UV protection for car paint can give you a good sense of how these protective principles work, setting the stage for a finish that doesn’t just shine, but truly endures.

Getting to Know Modern Marine Coating Tech

To really get why today’s boat clear coats are such a big deal, you have to look at the science behind them. Let’s pull back the curtain and see what separates these advanced formulas from the old-school products that have been used for decades. A few simple analogies will help make sense of the complex chemistry at play.

Think of a traditional polyurethane coating like a high-quality raincoat. It does a pretty good job of keeping water out and gives you a decent layer of protection. But it’s not invincible. It eventually wears down, leaving the surface exposed.

Then there’s clear gelcoat, which is basically the boat’s original, thick skin. When it’s new, it’s tough and glossy. But over time, the sun’s UV rays make it porous. This is what lets moisture and gunk seep in, causing that chalky, oxidized look we all know too well.

The Microscopic Revolution in Boat Protection

The real leap forward in marine protection is happening at the microscopic—or “nano”—level. This is where modern ceramic and elastomeric coatings completely change the game. They don’t just sit on top of the surface like a wax or a simple sealant. Instead, they create a true chemical bond with the gelcoat or paint underneath.

This bond creates a surface that’s incredibly dense and slick. If you looked at a traditional finish under a microscope, you’d see a rough landscape full of peaks and valleys. A nano-coating, on the other hand, creates a smooth, flat plain. This super-smooth structure makes it incredibly tough for water, dirt, and marine growth to latch on.

But hardness is only part of the equation. The biggest innovation is the introduction of the elastomer.

Imagine a material as hard as glass but as flexible as rubber. That’s the secret behind elastomeric coatings, a technology Titan Coatings pioneered. This unique combo solves a major problem that has frustrated boat owners and detailers for years.

Elasticity: The Key to Unbelievable Durability

Your boat’s surface is always on the move. It expands when the sun beats down and contracts when the temperature drops at night. This constant thermal cycling puts a massive amount of stress on any coating.

Older, rigid coatings just can’t keep up with this movement. Over time, they develop tiny, microscopic cracks from the strain. You can’t see them at first, but these fractures are an open invitation for water and contaminants to get under the coating, causing it to fail from the inside out.

This is exactly where Titan’s advanced elastomeric technology shines.

- Hardness: It gives you that diamond-hard protection you need to fend off scratches, scuffs, and chemical attacks.

- Flexibility: It can stretch and move right along with your boat’s surface, which stops those micro-cracks from ever forming during extreme temperature swings, from freezing cold to blistering heat.

This flexibility is the reason these coatings last so much longer. They don’t just fight the environment; they adapt to it. This blend of hardness and elasticity is the core of how a true marine ceramic coating should perform. By preventing the kind of structural failure that plagues brittle coatings, this technology keeps your boat’s finish looking perfect for years, not just a single season.

What Really Matters in a Boat Clear Coat

A mirror-like shine is what catches the eye, but that’s just the beginning of what a high-performance boat clear coating does. The real work happens below the surface, where the coating fights a constant, invisible battle against the harsh marine world. To truly appreciate what separates a good coating from a great one, you have to look past the gloss and understand the critical performance factors that give it strength and staying power.

Think of these factors as a highly trained crew, each with a specific role. If one member of the crew fails, the entire vessel is at risk. The very best coatings ensure every single one is performing at its peak, working in perfect harmony to protect your investment.

The Power of True UV Resistance

Day in and day out, the sun is the single most destructive force your boat’s finish will ever encounter. Its relentless UV radiation relentlessly attacks the molecular bonds in your gelcoat and paint, causing that chalky, faded look we all know as oxidation. A top-tier boat clear coating is like applying a permanent, high-SPF sunscreen.

But it’s more complex than just reflecting light. The most advanced coatings are engineered with specialized UV inhibitors that absorb and safely dissipate this harmful energy before it ever has a chance to damage the sensitive layers underneath. This is the secret to preserving that deep, rich color and preventing the gelcoat from becoming brittle and porous over the years.

Guarding Against Scratches and Abrasion

Let’s face it, boats live a rough life. From a fender rubbing against the dock to fishing gear being dragged across the deck, the risk of scratches is constant. Abrasion resistance is simply a measure of a coating’s toughness—its ability to handle this physical wear and tear without giving up.

