Picture this: you’ve just spent hours detailing your car. The paint is a liquid mirror, the glass is invisible, but then you step back and your eyes land on the wheels. They’re dull, grimy, and coated in a stubborn film of brake dust that just won’t quit. This isn’t just a story about being dirty; it’s a constant, brutal assault on your wheels, and winning this fight requires more than a simple bucket of soapy water.

The Unseen War on Your Wheels

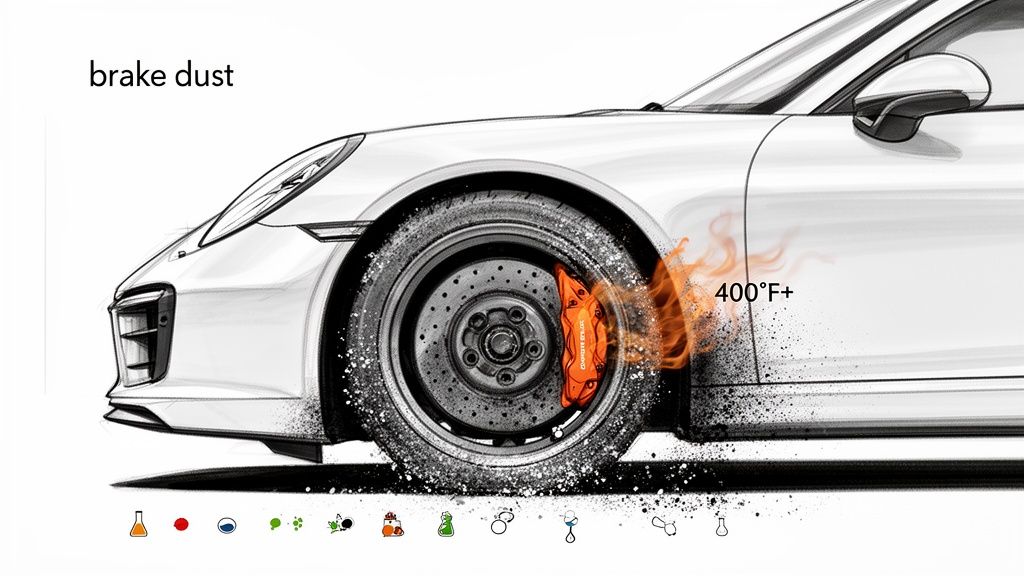

If your wheels could talk, they’d tell stories of being on the front lines. They take a beating that the rest of your car never experiences. Every single time you tap the brakes, a cloud of tiny, super-hot metal fragments sheds from your brake pads and rotors.

This isn’t ordinary dust. These particles, known as brake dust, can hit temperatures well over 400°F. At that heat, they don’t just land on your wheels; they literally bake themselves into the finish, etching and pitting the clear coat on a chemical level.

A Battle on Multiple Fronts

The intense heat is only part of the story. Your wheels are ground zero for a whole range of environmental and chemical attacks.

- Road Contaminants: They get blasted with tar, asphalt, and road grime that clings on for dear life.

- Corrosive Elements: Winter roads bring a corrosive cocktail of salts and de-icing agents that eat away at the finish.

- Harsh Chemicals: Even your cleaning routine can cause harm. Many aggressive, acid-based wheel cleaners can strip away the protective layers, leaving the raw finish completely exposed.

It’s a nasty, vicious cycle. The more the finish gets damaged, the more tiny pores and scratches open up for brake dust and dirt to grab onto. This makes every cleaning session more difficult than the one before. You scrub and scrub, but the grime seems to come back instantly. To see how to break this cycle, you can learn more about how a dedicated iron fallout remover dissolves these embedded particles.

Traditional waxes and polymer sealants are like bringing a knife to a gunfight. Sure, they provide a nice shine for a short time, but they stand no chance against the extreme heat and constant chemical abuse. They simply melt or wash away, leaving your wheels completely defenseless again.

