For as long as most of us can remember, protecting your car’s paint meant grabbing a tin of wax. It was a weekend ritual. The result was a satisfying, deep shine that, unfortunately, never seemed to last. You were constantly applying, buffing, and then doing it all over again just a few weeks later. This cycle created a real need for something better—a true, lasting shield, not just a temporary gloss.

From Traditional Wax to a Revolution in Protection

Imagine the classic car owner, meticulously applying a fresh coat of carnauba wax every other Saturday. They’re chasing that perfect, wet-look shine, and for a day or two, they have it. But then reality hits. A heavy downpour, a few days of intense sun, and that brilliant finish starts to fade, leaving the paint exposed all over again.

This is the all-too-familiar story for anyone who’s relied on old-school waxes and sealants. They just sit on top of the paint, creating a superficial barrier that breaks down fast. They look great for a moment, but they just don’t have the chemical backbone to handle what the modern world throws at a car.

The Problem with Old-School Protection

Let’s be blunt: traditional products just can’t provide the kind of defense today’s vehicles need. Their weaknesses become painfully obvious when you look at the day-to-day challenges.

- Weak Adhesion: Waxes and sealants don’t actually bond with the paint. They just lay on top, forming a weak layer that strong detergents can strip away and UV rays can break down in a matter of weeks.

- Poor Chemical Resistance: Bird droppings, bug guts, and tree sap are acidic nightmares. They can eat right through a layer of wax and permanently etch your clear coat.

- Zero Durability: These products offer virtually no real protection against the fine scratches and swirl marks that build up from normal washing, which is what dulls a car’s finish over time.

This constant need to reapply is exactly why the industry had to evolve. If you want to get into the nitty-gritty, we break down all the key differences between wax and ceramic coating in our dedicated guide.

The Next Leap Forward

The arrival of ceramic coatings completely rewrote the rules. Instead of just sitting on the surface, they create a semi-permanent, chemical bond with the paint itself. But the innovation didn’t stop there. We at Titan Coatings saw the one remaining weakness in hard coatings—their brittleness—and engineered the solution: Elastomer coatings.

By integrating advanced nano-tube structures and our proprietary Dark Matter tech, we became the first company to introduce truly elastic coatings to the market. You get the hardness and gloss of glass, but with the flexibility to survive in the real world.

This elasticity is a game-changer. A car’s body panels are always expanding and contracting with temperature swings. A standard, rigid coating can develop micro-fractures from that stress, which compromises the entire protective layer. Titan’s coatings, however, flex right along with the surface.

This unique resilience means the shield won’t crack under pressure, whether it’s a freezing winter night or a scorching summer afternoon. It’s this combination of hardness and flexibility that delivers a brilliant, long-lasting defense that was simply unimaginable just a few years ago.

How Modern Ceramic Coatings Actually Work

To really get what makes modern ceramic coatings so effective, let’s start with an analogy everyone understands. Think of traditional car wax like a layer of butter on toast. It sits on the surface, gives a nice temporary shine, but it’s soft and wipes away easily. It never really becomes part of the toast.

A standard ceramic coating is a different beast altogether. It’s more like soaking that toast in a liquid resin that hardens. It doesn’t just sit on top; it seeps into the pores of the surface and chemically bonds with it, creating a tough, semi-permanent shell. This is where the magic of nanotechnology comes into play.

The Science of a Standard Ceramic Shield

At its core, a typical ceramic coating is built around Silicon Dioxide (SiO2). When a detailer applies the liquid formula to your car’s clear coat, the carrier solvents flash off, leaving behind a tightly-packed, interlocking matrix of these nanoparticles. They then cross-link and form a powerful bond directly with the paint’s microscopic pores.

This chemical reaction, called covalent bonding, creates a transparent, glass-like layer that’s substantially harder than your vehicle’s factory clear coat. It acts as a sacrificial barrier, taking the hit from all sorts of environmental nastiness. But here’s the catch: that hardness can also be its biggest weakness.

