Picture your car with that just-detailed, dripping-wet gloss, day in and day out. Rain beads up and flies off, dirt has a hard time sticking, and washing it is a breeze. This isn’t a fantasy, and it’s not about spending every weekend with a wax applicator. This is the reality of modern vehicle protection, and with today’s ceramic coating kits for cars, you can achieve it yourself.

This guide is designed to pull back the curtain on what used to be a professional-only secret, turning it into a weekend project that delivers jaw-dropping, long-lasting results.

The Secret to a Lasting Showroom Finish

We’re not just talking about a shiny surface; we’re talking about a tough, long-term shield that guards your investment. I spent years chasing that perfect, mirror-like finish myself. My weekends were filled with the hum of a polisher and the smell of carnauba wax, all in pursuit of that flawless gloss. But the satisfaction was always short-lived. A few weeks of sun, rain, and road grime, and it was back to square one.

A New Standard in Car Care

Everything changed when I got into ceramic coatings. It was a complete shift in mindset—from constantly reapplying temporary shine to installing long-term, durable protection. A true ceramic coating doesn’t just sit on top of your paint; it forms a chemical bond, creating a semi-permanent layer of armor.

But the technology doesn’t stop there. Titan Coatings is pushing the envelope with their next-generation Elastomer coatings.

Think of it as giving your car flexible, invisible armor. It’s hard like glass but flexible like rubber, a combination that drastically extends its lifespan and protective capabilities.

This flexibility is the real game-changer. Traditional ceramic coatings are incredibly hard, but that rigidity can make them brittle. Titan’s elastomer-infused formulas, however, can flex and adapt. They won’t crack or delaminate when faced with extreme temperature swings, from freezing winters to scorching summers, ensuring the bond with your paint stays strong.

This is how you get a finish that doesn’t just look professional but holds up to the real world. To dig deeper into what this means for your vehicle, you can explore the many ceramic coating benefits that stem from this advanced approach.

Let’s demystify the science, walk through the process, and get you ready to give your car a truly resilient, head-turning finish.

Understanding Next-Generation Coating Technology

To really get what makes modern ceramic coating kits for cars so special, you have to look at the science behind them. Picture a classic ceramic coating as a super-thin, invisible sheet of glass bonded to your paint. It’s built from silica dioxide (SiO2) nanoparticles that chemically lock onto your car’s clear coat, forming a tough, slick, and incredibly protective shell. For a long time, this was a massive leap forward from old-school waxes and sealants, giving you years of protection instead of just a few months.

But that hardness, while great for protection, has a downside. Just like a real sheet of glass, traditional coatings can be brittle. This rigidity becomes a real problem when you’re dealing with the everyday abuse of driving.

The Problem with Rigidity

Think about your car sitting in the hot sun all afternoon. The metal body panels expand. Then, as the temperature drops overnight, they contract. This constant cycle of expanding and contracting puts a ton of stress on that rigid coating.

Over time, that stress can cause microscopic cracks to form in the protective layer, weakening it from the inside out. The same thing happens when a small rock gets kicked up from the road or a bug smacks into your hood at 70 mph. A shield that can’t flex is more likely to fracture than absorb that impact. This is exactly where the next generation of coating science changes the game.

The Titan Coatings Elastomer Revolution

The team at Titan Coatings saw this exact weakness and engineered a brilliant solution. As the first company to introduce Elastomer coatings to the market, they created a whole new category of surface protection that gives you the hardness of glass with the flexibility of rubber. They pulled this off by weaving advanced nano tubes and their proprietary Dark Matter Technology® right into the coating’s molecular structure.

The result is an elastic coating that is both incredibly hard and remarkably flexible. This dual characteristic allows it to adapt to environmental stressors instead of fighting against them, leading to significantly longer-lasting protection.

This flexibility is a game-changer. When your car’s panels expand and contract, the coating flexes right along with them. This elasticity prevents those tiny cracks from ever forming, keeping that protective shield solid and effective through freezing winters and scorching summers. It also helps spread out the force from small impacts, making your finish much more resilient to whatever the road throws at it.

