When you hear “ceramic coating,” you might think of cars, but for a boat, it’s a whole different ballgame. A professional marine ceramic coating isn’t just a polish; it’s a semi-permanent, hardened shield for your vessel’s gelcoat. It goes leagues beyond the temporary gloss of old-school waxes by creating a tough, chemical-resistant, and UV-blocking layer that keeps your boat looking new for years, not just a few months.

Think of it as a long-term investment in your boat’s health and your own peace of mind.

Why Your Boat Deserves More Than Just Wax

If you’re a boat owner, you know the drill. You spend a whole weekend waxing and polishing, getting that gelcoat to gleam, only to watch the sun, salt, and grime dull it down in no time. It’s a frustrating, back-breaking cycle that eats up the precious time you’d rather spend out on the water.

I’ve talked to countless seasoned mariners who were just plain tired of fighting this losing battle. They’d put in the hours, apply the best waxes, and still watch their boat’s finish get chalky and faded season after season. Their search for something better—something that actually lasts—is what led them away from traditional products and toward a real shift in protection technology.

The Problem with Brittle Coatings

Here’s the thing about many traditional “hard” coatings: they’re too rigid. A boat’s hull is always moving, flexing with the waves, and vibrating from the engine. Throw in extreme temperature swings, from a freezing dock in winter to baking in the summer sun, and a brittle coating will inevitably develop micro-cracks. Once that barrier is compromised, it’s game over.

This is where the science behind modern coatings has completely changed the game. Titan Coatings, for instance, was the first to bring elastomer coatings to the market, developing a formula that’s as hard as glass but also incredibly flexible. It’s not just a static layer sitting on top of your gelcoat; it’s a dynamic shield that works with your boat.

By incorporating advanced nano-tube and Dark Matter tech, these elastic coatings create a resilient surface that moves and flexes with the vessel. This elasticity is crucial—it prevents the coating from cracking under the stress of temperature changes or hull movement, which means the protection lasts dramatically longer.

A Smarter Investment in Your Vessel

This shift in thinking isn’t a niche trend; it’s being adopted by smart boat owners all over the world. The demand for better, more durable protection is driving huge growth in the market. In fact, the global marine ceramic coating sector is projected to expand significantly as more people recognize the need for superior, long-lasting aesthetic and physical protection for their boats.

Ultimately, choosing an advanced coating is about more than a great shine. It’s about protecting the value of your asset and, just as importantly, getting your weekends back. The clear difference between wax and ceramic coating is that you’re moving from a temporary fix to a genuine long-term solution. For boaters who make the switch, it means less time buffing at the dock and more time enjoying the open water, confident that their vessel is properly shielded from the elements.

Preparing Your Vessel for a Flawless Finish

Let’s be clear: getting that unbelievable, long-lasting shine from a ceramic coating marine application has almost nothing to do with the final wipe-on, wipe-off. It’s all about the hours of meticulous, often tedious, prep work that happens first. An amazing result is built on a perfectly prepared foundation. If you cut corners here, you’re just building a beautiful house on a foundation of sand—it’s destined to fail.

The entire goal of preparation is to get the surface surgically clean, perfectly smooth, and completely free of any contaminants. Why? Because the coating needs to form a direct, powerful chemical bond with the gelcoat itself. This isn’t just a quick wash; it’s a full-on restoration project for your boat’s finish.

