Think of a ceramic coating spray as a high-tech shield for your client’s vehicle. It’s a liquid polymer, packed with tiny Silicon Dioxide (SiO2) nanoparticles, that you can spray on to get a professional-level finish. Once applied, it doesn’t just sit there—it chemically bonds with the car’s clear coat. This creates a hard, incredibly slick layer that makes water fly off the paint and protects it from the daily grind, keeping your client’s car looking incredible with less effort.

What’s Really in a Ceramic Coating Spray?

This isn’t your grandfather’s car wax. A good ceramic spray is miles ahead of traditional waxes or sealants that just lay on top of the paint. The real magic is in the chemical bond it forms with the paint. This superior bond is what gives your clients real staying power and robust protection they can see and feel.

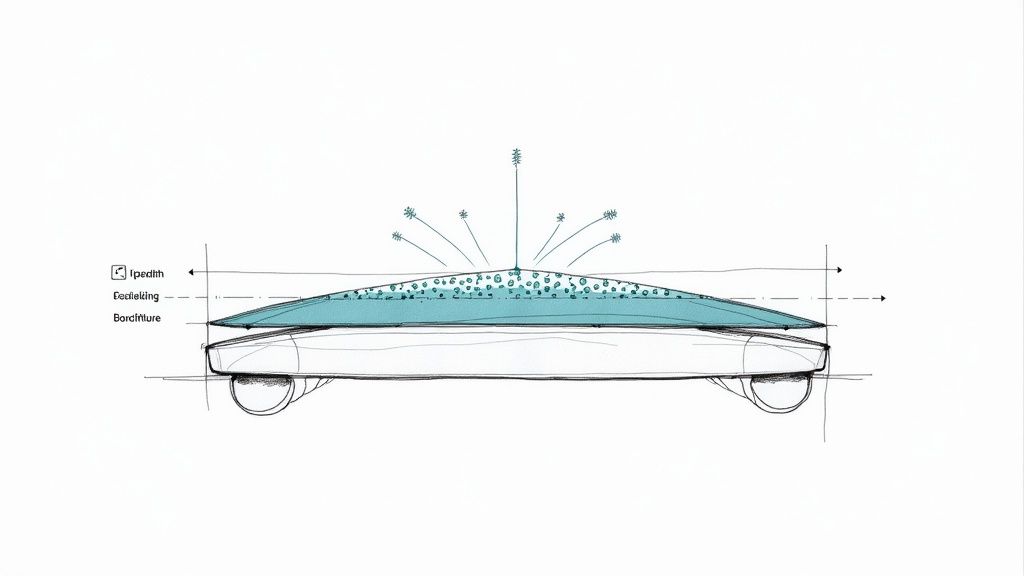

Picture a car’s clear coat under a microscope; it’s full of tiny peaks and valleys. The nanoparticles in the spray dive into these imperfections, leveling everything out to create a super smooth, uniform shield. For professional detailers, this is a game-changer. You can offer clients a service that delivers real, lasting results without the multi-day curing process of a full coating.

The Science Behind the Shine

The workhorse ingredient in any legit ceramic spray is Silicon Dioxide (SiO2)—basically, liquid glass. It’s suspended in a carrier solution, and when you spray it onto a panel, the solvents flash off and the nanoparticles start to cure and harden.

But here’s where the pros separate themselves from the amateurs: not all SiO2 formulas are the same. The real differentiator is how those nanoparticles are engineered to grab onto the surface. Most sprays create a decent protective layer, but the best ones do much more. At Titan Coatings, our Hyper-Bonding Nanosilicates are designed for a much stronger molecular grip.

This technology forces the nanoparticles to lock into a dense, cross-linked crystalline structure. For your clients, this translates directly into a tougher, more resilient shield against the elements, a deeper gloss that makes their car stand out, and water beading that lasts far longer than what they’d get from a generic product.

More Than Just a Pretty Face

The value of a professional ceramic coating spray goes way beyond just protecting the paint. It completely changes the behavior of the surface, which means the car becomes dramatically easier for your clients to clean and maintain—a huge selling point for any busy car owner.

