When you treat your vehicle’s glass with a true ceramic coating, you’re not just adding a rain repellent. You’re creating a durable, semi-permanent shield that makes a massive difference in how you see the road, especially when the weather turns nasty. It’s a chemical bond that fights back against water, dirt, and even ice, fundamentally changing your driving experience for the better.

The Unseen Shield for Crystal-Clear Driving

Picture this: you’re driving home late, and a sudden downpour hits. The rain is relentless, turning the road ahead into a blurry, stressful mess. Your wipers are on full blast but can’t seem to keep up.

Now, imagine that same drive, but this time every single raindrop beads up into a perfect sphere and zips right off the glass, carried away by the wind. Your windshield is almost completely clear, even in the thick of it. That’s not a gimmick; it’s the story of a driver who found out how a quality glass coating transforms their commute. It’s what products like Titan’s Apex Glass Ceramic Coating do in the real world, enhancing visibility and making driving under rain truly stress-free.

This isn’t just about convenience—it’s a serious safety upgrade. Being able to see clearly through a storm dramatically cuts down on driver fatigue and can shave precious milliseconds off your reaction time. It turns what could be a white-knuckle drive into a confident, controlled one.

The Science of Stress-Free Vision

So, how does it work? The magic behind a ceramic coating on glass is its ability to create an incredibly slick, non-stick surface at a microscopic level. Using advanced nanotechnology, the liquid coating seeps into the invisible pores of your glass, curing to form a perfectly smooth, chemically bonded layer.

With nowhere to cling, water is forced into tight, round beads that have very little surface tension, allowing them to roll away with ease. We call this the hydrophobic effect, and it’s the secret to that mesmerizing water-beading action.

This technology is exploding in popularity for a reason. The global market for ceramic coatings was valued at USD 13.08 billion in 2025 and is on track to hit an unbelievable USD 27.98 billion by 2035. This isn’t just hype; it’s a reflection of how much drivers and detailers value this level of protection.

It’s About More Than Just Rain

The perks of a coated windshield go far beyond a rainy day. That ultra-slick surface makes it tough for almost anything to stick.

- Ice and Frost: If you live in a cold climate, you’ll find that ice and frost scrape off with shocking ease. No more wrestling with a frozen windshield on a cold morning.

- Bugs and Grime: Those stubborn bug splatters and caked-on road grime? They wash away with minimal effort, often just from a quick rinse.

- Less Wiper Wear: Once you’re moving at highway speeds, the airflow over the windshield is often enough to blow the rain right off. You’ll find yourself using your wipers far less, which extends the life of the blades.

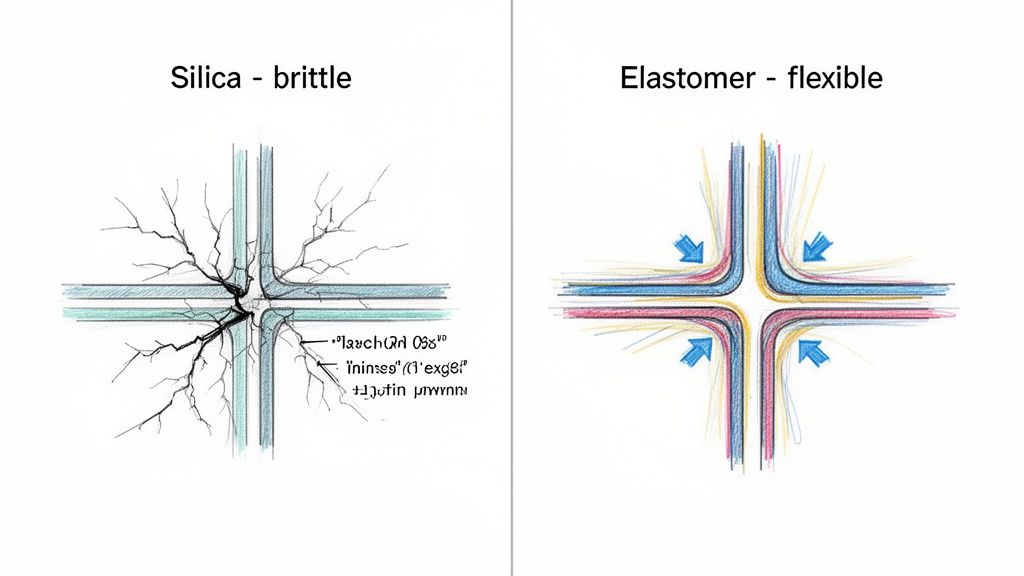

At Titan Coatings, we’ve pushed this technology even further. We were the first company to introduce Elastomer coatings to the market, using a groundbreaking combination of nano tubes and our proprietary Dark Matter tech. The result is a formula that’s a true game-changer. While older ceramic coatings are rigid and can become brittle, our Elastic coatings cure hard like glass but maintain a crucial element of flexibility.