This is where the unique chemistry of an elastomeric coating really shines. Traditional, rigid coatings might be hard, but that hardness often comes with brittleness, making them prone to chipping and scratching.

A truly advanced boat clear coating is different. It marries glass-like hardness with engineered flexibility. This allows it to absorb impacts and fend off scratches far more effectively, keeping the surface smooth and looking new for much longer.

That resilience is non-negotiable. Every tiny scratch in a lesser coating becomes a gateway for water and contaminants, which can quickly lead to blistering and total coating failure.

Chemical Resistance for Real-World Protection

The marine environment is a chemical cocktail, and many of those chemicals want to permanently stain or damage your boat’s finish. A superior coating has to create an impermeable shield against these everyday threats:

- Fuel and Oil Spills: We’ve all seen it. A little drip at the fuel dock can eat right through traditional waxes and weaker sealants in no time.

- Bird Droppings: The highly acidic nature of bird droppings can permanently etch an unprotected gelcoat in just a few hours.

- Harsh Cleaners: Using the wrong cleaning products can strip away protection, but a chemically resistant coating stands its ground.

- Salt and Acid Rain: These environmental aggressors are always working to corrode and dull your finish.

The ability to shrug off these attacks is what truly separates a professional-grade coating from a simple wax. To see how this technology creates such a robust barrier, you can explore the science behind our ceramic clear coating and its protective capabilities.

This level of protection isn’t just a luxury; it’s a cornerstone of the modern marine industry. Consider this: the global market for hull coatings, which depend on clear top layers for UV and scratch resistance, recently hit USD 8.6 billion and is projected to soar to USD 12.9 billion by 2033. This incredible growth is driven by the need to protect massive assets in a maritime trade industry valued at over $14 trillion annually. The data is clear—a properly coated hull can extend a vessel’s life by 15-20 years by drastically cutting down corrosion rates in seawater. You can see more about the trends in the hull coatings market to understand just how vital this technology has become.

The Titan Coatings Elastomeric Advantage

Captain Eva’s story probably sounds familiar. She was stuck in a cycle of endless waxing, polishing, and sealing, only to watch that brilliant gloss fade away after just a few weeks on the water. She was sick of products that over-promised and under-delivered. She didn’t just need a better wax; she needed a completely different kind of protection.

That’s when she found the real answer to her frustrations: the groundbreaking science from Titan Coatings, the first company to introduce Elastomers coatings to the market using nano tubes technology and Dark Matter tech.

For too long, the marine industry has settled for a trade-off. You could have a hard, glassy coating that was brittle and prone to cracking, or you could have a softer, more flexible one that offered next to no scratch resistance. Titan shattered that compromise. This isn’t just an improvement—it’s the new standard.

Hardness Meets Unbelievable Flexibility

Picture a material with the tough, defensive hardness of glass but the incredible flexibility of rubber. That’s the secret behind Titan’s elastic coatings advantage. Our unique combination of properties solves the single biggest failure point of traditional coatings: thermal shock.

Your boat’s surface is in constant motion, expanding in the hot afternoon sun and contracting on cold nights. A rigid coating simply can’t handle that stress. Tiny micro-cracks form, creating a pathway for moisture and contaminants to get underneath, causing the coating to fail from the inside out.

Titan’s elastic technology makes that entire problem obsolete.

The coating flexes and moves right along with your boat’s surface. Because it never gets rigid or brittle, it stops those cracks from ever forming. The protective shield stays completely intact, no matter the climate—from frozen temperatures to hot ones, the coating won’t crack down due to flexibility. This makes them last much longer.

This superior resilience is exactly why Titan coatings deliver that deep, lasting gloss that holds up season after season. To really get a handle on this game-changing tech, you should explore the science behind Titan Coatings’ advanced elastomer technology and see for yourself how it’s redefining marine durability.

Introducing Titan’s N1: The Ultimate Marine Shield

To bring this powerful technology to the water, Titan engineered its N1 formula. This is no rebranded car product. It’s built from the ground up with military-grade polymers designed to withstand the harshest marine environments imaginable. It sets a new benchmark for what a boat clear coating ought to be.