Here are the key benefits you’ll be delivering:

- Serious Hydrophobicity: Your client’s car will now repel water like never before. The coating creates extreme surface tension, making water bead up and fly off the paint. This “self-cleaning” effect means loose dirt gets washed away with the water, so their car stays cleaner, longer.

- Deep Gloss and Clarity: By filling in all those microscopic imperfections, the coating creates a perfectly flat surface that reflects light like a mirror. Your clients get that deep, wet-look shine that truly makes their vehicle pop with color and depth.

- Painless Maintenance: The super slick surface prevents contaminants like dirt, bird droppings, and bug guts from sticking. This means future washes are way faster and easier for your clients, saving them time and effort.

A quality ceramic spray is the perfect middle ground between a temporary wax and a full-blown, multi-year ceramic coating. If you want to get deeper into the technical side, you can learn more about what ceramic coatings are and how they work. It’s the ideal upsell for clients who want serious protection and a show-car finish without the downtime or cost of a traditional coating.

The True Benefits of a Professional Ceramic Spray

Once you understand what a ceramic coating spray is, you can really start to appreciate its real-world advantages. For professional detailers, these benefits aren’t just talking points—they translate directly into happier clients and a more reputable business. We’re not talking about a temporary shine here; this is about delivering tangible, long-lasting value that customers can see and feel every day.

It’s no surprise that demand for this level of protection is exploding. The global market for ceramic coatings, including these advanced sprays, hit USD 12.15 billion in 2024 and is on track to more than double to USD 25.60 billion by 2034. That kind of growth tells you something: both professionals and their clients are expecting more from vehicle protection. You can find out more about the ceramic coatings market growth and see where the industry is heading.

Incredible Water Repellency

The first thing any client will notice is the incredible hydrophobic effect. It’s dramatic. An untreated surface is like a dry sponge, letting water spread out and cling. A ceramic spray transforms the surface, forcing water into tight, perfect beads that look amazing.

But this isn’t just for looks. As those beads roll off the paint—a process we call sheeting—they actually pick up and carry away loose dirt and grime. This self-cleaning effect means your client’s car will stay looking sharp much longer between washes, which is a massive benefit for any car owner. It makes their maintenance washes faster and easier, too.

Powerful UV and Chemical Defense

Every day, a vehicle’s clear coat is fighting a battle. The sun’s UV rays cause paint to fade and oxidize, while things like bird droppings, bug guts, and acid rain can eat right into the finish, leaving permanent marks.

A professional ceramic spray forms a sacrificial shield against these attacks. Our formula’s specialized UV-blocking polymers absorb and scatter harmful radiation, so your client’s paint is preserved from sun damage. At the same time, the hardened ceramic layer offers serious chemical resistance, giving your clients a critical window to wash off corrosive messes before they cause any real damage.

As a detailer, this lets you sell genuine preservation, not just a shine. You’re giving clients peace of mind by protecting their investment from the slow, steady damage of daily life.

A Deep, Mirror-Like Gloss

Traditional waxes just sit on top of the paint, but a ceramic spray becomes one with it. The SiO2 nanoparticles in the formula are so small they fill in the microscopic pores and imperfections that exist in every clear coat.

This microscopic leveling creates an absolutely smooth surface that reflects light with incredible clarity. The result for your client is that deep, wet-look gloss that makes colors appear richer and more vibrant. It’s the jaw-dropping, mirror-like finish that confirms they made the right choice by coming to you.

Extended Durability and Value

This is where the real business advantage comes in: durability. A carnauba wax looks nice, but it’s gone in a matter of weeks. A professional-grade ceramic spray, on the other hand, uses advanced cross-linking technology to form a much stronger chemical bond with the paint.

That superior bond is why the protection and good looks last for many months, not weeks. For your detailing business, this means you can confidently sell a premium service that delivers clear, long-term value. Clients get protection that truly endures, justifying a higher price point and building loyalty because the results speak for themselves.