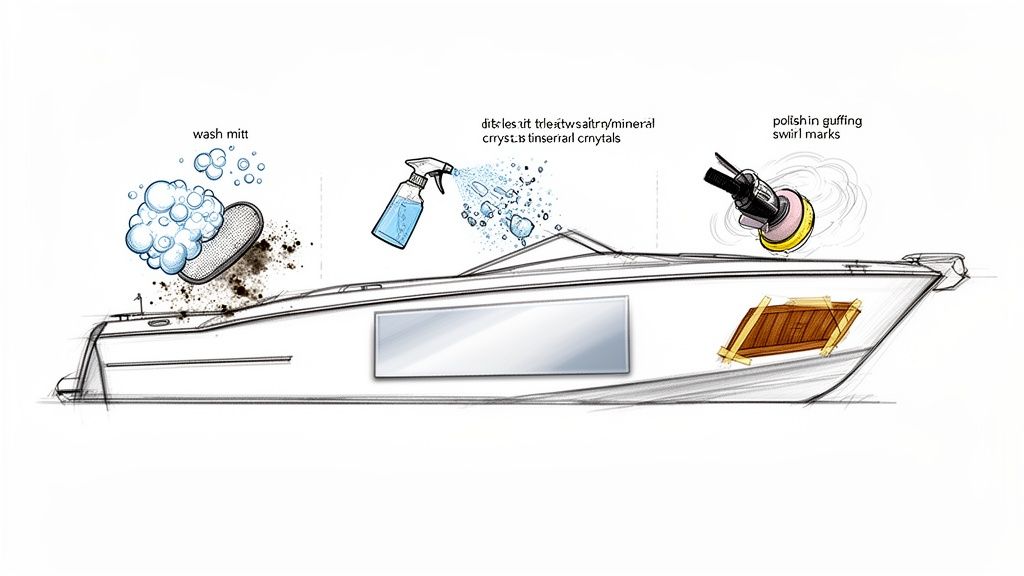

The Deep Clean and Decontamination Stage

Your boat’s hull is constantly being bombarded. We’re talking salt spray, hard water mineral deposits, bird droppings, and even industrial fallout that embeds itself right into the gelcoat’s pores. A simple soap-and-water scrub won’t even touch these deep-rooted contaminants.

A multi-stage wash is your first, non-negotiable step. This means using high-quality, marine-safe cleaners that lift away the grime without stripping away any existing sealants. After the wash, you have to decontaminate chemically to dissolve all the stubborn minerals and salt bonded to the finish. Think of it this way: the wash gets rid of the dirt you can see, but the chemical bath purges the invisible impurities that would kill a coating’s bond.

For those truly stubborn, embedded contaminants that even chemicals can’t lift, the clay bar is a professional’s secret weapon. When you glide a clay bar over a lubricated surface, it literally pulls out microscopic particles, leaving the gelcoat feeling as smooth as glass. It’s an absolutely essential step for creating a pristine surface.

Restoring the Canvas Through Paint Correction

Once the surface is truly clean, it’s time to deal with the visible damage. Years in the sun and salt spray cause oxidation, which is what gives your gelcoat that chalky, faded look. On top of that, you have the swirl marks and fine scratches from years of washing and use that rob the finish of its clarity.

This is where paint correction comes into play. It’s a process, not a product. Using a series of compounds and polishes with different levels of grit, a skilled technician carefully shaves off a microscopic layer of damaged gelcoat. This process strips away the oxidation, buffs out the swirls, and brings back the deep, rich color your boat had when it was new.

It’s a true art form that demands a steady hand and a lot of patience. You’re not just making the boat shiny; you’re creating a perfectly level, defect-free canvas for the coating to bond to.

Final Steps Before Application

With the gelcoat looking brand new, just a few final steps are left to guarantee a perfect application.

- Careful Masking: You have to protect every sensitive area. This means taping off teak decks, vinyl seats, non-skid surfaces, and any chrome or stainless steel hardware. Using high-quality painter’s tape is a must to keep the coating from bonding where you don’t want it.

- The Final Wipe-Down: Right before the coating touches the hull, the entire surface gets a wipe-down with a panel prep spray. This is a special solvent that flashes off any leftover polishing oils, waxes, or even fingerprints that could block the coating’s bond. This final wipe creates a completely sterile surface, ensuring the coating grabs on with maximum strength and durability.