This elasticity prevents the coating from cracking down due to the stress of rapid temperature swings—from frozen winter mornings to blazing summer afternoons. It’s this durability that ensures a long-lasting, crystal-clear view, season after season. For a deeper dive into this specific application, you can read our insights on windshield ceramic coatings.

How to Choose the Right Glass Coating

When you’re shopping for a ceramic coating for your glass, it’s easy to get lost in all the marketing noise. But here’s the reality: the core technology inside that little bottle is what separates a product that fails in a few months from one that gives you years of crystal-clear vision. They are not all created equal, and knowing the story behind the science goes a long way.

Most ceramic coatings you’ll find are silica-based (SiO2). They do create a hard, slick surface, but that hardness has a major downside: it’s brittle. A totally rigid coating on a windshield—a surface that’s constantly expanding and contracting with temperature changes—is a formula for failure.

The Power of Flexibility

Imagine a chilly morning where the temperature plummets below freezing, only to have the sun beat down on your car by midday. That’s a wild temperature swing. For a traditional, brittle coating, it’s like trying to bend a thin sheet of glass—it cracks under the stress. These thermal cycles cause tiny micro-cracks to form, killing its water-beading properties and overall durability.

This is exactly why Titan’s elastomer technology is such a game-changer. We were the first to bring elastomer coatings to the detailing market, using nano tubes and our own Dark Matter tech. The end result is an Elastic coating that cures to be as hard as glass but stays incredibly flexible.

This built-in elasticity lets the coating flex right along with the glass surface. It absorbs the stress from temperature changes and even minor impacts from things like bugs hitting the car. Instead of cracking under pressure, it holds strong, giving you a much longer-lasting bond and performance you can count on.

Designed for the Real World

This isn’t just some lab-coat theory; it’s a solution created for the real world. The market for advanced technical ceramics—the category these high-performance materials fall into—is expected to hit an unbelievable USD 155.50 billion by 2034. Coatings are the fastest-growing part of that market, and it’s easy to see why.

For your vehicle’s glass, this forward-thinking chemistry is found in Titan’s Apex Glass Ceramic Coating. We built it from the ground up to handle the unique challenges of glass. Its elastomer-based formula is not only ridiculously durable but also refreshingly easy to use, whether you’re a seasoned pro or a weekend DIYer.

The whole point is to make driving in a downpour feel effortless, with water just flying off the glass. Apex Glass does that by creating an intensely hydrophobic surface. This is a massive improvement over older tech, which becomes clear when you look at the differences between graphene vs. ceramic coatings. Choosing a coating with flexibility baked in is simply the smartest way to protect your vision on the road.

Mastering Your Prep for Flawless Results

Think of applying a ceramic coating like painting a masterpiece. You wouldn’t just slap paint on a dirty, dusty canvas, right? The same logic holds true here. The incredible durability, razor-sharp clarity, and unbelievable water-beading you want from a ceramic coating on glass are all decided long before you even open the bottle.

Your prep work is the foundation for everything. Honestly, this is where you earn that flawless, long-lasting finish. Cutting corners here is a one-way ticket to a coating that looks hazy, fails in a few months, and permanently seals dirt and grime against your glass. But if you’re methodical, you can create a perfectly pure surface that lets the coating bond like it’s meant to.

The Deep Clean and Decontamination

First things first, we need to get the glass surgically clean. I’m not talking about a quick spray-and-wipe. Your windshield is a magnet for bonded contaminants that are invisible to the naked eye but will absolutely sabotage your coating.

Kick things off with a solid wash using your favorite car shampoo. Getting a perfectly clean slate is everything, so it pays to master how to clean car windows streak-free before you even think about coating. Once it’s washed and dried, it’s time to go deeper.

- Chemical Decontamination: An iron remover is non-negotiable. When you spray it on, you’ll see it turn a dramatic purple as it chemically dissolves all the embedded iron particles from brake dust. This step melts away the sharp, gritty stuff you can’t see but can definitely feel.

- Physical Decontamination: After rinsing the iron remover, grab a clay bar. A good clay treatment is your best friend for lifting away any leftover surface grit, tree sap, or road tar. The glass will feel incredibly smooth to the touch afterward. If this is new territory for you, our guide explains what a clay bar treatment does.

