Imagine this: a brand-new car, gleaming under the showroom lights. Now, fast forward a few months. That perfect finish is under constant assault. From the second you drive it off the lot, it’s a non-stop battle against the elements. We’re talking about acid rain, brutal UV rays that fade your clear coat, and the surprisingly corrosive damage from bird droppings.

For years, the go-to defense was a good old-fashioned wax. But anyone who’s spent a Saturday afternoon detailing their car knows the drill. It looks incredible for a week, maybe two, and then that protective shine just… disappears. It’s a frustrating cycle of wash, wax, repeat.

This constant upkeep is precisely why the demand for a better solution has exploded. The global market for advanced automotive coatings is on track to hit $2.5 billion by 2025, a clear signal that owners are looking for something more than a temporary fix. They’re seeking real, lasting protection.

A Whole New Level of Defense

Enter the world of ceramic automotive coatings. This isn’t just a stronger wax; it’s a completely different approach to paint protection. Think of it less like a temporary coat of armor and more like a second skin for your vehicle.

While wax simply sits on top of your paint, a ceramic coating is a liquid polymer that creates a chemical bond with the factory clear coat. This process forms a semi-permanent, hardened glass-like layer that becomes an integral part of the surface itself.

Of course, for that bond to be perfect, the surface has to be surgically clean. Any contaminants left behind will get trapped under the coating, which is why a thorough decontamination wash is non-negotiable. If you’re curious about what that entails, understanding how to decontaminate car paint is the critical first step.

Ultimately, this technology changes the game. It offers a level of durability, gloss, and resilience that turns the tide in the constant war against environmental damage. You’re not just polishing your car; you’re investing in its long-term health and appearance.

The Journey from a Simple Shine to Flexible Armor

The quest for the ultimate paint protection is a story of constant innovation. For years, the gold standard was carnauba wax. Harvested from a Brazilian palm, it gave cars a beautiful, deep gloss that everyone loved. Think of it like a light rain jacket—it looked great and offered a simple, sacrificial layer of protection, but it was gone in a few weeks, washed away by the rain or a few trips through the car wash.

That short lifespan pushed the industry to find something better. Next came synthetic paint sealants, lab-created polymers that were a huge step up in longevity, often lasting for months. They were tougher and stood up to detergents far better than natural wax. Still, they were just a temporary film sitting on the surface, destined to wear down and need reapplication.

The True Game-Changer: Ceramic Coatings

The real leap forward came with SiO2 (silicon dioxide) based ceramic automotive coatings. This wasn’t just an improvement; it was a completely different approach. Instead of just sitting on top of the paint, these coatings form a chemical bond with the clear coat, creating a semi-permanent shell of hardened glass. This breakthrough delivered years of protection, not months, and brought a level of hardness that waxes and sealants simply couldn’t touch.

But even this incredible technology had a hidden weakness. The first-generation ceramic formulas were incredibly hard, but also very rigid.

Picture a standard ceramic coating as a thin, brittle sheet of glass. It’s strong, but when stressed—like the paint expanding and contracting from a freezing winter night to a scorching afternoon—it can develop microscopic cracks. This vulnerability was the next great challenge for the industry to overcome.

A New Era of Flexibility and Resilience

This is where the story gets really interesting. At Titan Coatings, we saw this problem not as a limitation, but as a chance to create an entirely new class of protection. We were the first company to introduce Elastomer coatings to the market, a true innovation powered by our proprietary nano tubes technology and Dark Matter tech.

Our goal was simple: create a coating with the toughness of glass but the flexibility of a high-tech polymer. This concept of “flexible armor” is what truly sets our technology apart.

- Hard Like Glass: It provides the scratch resistance and chemical durability you expect from a top-tier ceramic coating.

- Flexible and Resilient: It can expand and contract right along with your vehicle’s panels as temperatures swing wildly. This elasticity is key, as temperature changes won’t affect the coating anymore between frozen and hot temperatures; the coating won’t crack down due to its flexibility, ensuring a much longer and more effective lifespan.

