If you’ve spent any time looking into paint protection, you’ve probably seen the term “ceramic 9H coating” thrown around. It’s marketed as the ultimate shield for your car’s paint. But what does that “9H” actually mean?

Imagine this: a car enthusiast named Mark, obsessed with keeping his new ride looking perfect, dives headfirst into the world of paint protection. He hears “9H” and pictures an impenetrable force field. This is a common starting point for many. A ceramic 9H coating is a professional-grade liquid polymer that creates a chemical bond with your vehicle’s factory paint. Once cured, it forms a tough, long-lasting protective layer. The “9H” rating is a benchmark, indicating the coating’s hardness on the pencil scale. This means it’s built to resist the kind of minor scratches, swirl marks, and chemical stains that ruin a car’s finish over time. But as Mark would soon discover, there’s more to the story than just a number.

What Does 9H Hardness Really Mean?

Let’s clear the air on this one right away. When people hear “9H ceramic coating,” they often picture an invisible, diamond-hard force field. It’s easy to think your car will suddenly be bulletproof, which is why some owners are disappointed when a rogue shopping cart still leaves a deep gash.

The truth is, “9H” doesn’t mean the coating is as hard as a diamond. That’s a huge misconception, and it all comes down to a mix-up between two completely different hardness scales.

The 9H rating comes from a test using pencils, not the Mohs scale that geologists use to measure the hardness of minerals like talc, quartz, and, yes, diamonds.

The Pencil Hardness Test Explained

This test is a straightforward industry standard for measuring the scratch resistance of a coating. It uses a set of graphite pencils with hardness ratings from a soft 6B all the way up to a very hard 9H. A technician presses the pencil against the coated surface at a precise angle and pressure to see if it leaves a scratch.

So, a “9H” rating simply means the coating is tough enough to resist being scratched by the hardest pencil in the set. What does that mean for your car on a daily basis? It means it’s incredibly effective at warding off the everyday annoyances that dull your paint:

- Swirl Marks: Those fine, web-like scratches caused by improper washing and drying.

- Light Scratches: Minor scuffs from fingernails, zippers on a jacket, or branches brushing against the side.

- Chemical Etching: Nasty damage from bird droppings, bug guts, and acid rain that eats into your clear coat.

The automotive world has taken notice. In fact, the car care segment is expected to make up 32% of the high-performance ceramic coatings market by 2035. Why? Because properties like 9H hardness can slash reapplication costs by up to 70% compared to old-school waxes.

Pencil Hardness vs Mohs Scale: A Reality Check

To really drive the point home, it’s helpful to see just how different these two scales are. One measures a coating’s ability to resist a pencil scratch; the other measures a mineral’s ability to scratch another mineral.

| Scale Type | Measures | 9H on This Scale | Real-World Example |

|---|---|---|---|

| Pencil Hardness Test | A coating’s resistance to being scratched by graphite pencils. | The hardest rating. Resists damage from the 9H pencil. | Prevents swirl marks from a dirty wash mitt. |

| Mohs Scale | A mineral’s relative hardness and resistance to being scratched by other minerals. | Roughly a 6-7. Equivalent to quartz. | A diamond (Mohs 10) will easily scratch a 9H coated surface. |

This table shows why expecting a 9H coating to stop a rock chip or a deep key scratch just isn’t realistic. The forces and materials involved are on a completely different level.

Setting Realistic Expectations

So, while a 9H ceramic coating provides incredibly tough protection, it’s not invincible. It won’t stop deep, intentional scratches from a key, major rock chips flying at you on the highway, or dents from a parking lot fender bender.

Think of it as premium, sacrificial body armor for your paint. It takes all the daily abuse so your car’s clear coat doesn’t have to.

Key Takeaway: A 9H ceramic coating is a superior, long-term defense against the common environmental and chemical threats that degrade your car’s finish. It’s a massive upgrade from traditional waxes and sealants, keeping that deep, glossy look for years, not just a few months.

Understanding this is the first step. It shifts the conversation from “invincibility” to “elite-level resilience,” which is what these coatings are all about. You can get a deeper dive into the core benefits by checking out our guide on what ceramic coatings are.