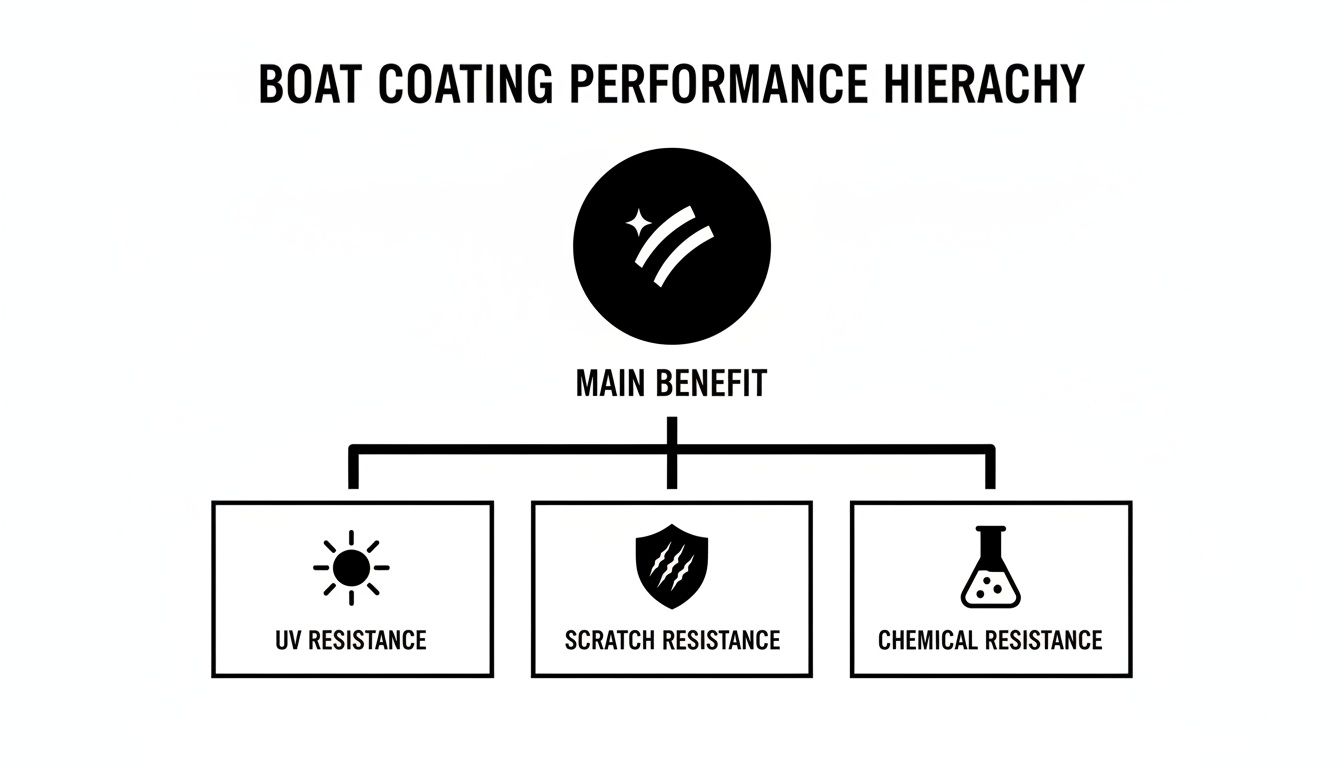

The diagram below breaks down the core performance pillars that any top-tier marine coating must have—all of which are mastered by our N1 coating.

As you can see, true, lasting gloss retention isn’t a standalone feature. It’s the end result of having a strong foundation of powerful UV blockers, superior scratch defense, and robust chemical resistance.

To give you a clearer picture of how our technology stacks up, you can check out our detailed product comparison page. Let’s break down the key performance differences.