This journey from a simple wax to a dynamic, flexible shield is the result of relentless innovation. If you want to dive deeper into how this new technology stacks up against older methods, you can explore the key differences between wax and ceramic coatings in our detailed breakdown.

The Titan Advantage in the Real World

Take a product like our Vulcan TX155. It’s the perfect example of this next-generation thinking. It isn’t just a hard shell; it’s a dynamic, adaptive shield built for the real world. A vehicle protected with Vulcan TX155 can bake in the desert sun and then get hit with a sudden cold snap without the protective layer being compromised.

This ability to absorb thermal shock is absolutely critical for long-term performance. While traditional ceramic coatings provide a solid barrier, our Elastic coatings offer a more durable, resilient defense that moves with your vehicle, not against it. This isn’t just a small step forward; it’s the next chapter in the evolution of automotive surface protection.

How Elastomer Coatings Create a Flawless Shield

So, how does a liquid from a bottle morph into a tough, semi-permanent shield on a car? It’s all about molecular science, creating a bond so deep and resilient that traditional waxes and sealants just can’t compete. The magic starts at the nano-level.

Think of your car’s clear coat not as a flawless sheet of glass, but as a surface full of microscopic peaks and valleys. When we apply a Titan elastomer coating, it doesn’t just sit on top. It flows into every one of those tiny imperfections, with its molecules creating thousands of anchor points that grip the paint. It’s a true chemical bond, making the coating one with the surface.

The Power of a Flexible Matrix

This is where Titan’s pioneering nano tubes technology really changes the game. Once the coating bonds, these nano tubes lock together, forming a dense, cross-linked matrix. Instead of picturing a rigid sheet of glass, imagine a tightly woven, incredibly strong, yet flexible net stretched over your paint.

That flexible structure is the secret to its superior performance. While traditional ceramic automotive coatings are famous for their hardness, that same rigidity is often their downfall. Titan’s elastic coatings give you that same glass-like hardness but add a critical ingredient: the ability to flex.

This flexibility allows the coating to absorb the stress of thermal expansion—the natural swelling and shrinking of your car’s panels as temperatures shift from freezing cold to blistering heat. A rigid coating can develop micro-fractures under this strain, but Titan’s elastomer shield moves with the vehicle, ensuring its integrity and longevity.