This high-stakes environment demands a solution built for the job—something engineered not just to look good, but to survive. The real problem isn’t just about keeping wheels clean; it’s about saving them from permanent damage. This is exactly where a true ceramic wheel coating enters the picture.

What Is A Ceramic Wheel Coating?

So, we know wheels take an absolute beating. What’s the answer? You need a shield specifically forged for that kind of battle. The best way to think of a ceramic wheel coating is like a liquid-applied, semi-permanent layer of tempered glass custom-fitted to every inch of your wheels.

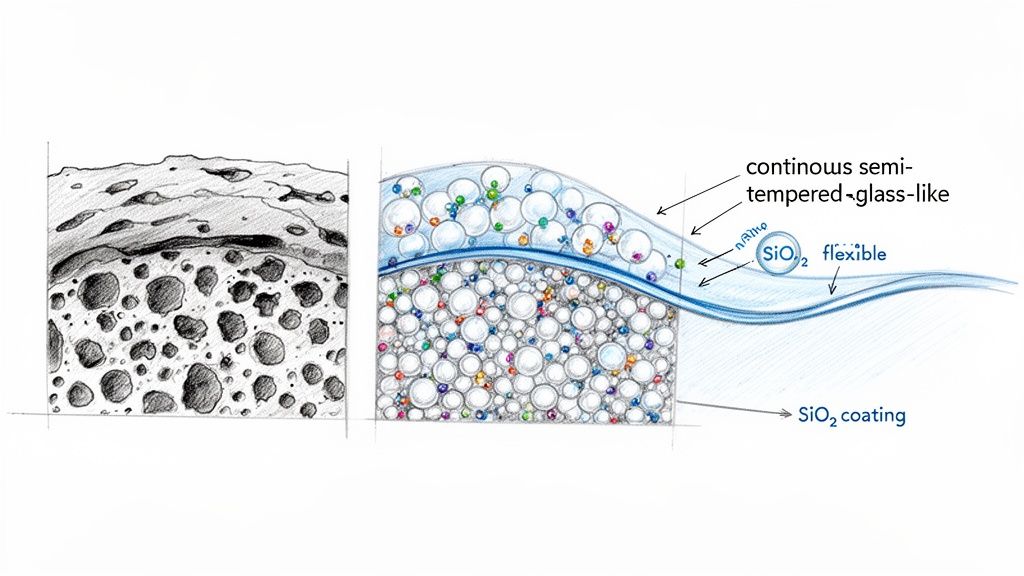

This isn’t just another wax or sealant that sits on the surface and washes away. A true ceramic coating is a liquid polymer, usually based on Silicon Dioxide (SiO2), that you apply directly to the wheel. When it cures, it doesn’t just dry—it undergoes a chemical reaction, creating a powerful molecular bond with the wheel’s finish. It literally becomes a functional part of the surface, forming an incredibly hard, slick, and heat-resistant barrier.

The Science Behind That “Easy-Clean” Sheen

The real genius of a ceramic coating is what happens on a microscopic level. Even a brand-new, perfectly painted wheel has a surface riddled with tiny, invisible pores. These little imperfections are exactly where corrosive brake dust and road grime dig in, making them a nightmare to clean properly.

A quality wheel coating uses nanotechnology to make that problem disappear. Picture pouring liquid glass over a rough, porous stone. The liquid instantly flows into every single crack and crevice, then hardens into a perfectly smooth, level surface. The nano-particles in the coating do the same thing for your wheel, creating a uniform, non-porous shield that contaminants can’t get a grip on. That’s the secret to why coated wheels are so ridiculously easy to clean—the dirt just has nowhere to stick.

If you want to explore the bigger picture, our guide on what ceramic coatings are covers the technology in more detail.

