The core difference between graphene and ceramic coatings lies in their chemical makeup and how they form a protective layer. A ceramic coating is built on silicon dioxide (SiO₂), which cures into a hard, glass-like shell. On the other hand, a graphene coating takes that same ceramic base and infuses it with graphene oxide. This adds a super-strong, flexible carbon honeycomb structure, making graphene coatings typically better at resisting water spots and handling high heat.

The Evolution of Automotive Paint Protection

We’ve all been there. You spend an entire Saturday detailing your car, getting that paint to a perfect, mirror-like finish, only to watch it get covered in swirl marks and ugly water spots a week later. It’s a frustration that has fueled decades of innovation in paint protection, pushing us far beyond old-school waxes and sealants.

For a long time, ceramic coatings were the undisputed king. Built on a foundation of silicon dioxide (SiO₂), they created a tough, durable shield that chemically bonded to the paint. Detailers and car lovers swore by them for locking in gloss and fending off chemicals. They were the gold standard.

But the world of detailing never stands still. Graphene-infused coatings have now stepped into the ring, challenging the reigning champ and promising to push the boundaries of durability and performance even further. This guide will walk you through that journey, setting the stage for the ultimate graphene coating vs ceramic coating showdown.

From Simple Wax to Nanotechnology

The road to today’s advanced coatings is a story of constant problem-solving. It started with natural carnauba wax, which gave a beautiful warm glow but didn’t last. Then came synthetic polymers that offered better longevity. Each new product was an attempt to solve the same fundamental challenge: how to protect a car’s fragile clear coat from the elements. Ceramic coatings were the first massive leap forward, bringing nanotechnology into the hands of professionals and enthusiasts.

The real game-changer was the shift from a temporary layer that sits on top of the paint (like wax) to a semi-permanent bond that becomes one with it. This created a far more resilient barrier against UV rays, harsh chemicals, and light scratches, fundamentally changing how we approach long-term car care.

A New Era of Flexible Protection

But even the best ceramic coatings had their weak spots, especially when it came to rigidity. This is where the story evolves again—not just with graphene, but with even smarter solutions. Here at Titan Coatings, we pushed the envelope. As the first company to introduce Elastomer coatings to the market using advanced nano tube technology and our proprietary Dark Matter Tech, we created a shield that’s both incredibly hard and remarkably flexible.

This unique elasticity means our coatings can handle extreme temperature swings without cracking—a common failure point for lesser coatings in harsh climates. A coating that is hard like glass but also flexible will last much longer, as it won’t break down when temperatures shift from freezing cold to scorching hot. It’s about delivering superior durability that lasts. This comparison will help you navigate your options, from the trusted standard to the next generation of paint defense.

| Protection Type | Primary Component | Key Characteristic |

|---|---|---|

| Traditional Wax | Carnauba or Beeswax | Temporary, warm gloss |

| Synthetic Sealant | Polymers | Better durability than wax |

| Ceramic Coating | Silicon Dioxide (SiO₂) | Hard, semi-permanent bond |

| Graphene Coating | Graphene Oxide + SiO₂ | Slick, heat-resistant |

| Titan Elastomer | Advanced Polymers | Hardness with flexibility |

Understanding Ceramic Coatings: The Industry Standard

For the better part of a decade, if you wanted serious, long-term paint protection, automotive ceramic coatings were the only game in town. They completely changed the way we protect our vehicles, setting the gold standard for durability. At their core, these are liquid polymers that chemically fuse with your car’s factory clear coat. Once cured, they create a hard, semi-permanent shell of protection that becomes the new top layer of your paint.

The magic ingredient here is silicon dioxide (SiO₂). When applied, SiO₂ organizes itself into a tightly packed, crystalline nanostructure right on your paint. It’s this incredibly dense and rigid layer that gives ceramic coatings their famous 9H pencil hardness rating. Think of it as a microscopic layer of glass shielding your car from the daily grind.

The Proven Power of SiO₂

A high-quality ceramic coating isn’t just a one-trick pony; it’s a full-on defense system for your paint. That hard shell does a fantastic job of fending off the light scratches and swirl marks that inevitably show up from washing. But it’s the chemical shielding that truly sets it apart.

In the real world, this translates to:

- Chemical Resistance: Acidic bird droppings, baked-on bug guts, and corrosive acid rain? The coating stops them from etching into your clear coat.

- UV Protection: It’s like a powerful sunscreen for your car, fighting off the harsh UV rays that dull and oxidize your paint over time.