Only after you’ve gone through this entire meticulous process can you have confidence that your ceramic coating marine shield will perform at its best. This detailed work is what separates a finish that looks good for a season from one that protects your vessel for years. If you want to dive deeper into this crucial decontamination step, you can learn more about what a clay bar treatment involves in our guide.

Choosing the Right Shield for Your Vessel

The marine environment is absolutely brutal. There’s simply no other way to put it. Between the relentless UV exposure, corrosive salt spray, and the inevitable fuel spills or bird droppings, your vessel’s gelcoat is under constant attack. In this fight, a standard automotive coating just won’t cut it—it’s like bringing a knife to a gunfight. That’s why selecting a true ceramic coating marine formula is so critical.

Making the right choice means moving beyond temporary waxes and polishes to give your boat a durable, long-lasting defense. You need to zero in on performance metrics that actually matter out on the water, not just what looks good in a marina.

What to Look for in a Marine-Grade Coating

When you’re comparing products, you have to cut through the marketing hype and focus on the technical capabilities that will genuinely protect your investment. Here’s what I tell every boat owner to prioritize:

- Extreme UV Resistance: The sun is your gelcoat’s worst enemy. It causes the oxidation that leaves that chalky, faded mess. A proper marine coating must be packed with UV inhibitors to stop this process cold and keep your boat’s color vibrant.

- Powerful Hydrophobicity: A super-slick, water-hating surface does more than just shine. It creates a self-cleaning effect where water, salt, and grime bead up and roll right off. This makes cleanup unbelievably easy and prevents hard water spots and salt from etching the finish.

- Robust Chemical Resilience: From saltwater and diesel to acidic bird droppings and fish guts, your hull is a magnet for harsh chemicals. Your coating needs to be chemically inert, forming an impenetrable shield that prevents these contaminants from staining or eating into the gelcoat.

Not All Coatings Are Created Equal: A Real-World Example

Let me share a quick story. A few years back, a client with a beautiful offshore sportfisher came to me completely fed up. He’d spent a small fortune on a “premium” ceramic coating, but it failed in less than a year under the intense Florida sun. The constant flexing of the hull as it pounded through waves caused the rigid coating to develop micro-cracks, leaving his expensive boat looking dull and vulnerable all over again.

His situation perfectly illustrates a fundamental flaw in many coatings: they’re too brittle for the dynamic marine world. This exact problem is why specialized solutions like Titan Coatings’ Poseidon Marine Graphene Coating were developed. This isn’t just a car product with a new label; it was engineered from the ground up to solve marine-specific challenges.

The game-changer with Poseidon is its graphene-infused elastomer formula. Titan was the first to pioneer elastomer coatings using nano-tube and Dark Matter technology. This creates a protective layer that’s hard as glass but also incredibly flexible, allowing it to move with the hull instead of cracking under stress. That elasticity is the secret to its survival in harsh marine conditions.

To help you sift through the options, here’s a table breaking down the essential performance metrics you should be looking for in any high-performance marine ceramic coating.

Key Performance Metrics for Marine Ceramic Coatings

| Performance Metric | Why It’s Critical for Marine Environments | What to Look For |

|---|---|---|

| Flexibility / Elasticity | A boat’s hull constantly flexes and vibrates. A rigid coating will micro-crack and fail prematurely under this stress. | Look for terms like “elastomer,” “flexible formula,” or data on elongation properties. Avoid overly brittle, glass-like coatings. |

| UV Inhibition | Gelcoat and paint oxidize and fade rapidly under constant, direct sun exposure, diminishing the vessel’s value and appearance. | The product should specify “high UV inhibitors” or “UV-blocking technology.” Ask for data on accelerated weather testing (e.g., QUV ASTM G154). |

| Hydrophobicity | A high water-contact angle sheds salt, dirt, and contaminants, making cleaning drastically easier and preventing etching. | Look for a water contact angle of 110 degrees or higher. This indicates superior water-beading and self-cleaning properties. |

| Chemical Resistance | Fuel, oil, acidic bird droppings, and saltwater can stain and damage the surface. A coating must act as a true chemical barrier. | The spec sheet should list resistance to specific chemicals like acids, alkalis, and solvents. Look for ISO 2812-1 test results. |

| Hardness (Pencil Scale) | A harder surface resists light scratches from docking, fishing lines, and general use, preserving the gloss and finish. | A hardness rating of 9H or higher is ideal. This signifies excellent scratch resistance for a coating. |

This table gives you a solid checklist. When you’re talking to an installer or reading a product spec sheet, these are the points you need to hit to ensure you’re getting true, purpose-built protection.

