Driving in a downpour can be one of the most stressful experiences behind the wheel. When your wipers can't keep up and oncoming headlights create a blinding, blurry mess, you're not just uncomfortable—you're unsafe. It's a white-knuckle fight against the elements just to see the road ahead.

This is a scenario every driver knows, and it’s the exact problem a high-quality ceramic glass coating solves. Think of it as an invisible, ultra-slick shield for your windshield and windows. It creates a powerful hydrophobic surface that literally forces water to bead up and fly off the glass, transforming a hazardous drive into a safe and clear journey.

An Invisible Shield That Makes a Visible Difference

We've all been there. The sky opens up, and suddenly you're battling sheets of rain that your wipers just smear around. For many drivers, this is just a frustrating reality of commuting, especially at night when the glare is at its worst. It leaves you feeling drained and on edge.

But what if you didn't have to fight so hard to see? This is where true nano-tech coatings change the game entirely. We're not talking about those temporary rain repellents that wear off after a few car washes. A ceramic glass coating is different. It forms a semi-permanent, molecular bond with the glass itself, fundamentally changing how your windshield deals with the world around it.

This bond creates an incredibly smooth, durable, and non-stick surface. Rain, sleet, dirt, and grime are repelled with unbelievable efficiency. For many drivers, this means rain droplets simply vanish from the windshield at highway speeds, often without even needing to turn the wipers on.

A Market Driven by Real-World Performance

It's no surprise that demand for this kind of protection is exploding. The global ceramic coatings market was valued at around USD 13.08 billion in 2025 and is on track to more than double, reaching a projected USD 27.98 billion by 2035. The automotive sector is leading the charge, expected to capture 32% of that market share as more and more drivers demand superior, long-lasting solutions.

More Than Just Rain Repellency

The "wow factor" is definitely watching water fly off your glass, but the benefits don't stop there. A quality coating makes cleaning off stubborn contaminants like bugs, bird droppings, ice, and road grime remarkably easy. You'll find yourself scrubbing less and using fewer harsh chemicals.

A ceramic glass coating is more than a convenience—it's a critical safety upgrade. By maintaining a clear field of vision in all conditions, it reduces driver fatigue and reaction time, turning a hazardous drive into a confident one.

This is the core principle behind our work at Titan Coatings. As the first company to introduce elastomer coatings using nano-tubes and Dark Matter Tech, we've developed advanced formulas that take protection to the next level. Our elastic coatings, including our user-friendly Apex Glass Ceramic Coating, are engineered to be hard like glass but with built-in flexibility. This unique elasticity prevents them from cracking or delaminating under the stress of extreme temperature swings, from freezing winters to blistering summers, ensuring they last much longer.

It’s the durable, unseen shield that makes every drive safer and less stressful—a real solution for a real-world problem.