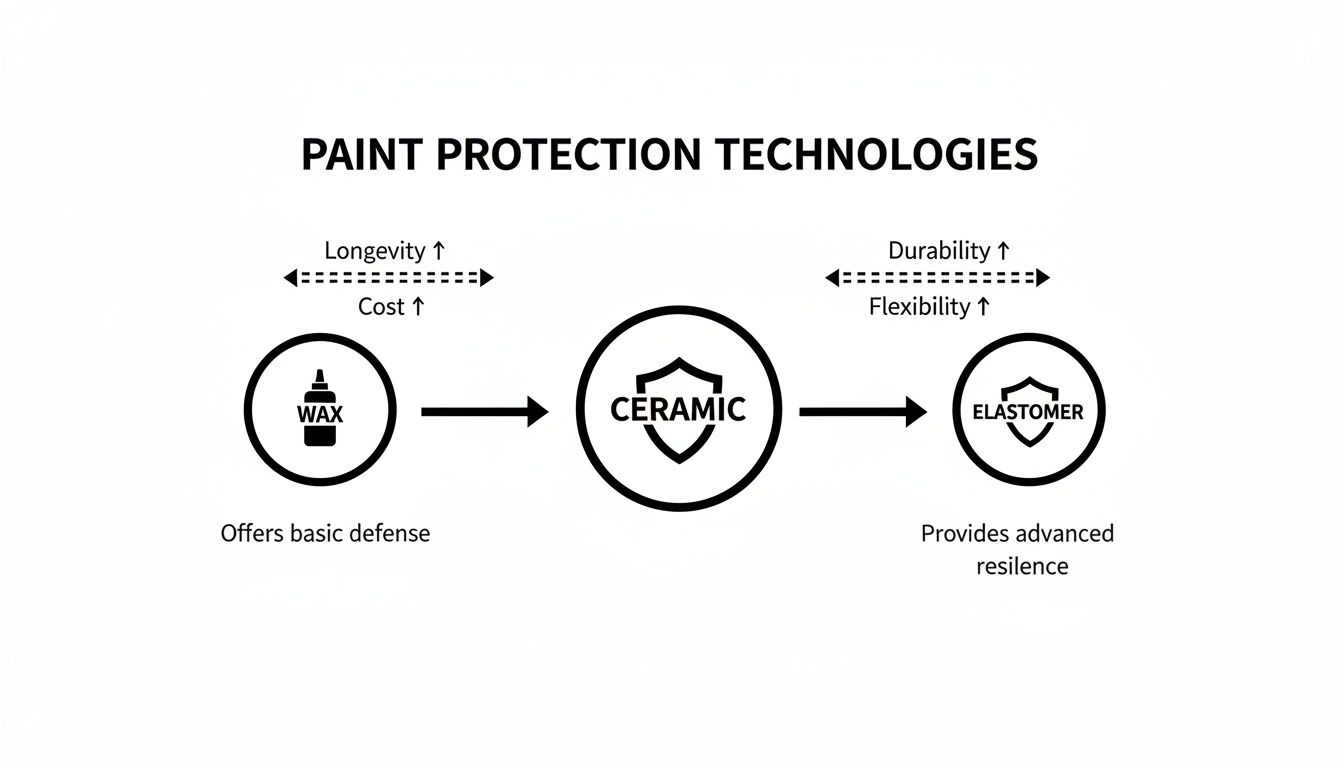

This diagram shows how paint protection has evolved over the years, from basic waxes to today’s incredibly resilient elastomer technology.

You can see the clear progression, with each step offering a more advanced and integrated defense for your vehicle’s paintwork.

The Titan Breakthrough: From Rigid to Resilient

I have a detailer friend, David, who was a huge proponent of traditional ceramic coatings for years. He absolutely loved the jaw-dropping gloss and hardness he could deliver to his clients. But he kept seeing the same problem crop up, especially in places with wild temperature swings. Cars would come back after a year or two, and the coating’s performance had just fallen off a cliff. Why? Tiny, microscopic cracks had formed all over that rigid, glass-like layer.

Think about it: a car’s metal body panels are constantly expanding and contracting, from a freezing winter night to a blistering summer afternoon. That puts an incredible amount of stress on an inflexible coating. It’s like trying to bend a sheet of glass—it’s only a matter of time before it shatters. This was the exact problem we decided to tackle head-on at Titan Coatings. Our goal wasn’t just to make a harder coating; it was to engineer a smarter one.