- Enhanced Gloss: Protection is one thing, but the look is another. Ceramics are famous for adding a stunning, candy-like gloss that makes colors pop with incredible depth.

- Hydrophobicity: Water just doesn’t want to stick. It beads up and rolls right off, taking dirt along with it. This makes washing your car faster and easier.

The Limitations of Rigidity

But that same rigidity that provides so much protection can also be a weakness. The hard, glass-like layer is tough, but it’s not bulletproof. Because it doesn’t have much flex, it can run into trouble under certain conditions.

Water spotting is probably the most common headache, especially if you live in an area with hard water. When water loaded with minerals evaporates, it leaves behind calcium and magnesium deposits. If you don’t wipe them away quickly, they can etch into that rigid coating.

This inflexibility also becomes a problem in climates with wild temperature swings. When you go from freezing nights to blazing hot days, the coating and the paint underneath expand and contract at different rates. Over time, this can lead to micro-cracking, which compromises the coating’s integrity and shortens its lifespan.

Even with the rise of graphene alternatives, there’s a reason ceramic coatings still dominate the market. They’ve been battle-tested since the early 2010s, building a massive following of enthusiasts and professional detailers who trust their proven reliability. When properly maintained, a good ceramic coating delivers years of dependable protection.

The Rise of Graphene Coatings: A New Challenger

Just when we all thought ceramic coatings were the final word in paint protection, a new player stepped onto the scene, and the detailing world hasn’t stopped talking about it since. This new challenger wasn’t a total rewrite of the rulebook but a clever and powerful evolution. Graphene coatings aren’t pure sheets of wonder material; they are, at their core, advanced ceramic formulas infused with a game-changing additive: graphene oxide.

This one addition completely changes the coating’s personality on a molecular level. Think of a standard ceramic coating as a strong, rigid shield. Now, imagine weaving a hyper-strong, flexible honeycomb lattice of carbon atoms into that shield. That’s what a graphene-infused coating brings to the table, creating a surface that’s slicker, more flexible, and far better at shrugging off heat.

How Graphene Changes the Game

This unique molecular structure tackles some of the inherent weaknesses of traditional SiO₂ coatings head-on. Take the increased slickness, for instance. It leads to a much higher water contact angle, meaning water beads up into tight, perfectly round spheres that roll right off the paint, taking dirt and grime along for the ride.

This superior water behavior is a critical point in the graphene coating vs ceramic coating debate. Because water gets off the surface so fast, the chance of it drying and leaving behind mineral deposits—the dreaded water spots that etch into the paint—is drastically reduced. It’s a huge relief for anyone who has ever dealt with the frustration of water spotting on a dark-colored, ceramic-coated car. You can get a much deeper look into the science behind this technology in our detailed guide on what graphene coatings are.

A Story of Smarter Protection

Let me paint a picture for you. A high-end detailer, let’s call him Alex, loved the gloss and durability of ceramic coatings but was constantly fighting water spots for his clients in hot, humid Florida. He’d heard the buzz about graphene but wrote it off as the latest marketing gimmick. On a whim, he decided to try a graphene-infused coating on his own black truck, and the results were stunning.

After a pop-up thunderstorm, he watched in amazement as the water practically jumped off the hood, leaving the surface nearly dry. His truck stayed cleaner for weeks longer, and the relentless sun no longer baked water spots into the finish. This is exactly why graphene coatings are gaining so much traction—they handle real-world problems better, especially heat.

One of their biggest advantages is how well they conduct heat, spreading it across the vehicle’s surface to reduce hotspots that can damage paint. Plus, that incredibly slick surface makes water bead up smaller and tighter, which is another nail in the coffin for water spotting.

This enhanced thermal conductivity isn’t just a minor perk; it’s a critical upgrade. By helping to dissipate heat, the coating actively protects the paint on hot days, while its improved molecular flexibility makes it far less prone to the micro-cracking that can plague rigid ceramics during extreme temperature changes.

That ability to flex is where Titan’s core philosophy clicks right into place. Our pioneering Elastic coatings were born from this exact idea: protection has to be both tough and flexible. A coating that’s hard like glass but can flex like rubber won’t crack under the stress of a freezing winter or a blistering summer. This built-in resilience is the secret to true, long-term durability—a principle that graphene technology also leverages to solve real-world problems for vehicle owners.