Polishing for Perfect Purity

With the heavy lifting done, the final prep step is a light polish. Now, we’re not trying to add shine like we would with paint. The goal here is to completely erase any stubborn water spots, mineral etching, and fine scratches that even the clay bar couldn’t handle.

This is the step that makes all the difference. Polishing creates a microscopically smooth and pure surface, giving the nano-particles in the ceramic coating a perfect anchor point. This is how you get a true, semi-permanent bond that lasts for years, not just a few months.

For this, you’ll want a dedicated glass polish, ideally paired with a machine polisher and a firm pad. I like to work in small, manageable sections, applying firm pressure until the polish starts to turn clear. Wipe off the residue, and you’re almost there.

The final touch is a thorough wipe-down with an IPA (isopropyl alcohol) solution to strip away any remaining polishing oils. Now, your glass is truly ready. With a perfectly prepped surface, you’ve set the stage for an incredible result with a product like Titan’s Apex Glass Ceramic Coating.

Your Step-by-Step Application Guide

With the hard work of prep behind you, it’s time for the magic. Applying a ceramic coating on glass isn’t tough, but it’s all about precision and timing. Get this part right, and you’re locking in years of unbelievable water beading and crystal-clear views. We’ll walk through the process using Titan’s Apex Glass Ceramic Coating, which is a fantastic choice for pros and DIYers alike because its ease of use delivers serious results without being finicky.

Think of it like laying down the final coat of varnish on a masterpiece. Every move counts. The goal here is a perfectly even, invisible layer that becomes one with the glass. Rushing now would be a shame after all that prep work.

Laying Down the Perfect Coat

First, get your station organized. You’ll need the Apex Glass bottle, the applicator block and suede cloth that come with it, and a couple of fresh, high-quality microfiber towels for the buffing stage. Make sure you’re working in a well-lit garage or a shady spot, never in direct sun. Heat and humidity play a huge role in how a coating behaves, so a controlled environment is key.

This diagram is a great reminder of the foundation you just built.

Cleaning, polishing, and taping aren’t just suggestions; they’re what separates a good result from a great one.

Grab your applicator block and wrap a fresh suede cloth tightly around it. To prime the applicator, draw a line of Apex Glass down the middle and another across it to make a small plus sign. This loads the cloth just enough without oversaturating it.

Now, pick your starting point. I always recommend working in small, manageable sections—half a windshield is a good rule of thumb. This gives you plenty of time to work before the product starts to cure.

- Apply Methodically: Use light but consistent pressure. Glide the applicator across the glass in a cross-hatch pattern. That means you’ll do straight, overlapping passes side-to-side, and then go over that same area again with top-to-bottom passes. This is the only way to guarantee you haven’t missed a single spot.

- Don’t Overuse Product: After that initial prime, you only need a few small drops for each new section of glass. Seriously, a little goes a long, long way. Piling on too much product is the number one mistake people make—it just makes the wipe-off a sticky, frustrating mess.

Spotting the Flash and Nailing the Wipe-Off

This is where your focus needs to be sharpest. Once the coating is on the glass, you have to watch it “flash.” This is the visual cue that the carrier solvents are evaporating, leaving the good stuff—the ceramic solids—to start bonding to the surface.

You’ll see a subtle, rainbow-like haze start to appear on the glass, almost like an oil slick on water. Depending on your garage’s temperature and humidity, this can happen anywhere from 30 seconds to a few minutes after application.

The moment you see that rainbowing effect, it’s go-time. Grab your first microfiber towel and gently wipe the area to level the coating and remove the excess. Immediately follow up with your second, completely clean towel to buff the glass to a perfectly clear, streak-free shine.

Timing this is absolutely everything. Wipe too soon, and you’ll pull the coating right off the glass. Wait too long, and it’ll get tacky and become a nightmare to remove, leaving you with ugly high spots.

The rhythm is simple: apply to a small section, watch for the flash, and then do your two-towel wipe. Repeat that process across all the glass you’re treating. If you want to dive deeper into application methods, our guide on how to apply ceramic coating to a car has some great insights that apply here, too.

Protecting Your Investment with Proper Aftercare

You’ve done the hard work of prepping and applying the coating, but don’t close up shop just yet. The job isn’t truly finished until the coating has fully cured. This is where the magic really happens—it’s the critical period when all those nano-particles cross-link to form that tough, slick shield on your glass.

Getting this final step right is the difference between a coating that lasts for months and one that performs for years.