Why Flexibility Is the Future of Surface Protection

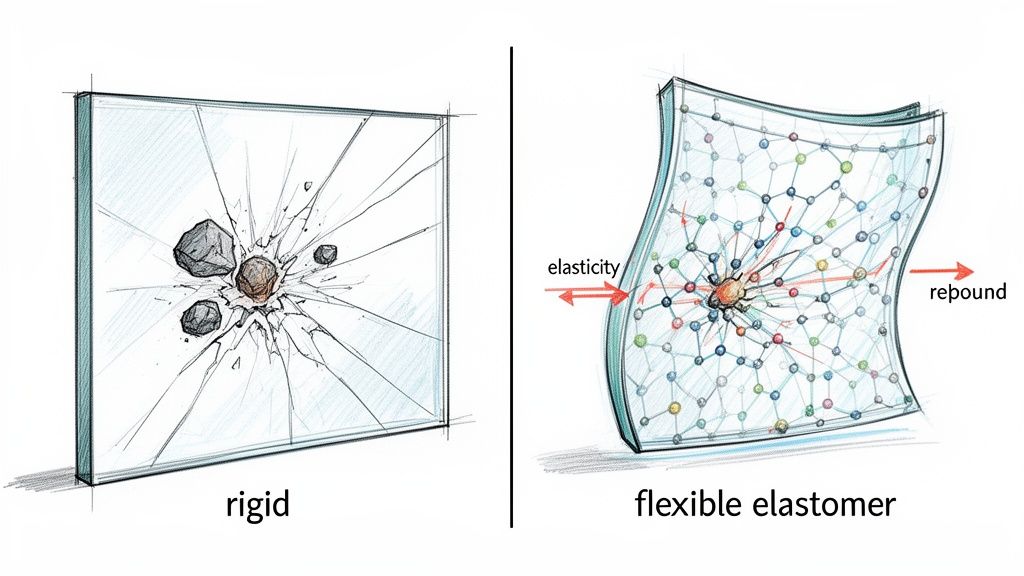

For years, the automotive protection industry was obsessed with one thing: hardness. The logic seemed sound—the harder the coating, the better it protects. The 9H rating became the holy grail, promising a literal shield of armor for your vehicle's paint.

But this singular focus on hardness ignored a massive, real-world flaw.

Think about what happens when a small rock hits a pane of glass. It shatters. That same principle applies to coatings that are too hard and brittle. Sure, they might fend off some fine scratches in a controlled test, but a real-world impact from road debris can cause them to chip, crack, or completely delaminate, leaving your paint exposed.

The Dawn of a New Era: Elasticity

We started asking a different question: what if a protective layer could be hard as glass but also flex and absorb energy? This question drove us at Titan Coatings to a genuine breakthrough. We became the first company to bring elastomer coatings to the market, completely rewriting the definition of durable surface protection.

By weaving in advanced nano-tubes and our proprietary Dark Matter Tech, we engineered an entirely new class of ceramic glass coating. This isn't just a slightly harder version of the old stuff; it's a smarter one. Our elastomer formulas have a unique quality we call elasticity.

This elasticity makes the coating incredibly resilient. Instead of shattering on impact, it can absorb and dissipate the energy from a stone chip or bug strike, preserving both the coating and the paint underneath. It’s the difference between a shield that breaks and one that bends.

Surviving the Extremes

This built-in flexibility solves another huge problem that plagues rigid coatings: extreme temperature swings. A car's surface can go from freezing cold overnight to baking in direct sun in just a few hours. That constant expansion and contraction puts incredible stress on anything bonded to it.

A rigid coating simply can't keep up. Over time, that thermal stress creates micro-cracks, compromising the coating’s integrity and letting contaminants sneak through to the paint. Our elastic coatings, on the other hand, expand and contract right along with the surface. They stay perfectly bonded and intact, whether you’re dealing with a Canadian winter or an Arizona summer. Temperature change won't affect the coating, as it won't crack down due to its flexibility.

- Impact Absorption: Flexes to absorb energy from road debris, preventing chips and pitting.

- Thermal Resistance: Stretches and shrinks with temperature changes, eliminating the risk of stress cracks.

- Enhanced Longevity: This fundamental resilience means the coating simply maintains its protective qualities for far longer.

The Screen Protector Analogy

It’s a lot like how screen protectors for phones have evolved. Remember the early ones? They were thick, rigid pieces of plastic or tempered glass. They offered decent scratch protection, but one bad drop and they’d spiderweb, forcing you to replace them immediately.

Today’s best screen protectors are thin, flexible films. They’re still tough enough to stop scratches, but they’re also pliable enough to absorb the shock from a fall without breaking. They provide better, more reliable protection precisely because they aren’t completely rigid.

This is the exact principle behind our coatings. By prioritizing smart resilience over simple hardness, we've engineered a solution that offers true, long-lasting defense against the real-world hazards your vehicle faces every single day. To dive deeper into the science behind this leap in durability, you can learn more about Titan Coatings' elastomer technology and see what truly sets it apart. This isn't just a feature; it's the future.

Choosing Your Armor: A Guide to Titan Coatings

Picking the right protection for your vehicle can feel like a huge decision, and honestly, it is. It’s the final, critical step in defending your investment. We've engineered a specialized arsenal here at Titan Coatings, and figuring out which product from our shop fits your specific needs is the key to getting those brilliant, long-lasting results you're after.