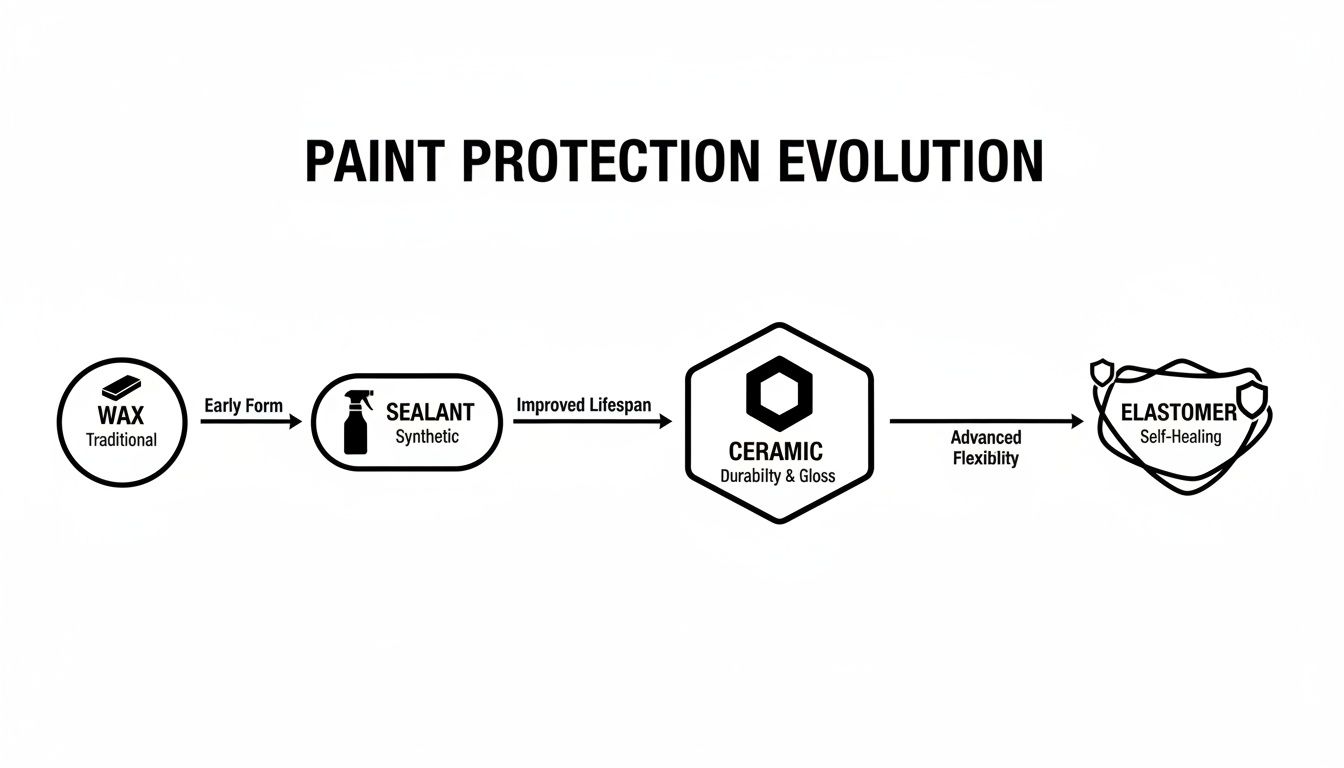

The progression in paint protection technology is clear, and elastomers represent a massive leap forward.

This visual journey shows how each step, from wax to today’s elastomers, has brought us closer to a truly dynamic and durable form of vehicle armor.

Amplifying Protection with Dark Matter Technology®

Building on this flexible foundation, Titan integrates another exclusive innovation: Dark Matter Technology®. This isn’t just a fancy name; it’s a proprietary blend of advanced polymers we engineered to push the coating’s performance to a whole new level.

Dark Matter Tech focuses on three key areas:

- Gloss and Depth: It dramatically boosts the reflective index, creating a liquid-like gloss and a depth of color that’s simply unbelievable to see in person.

- Slickness: The surface becomes exceptionally smooth, which reduces friction and makes it much harder for dirt, grime, and other contaminants to get a grip.

- Hydrophobicity: This is where you see that amazing water-beading. Water flies off the surface, taking dirt with it. This self-cleaning effect keeps the vehicle looking pristine for much longer.

This advanced hydrophobic shield also acts as a powerful defense against corrosion—an issue that costs the global economy an astounding $2.2 trillion annually. By keeping moisture and corrosive elements from ever reaching the paint, these coatings form a formidable barrier against oxidation and chemical etching. For those who like the data, you can dive into the research on the impact of ceramic coatings on corrosion prevention and see the numbers for yourself.

To truly understand the advantage, it helps to see a direct comparison. We’ve laid out how our advanced elastomers stack up against the more conventional ceramic coatings on the market.

Traditional Coatings vs. Titan Elastomer Coatings

| Feature | Traditional Ceramic Coatings | Titan Elastomer Coatings |

|---|---|---|

| Flexibility | Rigid and brittle; prone to micro-fracturing under stress. | Highly flexible; adapts to thermal expansion and contraction. |

| Durability | Hardness can lead to chipping and cracking over time. | Combines hardness with elasticity for superior impact resistance. |

| Self-Healing | No inherent self-healing properties. | Offers regenerative capabilities against minor swirls and scratches. |

| Chemical Resistance | Good resistance to common chemicals and environmental fallout. | Exceptional resistance due to a denser, cross-linked structure. |

| Slickness & Gloss | High gloss, but surface slickness can diminish over time. | Extreme slickness and enhanced gloss from Dark Matter Technology®. |

Ultimately, the science behind our coatings combines the best of both worlds. You can learn more about how Titan’s elastomer technology achieves this, but the core idea is simple: it marries the hardness of ceramics with the resilience of a high-tech polymer. The result is a flawless shield that doesn’t fight the environment—it adapts to it.