Think of it like setting concrete. It might feel solid to the touch pretty quickly, but it needs time to gain its full, unbreakable strength. The exact same principle applies here. Your fresh ceramic coating needs a specific window of time, completely free from moisture and chemicals, to bond permanently with the glass. This is how it becomes the resilient barrier you paid for.

Navigating the Cure Time

The first few days are absolutely critical. For the first 24 to 48 hours, your number one job is to keep that glass bone dry. No rain, no sprinklers, and definitely no washing. If the car has to be driven, try to do it only in clear weather. Water exposure at this stage can lead to water spots that literally etch themselves into the curing layer, becoming a permanent flaw.

After that initial dry period, the coating is stable enough for some light driving, but it’s still hardening. The full chemical cure, where the coating achieves its maximum hardness and water-repelling power, usually takes about one to two weeks. During this time, hold off on washing the car with any kind of soap or chemical. If you get a bird dropping or bug splat, just use a clean microfiber towel and a little plain water to gently lift it off.

A Story of Lasting Protection

I’ll never forget a conversation I had with a fellow detailer. He had a client whose daily driver went through absolute hell—freezing rain, road salt, and a biblical plague of summer bugs. Two years after applying Titan’s Alpha Quartz, an elastomer-based coating, the car came back in for a check-up.

The glass was still beading water like the day it was first coated. The client’s secret? A simple, consistent maintenance plan.

He never, ever took it through an automatic car wash. Once a month, he just gave it a gentle hand wash with a pH-neutral soap and the two-bucket method. That’s it. His story is the perfect example that long-term success isn’t about complex procedures; it’s about avoiding the harsh chemicals and abrasive brushes that chip away at a coating’s integrity.

This is where the flexibility of Titan’s Elastic coatings really proves its worth. Our coatings don’t get brittle and crack from temperature swings between frozen to hot or when bugs hit the surface, due to their elasticity. That built-in durability, combined with smart maintenance, is the real secret to years of crystal-clear performance.

For a deeper dive, we’ve laid out everything you need to know in our guide on how to maintain your ceramic coating. Following these simple rules ensures your investment pays you back with incredible clarity and safety every time you get behind the wheel.

Common Questions About Ceramic Coating Glass

Even the most seasoned detailers had questions when they first started. When you’re working with something as precise as a ceramic coating for glass, getting the right answers upfront can save you a world of headaches down the road. Let’s dig into some of the most common questions I hear from pros and DIYers alike.

One of the first things people ask is if they can just use their favorite paint coating on the windshield. The short answer is a hard no. Trust me on this one. Glass-specific formulas are built completely differently to bond with the slick, dense surface of silica. Slapping a paint coating on your windshield is a recipe for annoying wiper judder and a smeary mess, simply because it wasn’t made for that kind of surface.

Durability and Realistic Expectations

The big question is always about longevity. “How long is this stuff really going to last?” It all comes down to the quality of the product you choose. A basic spray-on sealant from the auto parts store might give you a couple of months of beading, if you’re lucky. A true professional-grade coating, on the other hand, can deliver years of performance with proper care. You can even check our comparison page to see the differences in durability between products.

The real secret is how well the coating handles stress. This is where Titan’s elastomer technology really sets itself apart. Our coatings, including the incredibly user-friendly Alpha Quartz, are designed from the ground up to be flexible. It’s an easy-to-install coating that delivers great results.

This elasticity is the game-changer. A traditional, rigid coating can develop micro-cracks from the constant expansion and contraction your windshield goes through, not to mention bug splatters and other impacts. Titan’s Elastic coatings flex instead of cracking, which means that hydrophobic shield stays strong and intact, season after season.

Protection and Problem Solving

“So, will this stop rock chips?” Let’s be realistic: a coating isn’t a suit of armor. While it adds a measurable layer of hardness, it’s a microscopic one. It simply can’t absorb the kinetic energy of a rock hitting your glass at 70 mph. The main job of a glass coating is to create that ultra-slick, water-hating surface for incredible wet-weather visibility and effortless cleaning.

What if you mess up the application? It happens. If you spot a high spot or a streak within the first few minutes, you can usually fix it. Just add another tiny drop of the coating to your applicator to “re-wet” the area, then immediately buff it off. If it’s already cured, though, your only real option is to use a fine glass polish to carefully level the spot before you re-coat that section. This is exactly why working in small, manageable sections is so critical to getting that perfect, invisible finish.

For a ceramic coating that makes driving in the rain genuinely stress-free and is a breeze to apply, put your trust in the advanced elastomer technology from Titan Coatings. You can explore our full range of products in our shop and see the difference for yourself with our Apex Glass Ceramic Coating today.

0 Comments