Durability Forged from Flexibility

The ability to handle thermal shock is another huge benefit of a flexible coating. When a hot hull is suddenly hit with cold water, or when temperatures drop overnight, a rigid coating can become brittle and fracture. An elastomer-based coating, on the other hand, simply expands and contracts with the surface, maintaining its integrity. This is the difference between a fleeting shine and genuine, multi-year protection.

When you look at the data, this elastic technology provides a clear advantage. If you want a real, battle-tested shield for your boat, it pays to investigate a dedicated marine solution like Poseidon. For a deeper dive into protecting your gelcoat, feel free to check out our boat clear coating in our comprehensive guide. Ultimately, choosing the right protection means less time maintaining your boat and more time enjoying it on the water.

The Art of a Professional Coating Application

With a perfectly prepped surface, the real artistry begins. This is where your precision, patience, and technique all come together to create that flawless, durable finish that makes a professional ceramic coating marine job stand out. It’s far less about speed and much more about a methodical, almost surgical approach that guarantees the coating bonds perfectly and performs for years.

A lot of people think you just wipe the stuff on and off, but it’s so much more nuanced than that. The real difference between an amateur job that looks streaky in a month and a pro-grade shield that lasts for seasons comes down to controlling every single variable.

Mastering the Application Environment

Your greatest allies—or your worst enemies—are temperature and humidity. A high-quality coating needs a stable environment to bond and cure the right way. Slapping it on in direct sunlight, in freezing temperatures, or on a humid, sticky day is just asking for trouble.

The sweet spot is a controlled indoor space, like a workshop or a clean garage, where you can keep the temperature steady, typically somewhere between 60°F and 80°F (15°C to 27°C). This stability is absolutely critical because it dictates the coating’s “flash time”—that window you have for the solvents to evaporate before you have to level the surface.

Think of it this way: a controlled environment gives you a predictable window to work with. Too hot, and the coating flashes almost instantly, becoming grabby and impossible to level smoothly. Too cold, and it takes forever, which just invites dust and debris to settle into the wet surface.

This is exactly why professionals are so obsessive about their workspace. It’s a non-negotiable first step if you want a perfect outcome.

The Section-by-Section Technique

Trying to coat an entire hull at once is a rookie mistake that will absolutely lead to an out-of-control mess. The only way to do it right is to work in small, manageable sections, usually no bigger than 2×2 feet. This systematic approach is what allows you to apply the product, watch it flash, and level it perfectly within that ideal window.

Here’s how that looks in practice:

- Apply Evenly: Using a dedicated applicator, spread the coating in a cross-hatch pattern. Go horizontally, then vertically. This ensures you get complete, even coverage in your little section.

- Watch for the Flash: This is the most critical part. You have to watch the surface for the visual cues that tell you it’s ready. You’re looking for a “sweating” or a faint rainbow-like effect as the solvents evaporate. That’s your signal.

- Level with Precision: Grab a clean, high-quality microfiber towel and gently wipe the section to level the coating, picking up any excess product. This is what eliminates high spots and gives you that perfectly smooth, uniform layer.

Once one section is done, you move right on to the next, slightly overlapping the previous one to create a completely seamless finish. It’s a slow, deliberate process that requires your full attention.