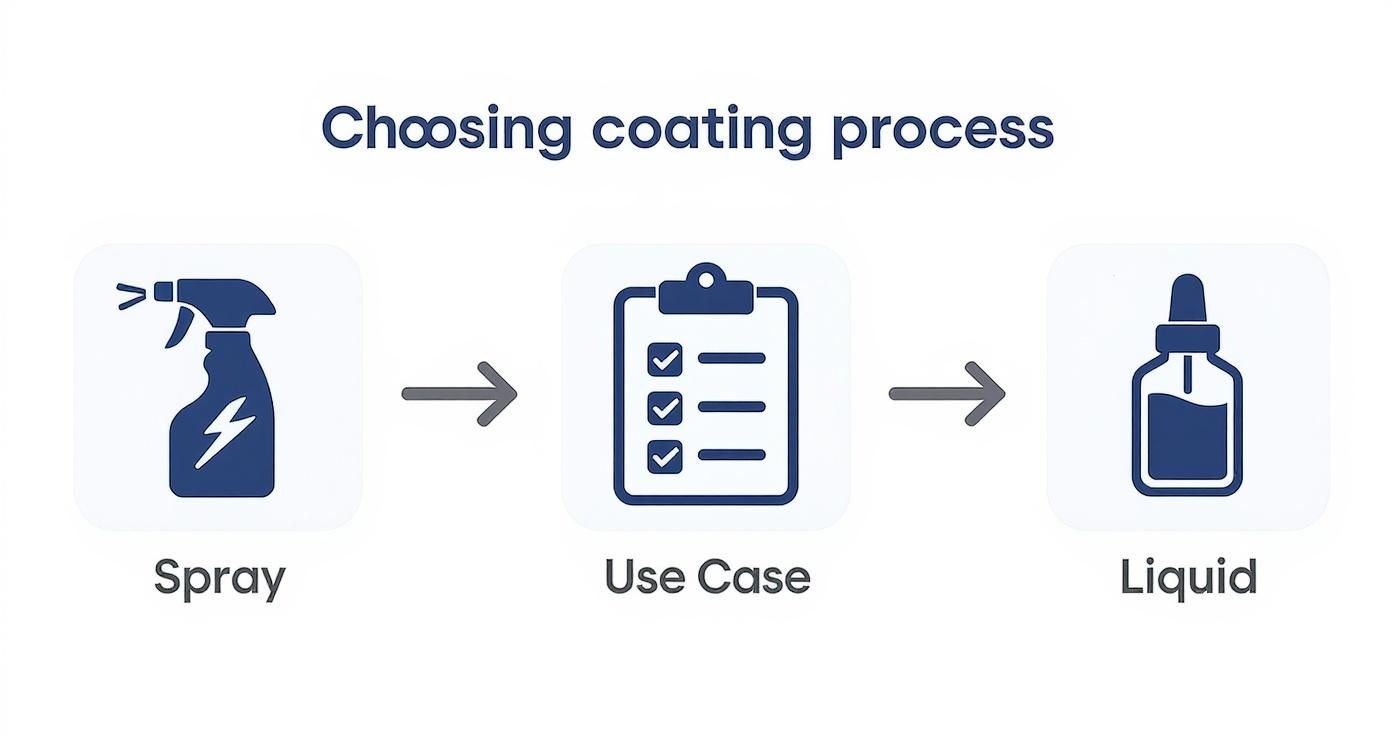

Choosing Between a Spray and a Liquid Coating

Any detailer worth their salt needs to know the real difference between a ceramic spray and a full, professional-grade liquid coating. These are two completely different tools for different jobs, and knowing when to use each one is crucial for managing your clients’ expectations and building a solid, profitable service menu.

Think of it this way: a spray is like a high-end, waterproof rain jacket, while a full liquid coating is a deep-sea diving suit. Both protect you from water, but they’re engineered for wildly different conditions and designed to last accordingly.

A ceramic spray is all about hitting that sweet spot between performance and practicality. It’s the perfect solution for clients who want real, noticeable protection and that signature ceramic gloss without shelling out for a multi-year coating. Offering a quality spray allows you to serve a much wider range of customers and budgets.