Choosing the Right Shield from Titan’s Lineup

So, you get the science behind Titan’s flexible, elastomer-based coatings. That’s the first hurdle. The next, and arguably more important one, is figuring out which one is the right fit for your car and, just as importantly, your life.

Let’s be honest, not all cars are treated equally. Is yours a daily warrior, braving the front lines of commuter traffic, road salt, and whatever the sky decides to throw at it? Or is it your weekend pride and joy, a showpiece where the ultimate goal is a jaw-dropping, mirror-like finish?

Every coating in Titan’s lineup was built with a specific job in mind. Once you understand what each one is designed to do, you can make a smart choice that gives you exactly the look and protection you’re after. It’s all about matching the right tool for the job.

The Daily Driver’s Ultimate Defense

For a car that gets you to work and back every day, you need protection that’s dead reliable. Your paint is under constant assault from road grime, industrial fallout, and even the aggressive soaps at the local car wash. You need a shield that’s tough, long-lasting, and doesn’t demand a ton of effort to keep it working.

This is exactly why we created a workhorse like Titan Vulcan TX155.

Think of it as a coating engineered for the harshest conditions imaginable. Vulcan TX155 is loaded with exceptional chemical resistance, meaning it just shrugs off things like harsh road salts and powerful cleaners that would eat away at lesser products. Its formula also delivers incredible self-cleaning abilities; the surface is so intensely hydrophobic that water and dirt just bead up and roll right off. For the owner who just needs dependable, set-it-and-forget-it protection, Vulcan TX155 is pure peace of mind.

The Show Car’s Secret to Flawless Gloss

Now, the weekend show car? That’s a completely different mission. Its job is to stop people in their tracks with a gloss that looks like it’s still wet. For this kind of car, the coating’s formula has to be dialed in for maximum visual punch—creating razor-sharp reflections and that deep, liquid shine.

This is where a premium aesthetic coating like Titan HyperQuartz steps into the spotlight.

HyperQuartz is all about visual perfection. We designed its unique formulation to amplify your paint’s natural clarity and color, wrapping it in a rich, candy-like shell that makes the finish look miles deep. It still provides serious protection, of course, but its number one job is to deliver that show-stopping pop that wins trophies and turns heads. It’s the finishing touch for a vehicle that’s less about transportation and more a piece of rolling art.

Choosing the right coating is about aligning its strengths with your needs. A daily driver benefits most from extreme durability and self-cleaning, while a show car demands the pinnacle of gloss and aesthetic enhancement.

Making an Informed Decision

Picking the perfect coating means you’ve got to look at the key performance metrics side-by-side. Things like longevity, gloss level, slickness, and chemical resistance vary from one product to the next. For example, one coating might offer over 5 years of certified protection, while another might trade a bit of longevity for an even higher level of gloss.

To make this easy, we’ve put together a detailed product comparison page that lays out the specific strengths of every coating in our lineup. This chart lets you compare options like Vulcan TX155 and HyperQuartz directly, so you can confidently pick the perfect shield for your car. Once you have an idea, you can head over to our shop to get a closer look at each one and find the perfect match for your vehicle’s mission.

Why Professional Application Unlocks Peak Performance

A top-tier ceramic automotive coating is a lot like a high-performance engine; its true potential is only ever realized in the hands of an expert. Think of a skilled installer, a true artisan of automotive surfaces, as they prepare to transform a vehicle. Their work doesn’t begin when they open the bottle—it starts with a meticulous, almost surgical, preparation process. This is what separates an average job from a flawless one that will last for years.