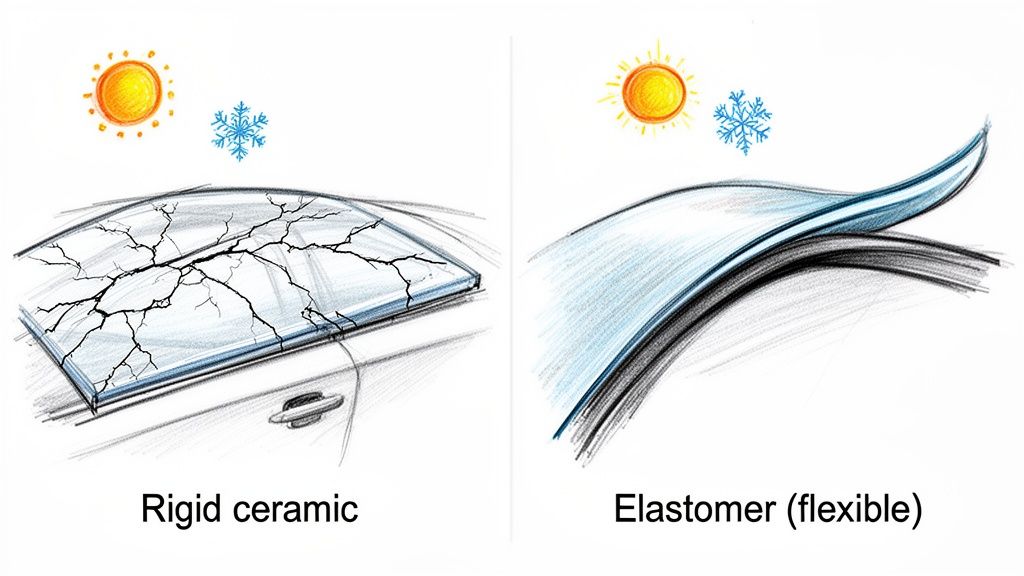

But as many have learned the hard way, hardness is just one part of the equation. True, lasting protection needs more than just scratch resistance—it needs flexibility, something that traditional, overly brittle ceramics often get wrong.

Why Flexibility Is the True Key to Durability

So, we’ve pulled back the curtain on the 9H hardness rating, and it’s clear that sheer hardness is only half the story. If you want protection that actually lasts, you need more than just a tough-as-nails surface. You need resilience. This is where you start to see the cracks—literally—in traditional, rigid ceramic coatings, and it’s where Titan Coatings’ technology completely changes the game.

Think of a standard ceramic coating like a super-thin sheet of glass. Sure, it’s hard, but it’s also incredibly brittle. Your car’s body panels are always moving, expanding just a little in the summer heat and shrinking back down in a winter freeze. Over time, that constant, subtle movement puts a rigid coating under stress, eventually causing microscopic cracks. These tiny fractures are a big problem; they break the seal and let moisture, chemicals, and dirt get to the paint underneath.

The Glass vs. Polycarbonate Analogy

Let’s make this simple. Imagine you need to protect a surface and you have two options: a stiff pane of glass or a flexible sheet of polycarbonate.

- The Glass Pane (Traditional Ceramic): It starts out very hard and scratch-resistant. But the moment you apply too much pressure or it goes through a sudden temperature shock, it has zero give. It just shatters.

- The Polycarbonate Sheet (Titan Elastomer): This material is also tough, but it has a game-changing ability to bend and absorb impacts. Under stress, it flexes and then bounces right back to its original shape, keeping its protective integrity.

Titan’s elastomer-based coatings act just like that polycarbonate sheet. They deliver an incredible blend of glass-like hardness and rubber-like flexibility—a quality that puts them in a league of their own.

How Elastomer Technology Prevents Coating Failure

Titan was the first to bring Elastomer coatings to the market, and it was a massive leap forward for paint protection. By using advanced nano tubes and our proprietary Dark Matter Technology®, we engineered a coating that solves the brittleness that plagues conventional ceramics. That elasticity is the secret sauce to real, long-term durability.

The ability to flex without cracking is what allows a coating to survive years of temperature swings, from scorching heatwaves to sub-zero winters. This flexibility prevents the coating from breaking down, ensuring the protective shield remains intact and effective for much longer.

Because our coatings can expand and contract right along with your vehicle’s panels, they hold a perfect, unbroken bond with the paint. This resilience means you get the 9H hardness you want, but without the risk of the coating failing early due to micro-cracking. It’s the same principle of tough, flexible protection that makes a high-quality marine ceramic coating so essential for boats, which have to deal with even more extreme environmental stress.

A Story of Innovation

We have a client, a detailer up in Minnesota, who used to be constantly frustrated with traditional ceramic coatings. His customers’ cars would look great in the fall, but after just one brutal winter, they’d come back in the spring with the coating’s performance visibly degraded. The freeze-thaw cycle was just too much for the rigid material.

