If you’re serious about protecting your bike and keeping it looking incredible, a quality ceramic coating for motorcycles is the single best upgrade you can make. It’s in a completely different league from old-school waxes. Imagine a rider, let’s call him Alex, who spent every weekend polishing his pride and joy, only to see it dulled by road grime and UV rays after a single long ride. He was trapped in a frustrating cycle until he discovered a new kind of armor: a liquid polymer that forms a chemical bond with his bike’s paint, creating a semi-permanent, hardened shield that laughs at the elements while locking in an unbelievable, deep gloss.

Why Your Motorcycle Needs More Than Just Wax

Think about it. Your bike isn’t just a way to get from A to B; it’s a passion, an escape, a piece of art you’ve poured your heart and soul into. You spend hours getting it to look just right, but it feels like a never-ending battle. You wash and polish, and a week later, new swirl marks have magically appeared. The paint just doesn’t pop like it used to, dulled by the sun’s relentless assault.

You’ve probably tried every wax out there. They all claim a mirror finish and lasting protection, but the results are always short-lived. That brilliant shine is gone after a few good rides or a single rainstorm. This constant cycle of washing, polishing, and waxing is exhausting, and for what? A temporary glow that leaves your bike’s finish vulnerable.

Shifting from Temporary Shine to Lasting Armor

This is where we need to change the conversation from temporary fixes to a real, lasting solution. The problem isn’t your effort—it’s the outdated products you’re using. A motorcycle lives a much tougher life than a car, facing down intense engine heat, constant vibration, and a barrage of road debris. It simply demands a higher caliber of protection.

That’s exactly why the market for advanced surface protection has exploded. The global ceramic coatings industry is on track to hit USD 3.32 billion by 2026, fueled by vehicle owners who are tired of weak, temporary solutions. For motorcycles, a true ceramic coating can reduce oxidation and corrosion by up to 50% compared to traditional waxes in harsh environments. That’s not a small difference; it’s a game-changer.

A ceramic coating for your motorcycle isn’t just a cosmetic touch-up. It’s a fundamental upgrade to its defense system, engineered to preserve its finish, its value, and the passion you have for your machine.

The Titan Coatings Philosophy

Here at Titan Coatings, we get it because we’re riders too. We saw the shortcomings of traditional products and knew there had to be a better way. Our entire philosophy is built on creating resilient, long-term protection that’s engineered for the real world, not just a showroom floor. This led us to become the first company to introduce Elastomer coatings to the market—a breakthrough that creates a shield that’s both incredibly hard and uniquely flexible.

This flexibility is our secret weapon. Traditional ceramic coatings can get brittle, cracking under the stress of rapid temperature swings from a cold garage to a sun-baked highway. Our Elastic coatings, however, expand and contract right along with your bike’s surfaces. This means the protective barrier stays fully intact, giving you unwavering protection season after season, whether in frozen or hot temperatures. You can dig deeper into the difference between wax and ceramic coating in our detailed guide. It’s about investing in peace of mind so you can spend less time waxing and more time riding.