The journey kicks off with a multi-stage decontamination wash, which is worlds away from a simple soap and rinse. The installer uses specialized iron removers to dissolve stubborn, bonded brake dust and rail dust. Next, a clay bar treatment lifts any remaining embedded grit from the clear coat. Every single square inch of the paint has to be absolutely pure. If it’s not, the coating will end up bonding to the dirt, not the car itself.

The Uncompromising Art of Paint Correction

Once the surface is sterile, the real artistry begins. The installer inspects the paint under intense lighting, which reveals a hidden world of imperfections—swirl marks from old automated car washes, fine scratches, and the dull haze of oxidation. Applying a coating over these flaws would be like putting a beautiful, permanent picture frame over a damaged photograph. You aren’t hiding the problem; you’re sealing it in forever.

This is exactly why paint correction is the most critical step of the entire process. Using a variety of polishers, pads, and compounds, the professional painstakingly levels the clear coat to erase every single imperfection. It’s a demanding process that can take dozens of hours, requiring immense skill and patience. The goal is simple but difficult: create a perfect canvas, a surface so flawless that it can forge a perfect, seamless bond with the coating.

A professional installer doesn’t just apply a product; they forge a permanent, molecular-level bond between the Titan coating and the vehicle. This expert preparation is directly tied to the coating’s performance, longevity, and warranty.

Forging the Final Shield

Only after the paint is perfected is the coating finally applied. The installer works in small, deliberate sections, carefully laying down the liquid polymer and then leveling it to achieve that signature high-gloss finish. They meticulously control the temperature and humidity, ensuring the coating cures correctly to form the hard, flexible armor it was engineered to be. This level of precision is something a DIY job can rarely, if ever, replicate. For those interested in seeing what goes into it, you can explore our guide on the meticulous process of applying ceramic coating to a car.

This professional touch is the final, essential ingredient. It ensures our advanced elastomer technology, Dark Matter Tech®, and nano tubes all work in concert to deliver years of incredible protection and that unbelievable gloss. In the end, a true professional isn’t just protecting a car; they are elevating its finish to a level of perfection that will endure.

Maintaining Your Coating for Lasting Brilliance

So, your car is now wrapped in a high-tech layer of protection. The big question is, what now? There’s a common misconception that ceramic automotive coatings are a “set it and forget it” solution. The truth is actually much better: they don’t eliminate maintenance, they just make it incredibly simple. Your focus shifts from hours of laborious paint correction to quick, satisfying upkeep.

Think of your new coating as a suit of armor. It’s tough, but it performs best when it’s clean. Letting things like bird droppings, bug guts, or hard water spots bake on the surface can eventually compromise its performance. The goal is to keep that just-detailed look with a simple routine that ensures your coating works at its peak for years to come.

The Foundation of Proper Care

The absolute bedrock of long-term coating health is proper washing. Forget the abrasive brushes and harsh, high-pH soaps found at most automatic car washes—those are your coating’s worst enemies. They can wear down the hydrophobic surface and even cause fine scratches over time. A gentle, smart approach is all you need.

A few best practices will go a long, long way:

- Use the Two-Bucket Method: This is non-negotiable. One bucket holds your soapy, pH-neutral car shampoo, and the other holds clean water for rinsing your wash mitt. This simple trick stops you from grinding dirt and grit right back into your paint, which is the number one cause of swirl marks.

- Choose High-Quality Tools: Get yourself some plush, high-GSM microfiber towels for washing and drying. Their job is to trap dirt and pull it safely away from the finish, not push it around.

- Dry with Care: Never let water air-dry on the paint. That’s how you get mineral spots. Gently pat the car dry with a dedicated, super-absorbent drying towel. For a truly touch-free dry, a leaf blower or a specialized car dryer works wonders.