We broke new ground by creating a whole new category with our Elastomer coatings—the very first of their kind. By weaving together advanced nano-tube technology with our proprietary Dark Matter tech, we built something that simply didn’t exist before: a protective layer with the hardness of glass but with incredible flexibility.

Imagine a shield as tough as quartz but as pliable as hardened rubber. That’s the core principle of Titan’s Elastic coatings. This unique property is our secret weapon against the elements.

This built-in elasticity is a game-changer. It allows our coatings to flex and move right along with the vehicle’s body panels. When the metal swells in the heat or shrinks in the cold, our coating moves with it, preventing the formation of those micro-cracks that plague and ultimately destroy traditional ceramic coatings. The result is a coating that maintains its structural integrity and protective power for far, far longer.

A perfect example of this philosophy in action is our Titan HyperQuartz Graphene. This formula is the embodiment of our obsession with durability and forward-thinking science, offering a shield that is both robust and remarkably flexible. This means dramatic temperature changes no longer threaten the coating’s structure, guaranteeing a lifespan and sustained performance that rigid coatings just can’t touch. You can check out our full line of advanced protective solutions on our shop page.

The Unmatched Benefits of an Elastomer Coating

This is where all that advanced science behind ceramic coatings pays off in the real world—benefits you can see and feel every single day. The unique formula in an elastomer doesn’t just put a protective layer on your car; it completely changes the experience of owning it. Tedious maintenance becomes a point of pride.

I have a friend who is absolutely meticulous about his car. He used to dread seeing rain in the forecast. Why? Because he knew it meant spending his next Saturday scrubbing away the stubborn water spots and grime that stuck to his paint like glue. After he finally made the switch to a professional elastomer coating, that dread just… vanished.

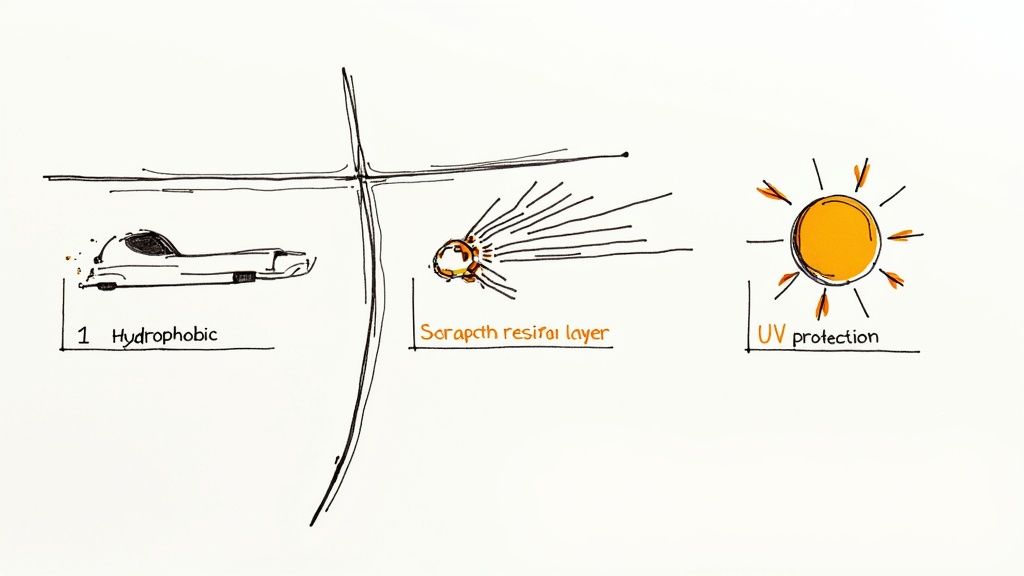

Now, he actually enjoys watching it rain. He’ll stand by the window and watch the water bead up into these perfect little spheres and roll right off the paint, taking almost all the dirt with it. That’s the magic of extreme hydrophobicity, and trust me, it’s one of the most satisfying benefits. Your car practically cleans itself, and when you do need to wash it, the process is incredibly fast and easy.