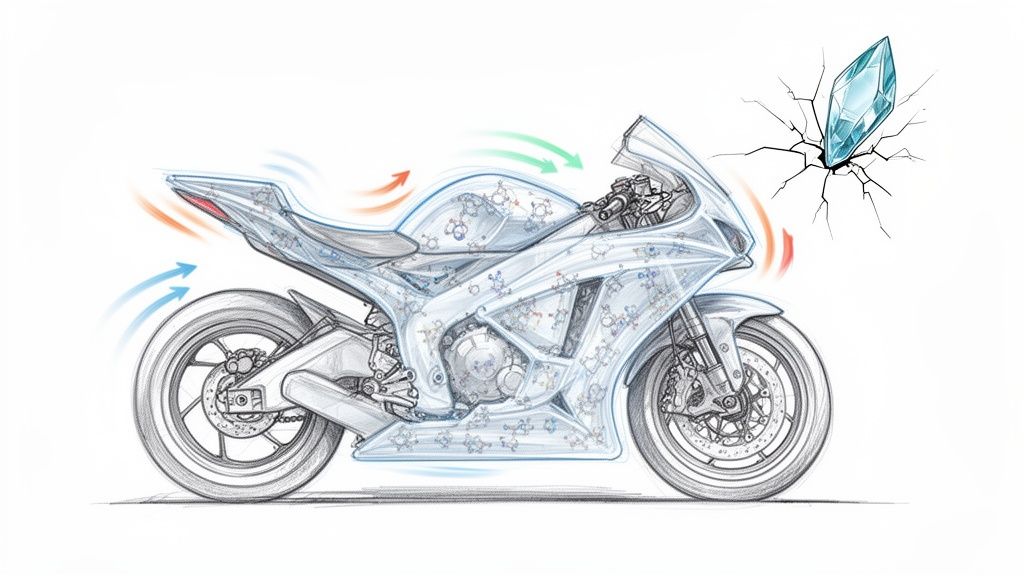

The Science of Flexible Ceramic Armor

Ever wondered if you could get protection for your bike that’s as hard as glass but bends like rubber? It sounds like something from a sci-fi movie, but it’s the exact science we’ve built into every bottle of Titan Coatings. See, your average ceramic coating has a major flaw when it comes to motorcycles: it’s completely rigid. That hardness is great, but it acts like a super-thin sheet of glass, making it brittle and almost guaranteed to fail under stress.

Think about what your bike goes through on a single ride. The engine is cranking out serious heat, the frame is buzzing with road vibrations, and you’re going from a cool garage to sun-scorched blacktop in minutes. All those forces make your bike’s metal and plastic parts expand and contract. A rigid coating just can’t hang. It develops tiny, microscopic cracks, and just like that, its protective shell is compromised.

Beyond Rigidity: The Elastomer Advantage

This is exactly where we decided to change the game. Titan was the first to introduce elastomer coatings, a completely different approach that finally solves the brittleness problem. After years in the lab, we developed proprietary formulas that blend the unbelievable hardness of ceramics with the flexibility of a polymer. The outcome? A shield that’s both incredibly tough and elastic.

Instead of cracking under pressure, a Titan coating flexes right along with your bike’s surfaces. That elasticity is the secret sauce to its durability and performance. It makes sure the protective layer stays intact as one solid, unbroken barrier, no matter how much vibration or temperature change you throw at it.

We engineered our Elastic coatings to be hard like glass yet flexible, a combination that prevents cracking and peeling. This unique resilience means your motorcycle’s armor won’t fail when temperatures swing from freezing to scorching, providing consistent, long-lasting protection.

How Dark Matter Tech and Nano-Tubes Work

Our drive to innovate didn’t stop there. We pushed further, leading to two massive advancements you won’t find anywhere else: Dark Matter Tech and our nano-tube technology. These aren’t just cool-sounding names; they fundamentally change how a ceramic coating works on a motorcycle.

- Nano-Tube Technology: Picture a microscopic, web-like structure of unbelievably strong and flexible tubes woven directly into the coating. This nano-structure acts a lot like rebar in concrete, reinforcing the entire matrix. It spreads the force from impacts—like a piece of gravel kicked up on the highway—across the surface, dramatically cutting down the chance of a chip or deep scratch.

- Dark Matter Tech: This is our signature self-healing chemistry. When minor swirls or light scratches happen, this tech allows the surface to gradually level itself back out, making daily wear and tear almost disappear. It keeps that amazing, liquid gloss locked in for the long haul.

By bringing these elements together, we created something much more than a simple coating; we built a suit of resilient armor. You can dive deeper into the core science and learn more about our elastomer technology that truly sets our products apart.

From The Lab To The Open Road

So, what does all this high-tech science actually mean for you when you’re out riding? It means real, tangible benefits that fix the biggest headaches of keeping a bike in showroom condition.

The unique flexibility means rock chips are far less likely to break through the armor. Bug guts and bird droppings—the bane of every rider’s existence—wash off effortlessly without etching into the finish. Best of all, that jaw-dropping shine you had on day one is still there, month after month, because the protective layer hasn’t broken down or filled with micro-cracks.

This isn’t just about being tough; it’s about being smart. It’s resilient protection engineered for the demanding, dynamic life of a motorcycle.

Choosing The Right Shield For Your Ride

So, you’re sold on the idea of Titan’s flexible armor for your bike. Smart move. You’ve seen the science and you’re officially done with temporary waxes and coatings that chip if you look at them wrong.

But now comes the big question: which specific shield is the right one for your ride? This is a common crossroads for many riders. You’ve moved past the why and landed squarely on the which. This isn’t about just grabbing a bottle off the shelf; it’s about matching the right tech to your bike, your budget, and how you ride.