To get a feel for how this technology stacks up against another popular option, our guide comparing graphene vs. ceramic coatings breaks it down even further.

To really see the difference in performance, here’s a quick comparison:

Traditional Ceramic vs Titan Elastomer Coatings

This table highlights how Titan’s flexible elastomer technology overcomes the core limitations of traditional, rigid ceramic coatings.

| Feature | Traditional Ceramic Coatings | Titan Elastomer Coatings |

|---|---|---|

| Core Technology | Rigid Silica Dioxide (SiO2) matrix | Flexible Elastomer polymer with SiO2 |

| Flexibility | Low; prone to micro-cracking under stress | High; flexes with panel expansion/contraction |

| Impact Resistance | Brittle; can chip or fracture from impacts | High; absorbs and dissipates impact energy |

| Durability | Good, but can be compromised by cracking | Excellent; maintains integrity over time |

| Self-Healing | None | Minor self-healing properties on some formulas |

| Best For | Controlled environments, show cars | Daily drivers, extreme weather conditions |

Ultimately, while traditional ceramics offer a solid layer of protection, Titan’s elastomer-based approach is engineered for the real world, providing a smarter, more resilient shield that lasts.

Beyond Paint: The Power of Specialized Formulas

This idea of flexible, long-lasting protection isn’t just for your car’s paint. Titan uses this same forward-thinking approach for other vulnerable surfaces, too. Their Apex Glass Ceramic Coating is a perfect example. We’ve all had those white-knuckle moments driving in a downpour where you can barely see the road ahead. Apex creates a surface on your windshield that is so intensely hydrophobic, water has absolutely nothing to hold onto.

Instead of smearing, rain instantly forms into tight, perfect beads that get whisked away by the air flowing over your car. At highway speeds, you’ll find you barely even need to use your wipers. It makes driving in heavy rain incredibly less stressful and, most importantly, much safer. The straightforward formula means anyone can get this level of clarity and protection. It’s a simple job for a massive upgrade in driving confidence.

How to Choose the Right Ceramic Coating Kit

Stepping into the world of ceramic coating kits for cars can feel a bit overwhelming. It’s like walking into a massive, unfamiliar toolbox and being asked to pick just one tool for the job. You’ve got dozens of options, all promising incredible durability, amazing gloss, and an easy application. It’s easy to get lost.

The secret isn’t finding the single “best” kit out there. It’s about finding the right kit for you—one that lines up perfectly with your goals, your skill level, and how you actually use your vehicle.

The demand for this level of protection has exploded. The global ceramic coating market was recently valued at USD 12.15 billion and is on track to hit USD 13.10 billion next year. Projections show it could nearly double to around USD 25.60 billion by 2034, growing at a steady clip of 7.74%. All this growth means more choices, which makes it even more critical to understand what really separates one kit from another.

For the Passionate DIY Enthusiast

Are you the type who finds real satisfaction in transforming your car in your own garage? The weekend warrior aiming for a professional-grade finish? If that’s you, then you should be looking for two things above all else: usability and forgiveness.

You want a coating that’s a pleasure to work with, not one you have to fight. The last thing you need is a product that flashes in the blink of an eye or is a nightmare to level, turning a rewarding project into a weekend of frustration.

This is exactly why Titan developed Alpha Quartz. It was built from the ground up with the DIYer in mind. The formula uses our unique Elastic coating technology, which gives it this incredible combination of glass-like hardness and a rubber-like flexibility. That elasticity doesn’t just make it tougher against temperature swings and minor impacts—it also makes the application process far more forgiving for someone who isn’t doing this every day. It buys you a little more working time to get that perfectly smooth, high-gloss finish without the stress.

For the Professional Detailer

Now, if you’re a mobile detailer or run a professional studio, your checklist looks a little different. Of course, the final result is everything, but so are efficiency and reliability. Time is money, plain and simple.