Application Time and Skill Level

The biggest split between these two products comes down to time and skill. Applying a professional liquid coating is a serious commitment—a meticulous, multi-hour job that really needs a controlled environment to cure properly, often over 24 hours or more. It takes a seasoned hand to get it right without leaving behind high spots or streaks, which is why it’s a service best left to highly trained pros.

A ceramic coating spray, on the other hand, is built for speed. You can knock out a full application in under an hour, from the final prep wipe to buffing off the last panel. This efficiency is a massive advantage for mobile detailers who need to deliver amazing results quickly while on-site. The simple spray-and-wipe process is far more forgiving, making it easier for your whole team to produce consistent, high-quality work.

For the mobile pro, time is money. A ceramic spray service lets you book more jobs in a day, boosting your revenue while still delivering the gloss and water-beading that wows customers and gets you referrals.

Durability and Protection Level

This is where the main trade-off happens. A professionally installed liquid ceramic coating creates a thick, glass-like shell that can last for years, offering the absolute best resistance to light scratches, harsh chemicals, and UV damage. This is your top-tier service, the one you sell to clients who want maximum, long-term preservation for their prized vehicle.

A ceramic coating spray offers protection that’s measured in months, not years. While it can’t match the scratch resistance of a thick, hardened coating, it absolutely delivers on the core benefits that clients see and feel: insane water beading, a slick and easy-to-clean surface, and solid protection from environmental hazards like bird droppings and UV rays. It’s a huge leap forward from old-school waxes and sealants, providing a legitimate protective layer that simply lasts longer. For those interested in seeing how this technology translates to an easier format, checking out a DIY ceramic coating kit is a great way to understand its potential.

Finding the Perfect Fit for Your Client

So, when should you reach for the spray? I find it’s the perfect answer in three main situations, making it a must-have in your detailing arsenal.

- The Value-Driven Client: For customers who want something better than wax but aren’t ready for the cost of a multi-year coating, a ceramic spray is the ideal middle ground. It gives them a premium, durable finish at a price they can feel good about.

- The Maintenance Topper: A spray is a fantastic maintenance product for cars that already have a full liquid coating. A quick application every few months recharges the hydrophobic properties and amps up the gloss, keeping the primary coating performing at its absolute best.

- The Quick Impact Service: For mobile detailers, this is the ultimate weapon. You can package a wash, a quick clay bar decon, and a ceramic spray application to deliver an immediate, stunning transformation that will leave any client completely thrilled.

Your Step-by-Step Professional Application Guide

Let’s get one thing straight: a flawless finish from a ceramic coating spray isn’t about the product. It’s about the process. The coating can only do its job if it bonds to a perfectly prepared surface, which means the prep work is absolutely non-negotiable for getting results that last.

When a coating fails early, looks streaky, or just doesn’t meet professional standards, it’s almost always because a corner was cut during prep. This guide breaks down the exact methodology the pros use to guarantee a perfect bond and a stunning outcome every single time. Think of it as a system where each step sets the stage for the next, all leading to a durable, high-gloss protective layer.

Thorough Decontamination

Before you even think about grabbing that spray bottle, the vehicle’s paint needs to be surgically clean. And no, a quick wash won’t cut it. Decontamination is an intensive process designed to strip away every impurity—both visible and invisible—that has bonded to the clear coat.

Start with a meticulous hand wash using the two-bucket method and a good pH-neutral shampoo to get rid of the loose dirt. Once that’s done, it’s time to tackle the stubborn stuff.

- Iron Removal: Hit the surface with a dedicated iron remover spray. You’ll see it turn purple as it works—that’s the chemical reaction dissolving embedded ferrous particles like industrial fallout and brake dust that washing alone leaves behind.

- Clay Bar Treatment: After rinsing off the iron remover, use a clay bar or clay mitt with plenty of lubricant. This step physically pulls out any remaining bonded contaminants like tree sap, road tar, and overspray, leaving the paint feeling glass-smooth.

Essential Paint Correction

Now that the surface is truly clean, it’s time to make it perfect. A ceramic coating is a layer of protection, not a magic filler. It will lock in and even highlight every existing imperfection in the paint. For any professional job, paint correction is a critical stage.