He decided to give our Titan Vulcan TX155, one of our signature elastomer formulas, a shot. The following spring, the same cars returned, but this time they looked just as glossy and hydrophobic as the day he coated them. Vulcan’s flexibility had allowed it to handle the extreme temperature swings without breaking a sweat. It proved that resilience, not just rigidity, is what really matters for longevity in the real world. That experience made him a believer, and it perfectly illustrates how our approach delivers results where others simply can’t.

Hardness is important, but flexibility is what ensures that hardness lasts.

The Titan Coatings Technology Advantage

Look, anyone can talk about hardness. It’s an easy number to throw around. But if a coating is just hard, it’s also brittle. Think about it—glass is hard, but it shatters under pressure. That’s the problem with so many traditional 9H ceramic coatings. They create a rigid shell that can’t handle the real world. This is where we decided to change the game. We’re not just focused on hardness; we’re delivering smart, adaptable protection built on some serious science.

Our big breakthrough was being the first company to introduce Elastomer coatings to the market. This wasn’t just another product; it was a fundamental shift in how paint protection works. Using our proprietary Dark Matter Technology® and advanced nano tubes, we created a coating that has the hardness you expect but with incredible flexibility. That combination is the secret sauce. It’s how we solve the biggest problem with rigid ceramics: micro-cracking from temperature changes. Our elastic coatings are hard like glass and flexible, making them last longer due to their ability to adapt.

The Power of Elasticity and Advanced Formulations

Your car’s body panels are constantly expanding and contracting with the heat and cold. A rigid coating can’t keep up. It develops tiny, invisible fractures that eventually let contaminants in, and the whole protective layer fails. Temperature changes between frozen and hot won’t affect our coating anymore because it won’t crack down due to flexibility.

Our unique elastomer base, however, moves with your vehicle. It expands and contracts right along with the metal, preventing those cracks from ever forming. This keeps the bond to your paint strong and sealed, year after year. That flexibility is why our coatings last through brutal summers and icy winters without breaking a sweat. You can learn more about the science behind our Titan Coatings Elastomer technology and see what makes it such a superior shield.

But we didn’t just stop at a flexible base. We use that foundation to build even more specialized formulas, like HyperQuartz®, loading them with unique materials to hit very specific performance targets. The end result is a multi-layered defense that goes way beyond simple scratch resistance.

Take our Titan Hyper-Quartz Graphene Coating as a perfect example:

- Elastomer Base: It all starts with our signature flexible backbone, which is the key to its durability against environmental stress.

- Graphene Infusion: We then weave in graphene—a Nobel Prize-winning material famous for its unbelievable strength, slickness, and ability to dissipate heat. This is what helps dramatically reduce water spotting and creates that slick, ultra-hydrophobic surface everyone loves.

This kind of intentional design gives you a coating that doesn’t just sit there and protect. It actively fights back against contaminants, pushes gloss to a whole new level, and makes washing your car almost effortless.

Transparent Performance Verified by Data

We’d rather prove our claims than just talk about them. That’s why we send our coatings out for tough, third-party ISO/ASTM testing. This validates their performance in a controlled, scientific setting, so you’re not just taking our word for it. We take complex military-grade polymer science, turn it into real-world benefits for your car, and show you the results.

Here’s a quick look from our comparison page. It clearly shows how our products measure up against each other and the competition on the metrics that actually matter.

This data-driven approach means you can see the measured differences in durability, chemical resistance, and gloss. No marketing fluff, just proof.

The global ceramic coatings market is projected to hit USD 13.08 billion by 2025, largely because car owners are demanding better, high-performance protection. Industry benchmarks show that a top-tier coating can keep 95% hydrophobicity even after three years—and we’re always aiming to beat that standard. You can discover more insights about the growing ceramic coatings market.

Our mission is to keep pushing forward. By combining a flexible elastomer foundation with powerful additives like graphene, we’ve built a ceramic 9H coating that truly gives you the best of all worlds: top-tier hardness, long-term flexibility, and elite resistance to chemicals and the elements. It’s more than just a coating—it’s an engineered shield built for the long haul.

Protecting Your Investment With Proper Care

Getting a high-performance ceramic 9H coating is a brilliant move for your vehicle, but the job isn’t finished once the installer hands you back the keys. If you want those years of jaw-dropping gloss and rugged protection you paid for, you have to do your part. Even the best coating on the market needs a little TLC to perform at its peak.