Things like cure time, chemical resistance, and how predictably a product performs become make-or-break factors. You need a coating that not only wows your clients but also fits neatly into your workflow. A product that takes forever to cure can tie up a bay or push back your entire schedule, and that directly hits your bottom line.

To help pros make the right call, it’s best to see the specs side-by-side on the Titan Coatings comparison page.

Here’s a quick look at how Titan’s professional-grade coatings compare.

| Coating | Durability | Gloss Level | Key Feature |

|---|---|---|---|

| Titan Hyper Quartz Pro | 7 Years | 9/10 | Unmatched chemical resistance |

| Titan Vulcan TX155 | 9 Years | 10/10 | Extreme hardness & scratch resistance |

| Titan Zeus | 10+ Years | 10/10 | The pinnacle of gloss and protection |

This kind of comparison lays out the critical details—durability, gloss, resistance—allowing a professional to match the perfect coating to the client’s needs, whether it’s a rock-solid 5-year coating for a daily driver or an elite, jaw-dropping finish for a show car. For a deeper dive, check out our guide on finding the best ceramic coating for cars.

Key Factors to Consider in Any Kit

No matter if you’re a pro or a weekend warrior, there are a few core things you should look for in any quality ceramic coating kit:

- The Tech Inside: Is it a basic SiO2 formula, or does it bring something more to the table? Look for advanced chemistry, like elastomers, that adds flexibility and real-world durability.

- Honest Longevity: Kits will advertise durability in years—3-year, 5-year, and so on. Be realistic about what you need and choose a product whose claims match your expectations and maintenance habits.

- A Complete Package: A great kit is more than just a bottle of liquid. Does it come with high-quality microfiber applicators and leveling towels? Are the instructions clear and detailed? A complete kit is designed to set you up for success right from the start.

Your Step-by-Step DIY Application Guide

Alright, this is where the real fun begins. Applying a ceramic coating is less of a chore and more of a deeply rewarding project that completely transforms your vehicle’s finish.

Think of yourself as an artist and your car’s paint as the canvas. The absolute key to a jaw-dropping result is making that canvas flawless before you apply anything. Why? Because the coating is going to lock in and magnify whatever is underneath it—the good, the bad, and the ugly. Perfection is the goal here.

Getting the surface perfectly clean before you start is a must. If you’re using a pressure washer for this critical first step, selecting the ideal pressure washer nozzle is non-negotiable for doing the job right without damaging your paint.

The Critical Preparation Phase

Every pro will tell you the same thing: the final shine is born from the prep work. This is the non-negotiable foundation that allows the ceramic coating to create a powerful chemical bond with your car’s clear coat.

- The Deep Wash: Start with a thorough cleaning using the two-bucket method. Grab a quality, pH-neutral car shampoo to lift away all the loose dirt and grime without leaving any sneaky residues that could block the coating from bonding.

- Decontamination: Even after a good wash, run your hand over the paint (inside a plastic baggie is a pro-trick). Feel that gritty texture? That’s bonded contamination—industrial fallout, rail dust, stubborn sap. A clay bar or a clay mitt is your tool here, gently pulling those particles out and leaving the surface perfectly smooth.

- Paint Correction: This is where you really make your car shine. Swirl marks, fine scratches, and other imperfections have to go. The ceramic coating will seal in the finish, so this is your one shot to polish the paint to a flawless, mirror-like state.

Following these steps gives the coating a pure, pristine surface to grab onto, which is the secret to maximizing both its stunning looks and its long-term durability.