Titan Elastomeric Coatings vs Traditional Options

This table illustrates the key performance differences between Titan’s advanced elastomeric coatings like N1 and conventional marine clear coats.

| Feature | Titan N1 with Elastomeric Technology | Traditional Ceramic Coatings | Polyurethane or Gelcoat |

|---|---|---|---|

| Flexibility | High; elastomeric properties prevent cracking from thermal shock. | Low; rigid and brittle, prone to micro-cracking. | Moderate, but can become brittle over time. |

| Scratch Resistance | 9H+ hardness with self-healing properties for minor swirls. | 9H hardness but lacks self-healing. | Low; easily scratched and swirled. |

| UV Resistance | Exceptional; advanced UV inhibitors prevent yellowing and fading. | Good, but can degrade without toppers. | Fair to Poor; prone to chalking and oxidation. |

| Chemical Resistance | High; military-grade polymers resist salts, fuels, and acids. | Good; resists most common chemicals. | Low; susceptible to staining from chemicals. |

| Longevity | 3+ years with proper maintenance. | 1-2 years before reapplication is needed. | 6-12 months before waxing is required. |

| Gloss Retention | Excellent; deep, “wet look” gloss that lasts for years. | Very good initially, but can dull as it degrades. | Good when new, but fades quickly. |

It’s pretty clear that elastomeric technology offers a comprehensive level of protection that older coating chemistries just can’t match.

This kind of advanced protection is becoming more critical than ever. The global marine coatings market was recently valued at USD 5.7 billion and is projected to hit USD 9.8 billion within a decade. With over 90% of all world goods moving by sea, these durable coatings are essential for preventing billions in annual damage to hulls and superstructures.

For Captain Eva, discovering N1 was the end of her maintenance cycle and the beginning of true, worry-free time on the water.

4. Getting That Flawless Finish: Application Is Everything

Let’s be clear: even the most advanced boat coating on the market is only as good as the person applying it. Getting that dripping-wet, deep gloss finish is a meticulous process, and the truth is, preparation is 90% of the job.

Think of it like painting a classic car. You wouldn’t just slap a new coat of paint over rust and dirt, would you? Of course not. The same exact principle applies to your boat’s hull. The journey to a perfect finish begins long before you even crack open the bottle of coating.

Laying the Groundwork for a Perfect Application

To get a true, lasting chemical bond, you have to start with a surgically clean and perfectly smooth surface. Any leftover contaminants, chalky oxidation, or ugly swirl marks will be trapped and magnified under the clear coat. This not only looks terrible but also cripples the coating’s ability to protect the surface.

Getting it right comes down to three non-negotiable stages:

- Deep Decontamination: First, you have to get the surface squeaky clean. This means stripping away everything—salt, grime, old wax, grease, you name it. A truly clean surface is the absolute starting point.

- Correction with Compounding: If your gelcoat is looking tired, with moderate oxidation or scratches, you’ll need to compound it. This is an abrasive step that carefully cuts away the damaged top layer, revealing the fresh, healthy gelcoat underneath.

- Polishing to Perfection: This is the final refinement step. Polishing smooths out the surface, removing any fine swirls left from compounding and creating a mirror-like finish. This is what gives the final job its depth and clarity.

The biggest mistake we see is people rushing the prep work. Plan on investing 80% of your time in these prep stages. Nailing this ensures the final 20%—the actual coating application—goes on smooth and delivers that jaw-dropping, long-lasting shine.

The Final Steps: Application and Curing

Once the surface is prepped to perfection, it’s time to apply the coating. This part demands precision. You’ll want to work in small, manageable sections, applying the product evenly with a proper applicator pad. Good lighting is your best friend here, as it helps you spot and level any high spots before they dry.

After the coating is on, the real magic begins: curing. This is the chemical reaction where the coating hardens and cross-links with the gelcoat, forming that tough, flexible, protective shield. Temperature and humidity are huge factors here, so always follow the manufacturer’s guidelines. This is the phase that locks in the coating’s durability and unbelievable water-beading properties.

For a more detailed, step-by-step walkthrough of the entire process from start to finish, this guide on clear coating a boat for a professional finish is an excellent resource. Following these best practices is the only way to ensure your boat gets the protection and shine it truly deserves.

Long-Term Care for Your Coated Boat

Getting a high-quality clear coat on your boat is a huge win against the elements, but the job isn’t quite finished. If you want that deep, wet-look shine to last for years, you need a smart but simple maintenance plan. Trust me, protecting your investment now is a whole lot easier than starting over from scratch later.

The golden rule is to be gentle. Harsh, high-alkaline detergents and aggressive wash chemicals are the sworn enemies of any coating. They’ll strip away that slick, water-beading top layer and start to eat away at the protective polymers underneath.