Think of it like this: the professional application, with all that painstaking decontamination and paint correction, is 90% of the battle. That prep work is what allows the coating to create a perfect, glass-like bond with your paint. From that point on, it’s your routine that keeps that flawless finish alive.

Building a Safe Wash Routine

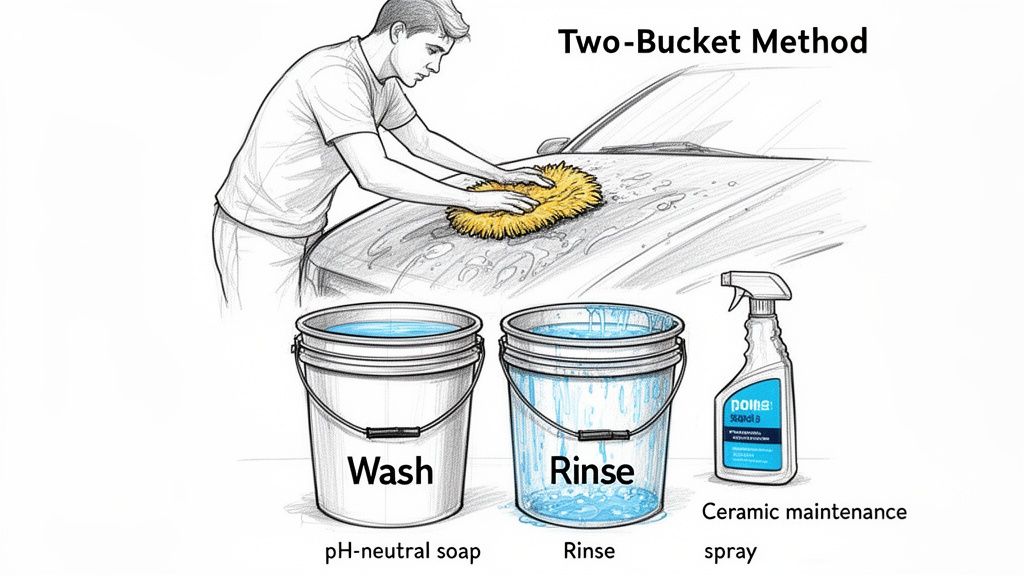

Honestly, the single biggest factor in your coating’s longevity is how you wash your car. Those drive-thru automatic car washes? They’re your coating’s worst enemy. Their abrasive brushes and harsh, recycled chemicals will chew through a protective layer and cover your paint in swirl marks in no time. A gentle, hands-on wash is the only way to go.

The two-bucket method isn’t just a suggestion; it’s the gold standard for anyone who cares about their paint. It’s a simple trick that drastically cuts down on the risk of dragging dirt and grit across the finish—the very thing that causes those ugly swirl marks.

Here’s how easy it is to get started:

- First Bucket (Rinse): Just plain, clean water. This is your “dirty” bucket where you’ll dunk and rinse your wash mitt after every panel.

- Second Bucket (Soap): Fill this one with water and a quality, pH-neutral car soap. This is your “clean” bucket.

- The Process: Grab your wash mitt, dip it in the soap bucket, and wash one section of your car. Before going back for more suds, rinse the mitt thoroughly in the rinse bucket. This simple step keeps the grime you just removed from contaminating your clean soapy water.

Choosing the Right Products for the Job

Your wash technique is half the equation; the products you use are the other half. Using harsh, acidic, or high-alkaline cleaners is a fast way to kill your coating’s hydrophobic properties, making it less effective over time.

Stick with pH-neutral car wash soaps, period. These formulas are engineered to be tough on dirt but gentle on your coating. They lift contaminants away without stripping or weakening the complex polymer structure you paid to protect your paint.

To really make your coating pop and perform its best, use a ceramic-infused maintenance spray every few washes. These act as a “topper” or a “booster,” reinforcing the water-beading action and adding an incredible layer of slickness and shine. Think of it as a quick vitamin shot for your coating. For a deeper dive into long-term care, check out our complete guide to ceramic coating maintenance.

Of course, protecting your investment goes beyond just the paintwork. While your coating guards the exterior, it’s wise to consider total vehicle security. For instance, you can understand how advanced security systems like a Ghost Immobiliser protect your car to add another critical layer of defense. By pairing a perfectly maintained finish with robust security, you’re safeguarding your vehicle from every angle, inside and out.

Making the Right Choice for Your Vehicle

Let’s circle back to Mark. He started this whole process just wanting the “best ceramic 9H coating,” but now he sees the bigger picture. He gets it now—that 9H rating is just one small piece of a much larger puzzle.