Advanced Techniques for Maximum Durability

If you’re after the absolute highest level of protection, you’ll want to apply multiple layers. A second or even a third layer of ceramic coating marine protection dramatically increases the overall thickness, hardness, and lifespan of the shield. Just make sure you respect the recommended time between coats—usually about one to two hours—to let the previous layer set up properly.

Another tool in the professional’s arsenal is an infrared (IR) curing lamp. These lamps blast the surface with specific short-wave infrared light, which massively accelerates the curing process. By gently heating the surface to a precise temperature, the IR lamp forces a much faster and more complete cross-linking of the coating’s molecules. This not only slashes the final cure time but helps the coating reach its maximum hardness and chemical resistance much, much quicker.

Understanding the full curing timeline is crucial for any boat owner. For a more detailed look at this final, critical phase, you can learn more by reading about how long ceramic coating takes to cure on our blog.

The broader ceramic coatings market, which covers everything from boats to cars and planes, is seeing huge growth. Valued at USD 13.08 billion in 2025, the global market is projected to hit USD 27.98 billion by 2035. A big part of this boom comes from more user-friendly spray applications, which are becoming a go-to for many. You can dive deeper into these trends and read the full research on the ceramic coatings market.

At the end of the day, a professional application is a testament to the power of getting the details right. It’s about patience, a keen eye, and a deep understanding of how the product actually works. That meticulous effort is what turns a simple liquid into a powerful, long-lasting shield for your vessel.

Keeping That Showroom Finish: A Guide to Ceramic Coating Care

You’ve made the investment and had a professional marine ceramic coating applied. The good news? The truly hard work is done. Your boat is now wrapped in a tough, slick shield, and keeping it that way is surprisingly straightforward. The game plan shifts from endless, back-breaking polishing to a simple maintenance routine that protects the coating and keeps it performing at its absolute best.

The secret isn’t about complicated steps or specialty tools; it’s all about gentle, consistent care. A few good habits will extend the life of your coating for years, guaranteeing your vessel looks unbelievable season after season. So, put away the heavy-duty buffers and aggressive compounds. Your new mantra is “less is more.”