Why Not All Coatings Are Built for Wheels

This is where things get interesting, and where the old way of doing things fell short. For a long time, the holy grail for coatings was hardness. But this created a major flaw: traditional ceramic coatings were incredibly hard, but also very brittle. Think of it like a pane of old glass—it can resist scratches, but a sharp impact or stress will cause it to shatter.

This was a constant headache for professional detailers. They’d apply a pricey coating to a set of performance wheels, only for the client to come back months later with the finish riddled with micro-cracks. The culprit? The massive temperature swings a wheel goes through. From a sub-zero winter night to the blistering heat of a track day, the rigid coating just couldn’t handle the expansion and contraction of the metal wheel underneath. It would simply fracture under the stress.

This is the exact problem Titan Coatings set out to solve. As the first company to introduce Elastomer coatings to the market, we knew there had to be a better way. This innovation completely changed the game.

By integrating advanced nano tubes and our proprietary Dark Matter Technology®, we created a coating that is hard like glass but remains flexible. This flexibility is the absolute key to durability in the extreme environment of a wheel.

This unique elastic property means our coatings can expand and contract right along with the wheel’s metal as temperatures fluctuate wildly. A frozen morning won’t compromise the bond, and the intense heat coming off the brakes won’t cause it to crack down. The coating moves with the wheel instead of fighting against it.

This is what prevents the micro-cracking that plagues older, more rigid formulas. It’s the innovation that allows Titan’s wheel coatings to last longer and perform better under the real-world pressures your wheels face every single day. This isn’t just protection; it’s adaptable, resilient armor.

Why Your Wheels Need Their Own Armor, Not Your Car’s Leftovers

It’s a question I hear all the time, both from seasoned detailers and weekend warriors: “I’ve got some ceramic coating left from the paintwork. Can I just use that on my wheels?” On the surface, it makes perfect sense—why let good product go to waste?

But here’s the hard truth: using a paint-specific ceramic coating on your wheels is like wearing dress shoes to run a marathon. They might look good at the starting line, but they’ll fall apart before you hit the first mile. The environment your wheels endure is a world away from the relatively gentle life of your car’s body panels.

Your car’s paint has to deal with sun, rain, and the odd bird dropping. Your wheels are in a constant, brutal street fight. They are on the front lines, taking a beating from enemies a body coating was never designed to face.

The Gauntlet Your Wheels Run Every Day

To really get why a specialized ceramic wheel coating is non-negotiable, you have to understand the three core threats that make your wheels’ job so tough:

- Unbelievable Heat Cycles: This is the big one. Your hood might get hot on a summer day, but your wheels can skyrocket to temperatures well over 400°F during heavy braking, then cool down rapidly. This constant, extreme expansion and contraction is a killer for rigid coatings designed for stable body panels, leading to micro-fractures and total failure.

- Weaponized Brake Dust: That black dust caked onto your wheels isn’t just dirt. It’s a cocktail of superheated, sharp metallic particles mixed with carbon and adhesive resins. At high temperatures, this corrosive grime literally bakes itself into a wheel’s finish, causing permanent pitting and damage. A standard body coating just doesn’t have the chemical backbone to fend off this specific type of assault.

- The Road’s Worst Rubble: Wheels are magnets for everything nasty on the road. They get blasted by gravel, sand, and other debris. They’re constantly sloshed with road grime, sticky tar, corrosive salts, and harsh de-icing chemicals. A proper wheel coating is formulated for maximum resilience against this chemical and physical bombardment. As our guide on how to remove road tar shows, these contaminants are notoriously difficult to deal with without a tough protective layer.

To put it in perspective, let’s compare the two environments side-by-side.