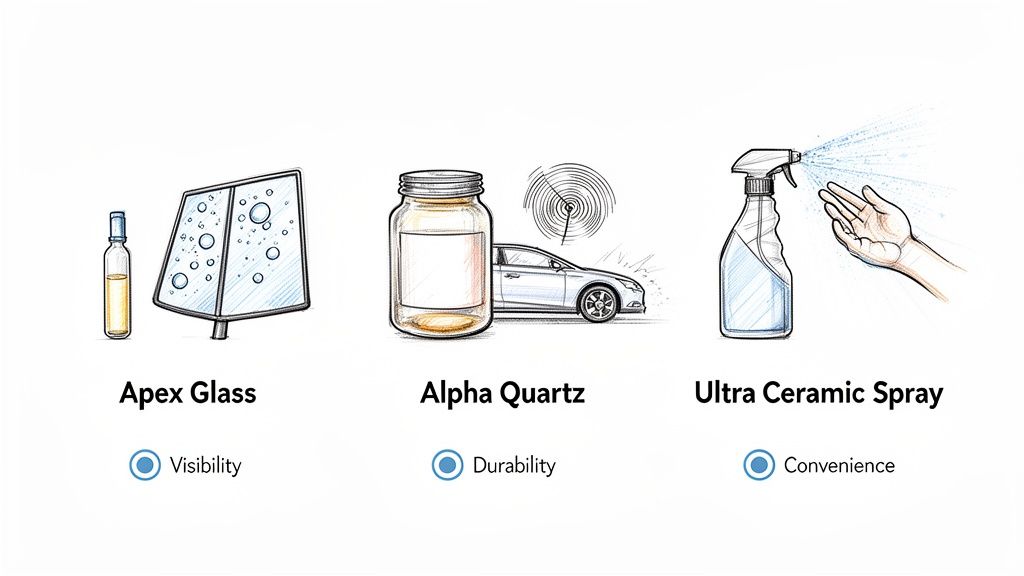

Each formula is built for a different job—from creating an impossibly clear view through your windshield in a storm to forming a flexible, rock-defying shield over your paint. Let’s break down the options so you can choose with confidence.

For The Safety-Conscious Driver: Unmatched Visibility

Picture this: you're driving down the highway when a sudden, blinding downpour hits. For most drivers, that’s a white-knuckle moment. Visibility drops to near zero, and the stress goes through the roof. This is exactly where Apex Glass Ceramic Coating proves its worth, turning a dangerous situation into a non-event.

Apex was designed with one job in mind: to make your glass so slick that water simply can't stick. The application is dead simple, meaning any DIYer can get professional results right in their own garage. Once cured, the surface becomes so hydrophobic that raindrops bead up and fly right off the windshield at speed, often making your wipers completely unnecessary. Driving in the rain becomes clear, calm, and, most importantly, stress-free.

For The Ultimate Protector: Maximum Durability

If you're a detailer or a die-hard enthusiast who demands the absolute pinnacle of paint protection, there's no substitute for a true elastomer coating. This is where Alpha Quartz sits in a class all its own. It's the embodiment of our core belief: real-world durability comes from flexibility, not just hardness.

Alpha Quartz is our flagship formula, engineered to be as tough as glass but flexible enough to absorb impacts. Think about it—traditional hard ceramic coatings can get brittle and crack under the stress of a rock chip or wild temperature swings. Alpha Quartz flexes. That elasticity is what stops it from fracturing when a bug hits your bumper at 80 mph or when the metal panels expand and contract from a freezing winter night to a scorching summer day. Its easy installation delivers great results, providing the ultimate armor for anyone who wants years of resilient, reliable protection.

Choosing the right coating is an investment in your vehicle’s longevity and your own peace of mind. Whether you prioritize safety, durability, or convenience, there is a Titan solution engineered to exceed your expectations.

For The Practical Enthusiast: Incredible Results, No Hassle

Look, not everyone has a full weekend to dedicate to a multi-stage coating application. That shouldn't mean you have to settle for weak protection. We created Ultra Ceramic Spray for the weekend warrior and the busy car owner who wants amazing results without the back-breaking labor.