Instead, get into the habit of regular washes using a quality, pH-neutral boat soap. This stuff is designed to lift away salt and grime without harming the coating. Always use a soft wash mitt and the classic two-bucket method to avoid grinding dirt back into the finish and creating new swirls.

Periodic Maintenance and Troubleshooting

Even the toughest coatings appreciate a little TLC. A simple upkeep routine will keep the water-beading action intense and extend the life and performance of your coating.

- Boost with a Topper: Every few months, apply a sacrificial topper spray. Products like Titan Coatings’ Hyper-Shield are perfect for this. They act like a tune-up for your coating, rejuvenating its hydrophobic properties and slickness, essentially reinforcing the primary shield.

- Erase Water Spots: If you start seeing mineral deposits (water spots), deal with them quickly. Use a dedicated water spot remover that’s safe for coatings. It will gently dissolve the minerals before they have a chance to etch into the surface for good.

- Fix Minor Scuffs: For light scuffs, you can often buff them out by hand with a light polish. Maintaining your boat’s finish is a crucial skill, and for gelcoat owners, learning about effective boat gelcoat repair tips can be a real game-changer.

Knowing When to Go Deeper

Over time, your boat will pick up contaminants that a simple wash just can’t handle. If you notice water isn’t sheeting off like it used to, don’t panic—it doesn’t mean the coating has failed. More often than not, it just means the surface is clogged with microscopic gunk.

This is your cue for a decontamination wash. Using an iron remover and a gentle clay bar treatment can pull these bonded contaminants off the surface. You’ll be amazed as it instantly restores the coating’s slick, hydrophobic behavior without damaging the protective layer itself.

This proactive approach to care is a core principle in the marine industry. In fact, anti-corrosion clear coatings for boats make up about 40% of the entire marine coatings market—a sector recently valued at USD 6.28 billion and still growing.

By preventing problems like fouling (which can cost the shipping industry billions in extra fuel), these coatings prove their immense value. A simple maintenance routine ensures your vessel enjoys these same protective benefits for the long haul.

Your Top Questions About Boat Coatings Answered

Stepping into the world of high-tech marine coatings can feel a little overwhelming. Let’s clear the waters and tackle some of the most common questions we hear from boat owners.

How Long Does a Professional Boat Clear Coating Last?

This is the big one, and the honest answer is: it depends. The lifespan of any boat clear coating really boils down to three things: the quality of the coating itself, how well it was applied, and how you care for it afterward. A traditional wax might look good for a few months, but it’s a temporary fix that traps you in a constant cycle of reapplication.

But that’s not the game we’re in. Advanced elastomeric coatings are built for the long haul. A professionally installed Titan system is engineered to last for years, giving you a tough, high-gloss shield that completely outclasses the short-lived protection from old-school sealants.

Can a Clear Coating Be Applied Over an Old Gelcoat?

Absolutely, provided the old gelcoat is in decent shape and properly prepped. You can’t just slap a high-tech coating over a chalky, oxidized surface and hope for the best. A great coating will preserve a healthy gelcoat, but it’s not a miracle cure for deep cracks or delamination.

Getting it right is all about the prep work. It’s a multi-step process that can’t be rushed:

- Deep Cleaning: First, a thorough wash to get rid of all the surface grime.

- Decontamination: Next, we use specific products to chemically remove anything that’s bonded to the surface, like stubborn salt deposits.

- Paint Correction: This is where the magic happens. We compound and polish the gelcoat to strip away oxidation and bring back that deep, rich color and shine.

Once that gelcoat looks brand new, we can apply the boat clear coating to lock in that perfect finish and protect it for years.

Is an Advanced Boat Coating Worth the Investment?

Without a doubt. While the initial cost is more than a bottle of wax from the marine store, the return on that investment is massive. You’re buying back your time and giving your boat a level of protection that wax can’t even touch.

Just think about it: no more weekends spent waxing and buffing. More importantly, you’re putting a powerful barrier between your vessel and the sun’s damaging UV rays—the number one cause of gelcoat failure and depreciation. A coated boat doesn’t just turn heads at the dock; it holds its value far better when it comes time to sell.

Ready to give your boat the tough, long-lasting protection it deserves? The Titan Coatings Marine Multi-Purpose Coating uses our groundbreaking elastomeric technology for a finish that’s both diamond-hard and incredibly flexible. See what the future of marine care looks like today.

0 Comments