A Flexible Shield Against Real-World Threats

Look, traditional hard coatings offer decent protection, but they have a built-in weakness: they’re brittle. Titan’s elastomer technology fixes this problem by blending the hardness of glass with incredible flexibility. This one-two punch delivers a level of protection that rigid coatings just can’t touch.

- Superior Scratch Resistance: The hardened-yet-flexible layer acts as a sacrificial barrier, specifically engineered to defend against those light swirl marks and micro-scratches from washing that slowly rob your paint of its shine.

- Intense UV Protection: The sun is relentless, causing paint to oxidize and fade over time. An elastomer coating is like a powerful, permanent sunblock for your car, preserving its deep color and gloss for years on end.

- Unmatched Chemical Resistance: Nasty stuff like acidic bird droppings, bug guts, and tree sap can etch into your clear coat in a matter of hours. Our coatings create an impenetrable shield, giving you plenty of time to wash them off safely before any damage is done.

The real game-changer in Titan’s technology is that fusion of hardness and flexibility. This elastic quality is the secret to its incredible longevity, ensuring the coating won’t get brittle and fail. It’s years of reliable protection and pure peace of mind.

And this idea of durable, flexible protection isn’t just for cars. It’s being adopted in some of the most demanding industries on the planet. The aerospace, automotive, and energy sectors all rely on this kind of technology for its resilience. In fact, one analysis points to aerospace and defense as the most valuable segment, where coatings provide critical thermal barriers and fight corrosion on things like jet engines. It just goes to show how trusted this technology has become.

Longevity Through Elasticity

This brings us to what might be the most important benefit of all: durability that lasts. The number one reason traditional ceramic coatings fail before their time is the development of micro-cracks. Think about it—a car’s body panels are always expanding and contracting with temperature, from a freezing winter night to a blistering summer afternoon.

A rigid coating just can’t keep up with that stress. Eventually, it fractures on a microscopic level, and its protective shield is compromised. This is where Titan’s coatings truly shine. Our elastic technology allows the coating to flex right along with the vehicle’s panels. It moves, it bends, it adapts without breaking down. This built-in flexibility means the coating remains intact, doing its job for its full lifespan.

This is precisely why Titan Coatings Elastomer technology is such a massive leap forward. It gives you the jaw-dropping gloss and hardness you expect from a top-tier ceramic coating, but it adds the intelligent flexibility needed for true, long-term performance. It’s not just another coating; it’s a dynamic, resilient second skin for your vehicle.

Choosing the Right Shield for Your Vehicle

Stepping into the world of ceramic coatings can feel a lot like walking into a pro-grade tool shop. You’ve got the heavy-duty gear for the seasoned experts, and you’ve got the more straightforward options for the weekend enthusiast. Knowing the difference isn’t just about avoiding frustration—it’s the key to making a smart investment in your vehicle’s future. This isn’t about a quick, temporary shine; it’s about choosing a durable, long-term shield that actually fits your goals, budget, and comfort level.

Professional vs. Consumer-Grade: What’s the Real Difference?

On one side of the aisle, you have consumer-friendly spray coatings. These are undeniably easy to use and give you an instant pop of gloss and that satisfying water-beading effect. The catch? Their lifespan is measured in months, not years, and they offer very little real protection against things like swirl marks or chemical stains. Think of them as a great starting point, but they just don’t have the chemical muscle of a true professional coating.

That’s where professional-grade coatings come in. These are the serious contenders, the ones that create a semi-permanent, chemically bonded layer of protection over your paint. This is where you find the real innovation—coatings that deliver years of durability, an almost liquid gloss, and hardcore resistance to whatever the road throws at you. And this is exactly the space where Titan Coatings thrives, engineering products for people who simply refuse to settle for second best.

The Professional Powerhouse: Titan Vulcan TX155

For the professional detailer or the hardcore enthusiast, “good enough” is never good enough. This is where Titan Vulcan TX155 lives. Frankly, it’s more than just a coating; it’s a statement about what’s achievable when you push the limits of material science. Vulcan is the result of our most advanced R&D, built around our proprietary Dark Matter technology to create a shield with unbelievable hardness, gloss, and chemical resilience.