Ultra delivers a show-car gloss and serious hydrophobic punch with a simple spray-on, wipe-off process. It’s the perfect way to add a tough layer of ceramic protection in a fraction of the time, whether you use it as a maintenance topper for an existing coating or as a standalone sealant. Its ease of use reflects a huge shift in the industry toward user-friendly products. In fact, the thermal spray segment became the dominant force in the ceramic coatings market, grabbing about 50% of the total market share in 2020. This trend, driven by powerful yet simple formulas, is projected to swell the market to USD 8 billion by 2027.

Titan Coatings Product Comparison

Still weighing your options? This table breaks down our core technologies to help you pinpoint the perfect coating for your needs, whether you're protecting glass, paint, or anything in between.

| Product | Primary Use | Key Technology | Primary Benefit | Ideal User |

|---|---|---|---|---|

| Apex Glass | Automotive Glass | HyperQuartz® | Extreme Hydrophobicity & Safety | The safety-focused daily driver |

| Alpha Quartz | Paint Protection | Elastomer | Flexible Durability & Impact Resistance | The perfectionist seeking long-term armor |

| Ultra Ceramic Spray | Paint Sealant | SiO2 Spray Tech | Convenience & High Gloss | The busy enthusiast or weekend detailer |

Each of these formulas offers a distinct advantage. By matching the right product to your goals, you're not just protecting your car—you're upgrading it with the best technology the industry has to offer.

To make your decision even easier, our product comparison page provides a detailed side-by-side look at each coating’s strengths. And for an even deeper dive, be sure to read our complete guide on choosing the best ceramic coating for cars.