Body Coating vs. Wheel Coating: A Head-to-Head Comparison

It quickly becomes clear that these two components live in completely different worlds, each demanding its own unique form of protection.

| Challenge | Car Body Panels | Car Wheels | Why It Matters for Coatings |

|---|---|---|---|

| Heat Exposure | Moderate, primarily from sunlight. | Extreme, with rapid spikes over 400°F from braking. | A wheel coating must be flexible and thermally stable to prevent cracking under intense heat cycles. |

| Contaminants | Bird droppings, tree sap, rain. | Hot, corrosive brake dust, road tar, salts, harsh chemicals. | A wheel coating needs a specialized chemical structure to repel metallic, high-temp contaminants. |

| Physical Impact | Occasional rock chips on the front end. | Constant bombardment from gravel, sand, and road debris. | Durability and hardness are critical for a wheel coating to resist chipping and abrasion. |

This table lays it out plainly: a wheel coating isn’t just a “stronger” body coating. It’s an entirely different formulation engineered for a far more hostile environment.

Titan’s Solution: Armor Forged in the Fire

This is exactly why we never took a one-size-fits-all approach. Our wheel-specific coatings, like Titan Graphene V2.1 and HyperQuartz, were engineered from day one to thrive in this high-heat, high-abuse environment. They aren’t just tweaked paint coatings; they are purpose-built chemical solutions. You can check our comparison page to see the differences and find the perfect match for your needs.

“A wheel coating needs to do more than just shine; it needs to survive. We built our formulas to handle the intense heat and chemical stress that would cause a standard body coating to fail within months.”

We pushed the science even further by incorporating our Dark Matter Technology®. This isn’t just marketing fluff. It’s a process that creates a super-dense, heavily cross-linked protective matrix on the surface. Think of it as the difference between a simple chain mail shirt and a full suit of interlocking plate armor. This denser molecular structure provides a far more robust shield against both high-velocity impacts and aggressive chemical attacks.

The market backs this up. The global demand for specialized automotive wheel coatings hit an estimated US$3.3 billion in 2025 and is on track to reach US$4.7 billion by 2032. Industry trends clearly show that advanced ceramic coatings are becoming the gold standard, especially for performance vehicles where wheel protection is just as important as paint protection. You can discover further insights into automotive wheel coatings and see how the technology is evolving.

At the end of the day, using a dedicated wheel coating isn’t a luxury—it’s just smart. It’s about using the right tool for the job and giving your wheels a shield forged specifically for the battle they face every single day.

So, What Does This Actually Do for My Wheels?

It’s one thing to talk about molecular structures and advanced chemistry, but what does all that science really mean for you, standing in your driveway or workshop? Let’s get down to the brass tacks and talk about the real, tangible difference you’ll see and feel when you protect your wheels with a top-tier ceramic coating. This isn’t just about a fleeting shine; it’s about fundamentally changing how you care for your car.

The payoff is instant, deeply satisfying, and it lasts. You’ll save time, you’ll save effort, and you’ll protect your investment. It’s a genuine upgrade to the entire ownership experience.

Finally, Cleaning Wheels Becomes Effortless

If you ask any car enthusiast what the absolute worst part of washing their car is, nine times out of ten, they’ll say, “the wheels.” It’s a brutal, back-breaking chore. You’re on your knees with harsh chemicals and a dozen different brushes, scrubbing away at that caked-on, burnt-on brake dust.

A ceramic wheel coating flips that script completely. Picture this: your wheels are caked in a week’s worth of grime and that familiar layer of black dust. But instead of grabbing the degreaser and brushes, you just pick up the pressure washer. With a simple spray of water, you watch in amazement as all that grime just sheets right off, revealing a perfectly clean, gleaming wheel underneath.

It’s not magic—it’s the power of extreme hydrophobicity and creating a slick, non-stick surface. Dirt and brake dust simply have nothing to grab onto. What used to be a thirty-minute, knuckle-scraping nightmare becomes a two-minute rinse. It’s one of the most satisfying things you can experience as a car owner.

Your Best Defense Against Permanent Damage

Your wheels are constantly at war. Hot, metallic particles from your brake pads fly off and try to etch themselves permanently into the finish. Road salt and harsh chemicals try to stain and corrode the surface. And the sun’s UV rays are always working to fade and oxidize the paint.