Your Go-To Options From Titan

For a lot of folks, the search starts and ends with one standout product: TITAN Vulcan TX155. Imagine you’re preparing for a cross-country trip. You need a coating that can handle everything from desert heat to mountain cold, repelling road grime and bug splatters for thousands of miles. Vulcan TX155 is that workhorse. It leverages our signature Dark Matter Tech, offering incredible chemical resistance and a slickness that makes cleanup almost laughably easy.

The results speak for themselves. This coating delivers an amazing, liquid-like gloss that makes your paint look a mile deep. But for a rider, the real magic is its shocking hydrophobicity. Water, mud, and road grime have almost nothing to cling to. It all just sheets right off, making cleanup after a gritty ride a simple wipe-down instead of an hour-long chore.

For a motorcycle, which is a magnet for everything from bug guts to chain lube, that level of slickness isn’t just a cool feature. It’s the key to keeping your bike looking sharp with way less elbow grease.

A Coating For Every Rider

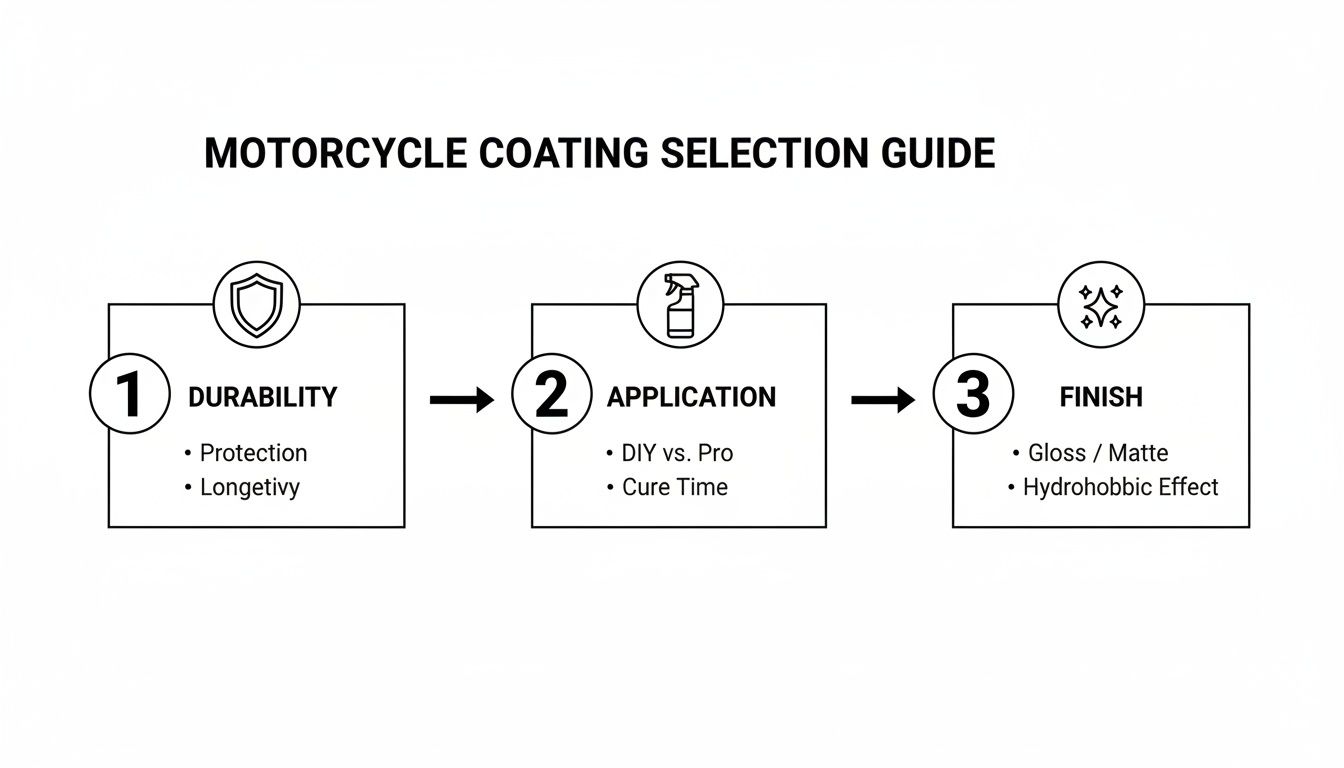

While Vulcan TX155 is a fantastic choice, we know the perfect ceramic coating for motorcycles is different for everyone. That’s why we’ve engineered a whole range of solutions. To pick the best one, think about what matters most to you:

- Durability and Protection: How long do you need it to last? Our coatings offer different levels of longevity and scratch resistance to handle anything from daily commuting to weekend canyon carving.