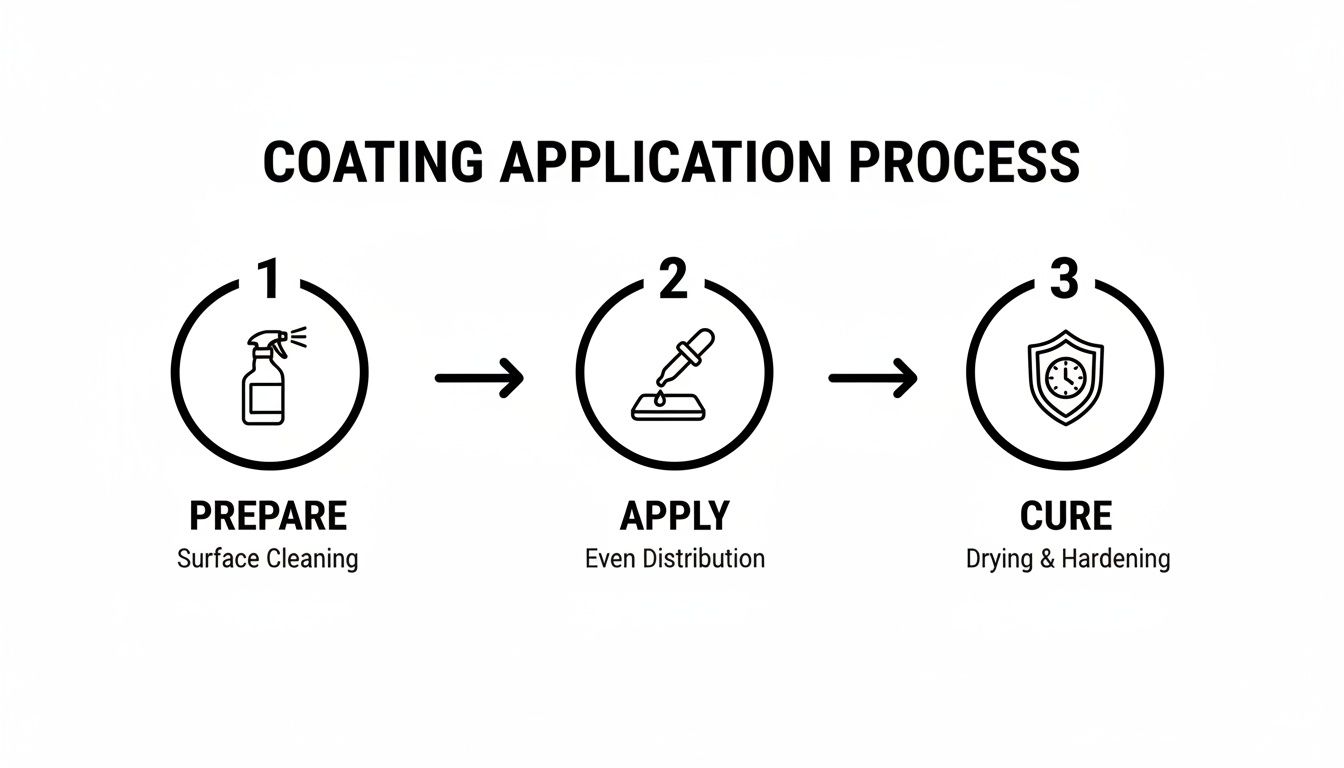

Achieving a Flawless Ceramic Coating Application

A world-class ceramic coating demands a world-class application. The incredible technology inside every bottle of Titan Coatings is potent, but unlocking its true power comes down to one thing: meticulous surface preparation. The final bond is only as good as the surface it’s applied to, making this stage the most critical part of the entire job.

Think of it like a master painter preparing a canvas. You wouldn't slap expensive oil paints onto a dirty, bumpy surface and expect a masterpiece. It's the exact same principle with coatings. The ceramic layer will lock in and amplify everything underneath it—pristine gloss or ugly flaws. A perfectly prepped surface is the only way to get that flawless, liquid-glass finish that performs as designed for years to come.

The Foundation of a Perfect Finish

Before you even think about cracking open a bottle of coating, the vehicle's surface needs to be surgically clean and perfectly smooth. This isn't just about a quick Saturday wash. It's a multi-stage assault on every contaminant that could get in the way of a proper bond. Cutting corners here is the number one reason applications fail.

The prep work boils down to three key phases:

- Decontamination: This always starts with a thorough wash, but the real work comes next. Chemical decontamination with an iron remover and a tar remover is essential. These products dissolve the stubborn, embedded industrial fallout and road grime that soap and water just can't touch. You’ll know the iron remover is working when you see it turn deep purple as it dissolves microscopic brake dust particles.

- Claying: Once the chemicals have done their job, a clay bar or clay mitt is used with a slick lubricant to physically pull out anything left behind. When you’re done, the paint should feel unbelievably smooth—like a sheet of glass.

- Paint Correction: This is where the magic happens. Using a machine polisher, you carefully level the clear coat to eliminate swirls, fine scratches, and oxidation. This step is absolutely crucial because the ceramic coating will permanently seal in any imperfections. The goal is to create a perfect, mirror-like canvas for the coating to bond to.

Applying Alpha Quartz: A Step-by-Step Narrative

With the surface now flawless, it's time to lay down the armor. Let's walk through the application of a professional-grade elastomer coating like our Alpha Quartz. Make sure you’re working in a well-lit, temperature-controlled space, like a garage. Good lighting is non-negotiable for seeing your work clearly and avoiding mistakes.

You’ll want to work in small, manageable sections, usually about 2×2 feet. This panel-by-panel approach gives you total control over the application and removal before the product starts to cure.

Apply a few drops of Alpha Quartz onto your applicator and spread it over the section using a cross-hatch pattern—first go side-to-side, then up-and-down. This simple, methodical motion ensures you get perfectly even coverage every time.

Pro Tip: Keep a close eye on the product's "flashing" time. This is the visual cue that tells you the solvents are evaporating. You’ll see a rainbow-like or hazy effect sweep across the surface. That’s your signal to move on to the next step.

Once the coating has flashed, it's time for the crucial leveling step. Take a clean, high-quality microfiber towel and gently wipe the area to remove the excess product. This "knocks down" any high spots and leaves a completely uniform layer. Immediately follow up with a second, fresh microfiber to buff the section to a brilliant, streak-free shine.

The Curing Process: Patience Is a Virtue

After the last panel is coated and buffed, the real work for the coating begins: curing. It needs undisturbed time to fully harden and forge a permanent bond with the paint. For the first 24-48 hours, it is absolutely critical to keep the vehicle dry and sheltered from the elements.