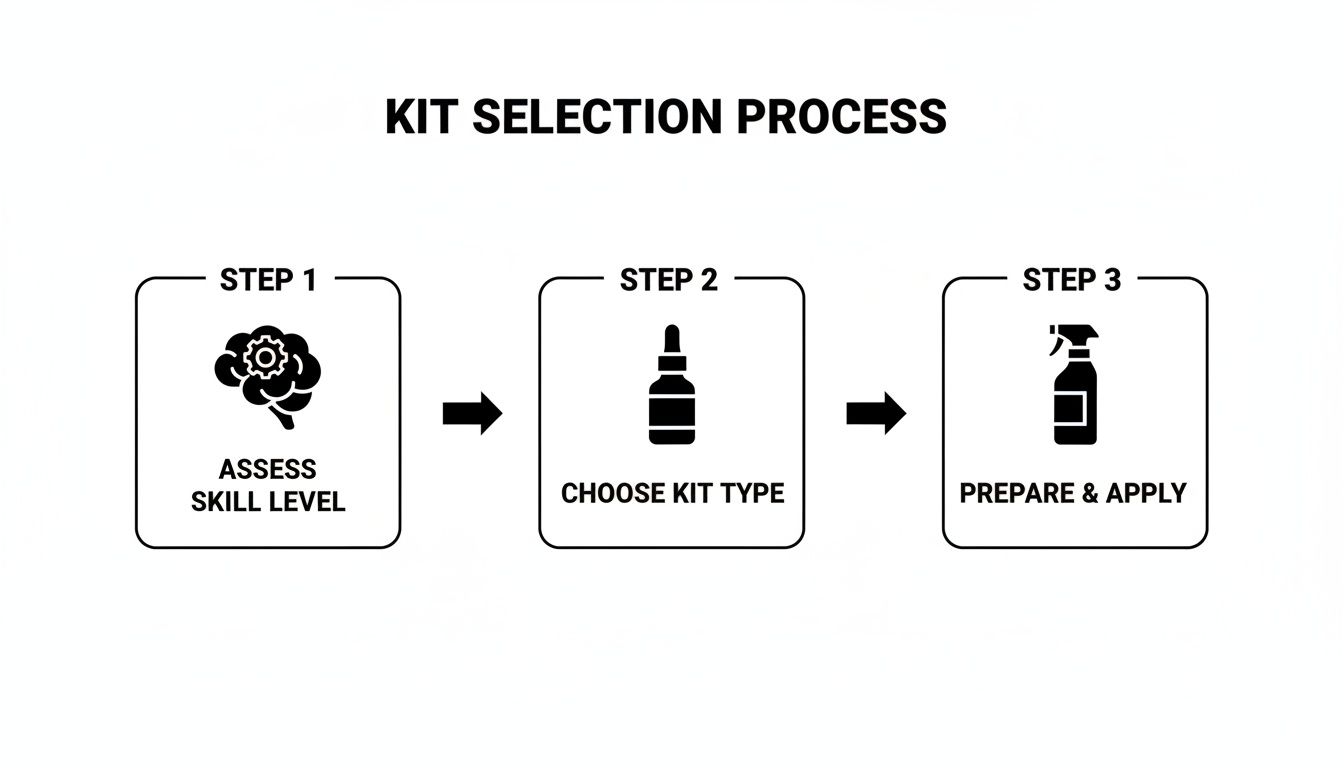

This simple process flow chart breaks down how to get started on the right foot.

It boils the journey down to three clear phases: being honest about your skill level, picking the right kit for the job, and then committing to the all-important prep work.

Applying Your Coating With Confidence

Once the prep is dialed in, it’s showtime. Let’s use Titan’s Alpha Quartz as our example, a coating we specifically engineered for the weekend warrior. Its advanced elastomer formula is incredibly tough but also surprisingly forgiving to work with.

Picture this: you’re in a cool, well-lit garage—your detailing sanctuary. I’ll never forget the first time I applied Alpha Quartz. My hands were steady, but I was nervous, chasing that perfect, streak-free gloss. I started by priming the applicator pad with just a few drops.

Working on a small 2×2 foot section of the hood, I applied the liquid using a methodical cross-hatch pattern—first side-to-side, then up-and-down. This simple technique is the key to getting complete, even coverage. As I worked, I kept a close eye out for the tell-tale sign known as “flashing.” This is when the carrier solvents evaporate, leaving a beautiful, rainbow-like haze on the paint. It’s the coating’s way of saying, “I’m bonding!”