This means machine polishing the clear coat to eliminate swirls, fine scratches, and oxidation. The goal is to refine the surface, restoring its clarity and depth of color. Sealing a swirled, dull finish under a ceramic coating is simply unacceptable for a client paying for a premium service. Polishing is what creates that deep, reflective shine the coating is meant to protect.

A perfectly corrected surface is the canvas for your work. The gloss you see after applying a ceramic coating is 90% the result of the paint correction underneath it. The coating is there to protect and enhance that perfection.

Final Surface Preparation

This is the last and most crucial step before application. Polishing leaves behind oils and residues that will absolutely kill a ceramic coating’s ability to bond. The pro solution is an IPA (Isopropyl Alcohol) wipe-down.

Mix IPA with distilled water (a 15-50% IPA concentration is typical), spray it onto a clean microfiber towel, and wipe down every panel. This simple step strips away any remaining oils, waxes, or silicones, leaving behind a completely sterile surface. That pure, bare clear coat is exactly what the coating needs to form a strong, permanent chemical bond.

The infographic below helps visualize when a versatile spray is the right call versus a more intensive liquid coating.

As you can see, the choice often comes down to balancing the client’s needs with the application speed and desired longevity of the protection.

Pro Application Technique

With a fully prepped surface, you’re ready to go. Make sure you’re working in a cool, shaded spot with good ventilation. The key is to work in small, manageable sections, like half a hood or a single door panel at a time.

- Mist the product lightly onto a microfiber applicator or directly onto the panel. Don’t overdo it.

- Spread the product evenly using a cross-hatch pattern—first go side-to-side, then up-and-down. This ensures you don’t miss any spots and get total coverage.

- Let the product “flash.” This is when the carrier solvents evaporate, leaving a hazy or rainbow-like film. Flash time can be anywhere from 30 seconds to 2 minutes, depending on the temperature and humidity.

Perfecting the Finish

The final buff-off is where you make or break the finish. This is where streaks and high spots happen. To get it right, use the two-towel method—it’s standard practice for a reason.

- Towel One (Initial Wipe): Take a clean, short-nap microfiber towel and gently wipe away about 80% of the coating residue.

- Towel Two (Final Buff): Immediately follow up with a second, clean, plush microfiber. Buff the area to a brilliant gloss, removing any last trace of residue. Keep flipping this towel to a fresh side.

Once a panel is done, grab a handheld light and inspect your work from several different angles before moving on. This diligence is what separates the pros from the amateurs—it lets you catch and fix any high spots before they cure, ensuring the flawless finish your clients are paying for.

How to Maximize Your Coating’s Durability

Applying a professional ceramic coating spray is a huge first step, but the job isn’t done when your final microfiber towel touches the paint. The real secret to making that protection last is all in the aftercare. When you teach your clients these simple practices, you’re not just helping them get the most value from your service—you’re cementing your status as the expert they trust.

The golden rule of ceramic coating care is simple: wash gently and wash often. Things like dirt, bird droppings, and industrial fallout will still land on the surface. If you let them sit, they can start to clog the coating, hiding its hydrophobic properties, or even etch into it. Regular cleaning stops this buildup dead in its tracks and keeps that protective layer working like it should.

The Foundation of Proper Maintenance

The cornerstone of any solid maintenance routine is the wash process. Nothing kills a coating’s lifespan faster than aggressive, sloppy washing. To avoid putting fine scratches right back into the finish you just perfected, safe washing habits are a must.

This is where the two-bucket wash method is non-negotiable. One bucket is for your pH-neutral car soap, and the other is just for clean rinse water. Before you dip your wash mitt back into the suds, you rinse it in the clean water bucket first. This simple step traps all the dirt and grit at the bottom of the rinse bucket instead of dragging it all over the car’s paint.

A proper wash routine doesn’t just get the car clean; it actively protects the integrity of the ceramic coating. Using a gentle, pH-neutral car shampoo is an absolute must, as harsh detergents can slowly strip away the protective layer you worked so hard to apply.

For detailers wanting to offer a complete care package, showing clients the right products to use is a massive value-add. You can dive deeper into the specifics of a coating-safe wash by checking out our guide on the ideal ceramic car wash.