Avoid washing the car with any kind of soap for at least one week. This gives the coating time to achieve its maximum hardness and chemical resistance. This period of patience is what guarantees the flexible, resilient shield you just applied will deliver the incredible long-term protection you expect.

By following these steps with precision and care, you can achieve a finish that will rival any pro detailer. For an even more detailed walkthrough, check out our guide on how to properly apply a ceramic coating to your car, which is packed with more tips and tricks of the trade.

Maintaining the Shine of Your Coated Vehicle

So, you've invested in a top-tier ceramic glass coating, and your vehicle now wears a slick, hydrophobic shield that gleams like nothing else. The job's done, right? Almost. The next step is preserving that stunning finish, and thankfully, it’s far easier than you might think. Proper maintenance isn’t about more work; it’s about working smarter to ensure years of peak performance from your coating.

Let’s clear up the biggest myth right away: a coated car still needs a bath. While the coating makes cleaning incredibly easy, you still need to wash away the surface grime that can eventually clog the coating’s pores and dull its water-beading magic.

The Do's and Don'ts of Coating Aftercare

Protecting your investment really boils down to having a few good habits. The whole point is to clean the surface without introducing new scratches or using harsh chemicals that could weaken that protective layer. This means those automated car washes with their giant, abrasive brushes and aggressive, high-pH soaps are officially your enemy. Avoid them.

Instead, a gentle, hands-on approach is your best friend. The two-bucket wash method is the gold standard for a reason. You have one bucket for soapy water and a separate one with clean water to rinse your wash mitt. This simple separation keeps the dirt and grit you just removed from being dragged right back across your paint—the number one cause of swirl marks.

Here’s what you need to remember:

- Use pH-Neutral Soap: Stay away from harsh, acidic, or alkaline soaps. They can slowly eat away at your coating. A quality, pH-neutral car shampoo is all you need to lift dirt without causing damage.

- Wash Regularly: Don't let things like bird droppings, bug guts, or tree sap bake into the finish. A quick wash every week or two is perfect for keeping things pristine.

- Dry with Care: Grab a few high-quality, plush microfiber towels to gently pat or blot the surface dry. Never rub aggressively, and please, don't even think about using that old, scratchy towel from the garage.

The application process is the foundation that this maintenance routine protects.

As you can see, the Prepare, Apply, and Cure stages are critical. Your aftercare ensures the results of that careful process last.

Boosting and Extending Protection

Want to keep your coating performing like it was just applied? Look into a maintenance spray, often called a "topper." These are typically SiO2-infused products, like our Ultra Ceramic Spray, built to rejuvenate your coating on the fly.

Think of it as a quick tune-up for your vehicle’s armor. It adds a fresh layer of slickness, amps up the hydrophobic properties, and can even fill in microscopic signs of wear, stretching the life of the base coat.

A great maintenance routine doesn't just keep your car clean; it actively extends the lifespan and enhances the performance of your ceramic glass coating, ensuring you get the maximum return on your investment.

By following these simple steps, you'll make sure your Titan coating delivers that unbelievable gloss and effortless self-cleaning effect for years. For a complete deep-dive, check out our guide on https://titancoatings.us/ceramic-coat-maintenance/. And while you're focused on preserving that perfect finish, electric car owners might also benefit from understanding the overall electric car maintenance costs to get a full picture of vehicle care.

What Makes Titan Different? It’s Not Just Marketing Hype.

Look, the coatings market is crowded. Everyone claims to be the best, and it's easy to get lost in the noise. But the difference with Titan Coatings isn't some slick slogan—it's a result of our history. We were the first to introduce Elastomer coatings to the market, pioneering a technology that redefined durability. We’re not here to just follow the rules; we’re here to write them.

Our whole approach started by asking a better question. Most brands were chasing after pure hardness, but we knew that wasn't the whole story. We went after intelligent resilience. This led us down the path to creating our elastomer coatings, which have completely changed the game.

By weaving in nano-tubes and our own Dark Matter Tech, we engineered a protective layer that’s as hard as glass but has a unique flexibility you won't find anywhere else. Think of it like a sheet of high-tech armor that can bend without breaking.