Applying Vulcan TX155 is a meticulous craft, one reserved for professionals who understand that perfection is found in the details. The reward for that effort is a finish that’s not just breathtaking to look at but also incredibly tough.

Titan Vulcan TX155 is built for those who see their vehicle as more than just a way to get from A to B. It’s for the perfectionist demanding a shield that performs at the highest possible level, offering extreme gloss and a defense that laughs in the face of the harshest conditions, year after year.

This level of performance isn’t just marketing hype; it’s the standard for detailers who stake their reputations on delivering flawless, lasting results. While a product this advanced requires skill to apply correctly, the payoff is a depth of shine and a level of durability that spray-on products can’t even dream of.

Finding the Perfect Balance for Your Needs

Of course, not everyone needs the absolute pinnacle of professional-grade protection, and that’s why having a spectrum of options matters. When you’re choosing the right shield, looking at the various methods for protecting car paint is a crucial step toward getting that lasting, flawless look. For many car lovers, the sweet spot is that perfect blend of high-end performance, great longevity, and a slightly more forgiving application.

That’s precisely where Titan HyperQuartz Graphene shines. It’s absolutely a professional-grade formula, but it’s designed to be a versatile workhorse. It harnesses the strength of graphene and our signature HyperQuartz technology to deliver amazing hydrophobic properties and a deep, rich gloss that makes paint pop. It offers a huge leap in protection over any spray product—we’re talking multi-year durability—without the same intense application demands as our flagship, Vulcan.

To help you visualize where our key formulas stand, here’s a quick breakdown:

Titan Coatings Product Comparison

| Product Feature | Titan Vulcan TX155 | Titan Hyper-Quartz Graphene | Typical Spray Coating |

|---|---|---|---|

| Durability | 7+ years | 3-5 years | 3-6 months |

| Hardness | Extreme (10H+) | High (9H+) | Minimal |

| Gloss Level | Ultimate, candy-like | Deep, rich gloss | Good |

| Hydrophobicity | Extreme | Excellent | Good |

| Application | Professional Only | Pro-sumer/Professional | DIY Friendly |

| Primary Benefit | Unmatched protection & gloss | Balanced performance & durability | Ease of use & temporary shine |

This table makes it clear: the choice comes down to your specific goals for your vehicle.

The massive growth in the ceramic coatings market isn’t a fluke. Car owners everywhere are finally realizing the incredible value this technology brings to the table. In fact, one market analysis valued the global ceramic coating market at USD 12.15 billion in 2024, with projections showing it could hit USD 25.60 billion by 2034.

This trend shows a clear and growing demand for better paint protection. The trick is to remember that “ceramic coating” is not a one-size-fits-all term. It’s also important to understand how these coatings stack up against other options; for a detailed look, check out our guide on paint protection film vs ceramic coating. At the end of the day, the right choice gives you the power to protect your vehicle on your own terms.

Getting the Application and Aftercare Right

A world-class ceramic coating is an incredible investment in your vehicle, but its success boils down to one critical factor: the quality of the surface it’s applied to.