With this new understanding, he realizes that a super-hard coating without any give is a disaster waiting to happen, especially with the wild temperature swings his car goes through every season. He’s not just buying a product off a shelf anymore; he’s investing in smart, resilient paint protection.

After looking at everything, Mark’s choice is easy. He confidently picks Titan’s Hyper-Quartz Graphene Coating, a formula engineered with an advanced elastomer base. He knows this isn’t just about getting a hard, scratch-resistant surface. It’s about getting a coating that can actually flex and move with his car’s body panels, avoiding the tiny stress fractures that kill lesser, brittle coatings.

From Confusion to Confidence

Mark’s journey is a perfect example for any car owner. He learned that the true value of 9H isn’t about making your car bulletproof; it’s about giving it a fighting chance against the daily grind. But the real game-changer? The elasticity that Titan Coatings pioneered. That’s the secret to genuine, long-term durability. It’s the difference between a coating that just hangs on and one that truly performs.

The moment he saw his car after the application, the satisfaction was instant. The gloss was unbelievable, giving the paint a deep, liquid look that made people stop and stare. But the real peace of mind came during that first wash. All the dirt and grime just sheeted off with the water. What used to be a weekend-killing chore was now a quick, almost effortless rinse. The hydrophobic beading was so intense the car practically dried itself.

His vehicle wasn’t just a car anymore. It was a protected investment. Mark now drives knowing his paint is shielded by technology that’s both tough as nails and flexible enough to handle the real world without cracking under pressure.

This is what it feels like to choose the right technology. It’s not about a fleeting shine; it’s about locking in lasting protection that makes owning your car easier and way more fun. To see how our coatings stack up against other options, check out our in-depth comparison of Paint Protection Film vs Ceramic Coating.

Your Turn to Experience the Titan Difference

Mark’s story isn’t unique—we hear it all the time. And the solution he found is right here for you. Take a look at our full line of elastomer-based coatings in our shop to find the perfect fit for your vehicle and your needs.

Give your vehicle the intelligent, durable protection it deserves. Explore our products or find a certified installer today to get that same confidence that comes from a truly superior ceramic 9H coating. Your peace of mind is just an application away.

Got Questions About 9H Coatings? We’ve Got Answers.

When you start digging into ceramic coatings, especially the whole 9H thing, a lot of questions pop up. It’s totally normal. Let’s clear the air and tackle some of the most common ones we hear from drivers just like you.

Will a 9H Coating Make My Car Scratch-Proof?

In a word, no. Think of a 9H ceramic coating as high-end body armor for your paint. It offers incredible resistance against the everyday enemies—swirl marks from car washes, light scuffs, and fine scratches. It’s a sacrificial layer that takes the hit so your clear coat doesn’t have to.

But it isn’t bulletproof. A deliberate key scratch or a sharp rock flying up on the highway can still get through. A 9H coating makes your paint dramatically tougher, but it doesn’t make it invincible.

What Makes an Elastic Coating Different From a Standard Ceramic One?

The real game-changer here is flexibility. Most standard ceramic coatings are incredibly rigid. While that sounds good, it can be their downfall. Your car’s body panels are constantly expanding and contracting with temperature swings, and a rigid coating can develop micro-cracks under that stress, eventually failing.

Titan’s elastomer-based coatings, infused with our Dark Matter tech and advanced nano tubes, are engineered differently. They are designed to be both hard and flexible. This elasticity means the coating flexes right along with your car’s panels, preventing those cracks and massively extending its protective lifespan, especially if you live somewhere with wild weather changes.

Can I Just Apply a 9H Ceramic Coating Myself?

Sure, there are plenty of consumer-grade DIY kits out there. But getting that jaw-dropping, glass-like finish from a true professional coating is a whole different ball game. It demands a flawless canvas, which means a meticulous process of decontamination and paint correction. Any mistake gets locked in under the coating for years.

This is why we always recommend a certified installer for Titan’s professional-grade formulas. It’s not just about a perfect application; it’s about guaranteeing you get every ounce of performance you’re paying for. Plus, it activates the product warranty, so you can drive away with complete confidence.

Ready to give your vehicle the kind of flexible, long-lasting protection it truly deserves? The team at Titan Coatings is here to help. Take a look at our advanced elastomer-based coatings, like the industry-leading Titan Hyper-Quartz Graphene Coating, and see what a real blend of hardness and resilience can do for your ride.

0 Comments