A dedicated wheel coating is like a sacrificial shield, taking all the abuse so your expensive wheels don’t have to. It forms a tough, chemically-resistant barrier that stops these enemies cold.

- No More Brake Dust Etching: The coating stops hot, sharp brake dust particles from bonding with and pitting your wheel’s clear coat.

- Stain-Proofing: It provides a bulletproof defense against road salt, tar, iron fallout, and other corrosive gunk.

- UV Protection: Powerful UV inhibitors are baked into the formula, preserving the deep, rich color of your wheels’ finish.

This is where a truly advanced formula shows its worth. For example, the technology inside Titan’s coatings is designed to handle extreme temperatures from a frigid -40°F to a blistering 500°F, all while blocking 99% of UV radiation. The demand for this level of protection is exploding—some analyses project the market for high-performance wheel coatings will surge by almost 50% by 2030, adding over USD 140 million in value. You can learn more about the growth of the ceramic coatings market and see where the industry is headed.

A Deeper Shine and Smarter Long-Term Value

A great coating doesn’t just protect; it makes your wheels look absolutely stunning. It adds a slickness and depth of color that you just can’t get from a wax or sealant. Gloss wheels look wetter and more brilliant, while satin and matte finishes take on a richer, more uniform look without adding any cheap-looking shine. Your wheels will genuinely look better than they did the day they left the factory.

Don’t think of a wheel coating as just another cleaning product. See it as a long-term investment in your vehicle’s health and appearance.

When you shield your wheels from the permanent damage that devalues a car, you’re directly protecting its resale value. You’ll also save a surprising amount of money by ditching all those expensive, aggressive wheel-cleaning chemicals you no longer need. This powerful combination of stunning looks, minimal maintenance, and preserved value makes a ceramic wheel coating one of the smartest upgrades any car lover can make.

A Step-by-Step Guide to Flawless Application

Getting professional-grade results with a ceramic wheel coating isn’t about some secret trick. It’s all about discipline and process. The truth is, the final shine and toughness of the coating are locked in long before you even open the bottle. Think of it like a master painter preparing a canvas—the quality of that prep work dictates everything. Your wheels are that canvas.

Here’s the deal: proper preparation is 90% of the job. If you cut corners here, you’re just setting yourself up for failure. A weak bond, spotty performance, and a coating that dies an early death are practically guaranteed. But if you follow a methodical process, you create a surface so clean and pure that the coating can form an unbreakable molecular bond. That’s how you get the stunning looks and relentless protection you’re after.

This is how you transform your wheels from dirty and vulnerable to flawlessly prepped for their new armor.

This flowchart nails it—every step you take directly impacts the final outcome. Each one builds on the last to create a protective layer that’s as beautiful as it is tough.

Step 1: Deep Cleaning and Decontamination

First things first, you need to wash the wheels. A good pH-neutral shampoo will get rid of all the loose surface dirt and grime. But that’s just the warm-up act. The real enemies are the contaminants you can’t even see.

This is where chemical decontamination comes in. Grab a quality iron fallout remover to dissolve all the nasty, embedded brake dust. You’ll see it start to “bleed” a deep purple color—that’s the satisfying sign that it’s melting away the metallic particles that would otherwise sabotage your coating. Rinse it clean, then follow up with a clay bar or clay mitt and some lubricant. This step physically pulls out any remaining gunk like tar or sap, leaving the surface feeling perfectly smooth.

Step 2: Light Polishing for the Perfect Bond

Many people skip this part, but it’s a non-negotiable step for pros. Even brand-new wheels have tiny imperfections or leftover factory waxes that will get in the way. A light machine polish with a fine compound is the answer.

This isn’t about correcting deep scratches; it’s about microscopically abrading the surface. This process massively increases the surface area for the coating to grab onto, creating a far stronger, more durable bond. It’s the difference between trying to stick a decal to a dusty wall versus one that’s been perfectly primed.