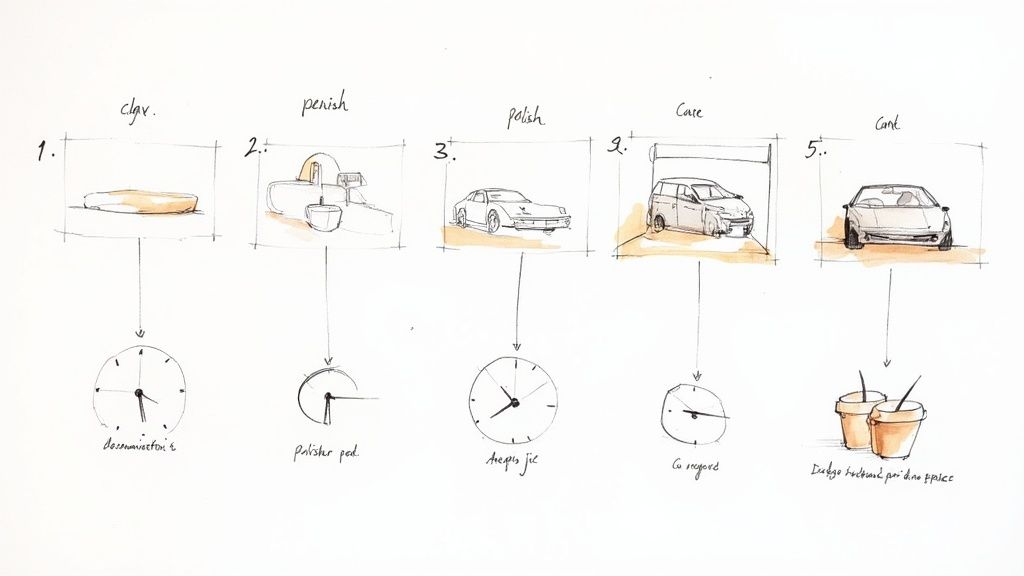

Think of it this way: a ceramic coating is like a sheet of crystal-clear glass laid over your paint. It won’t hide the imperfections underneath; it will magnify them. That tiny swirl mark you barely noticed before? It’ll become a glaring flaw under the coating’s high-gloss finish. This is why meticulous prep work isn’t just a step—it’s the entire foundation.

Getting that perfect canvas ready is a multi-stage process. We start with a deep decontamination wash to strip away any old waxes, sealants, and stubborn grime. Then comes claying, a crucial step that pulls out embedded contaminants from the paint’s microscopic pores, leaving it feeling impossibly smooth. The final and most important part is paint correction. Here, a skilled professional uses specialized polishers to hunt down and eliminate every swirl, scratch, and sign of oxidation, creating a pristine, mirror-like surface ready to bond with the coating.

The Application and Curing Process

Once the paint is flawless, the real magic begins. Applying a professional-grade ceramic coating is a true craft, demanding precision, patience, and a tightly controlled environment. Temperature and humidity have to be just right for the coating to “flash” properly—that’s the moment the carrier solvents evaporate, leaving the protective nanoparticles behind to do their work. A steady, methodical hand is essential to avoid high spots or streaks that can mar the final finish.

After the last swipe of the applicator comes the waiting game: curing. This is where the chemistry happens, as a permanent covalent bond forms between the coating and the vehicle’s clear coat. The surface might feel dry within hours, but a full, rock-hard cure can take several days, sometimes even weeks. During this critical window, the vehicle has to be shielded from rain, chemicals, and bird droppings to let the coating harden and achieve its maximum strength.

Our guide on the professional process, which you can find here https://titancoatings.us/applying-ceramic-coating-to-car/, dives much deeper into these specifics.

A common mistake is rushing the curing stage. Patience here isn’t just a virtue; it’s the final ingredient that locks in years of gloss and protection. Interrupting this chemical process is the surest way to compromise the coating’s longevity.

Let’s Debunk the “Maintenance-Free” Myth

One of the biggest misunderstandings about ceramic coatings is that they make a car completely maintenance-free. While they make cleaning incredibly easy, they aren’t a set-it-and-forget-it shield. The truth is, a simple but consistent care routine is the key to preserving those amazing hydrophobic properties and brilliant shine for years.

Even a coated car needs regular washing to remove the dust, pollen, and road grime that can clog the coating’s pores and diminish its water-beading magic. The secret isn’t to stop washing your car; it’s to start using the right methods and products to protect your investment.

Your Simple and Effective Care Routine

Keeping your coated vehicle looking showroom-new is actually quite simple. Just follow these guidelines to keep it looking its best.

- Use pH-Neutral Soap: Harsh, acidic, or high-alkaline soaps are the enemy. They can slowly degrade the coating. Always reach for a quality, pH-neutral car shampoo.

- Embrace the Two-Bucket Wash Method: It sounds simple, but it’s a game-changer. Use one bucket for your soapy water and a separate one with clean water to rinse your wash mitt. This prevents you from dragging dirt and grit back across the paint, which is what causes swirl marks in the first place.

- Steer Clear of Abrasive Car Washes: Those tunnel washes with the giant spinning brushes? Their aggressive action and harsh chemicals can wreak havoc on a ceramic coating. Stick to touchless washes or, even better, a careful hand wash.