This elasticity is crucial. It’s why our coatings, like the legendary Alpha Quartz, won't crack or peel when a car's panels expand and contract with wild temperature swings. From a frozen Minnesota winter to a scorching Arizona summer, that protective shield stays put, moving with the vehicle, not against it.

From the Lab to the Real World

We don't just rely on pretty lab reports to prove our coatings work. We're an ISO 9001 certified company, which is a big deal. It means our quality control and obsession with getting better are held to the highest international standards. Before a single bottle leaves our facility, it's been through hell and back in some of the globe's harshest climates. We make sure it delivers the kind of relentless, long-term protection you can actually count on.

And it seems the world is catching on. The demand for truly advanced protection is exploding, especially in the Asia-Pacific region. In fact, that market is on track to account for over 50% of the entire global ceramic coatings market share by 2035. This isn't a small trend; it's a massive shift driven by the booming car scenes in China and India, and it shows people everywhere are demanding better preservation for their vehicles. You can read more about this market trend to see just how big this movement is.

At Titan Coatings, our proprietary technologies like DiamondTech and HyperQuartz® aren't just bullet points on a feature list. They’re a promise. A promise of unmatched UV resistance, outrageous chemical resilience, and a regenerative quality that keeps your investment protected for the long haul.

At the end of the day, our science connects directly to what you really want: a jaw-dropping finish and the peace of mind that comes with it. We don't just sell coatings. We deliver armor, engineered for the real world.

Common Questions About Ceramic Coatings

Jumping into the world of high-tech vehicle protection can feel like learning a new language. As pioneers in coating technology, we get it. We're here to cut through the noise and give you clear, straight-up answers so you can understand what you're really getting when you upgrade your vehicle's armor. Knowing the facts is the first step to getting that brilliant, long-lasting finish you're after.

We talk to everyone from pro detailers to weekend warriors, and a lot of the same questions pop up. Let's tackle some of the most common ones.

How Is an Elastomer Coating Different from a Standard Ceramic Coating?

This is probably one of the most critical questions in modern surface protection. A standard ceramic coating lays down a super hard, rigid layer. While that hardness is great for fending off fine scratches, it also has a downside: it can be brittle. Picture a thin sheet of glass—it's tough, but a sharp impact will crack it.

An elastomer coating, like our flagship Alpha Quartz, is built on a totally different principle. We use our Dark Matter Tech and nano-tubes to weave flexible polymers into the coating's structure. The result? A surface that's hard like glass but also has the give of rubber. This elasticity allows it to absorb the energy from rock chips and other road debris instead of just shattering. It also means the coating can expand and contract with drastic temperature swings, from freezing winters to scorching summers, which gives it incredible durability and a much longer life.

Can I Apply a Ceramic Glass Coating Like Apex Myself?

You bet. We specifically formulated products like our Apex Glass Ceramic Coating and Ultra Ceramic Spray for the DIYer who wants pro-level results without the pro-level complexity. The science behind it is advanced, but we made sure the application is straightforward.

The real secret to a killer DIY application isn't your wiping technique—it's all in the prep work. The surface, whether it's glass or paint, has to be obsessively clean and decontaminated before you even think about opening the bottle. Follow the instructions to the letter, and you'll get that amazing water repellency and clarity you're looking for, right in your own garage.

How Long Does a Titan Ceramic Coating Really Last?

Honestly, the lifespan of any ceramic glass coating boils down to three things: which product you choose, how well it was applied, and how you take care of it afterward. Our pro-grade elastomer coatings are engineered to last for years when they're properly maintained. For our more accessible options like Ultra Ceramic Spray, you can expect months of solid protection, and topping it up is a breeze.

The key to getting the most out of your coating is a simple, safe wash routine. Stick to pH-neutral soaps, use smart techniques like the two-bucket method, and stay far away from those abrasive automatic car washes with their paint-swirling brushes. A little bit of care goes a long, long way in keeping your coating working at its best.

Ready to completely change your view from behind the wheel with a durable, crystal-clear barrier? Titan Coatings has the solution engineered and ready to go.

Discover the difference stress-free driving makes with Apex Glass Ceramic Coating. It's your ticket to a safer, clearer journey, no matter what the sky throws at you.

0 Comments