Performance Showdown: Graphene vs. Ceramic Compared

When it comes down to it, performance is what really matters. In the clash between graphene coating vs. ceramic coating, we have to look past the marketing hype and get into how these technologies actually perform against the daily abuse your car endures. This isn’t just a list of features; it’s a real-world, side-by-side breakdown of the metrics that define true, long-term paint protection.

We’re going to dive into everything from how each coating handles brutal weather and chemical exposure to the quality of the gloss it leaves behind. By stacking them up in practical situations—from the daily grind to a showroom spotlight—you’ll get an unfiltered view of their distinct strengths and weaknesses. Think of this as your go-to reference for weighing the pros and cons against your own needs, local climate, and how you care for your vehicle.

Durability and Longevity

The first thing everyone wants to know is, “How long will it last?” Traditional ceramic coatings really set the standard here, with professional-grade formulas delivering solid protection for 2 to 5 years. Their tough, bonded SiO₂ structure is fantastic at resisting the slow grind of daily driving. The flip side? Their rigidity can become a liability in places with big temperature swings, which can sometimes lead to micro-cracking over time.

This is where graphene-infused coatings really start to pull ahead. That unique carbon honeycomb structure introduces a bit of flexibility into the otherwise rigid ceramic foundation. This elasticity allows the coating to expand and contract right along with your car’s body panels, making it far more resilient to the stress of thermal shock. Because of this, pro-level graphene coatings often come with a much longer lifespan, typically in the 5 to 7-year range. If you want to dig deeper into what makes a coating last, check out our guide on how long ceramic coatings last.

A coating’s real lifespan isn’t just a number on a bottle; it’s a direct result of its ability to adapt. A rigid shield is strong until it’s stressed, but a flexible one endures. This principle is why Titan’s Elastomer coatings, which are hard like glass yet flexible, represent the next step, as they are engineered to resist cracking from temperature changes, ensuring a longer, more resilient protective layer.

Water Spot and Chemical Resistance

Water spots are the absolute enemy of a perfect finish, and this is a major battleground in the graphene vs. ceramic debate. Ceramic coatings are famously hydrophobic, making water bead up into tight, impressive-looking droplets. The problem is, these high-angle beads can act like tiny magnifying glasses, focusing the sun’s rays and letting mineral deposits etch into the surface as the water evaporates.

Graphene coatings offer a much smarter solution. Their surface is so slick that they have a lower “sliding angle,” which simply means water is more likely to sheet off the vehicle entirely instead of beading up. This rapid water evacuation dramatically cuts down the risk of leaving nasty mineral deposits behind.