- Ease of Application: Are you a die-hard DIYer who enjoys a Saturday in the garage? Or a pro demanding the absolute best? We have user-friendly sprays and pro-grade formulas to match your skill level.

- Targeted Resistance: Different parts of your bike face different enemies. Our Pyro TX155 Heat Resistant Coating is specifically designed for exhausts and engine parts that face extreme temperatures.

To make this choice dead simple, we put together a quick comparison table to help you find the perfect fit. You can see even more details on our comparison page.

Titan Coatings Product Comparison for Motorcycles

Here’s a quick-glance guide to help you choose the best Titan coating based on your bike’s needs and your experience level.

| Product Feature | TITAN Vulcan TX155 | Pyro TX155 Heat Resistant Coating |

|---|---|---|

| Primary Benefit | Maximum gloss, slickness & durability | Extreme heat and chemical resistance |

| Experience Level | Professional / Experienced DIYer | Professional / Experienced DIYer |

| Key Technology | Dark Matter Tech, Elastomer Base | Advanced Heat-Dissipating Resins |

| Durability | 5+ Years | 2+ Years |

| Ideal Use Case | Painted surfaces, wheels, plastics | Exhaust systems, engine components, calipers |

This table gives you a starting point. For a more detailed breakdown, you can always explore our full shop to see how each product stacks up.

Making The Final Call

High-performance ceramic coatings (HPCC) are completely changing the game for riders. The market, valued at USD 7,844 million in 2018, is on track to hit USD 12,633.3 million by 2026 for a reason—this stuff works.

Unlike wax, a top-tier coating can withstand temperatures soaring up to 1,200°C, protecting hot engine parts and exhaust headers from discoloring. They also repel grime up to 70% better than old-school sealants. You can get more details on how high-performance ceramics are impacting the market here.

Ultimately, it comes down to your priorities. If you want the absolute best gloss, water-beading, and long-term durability for your bike’s body, a professional-grade coating like TITAN Vulcan TX155 is the clear winner. If you’re looking for specialized protection for high-heat areas, other products in our lineup are a better fit.

And while a ceramic coating is a fantastic shield, it’s also smart to understand how it compares to paint protection film to make a fully informed decision for your pride and joy.

The Pro-Level Motorcycle Coating Process: From Prep to Perfection

Alright, this is where the rubber meets the road—or rather, where the coating meets the paint. You’ve done the research, you’ve picked your poison, and now it’s time to give your motorcycle that professional-grade, glass-like finish.

Let’s walk through this together. We’re going to treat this not as a chore, but as a meticulous process broken down into three critical phases. Forget just wiping a product on and calling it a day. This is about patience, precision, and building a foundation that will protect your ride for years to come. A show-quality finish is absolutely within your reach, right in your own garage.

Phase 1: The Art of Preparation

I can’t stress this enough: a spectacular finish is built on a flawless canvas. You can have the best coating in the world, but if you apply it over a dirty, swirled-up surface, you’re just locking in those imperfections. Any lingering contaminants or blemishes will be magnified under that glossy ceramic layer.

Honestly, prep work isn’t just a step; it’s 90% of the job.

This is all about deep cleaning and correcting the paint to perfection.

- The Decontamination Wash: Start with a solid two-bucket wash using a good, pH-neutral motorcycle shampoo. Don’t stop there. Hit the paint with an iron remover spray—you’ll see it “bleed” purple as it dissolves the tiny metal particles embedded in your clear coat. Follow that up with a tar remover to get rid of any stubborn road gunk.

- The Clay Bar Treatment: Even after a good wash, your paint will likely feel gritty to the touch. Those are bonded contaminants. Grab a clay bar and some proper lubricant, glide it over the surface, and feel the difference as it pulls those impurities out. The goal is a surface that’s as smooth as glass.

- Paint Correction: This is where the magic really happens. Using a machine polisher with the right pads and compounds, you’ll methodically remove swirl marks, light scratches, and any oxidation. You’re aiming for a perfect, mirror-like surface before a single drop of coating touches it. You’re sealing in perfection, not flaws.

The environment where you do this work matters immensely. Having a clean, well-lit space is non-negotiable for getting pro-level results, and understanding the principles of setting up an efficient automotive workshop can make a huge difference in controlling quality.