Step 3: The Final Wipe-Down

You’re so close. But this last prep step is arguably the most critical. Any leftover polishing oils, fingerprints, or lingering residue will act as a barrier, preventing the coating from bonding properly. Your best friend here is an Isopropyl Alcohol (IPA) panel wipe.

Give every single part of the wheel a thorough spray and wipe—the face, between the spokes, the inner barrel—using a fresh, clean microfiber towel. This final cleansing makes the surface surgically clean and guarantees the strongest possible chemical bond. Whatever you do, don’t skip it.

Step 4: Applying Your Armor

Alright, it’s time for the main event. Let’s say you’re working with a top-tier product like Titan Graphene V2.1, which uses Dark Matter Technology® to build a dense, ultra-protective matrix that’s ideal for the harsh environment wheels live in.

- Load the Applicator: Give the bottle a good shake and put a few drops onto your suede applicator block.

- Work in Small Sections: Don’t try to coat the whole wheel at once. Break it down into manageable chunks, like two spokes at a time or a quarter of the barrel. Apply the coating using a cross-hatch pattern (first up-and-down, then side-to-side) to make sure you get even coverage.

- Level the Coating: After applying to a section, you need to watch for it to “flash.” This usually takes 30-60 seconds (always check the product instructions). The liquid will start to look a bit like an oil slick or get a sweaty appearance. That’s your signal to gently wipe the area with one clean microfiber to level the high spots, then immediately follow with a second, dry microfiber to buff away the last bit of residue for a perfect, streak-free shine.

If you want to dive deeper into application techniques, our guide on how to apply a ceramic coating to your car has more tips that work great for wheels, too.

Remember, the goal isn’t to rub the coating off—it’s to smooth it out. Use very light pressure. You’re just knocking down the excess product to leave behind a perfectly uniform layer.

Step 5: The All-Important Cure

Once the last section is coated and buffed, your part is done, but the coating’s work is just beginning. It now needs to cure, which is the chemical process where it hardens and cross-links with the surface. For the first 24-48 hours, keeping the wheels away from water, chemicals, and dirt is absolutely essential.

That means no driving in the rain and making sure morning dew doesn’t settle on them. After that initial period, the coating is tough enough for light driving, but the full chemical cure can take up to a week. Hold off on washing the car with any soaps during this time. A little patience here ensures that flexible, durable shield you just applied will perform at its peak for years to come.

Keeping Your Coated Wheels Looking Their Best

So, you’ve put in the work and given your wheels an incredible shield against the elements. The constant fight against brake dust, road grime, and tar is finally tilted in your favor. A top-tier ceramic wheel coating is about as low-maintenance as it gets, but it’s crucial to remember that it isn’t no-maintenance.

Think of it like a high-end non-stick skillet. It makes cooking and cleanup ridiculously easy, but you wouldn’t take a steel wool pad to it or blast it in an industrial dishwasher. The same principle applies here—a little bit of the right kind of care is all it takes to keep that brilliant gloss and easy-clean surface performing for years.

The New Rules of Washing Your Wheels

The best part? Your old, aggressive wheel cleaning routine is a thing of the past. Forget the harsh, acidic chemicals and stiff, scratchy brushes you used to rely on. The goal now is simply to gently lift off surface contaminants without compromising the protective coating underneath.

Your new, simplified wheel cleaning kit is pretty straightforward:

- pH-Neutral Soap: Forget the heavy-duty wheel cleaners. Harsh chemicals, whether acidic or highly alkaline, will slowly eat away at your coating. A quality, pH-balanced car shampoo is all you’ll need.

- Dedicated Microfiber Tools: Always use a separate wash mitt and drying towel just for your wheels. This is non-negotiable. It prevents cross-contamination, stopping you from dragging tiny, sharp brake dust particles all over your car’s paintwork.