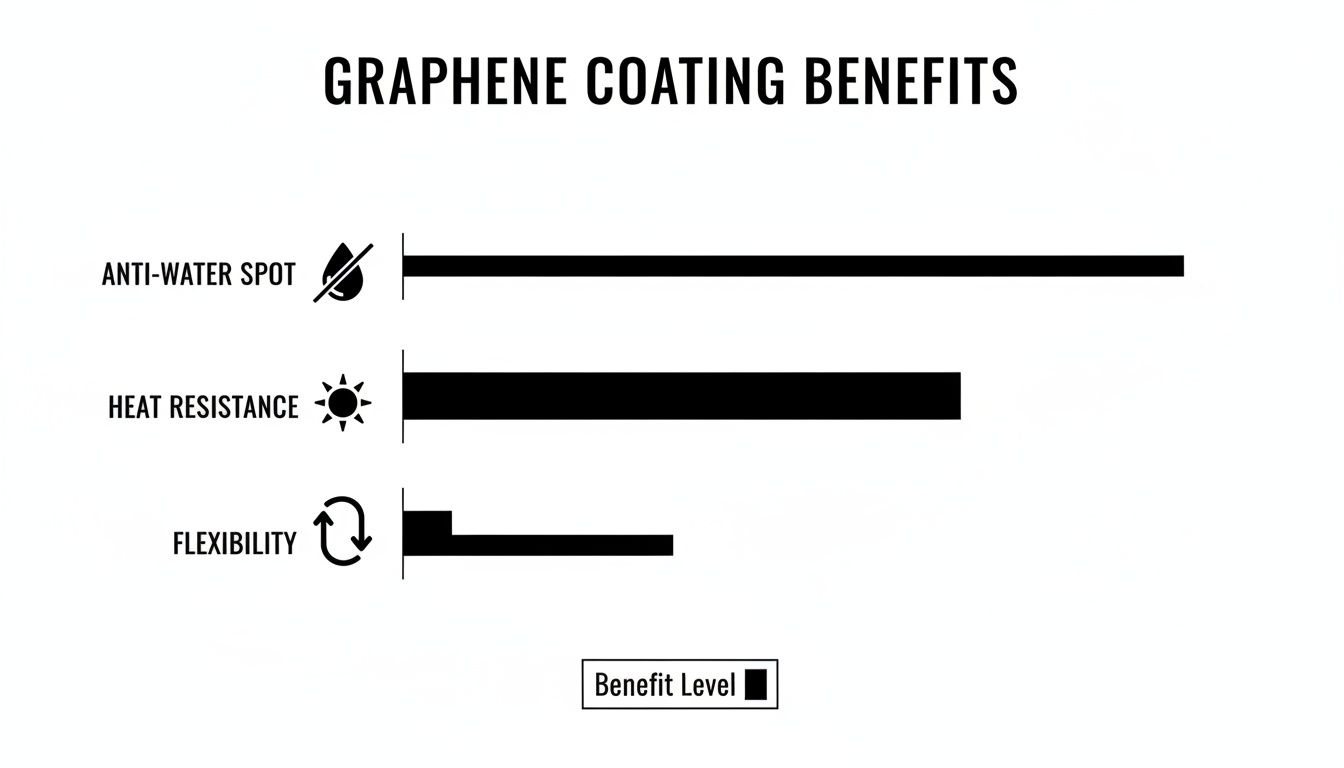

This chart does a great job of showing the core benefits that give graphene-infused coatings a serious performance edge.

You can see how graphene’s incredible water repellency, heat resistance, and flexibility work together to create a tougher, lower-maintenance shield for your paint.

When we talk about chemical resistance, both technologies provide robust protection against the usual suspects: bird droppings, bug guts, and road grime. But graphene has an ace up its sleeve—its thermal conductivity. By spreading heat out more effectively, it helps stop harsh chemicals from baking onto the paint on a hot day, preventing them from etching into the clear coat.

To make these differences crystal clear, let’s break them down side-by-side.

Graphene vs Ceramic Coating Performance Matrix

This table offers a direct comparison of key performance attributes, cutting through the noise to show you exactly where each technology shines.

| Performance Metric | Ceramic Coating (SiO₂) | Graphene-Infused Coating | The Bottom Line |

|---|---|---|---|

| Water Spotting | Prone to beading, which can cause mineral etching. | Promotes sheeting, drastically reducing water spot risk. | Graphene is the clear winner for preventing water spots. |

| Durability | Typically lasts 2-5 years; can be brittle. | Often lasts 5-7 years; more flexible and resilient. | Graphene offers superior longevity due to its flexibility. |

| Slickness | Very slick, but can be surpassed. | Exceptionally slick, creating a low-friction surface. | Graphene provides a slicker, more self-cleaning surface. |

| Heat Dissipation | Average thermal resistance. | Excellent heat dissipation reduces chemical etching risk. | Graphene handles heat better, protecting from baked-on contaminants. |

| Chemical Resistance | High resistance to acids and alkalis (pH 3-12). | Very high resistance (often pH 2-13). | Both are excellent, but Graphene often has a slight edge. |

As you can see, while traditional ceramics are still a fantastic choice, graphene-infused formulas push the boundaries of performance in nearly every key area that matters for daily drivers and enthusiasts alike. For an even clearer view of these differences, check out the Titan Coatings Comparison page to see how our products stack up.

Visual Appearance and Gloss

Let’s be honest, we all want that jaw-dropping shine. Both coating types deliver a deep, stunning gloss that blows any wax or sealant out of the water. But the character of that shine is where they differ.

- Ceramic Coatings: These are known for producing a sharp, candy-like gloss. They create a hard, glassy layer that makes paint look like it’s been encased in crystal. It’s an incredibly crisp and reflective look.

- Graphene Coatings: These tend to create a richer, darker, and “wetter” appearance. The carbon elements in the formula can slightly darken the paint, adding a remarkable level of depth and richness.

I know a detailer who works almost exclusively on high-end black cars. He used to swear by ceramics for their brilliant shine, but once he tried a premium graphene coating, he never went back. He found that it delivered a deep, liquid-like pool of black that his clients went wild for, often describing the finish as looking “miles deep.” For those chasing the ultimate aesthetic, that subtle difference in graphene’s finish is often the deciding factor.