To help you choose the right product for the job, this simple guide breaks down the key decision points.

It boils down to three things: how long you want it to last, how you want to apply it, and the kind of look you’re after.

Phase 2: The Application Ritual

With the bike prepped and gleaming, it’s time to apply the coating. This part is a game of patience and technique. You’ll want to work in small, manageable sections to ensure you get a perfectly even layer.

Let me share a classic mistake I’ve seen countless times: applying a coating in direct sunlight or a hot environment. This is a recipe for disaster. It causes the coating to “flash” (start curing) way too fast, making it nearly impossible to level correctly and leaving you with a streaky mess.

Pro Tip: Always apply ceramic coatings indoors or in a cool, clean, well-shaded area. A controlled environment is your absolute best friend for a flawless finish.

Working on one small area at a time—think a 2×2 foot section of the fuel tank—is the way to go. Apply a few drops to your applicator and wipe it on in a deliberate crosshatch pattern (up-and-down, then side-to-side).

Now, watch closely. You’ll see the carrier solvents evaporate, creating a “rainbow” or oil-slick effect. That’s your signal. It’s time to gently level the coating with a high-quality microfiber towel, then follow up immediately with a second, perfectly clean towel for the final buff.

You’ll need to develop an eye for “high spots”—little dark patches where you’ve left too much product. If you catch them within a few minutes, you can often re-activate the area with a tiny bit more coating on your applicator and wipe it away. For more in-depth tips on this, our guide on how to apply ceramic coating covers the core techniques that apply here, too.

Phase 3: The Curing and Aftercare

You’ve buffed the last panel to a perfect shine, but you’re not done yet. The final phase—curing—is what locks in all your hard work and ensures the coating’s durability.

The coating needs to stay in a dry, stable environment for at least 24-48 hours. This allows the chemical bond to form and the coating to harden. During this window, it is absolutely critical to keep it away from water, chemicals, and even morning dew.

For the next 7-14 days, the coating is still finishing its cure. You should avoid washing the bike with any soaps during this time. If it gets a little dusty or a bird decides to use it for target practice, just gently wipe the spot with a clean microfiber or a dedicated ceramic maintenance spray.

After that initial period, the coating is fully hardened. Your bike’s new, super-hydrophobic armor is now ready for anything the road throws at it. Following this meticulous process, from prep to cure, is what separates a good result from an absolutely extraordinary one.

Long-Term Performance In The Real World

The true test of a ceramic coating for motorcycles isn’t how it looks gleaming in your garage right after you’ve applied it. The real proof comes on day 365, after thousands of miles, brutal heat cycles, and getting caught in a few unexpected downpours. It’s all about real-world resilience, not just a fleeting shine.

Let’s catch up with our rider, Mark, six months after he painstakingly coated his bike with Titan. He just got back from a long highway blast, and his front fairing is a bug graveyard. In the past, this would have been a nightmare of soaking, scrubbing, and frustration. Now? He just gives the area a quick mist with a pH-neutral cleaner and wipes. The bugs slide right off without a fight, leaving zero trace or acidic etching. That deep, wet gloss is still there, looking just as good as it did on day one.

A Year Later And Still Turning Heads

Let’s jump forward to the one-year mark. Mark’s bike has been through it all—blistering summer sun that would melt traditional wax in a few days, frigid winter mornings, and a memorable ride home through a sudden, torrential downpour. He vividly remembers watching the rain hit his tank. Instead of smearing or pooling, it formed these perfect little beads that just flew right off as he kept riding. The water and road grime simply had nothing to hold onto.

This is exactly what a high-quality, flexible coating is supposed to do. A lesser, more rigid coating would have already developed micro-cracks from the constant thermal expansion and contraction of the bike’s metal and plastic parts. But Titan’s unique Elastic coatings, formulated with nano tube technology and Dark Matter tech, are engineered differently. They’re hard as glass but built to be flexible. This elasticity is the secret sauce, allowing the coating to move with the bike and preventing the kind of breakdowns that plague other products.

The real payoff of a premium ceramic coating isn’t just the shine; it’s the freedom. It’s the peace of mind knowing your investment is wrapped in a tough, semi-permanent shield. You get to spend way more time riding and a whole lot less time cleaning.

Preserving That Protection For The Long Haul

Mark quickly realized that keeping that showroom finish was surprisingly straightforward. It didn’t mean he had to constantly wax or polish the bike; it just required a small adjustment to his cleaning routine. A few best practices are all it takes to keep the coating performing at its peak for years to come.