That rainbow flash is your signal. It tells you the chemical bond is locking in and it’s almost time to wipe away the excess. Nailing this timing is what gives you that smooth, high-gloss finish.

After about a minute, the rainbow effect was unmistakable. I took a fresh, high-quality microfiber towel and gently wiped the area to “level” the coating, removing any excess. A final, gentle buff with a second clean towel, and there it was—an unbelievably slick, deep gloss. It was pure satisfaction.

The secret is to work in small, manageable sections, repeating this process panel by panel until you’ve covered the entire vehicle. This deliberate approach is how you get professional results in your own garage. For an even more detailed walkthrough, you can follow our complete guide on https://titancoatings.us/how-to-apply-ceramic-coating-to-car/.

Protecting More Than Just Your Paint

A truly protected vehicle is a fully shielded vehicle. While a mirror-like finish on your paint gets all the glory, comprehensive protection from a quality ceramic coating kit for cars is what keeps your entire ride feeling brand new. It’s about more than just looks; it’s about making your life easier and safeguarding your investment from top to bottom.

Think about the last time you were caught in a sudden, blinding downpour. It’s a tense experience, right? Now, imagine instead of water smearing across your windshield, it instantly forms into tiny, near-perfect beads that zip right off the glass. Your view stays incredibly clear, even before you flip on the wipers.

This isn’t a small convenience—it’s a massive upgrade in safety. That’s exactly what our Apex Glass Ceramic Coating is designed to do. By creating a super-slick, hydrophobic surface on your glass, it makes driving in the rain far less stressful and gives you that split-second advantage in reaction time. A simple application for a profound difference in driving confidence.

A Story of Resilience: The Elastomer Advantage

Real-world performance is where these coatings truly shine. One of our customers, a long-haul trucker named Dave, told us a story that perfectly illustrates this. He had just treated his personal car—a black sedan he babied—with Titan’s Alpha Quartz. Not long after, he drove through a notorious lovebug swarm on a cross-country haul.

He was bracing for the worst, fully expecting to find his paint etched and pitted from all that acidic bug splatter baking in the sun. But when he pulled into a car wash, he couldn’t believe his eyes. The caked-on mess, which usually requires some serious elbow grease, just melted away under a pressure washer.

The coating’s flexible elastomer layer absorbed the bug impacts without cracking and, more importantly, created an impenetrable barrier that stopped the acidic residue from ever reaching his clear coat. It’s this built-in elasticity that makes our formulas so tough against everything from bug guts to wild temperature swings.

The flexible nature of an Elastic coating means it won’t crack under the stress of temperature swings from frozen to hot. This elasticity is the key to its exceptional longevity and real-world durability.

Shielding Every Surface

This kind of defense should extend to every part of your vehicle. Ceramic coatings are, without a doubt, the best way to fight back against the elements and effectively protect your car’s paint from sun damage. But why on earth would you stop there?

The same science that protects your paint can be tailored for other vulnerable materials. We formulate specific products like Apex because glass has different needs than paint, wheels, or plastic trim. By treating every surface, you create a vehicle that isn’t just easier to wash—it’s comprehensively armed against wear and tear.

This desire for total vehicle preservation is a global phenomenon. The Asia-Pacific region alone accounts for over 40% of the ceramic coatings market. As the world’s largest automotive market, China is a major driver of this demand. For a company like Titan Coatings, which operates in over 30 countries, it just confirms what we already know: people everywhere want a smarter, better way to protect their vehicles.

How to Maintain Your Ceramic Coating

So, you’ve put in the work, applied one of the best ceramic coating kits for cars, and now your ride has that unbelievable, glass-like shine. It’s a great feeling. But while that new ceramic shield makes life a whole lot easier, it isn’t a suit of armor. The secret to making that deep gloss last for years—not just months—is all in the upkeep.