- The Two-Bucket Method: This isn’t just for your paint. Using one bucket for your soapy water and a separate one to rinse your mitt ensures you aren’t just grinding dirt right back into the wheel’s surface.

A Story of Lasting Shine

One of our long-time clients, a mobile detailer who specializes in high-performance vehicles, shared a great story with us. He had coated a client’s ridiculously intricate, multi-spoke sports car wheels with one of our elastomer-based coatings. A year later, the owner came back, completely blown away. “I used to spend 45 minutes on the wheels alone,” he said. “Now, it’s a five-minute job with the pressure washer and some gentle soap.”

That’s what proper maintenance looks like in the real world. For professionals and car lovers, a good wheel coating can extend the life of the finish by 5-7 years compared to old-school polishes and waxes, cutting annual detailing time and costs by over 40%. As the North American market for advanced ceramics continues to expand, the demand for truly hydrophobic, self-cleaning finishes that deliver this kind of value is only going up. You can read more about the growth of the ceramic coatings industry here.

Boosting Your Coating for the Long Haul

If you want to get the absolute maximum life and performance out of your coating, a little boost every few months makes a huge difference. This is exactly why we developed our Vulcan TX155, a ceramic maintenance spray or “topper.” It’s an incredibly simple spray-and-wipe product you use right after a wash.

Think of it as recharging the shield. It instantly replenishes the slick, water-hating top layer of the coating, adds a fresh sacrificial layer of protection, and brings back that intense, “just-coated” water beading.

Using a product like Vulcan TX155 every 3-6 months is the secret to making your coating last. It’s a quick, easy step that keeps your wheels shedding water and dirt like new, ensuring they look incredible year after year. By following these simple guidelines, you’re working with the technology to guarantee a brilliant finish that endures. To learn more, check out our complete guide on how to properly maintain your ceramic coating.

Got Questions? We’ve Got Answers.

It’s totally normal to have a few questions before diving into ceramic wheel coatings. Let’s tackle some of the most common ones we hear from car lovers and pro detailers.

How Long Does a Good Ceramic Wheel Coating Actually Last?

When you invest in a top-tier, professional-grade coating like those from Titan Coatings, you can realistically expect it to last anywhere from 2 to 5 years. Of course, this depends on how you drive, how well it was applied, and your maintenance routine.

But the real secret to that kind of staying power is in the coating’s DNA. Titan’s flexible elastomer technology is a game-changer here. It allows the coating to expand and contract with the metal during those wild temperature swings, preventing the tiny cracks that kill lesser, more brittle coatings. A proper wash routine and the occasional topper will stretch that lifespan even further.

Can I Put This Stuff on Any Kind of Wheel?

Yep, you absolutely can. That’s one of the best things about a quality ceramic coating—it’s incredibly versatile. You can apply it safely and effectively to just about any wheel finish out there.

We’re talking about:

- Gloss painted and clear-coated wheels

- Tough powder-coated finishes

- Mirror-like polished aluminum or chrome

- Tricky satin and matte finishes

On matte wheels, a dedicated coating is a lifesaver. It deepens the color and gives you serious protection without adding that gloss you don’t want. It finally makes those notoriously difficult finishes easy to live with.

Seriously, Is Coating My Wheels Worth the Hassle and Cost?

For anyone who cares about their car’s look and would rather spend less time scrubbing brake dust, the answer is a definite yes.

Think of it this way: the upfront cost pays you back over and over again. You’re buying back countless hours you would have spent cleaning. You’re shielding your expensive wheels from permanent pitting and etching. And you’re locking in that showroom-fresh look that protects your car’s value. It’s one of the smartest investments you can make for your vehicle.

Ready to give your wheels the bulletproof, long-lasting protection they deserve? Titan Coatings offers advanced, flexible elastomer coatings engineered to take on the toughest road conditions. Check out our pro-level solutions on our shop page today.

0 Comments