Ultimately, choosing between them comes down to your personal taste. Do you want that sharp, mirror-like reflection, or a deep, warm glow? Both will make your vehicle look incredible, but they get there in slightly different ways.

The Next Frontier: Introducing Elastomer Coatings

While everyone is busy debating graphene coating vs. ceramic coating, a completely different class of protection is changing the game. Here at Titan Coatings, we weren’t satisfied with simply improving on existing formulas. We decided to engineer something fundamentally better, leading to our proprietary Elastomer technology. The concept is beautifully simple yet incredibly difficult to perfect: a coating with the hardness of glass and the flexibility of rubber.

This isn’t just a small step forward; it’s a total re-think of how paint protection should work. Traditional coatings form a hard, rigid shell. Think of it like a thin pane of glass—strong, but brittle. Our Elastomer technology creates a shield that’s not just tough but also incredibly resilient. This unique elasticity is the secret sauce, creating a surface that doesn’t just resist damage—it endures it.

Hard Like Glass, Flexible Like Rubber

Picture a small rock kicking up from the highway and smacking your hood. A rigid coating, whether ceramic or graphene-infused, might chip or form a spiderweb crack under that focused impact. An Elastomer coating, on the other hand, can absorb and dissipate that energy, dramatically reducing the odds of a chip. This is the core principle that makes this technology a true game-changer.

This flexibility is also crucial for handling one of the biggest silent killers of paint protection: temperature swings. Your car’s panels are constantly expanding and contracting, from a freezing winter morning to a blazing hot summer afternoon.

This constant thermal stress is a primary reason many coatings fail over time. It leads to micro-cracking that quietly compromises the protective barrier. Our Elastomer coatings are engineered to flex with these changes, preventing those cracks from ever forming and ensuring the protective layer stays intact year after year, no matter the climate.

This built-in resilience ensures your vehicle’s protection won’t break down under the stress of real-world driving conditions.

The Power of Titan Vulcan TX155

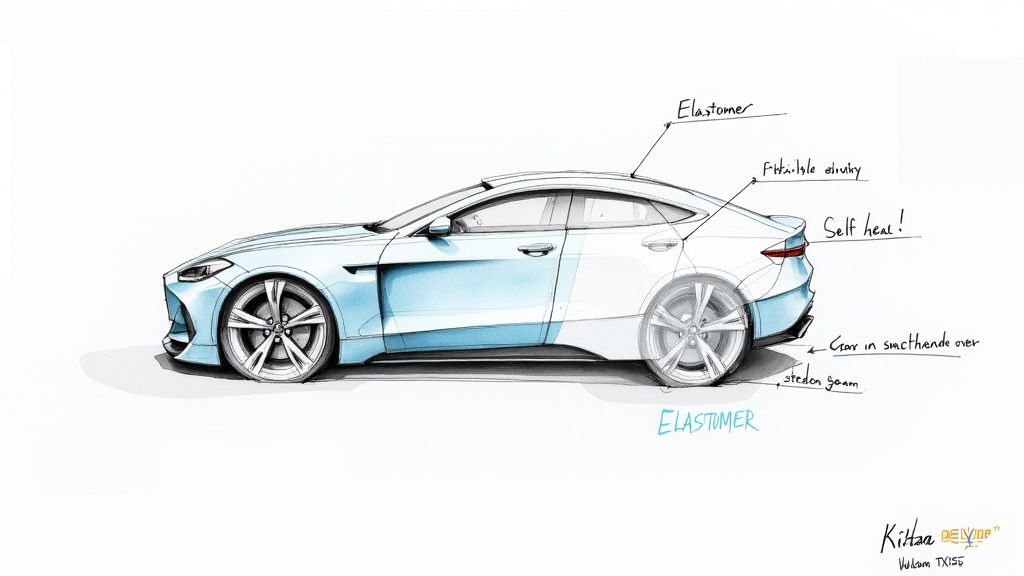

The pinnacle of this technology is our flagship product, Titan Vulcan TX155. This isn’t just another coating; it’s a sophisticated formula combining our most advanced sciences. We start with our Elastomer base and then infuse it with our proprietary Dark Matter Technology® and advanced nanotubes. The result is a level of performance that neither ceramic nor graphene alone can touch.

Here’s a closer look at what makes Titan Vulcan TX155 the new benchmark for durability.

This product shows how we’ve stacked multiple technologies to create a solution that delivers superior durability, a dripping-wet gloss, and even self-healing properties against minor abrasions.