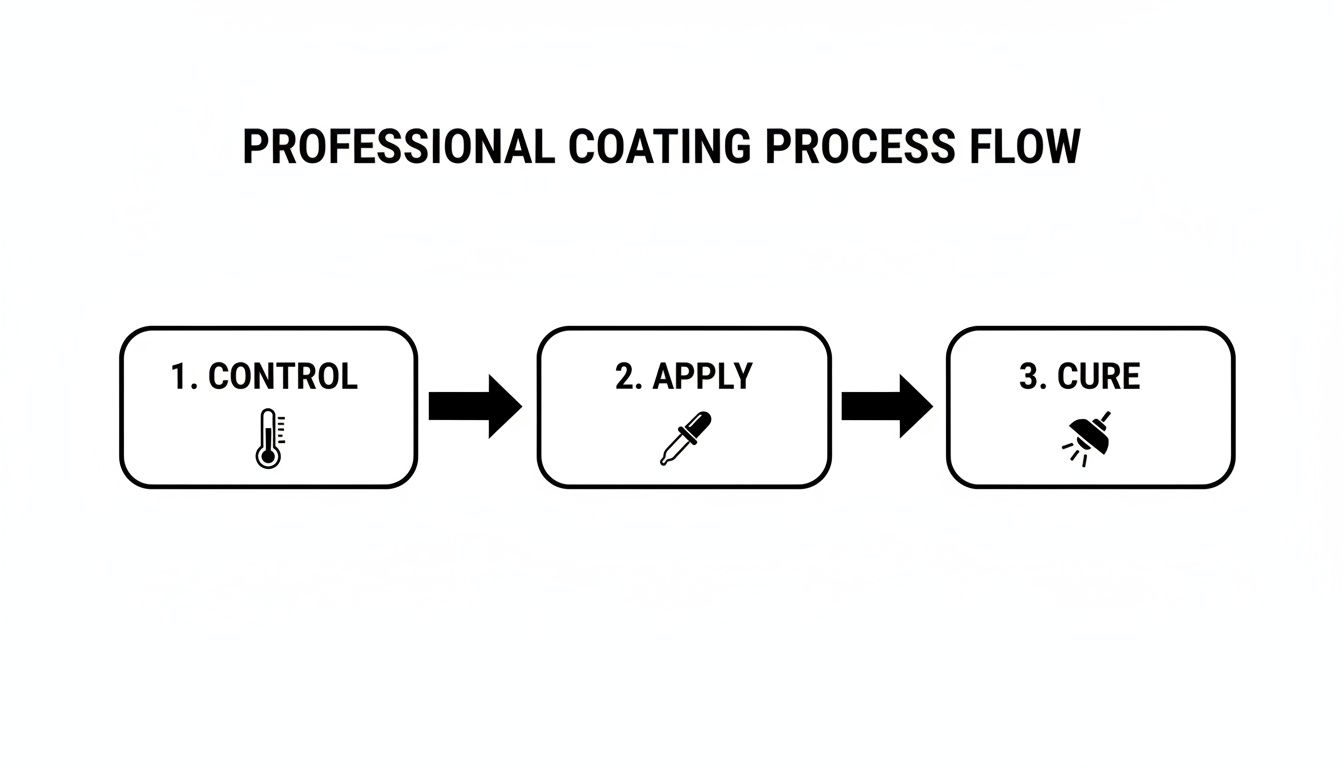

This flowchart gives you a peek into the controlled environment required for a professional application, which is the foundation for the coating’s longevity.

It’s this methodical process of controlling the environment, application, and curing that creates that perfect, durable bond with the surface.

The Cornerstone of Maintenance: The Perfect Wash

How you wash your boat is, without a doubt, the single most important part of your maintenance plan. While the slick, hydrophobic surface does much of the heavy lifting by repelling grime, you’ll still need to give it a proper clean. Using the right products and techniques here is non-negotiable.

First up, pH-neutral boat soap is a must. Aggressive, high-alkaline, or acidic cleaners are the enemy of your coating. They can slowly eat away at it, weakening its protective properties over time. Always stick with gentle soaps specifically formulated for coated surfaces.

Next, throw out your old-school abrasive brushes. Your new best friend is a high-quality microfiber or chenille wash mitt. These materials are incredibly soft, designed to lift dirt away from the surface without causing the fine micro-scratches that will inevitably dull your boat’s shine. Pros swear by the two-bucket wash method—one for your soapy water, and a separate one with clean water for rinsing the mitt. This simple trick prevents you from dragging abrasive grit right back across your hull.

Recharging Your Coating’s Superpowers

Even the toughest ceramic coatings can use a little boost every now and then. Over time, an invisible layer of environmental contaminants can build up, making the surface seem less hydrophobic. This is where people often think their coating is failing, but in reality, it’s just a little “clogged.”

This is where a quality maintenance spray comes into play. I’ve found that using a silica-based topper, such as Titan Coatings’ Graphene Detailer, every couple of months is the real secret to keeping a coating in prime condition. A quick spray and wipe after a wash will:

- Instantly Recharge Hydrophobics: That jaw-dropping water-beading effect comes right back.

- Boost the Gloss: It adds a noticeable layer of slickness and visual depth.

- Add a Sacrificial Layer: This topper takes the hit from daily exposure, preserving the base coating underneath.

Think of a maintenance spray like a conditioner for your coating. It doesn’t replace the hard base coat; it revitalizes the top layer, ensuring the permanent protection beneath stays untouched and pristine.

This kind of proactive care is a smart move. With more people investing in high-end boats and yachts, protecting that asset has never been more critical. Taking care of the finish is just one part of the puzzle.

For a more detailed look at extending your coating’s lifespan, take a look at our full guide here: https://titancoatings.us/ceramic-coat-maintenance/. And remember, proper coating care fits into a larger strategy of comprehensive boat maintenance that will protect your investment and keep your vessel turning heads for years to come.