For a more comprehensive look at long-term care, especially for a work vehicle or an entire fleet, this an ultimate fleet vehicle maintenance checklist offers some great strategies. Following this simple routine ensures your coating performs at its peak, delivering that jaw-dropping gloss and effortless cleaning you paid for from day one.

Your Ceramic Coating Questions Answered

Even with all the information out there, stepping into the world of professional ceramic coatings can feel a bit overwhelming. It’s a serious investment in your vehicle’s future, so you absolutely deserve clear, straight-up answers. Let’s tackle some of the questions we hear all the time and bust a few myths while we’re at it.

First off, let’s talk about the sheer growth of this market—it’s not just for hardcore enthusiasts anymore. This is a global industry. You’ll see different numbers depending on who you ask, mainly because everyone defines “ceramic coatings” a little differently. But the trend is undeniable. One report, for example, pegged the market at USD 9.37 billion in 2025 and projected it to hit USD 20.68 billion by 2035. That’s a huge jump, showing just how many people are seeking this level of protection.

How Long Do Titan Elastomer Coatings Really Last?

This is the big one, isn’t it? The answer is rooted in our unique technology. Forget traditional waxes that give you a few months of shine if you’re lucky. Titan’s professional elastomer coatings are engineered for years of relentless durability, provided you give them a little basic care. The secret ingredient? Flexibility.

Think about it: traditional hard coatings can get brittle over time. As temperatures swing from hot to cold, they can develop tiny micro-cracks under the stress. Our elastic coatings are built differently. They’re hard like glass but have a flexible backbone, allowing them to expand and contract right along with your car’s body panels. This built-in resilience stops the coating from breaking down, ensuring that head-turning gloss and amazing water-beading stick around for years, not just a single season.

Will a Ceramic Coating Make My Car Scratch-Proof?

This is a really important one to clear up. Let’s be blunt: no coating on the planet is completely scratch-proof. What a high-quality coating like Titan Vulcan TX155 does is add an incredibly hard, sacrificial layer over your precious paint.

Picture it as a suit of armor. It’s designed to take the hits from light scratches and swirl marks—the kind you get from routine washing and daily driving. While it won’t stop a deep, intentional key scratch or a parking lot collision, it’s a master at defending against the everyday hazards that dull your finish. Your paint stays looking flawless and swirl-free for so much longer.

Can I Apply a Professional Titan Coating Myself?

While we do make some products for skilled DIYers, our most advanced elastomer coatings really belong in the hands of a certified professional. The reason is simple: surface preparation is everything. It is the absolute foundation for the coating’s performance and longevity.

A professional detailer has the right tools, the right training, and the eye for perfection needed to perform a full paint correction, ensuring the surface is perfectly smooth and 100% free of defects before the coating ever touches it. That painstaking prep work is what guarantees you get the jaw-dropping results and durability you’re paying for. The application and curing phase is just as vital, and you can learn more about how long ceramic coating takes to cure in our detailed guide.

What Exactly Is an Elastomer Coating?

The game-changing difference is flexibility. Standard ceramic coatings cure into a very rigid, glass-like shell. That hardness is great for protection, but it has a hidden weakness. A car’s metal and plastic panels are constantly expanding and contracting with temperature changes, and over time, this can stress a rigid coating and create those microscopic cracks.

Titan’s elastomer coatings, born from nano-tube and Dark Matter tech, are engineered to be just as hard but also flexible, like hardened rubber. This elasticity allows the coating to flex with the vehicle’s panels without cracking, dramatically increasing its real-world durability and lifespan. It’s the evolution of protection.

This innovative approach means the coating doesn’t fatigue when the temperature swings from a freezing winter morning to a scorching summer afternoon. The shield stays intact and uncompromised for its entire service life. It’s just smarter, more resilient protection.

Ready to experience the next generation of vehicle protection? Titan Coatings offers a full lineup of advanced elastomer coatings designed to deliver unmatched gloss, durability, and resilience.

Explore our product comparison and find the perfect shield for your vehicle. Discover the Titan difference at our comparison page.

0 Comments