Boosting Protection and Slickness

To keep that amazing slickness and water-beading action going strong, a good maintenance product is your secret weapon. It’s like a quick tune-up for your coating. A spray like Titan’s Graphene+ Detailer is designed to work with the coating, not just sit on top of it. It reinforces the protective layer and brings back that fresh-application feel.

Just a quick spray and wipe every few washes will crank up the gloss and recharge the hydrophobic effect, making your next wash even faster. This easy step ensures your car always looks its best. For a deeper dive, check out our complete guide to ceramic coat maintenance—it covers everything you need to know to protect your investment.

This kind of easy upkeep is exactly why the demand for high-performance coatings is exploding, with the market projected to hit $22.14 billion by 2032. When a coating can provide years of protection and simplified care where a traditional wax might only last a few months, the value is undeniable. You can learn more about this industry-wide shift by reading up on the high-performance ceramic coatings market and its incredible growth.

Got Questions About Titan Coatings? We’ve Got Answers.

Diving into the world of professional-grade ceramic automotive coatings can feel complex. As the innovators behind elastomer and nanotube technologies, we believe in keeping things simple. Here are some straightforward answers to the questions we hear most often.

How Is a Titan Elastomer Coating Different from a Standard Ceramic?

In a word: flexibility.

Picture a typical ceramic coating as a super-thin sheet of glass. It’s incredibly hard, which is great, but that hardness comes with a price—it’s brittle. Your car’s body panels are constantly expanding and contracting with temperature changes. A rigid coating can’t keep up, leading to micro-fractures that eventually compromise the entire protective layer.

That’s precisely where our elastomer technology—a breakthrough we pioneered—rewrites the rules. We engineered our coatings to be both hard and flexible. This built-in elasticity lets the coating flex with your vehicle’s panels, absorbing stress instead of cracking under it. It’s the difference between a fragile shield and truly resilient armor.

Can I Just Apply a Professional Titan Coating Myself?

While we do offer some fantastic products for the DIY enthusiast, our professional coatings are a different league. Achieving their legendary performance isn’t just about the liquid in the bottle; it’s about the meticulous process, and the single most critical step is paint correction.

A certified professional will spend hours meticulously polishing your vehicle’s paint, removing every single swirl, fine scratch, and imperfection before the coating ever touches the surface.

Think about it: applying a semi-permanent coating over flawed paint means you’re locking those flaws in for years. For a truly perfect finish and to qualify for our full warranty, you need a certified Titan installer. They aren’t just applying a product; they’re preparing the perfect canvas for a flawless, long-term bond.

Seriously, How Long Does a Titan Coating Last?

This is where you really see the value. But the answer depends on two things: the specific coating and how you care for it. Our top-tier professional coatings, like Vulcan TX155, are certified to provide over 5 years of rock-solid protection, and some of our other formulas go even longer.

Getting that kind of lifespan boils down to two key factors:

- Expert Installation: It must be applied to a perfectly prepared surface.

- Proper Maintenance: A simple, consistent wash routine using pH-neutral soaps is all it takes.

Forget waxing your car every few weeks. A Titan coating is a semi-permanent layer of defense built to protect your investment for years on end.

So, Will This Make My Car Scratch-Proof and Rock-Chip-Proof?

Let’s be clear on this one. While our elastomer coatings offer incredible resistance to light scratches and wash-induced swirls, they aren’t magic. No coating can make your car completely bulletproof against deep scratches or high-speed rock chips.

The best way to think of it is as a sacrificial shield that is significantly harder and more durable than your factory clear coat. It will absolutely defend against the vast majority of daily hazards. But if a sharp object hits with enough force, it can still get through. For the ultimate defense against rock chips, the best combination is a high-quality Paint Protection Film (PPF) topped with a Titan coating.

Ready to give your vehicle the flexible, long-lasting protection it deserves? Explore the Titan Coatings lineup and find the perfect shield for your ride. Head over to our product comparison page to see exactly how our technologies stack up and choose the right solution for you.

0 Comments