Your Top Questions About Marine Ceramic Coatings, Answered

When you’re looking into advanced protection for your boat, it’s natural to have a lot of questions. You’re making a serious investment in your vessel, and you need to be sure you’re making the right call. Let’s cut through the chatter and get you some straight answers to the questions we hear most often.

Can I Just Apply a Marine Ceramic Coating Myself?

Look, I get the appeal of DIY. But when it comes to a true ceramic coating marine shield, this is one job best left to the pros. While there are kits out there, the final result lives or dies by the prep work. Getting a gelcoat perfectly clean, decontaminated, and corrected requires specific tools, compounds, and frankly, a ton of experience.

A DIY job gone wrong can leave you with high spots, streaks, or a hazy finish that’s a nightmare to fix—and an expensive one at that. A professional works in a controlled environment, which is absolutely critical for the coating to properly bond and give you that multi-year protection you’re paying for. Certified installers have the training and the touch to nail a perfect finish that actually performs as advertised.

What Makes a Marine Coating Different From a Car Coating?

This is a big one, and the difference is night and day. A marine coating is engineered for an environment that is brutally harsher than anything a car will ever see. The entire formulation is built from the ground up to handle challenges unique to the water.

- Serious UV Blockers: Boats are constantly bombarded by the sun, both from above and reflecting off the water. Marine coatings are packed with a much higher concentration of UV inhibitors to fight off the gelcoat oxidation that fades and chalks your finish.

- Tough Chemical Resistance: These coatings are designed for constant immersion and contact with corrosive saltwater, algae, fish guts, and other grime that would eat an automotive coating for lunch.

- Unmatched Flexibility: This might be the most crucial difference. A boat hull is always flexing, vibrating, and expanding or contracting with temperature swings. Titan’s coatings, built on an advanced elastomer base with Dark Matter Technology, are engineered to be flexible. This elasticity lets the coating move with the hull, preventing the micro-cracking that causes rigid, brittle coatings to fail spectacularly in the marine world.

So, How Long Does a Professional Marine Coating Really Last?

When you get a high-quality marine ceramic coating applied by a professional, you can expect it to last for several years. It completely blows traditional waxes, which might give you a few months at best, out of the water. Unlike a wax that just sits on top, a ceramic coating forms a semi-permanent chemical bond with the gelcoat itself.

How long it ultimately lasts comes down to three things: the quality of the coating, how well it was applied, and how you take care of it. With a top-tier product and a simple maintenance plan—like washing with pH-neutral soaps and using a maintenance topper—you can easily keep it performing for years on end.

Some people think a ceramic coating is a “set it and forget it” deal. While it absolutely slashes your maintenance time by over 90%, a little proactive care is what ensures you get the maximum life and value from your investment.

Will a Ceramic Coating Stop Scratches and Dock Rash?

A ceramic coating marine application adds a serious layer of hardness to your gelcoat, usually rating 9H or higher on the pencil hardness scale. This gives you fantastic protection against the micro-scratches you get from washing, tossing a fishing line, or general light use that dulls the finish over time.

But let’s be realistic: it’s scratch-resistant, not scratch-proof. No coating on the market is going to stop a deep gouge from a hard collision with a dock piling—that’s “dock rash.” The real advantage of Titan’s flexible elastomer coatings is their superior ability to absorb and deflect those minor bumps and impacts far better than brittle traditional coatings. At the end of the day, though, careful docking is still your best defense against heavy physical damage.

You can dive into the specifics of our different coating technologies on our product comparison page to see what level of hardness and flexibility makes the most sense for your vessel.

Ready to give your vessel the tough, long-lasting shield it deserves? Titan Coatings offers specialized marine solutions built for the harshest environments on the planet. Check out our advanced elastomer coatings and find the perfect protection for your boat by visiting our online shop.

0 Comments

Trackbacks/Pingbacks