Revitalize and Boost for Lasting Performance

Even with perfect maintenance, the insane slickness and water-beading of a ceramic spray can start to mellow out after a few months on the road. This is the perfect opportunity to introduce a powerful maintenance strategy that helps your client’s car and your bottom line: a maintenance booster.

A quick application of a quality ceramic coating spray every three to four months is the perfect pick-me-up. This “booster” shot lays down a fresh layer of protection right on top of the original, instantly bringing back that deep gloss and intense water beading. It’s a quick, easy service that makes the car look like you just detailed it all over again.

This approach creates a fantastic recurring revenue stream for your business and helps you build long-term relationships with clients who love seeing consistently amazing results.

The demand for long-lasting automotive protection is a major force in our industry. Projections estimate the North American ceramic coatings market will jump from USD 11.95 billion in 2025 to USD 19.23 billion by 2033. This growth is largely driven by the automotive world’s need for both efficiency and aesthetic preservation. You can read more about this trend in the North American ceramic coating market report. By offering smart maintenance plans, you’re positioning your business to directly meet this growing client demand for lasting vehicle care.

Answering Common Questions About Ceramic Sprays

Even when you’ve got the process down, clients (and even fellow detailers) will always have questions about what a professional ceramic coating spray can really do. Getting the answers straight is how you build trust and manage expectations around how the coating will look and how long it’ll last. Let’s tackle some of the most common questions we hear out in the field.

How Long Does a Ceramic Spray Really Last?

The honest answer? It all comes down to the prep work and how the car is treated afterward. You’ll see all sorts of claims on the bottle, but for a professional job done right—on a surface that’s been properly decontaminated and corrected—you can realistically expect 6 to 12 months of solid protection.

Now, that lifespan can get cut short. Constant exposure to harsh weather, running it through abrasive automatic car washes, or using cheap, high-pH soaps will definitely weaken the coating. The single most important factor is proper aftercare, which means gentle hand washing with quality, pH-neutral shampoos. When you maintain it correctly, that bond stays locked in, and you’ll get that slick gloss and crazy water beading for a long time.

Can I Layer It Over an Old Wax or Sealant?

Let me be crystal clear on this one: absolutely not. For a ceramic spray to work, it has to form a direct chemical bond with the clear coat. Think of it like trying to put a high-quality decal on a greasy, dusty panel—it’s just not going to stick.

Any old wax or sealant left on the paint creates a barrier, and the SiO2 nanoparticles have nothing to grab onto. If you spray a ceramic coating over wax, you’ll get a weak, superficial layer that will fail in a few weeks, not months. To get a durable, professional finish, you have to strip that surface bare. That means a full wash, a thorough decontamination, and a final IPA wipe-down to ensure the paint is perfectly clean.

Is It Safe for Matte and Satin Finishes?

Yes, and it’s actually one of the best ways to protect these unique finishes, but your application method has to change. Matte and satin paints get that flat look from a microscopic surface texture that scatters light instead of reflecting it. The minute you try to polish or buff these surfaces, you’ll create permanent shiny spots.

The trick is to apply the spray lightly and evenly. You’re not looking to work it into the paint. Just mist it on, then gently wipe away the excess with a clean, plush microfiber towel. No aggressive rubbing. The goal is simply to lay down a protective shield that deepens the color without adding any gloss, protecting that unique finish from stains and making it way easier to clean.

How Is This Different from a Quick Detailer?

This is where a lot of people get mixed up. A quick detailer is basically a lubricant with a little gloss enhancer mixed in. It’s meant for wiping away light dust or fingerprints between washes and offers virtually zero protection. Its effects are gone in a matter of days.

A ceramic coating spray is a true surface protectant. It creates a semi-permanent, hardened layer of Silicon Dioxide that chemically bonds to the paint, offering months of durability, chemical resistance, and intense water repellency—something a quick detailer simply cannot do.

Ready to deliver professional-grade results with unmatched durability and gloss? Explore the advanced technology behind Titan Coatings and see how our ceramic coating spray can elevate your detailing services. Visit our website at https://www.titancoatings.us to learn more.

0 Comments