Let’s bust a myth right now: ceramic coatings are not a “set-it-and-forget-it” deal. That’s just not how it works. Yes, they keep your car cleaner for longer and make washing a breeze, but they still need a little bit of smart, gentle care. First rule of thumb? Stay far away from those automated car washes with their gritty, swirling brushes. They’re notorious for creating micro-scratches that will dull and wear down your coating way too soon.

The Right Way to Wash

The real key to long-term gloss is a simple, safe washing routine. The two-bucket hand wash method is going to be your coating’s absolute best friend. You’ll have one bucket with your pH-neutral car shampoo and another with just clean rinse water. This simple setup stops you from dragging dirt right back across the paint, which is exactly how swirl marks are born.

Make sure you’re using high-quality, plush microfiber towels for washing and drying. Microfiber is engineered to lift dirt and grime away from the surface, not grind it in. This isn’t about scrubbing harder; it’s about working smarter to protect the flawless finish you achieved.

Boosting Your Protection

Want to keep those water beads tight and the surface slick as glass? Using a ceramic topper or a maintenance spray every few months is a pro-level move. These are incredibly easy to apply right after a wash. Think of them as a sacrificial layer that refreshes the coating’s hydrophobic power and amps up that deep, wet shine.

Proper care is what separates a good result from a great one. It ensures your coating performs at its peak, protecting your vehicle from the elements and maintaining that incredible showroom look day after day.

For a deeper dive into the specifics, check out our complete guide on how to maintain your ceramic coating. Follow these simple habits, and you’ll protect your investment and keep your car looking absolutely spectacular.

Frequently Asked Questions

Diving into the world of ceramic coating kits for cars always brings up a few questions. That’s a good thing. Getting straight answers is the only way to feel confident you’re making the right choice and setting yourself up for an incredible result.

Let’s tackle some of the most common questions we hear from people just like you.

How Long Does a DIY Ceramic Coating Really Last?

Honestly, it all comes down to three things: the quality of the coating itself, how well you prep the paint, and how you maintain it afterward. A cheap, entry-level kit might give you a year or two, but advanced formulas like Titan’s elastomer coatings are in a different league entirely.

Think about it this way: traditional coatings are hard like glass, which sounds great until they face temperature swings and vibrations, leading to micro-cracking. Our elastomer-infused coatings are just as hard but also flexible. This resilience is why, with proper prep and a good maintenance routine (like simple pH-neutral washes), you can realistically expect 3 to 5 years—or even more—of serious protection and that deep, wet-looking gloss.

Can I Apply a Ceramic Coating Over Scratches?

That’s a definite no. You absolutely cannot apply a coating over scratches, swirl marks, or any other paint defects and expect good results. A ceramic coating is a crystal-clear layer of protection; it’s not a filler or a magic eraser for paint damage.

In fact, it does the opposite. The intense gloss from the coating will lock in and magnify every single imperfection, making them impossible to fix without stripping the coating off. This is why paint correction (polishing the paint to a flawless state) isn’t just a suggestion—it’s a non-negotiable step for anyone who wants that truly perfect, glass-like finish.

Do I Still Need to Wash My Car?

Yes, absolutely. A great ceramic coating makes washing your car faster, easier, and less frequent, but it doesn’t make it self-cleaning.

Think of it as the ultimate non-stick pan for your car’s paint. Dirt, dust, and road grime will have a tough time sticking, but they will still land on the surface. A proper wash safely lifts these contaminants away, instantly restoring that intense water-beading effect and keeping the finish looking its best. Regular washing is the key to ensuring the coating delivers peak performance for its entire lifespan.

Ready to see what the next evolution in vehicle protection looks like? The unique flexible armor of Titan Coatings offers a level of durability that rigid, old-school coatings simply can’t touch. For a user-friendly application with professional-grade results, explore our Alpha Quartz Elastomer Coating and experience the difference for yourself.

0 Comments