- Two-Bucket Wash Method: He now keeps one bucket for his soapy water and a separate one with clean water to rinse his wash mitt. This simple trick is a game-changer, preventing dirt and grit from being dragged back across the paint.

- pH-Neutral Shampoos: Harsh chemicals are the enemy. Soaps that are too acidic or alkaline will eat away at the coating’s hydrophobic properties. Mark sticks with gentle, pH-neutral formulas designed to clean effectively without stripping away the protection.

- Safe Drying: Old bath towels are out. He now uses a plush microfiber drying towel or an air blower to get the bike dry without introducing swirl marks.

That’s it. This minimal maintenance routine is all that’s needed. The market for ceramic coatings for motorcycles is projected to climb to USD 27.98 billion by 2035, and it’s this combination of incredible protection and easy upkeep that’s fueling the demand. Studies show that bikes with high-end coatings retain up to 95% of their original water-beading ability after two years, which speaks volumes about their durability. You can discover more insights about the growing ceramic coatings market and see where the industry is headed.

How long a coating lasts is a major question for any rider, and for good reason. You can dive deeper into the factors that impact durability in our guide on how long does ceramic coating last. For Mark, the answer is crystal clear: when you use the right product and give it the proper care, the performance is built to last.

Got Questions About Ceramic Coating Your Motorcycle?

Even after getting the rundown on how ceramic coatings work, it’s totally normal to have a few questions rolling around in your head before you take the plunge. We get it. Let’s walk through some of the most common questions we hear from fellow riders, so you can feel 100% confident about giving your bike the best protection out there.

Can I Put This Stuff On More Than Just The Paint?

You bet. In fact, this is where a quality coating really proves its worth on a motorcycle. Our elastomer-based formulas are designed from the ground up to be incredibly versatile.

You can—and absolutely should—apply them to just about everything:

- Painted Surfaces: Your tank, fenders, and fairings are the obvious starting point.

- Chrome & Metal: Think exhaust pipes and engine casings. Our coatings have serious heat resistance, so they won’t back down.

- Wheels & Rims: This makes cleaning off that stubborn brake dust a breeze.

- Plastics & Matte Finishes: It’s a lifesaver for preventing UV fading and discoloration on those tricky surfaces.

Covering the whole bike gives you seamless protection. Everything gets that same slick, water-beading, easy-to-clean finish.

How Is A Motorcycle Coating Different From A Car Coating?

Good question. While the basic idea of nano-technology is the same, a motorcycle is a completely different beast. The sheer complexity of a bike—all those tight corners, weird angles, and mix of materials packed together—demands a coating that’s flexible and easy to work with.

But the real test? The constant vibration and wild temperature swings from the engine and exhaust. This is where most car coatings will literally crack under the pressure. Our Titan coatings are different; they’re elastic. They’re built to flex and move with the bike, so they won’t develop those tiny micro-cracks you see in more rigid coatings. That protective shell stays strong and intact, no matter how hard you ride.

What If I Mess Up During The Application?

It happens to the best of us, but don’t panic. If you catch it quickly, it’s usually an easy fix. You might see a “high spot,” which looks like a darker, slightly oily patch where you left a little too much product.

If you spot one within the first hour or so, just re-apply a tiny bit of coating right over it. This reactivates the solvents and lets you wipe it off cleanly with a fresh microfiber towel. Problem solved.

If you notice it after the coating has cured, you’ll have to break out the machine polisher to level that spot before you can re-apply the coating. This is exactly why we always say: work in small, manageable sections. It’s the secret to getting that perfect, streak-free finish.

Does A Brand New Bike Really Need Paint Correction?

Yes. We can’t stress this enough. Even a bike fresh off the showroom floor often has fine swirl marks from transport or a quick wash by the dealership staff.

Think of it this way: a ceramic coating is like putting a sheet of glass over your paint. It locks in whatever is underneath. By taking the time to do at least a light polish, you’re making sure you’re sealing in a flawless, pristine surface. This single step is what makes the difference between a good result and that jaw-dropping, mirror-like gloss that a ceramic coating for motorcycles is famous for.

Ready to give your bike the tough, long-lasting protection it deserves? The flexible armor of Titan Coatings is engineered to handle the unique demands of a motorcycle while delivering a shine that has to be seen to be believed.

Check out our full lineup of elastomer-based coatings and find the perfect shield for your ride at Titan Coatings.

0 Comments