The benefits are real and immediately noticeable for any car owner:

- Unmatched Durability: The flexible structure resists impacts, chipping, and cracking far better than rigid alternatives.

- Extreme Weather Resilience: It stands up to drastic temperature shifts without losing its integrity, making it perfect for any climate.

- Self-Healing Properties: Minor swirl marks and light scratches can actually regenerate and disappear when exposed to heat.

- Incredible Gloss and Depth: It produces a rich, liquid-like shine that makes paint color pop with stunning clarity.

One of our certified installer’s clients, Mark, owns a classic muscle car that he loves to drive. After getting Vulcan TX155 applied, he got caught in an unexpected hailstorm. He was devastated, expecting the worst. But to his astonishment, while cars parked nearby were covered in dents and paint chips, his finish was almost untouched. The flexible coating had absorbed the light impacts, saving the paint underneath. That’s the real-world value of a coating engineered to be both tough and adaptable.

We didn’t just want to join the conversation about paint protection; we wanted to start a new one. By solving the core problem of rigidity, we’ve developed a solution that goes far beyond the limits of both graphene and ceramic. To truly grasp this leap in technology, you can explore our detailed breakdown of Titan Coatings Elastomer technology and see for yourself how we’re setting a new standard for lasting protection.

How to Choose the Right Coating for Your Car

The whole graphene coating vs ceramic coating debate can feel like a lot of noise. But honestly, the “best” coating isn’t about what’s new and trendy—it’s about what’s right for you. The secret is matching the right technology to your car, your life, and what you actually expect from it. What works for a daily commuter battling harsh winters is completely different from what a weekend show car enthusiast needs.

This whole process really begins with getting clear on your priorities. Are you just trying to get solid, low-maintenance protection that makes your weekly wash a breeze? Or are you chasing that deep, jaw-dropping gloss for the next car meet? Once you know the answer, you’re halfway to the right solution.

For the Daily Driver and Practical Enthusiast

If your car is your daily workhorse, constantly up against rain, sun, and road grime, your main goals are durability and easy upkeep. You need a coating that keeps the car looking sharp with minimal fuss and stands up to the elements without giving you a headache.

For this kind of real-world use, a modern graphene-infused coating often pulls ahead of older ceramics. Its enhanced resistance to water-spotting is a huge win, especially if you can’t run out and wash your car after every single rainstorm. The anti-static properties are another practical benefit, helping to push dust away and keeping the car looking cleaner, longer.

Of course, a great coating is just one part of keeping your vehicle in top shape. True longevity comes from a holistic approach, like following an ultimate car maintenance checklist.

For the Show Car Owner and Gloss Chaser

For the enthusiast who treats their car like a work of art, it’s all about the looks. You’re after that dripping “wet look” gloss that makes people stop and stare. While both coatings deliver a fantastic shine, they do it differently. Traditional ceramics give you a sharp, candy-like gloss, whereas graphene tends to produce a deeper, richer finish that adds a lot of dimension.

But if you’re looking for the absolute peak of gloss and want it to last, neither one is the final word. This is exactly where Titan Coatings’ Elastomer technology comes into play. I’m thinking of a story one of our certified installers told me about a customer—a classic car collector named David.

David was completely obsessed with getting a perfect finish on his vintage 1969 Camaro. He’d been through countless high-end waxes and even some pricey ceramic coatings, but he was never quite happy. After our installer applied Titan Hyper Top, an Elastomer-based top coat, David was floored. He said it created a liquid-like depth that was “miles deep,” and he could finally relax knowing its flexible, glass-hard protection could handle temperature swings without cracking.

A Smart Investment for Long-Term Value

Finally, let’s talk about the investment. The cost versus benefit is a huge part of this decision. Professionally installed graphene coatings are often marketed with lifespans of 5-10 years, with prices sitting anywhere from $300 to $900 for a full job. This puts them in direct competition with high-end ceramic coatings, which typically last 2-5 years and can sometimes cost even more. You can see a detailed breakdown of how graphene and ceramic coating costs compare on GloveBoxDetail.com.

But real value isn’t just about the price tag today; it’s about the total cost of ownership down the road. An Elastomer coating from Titan might be a bigger investment upfront, but its incredible resilience against cracking and its much longer lifespan mean fewer reapplications and less maintenance over time. That’s how you get exceptional long-term value.

Got Questions? We’ve Got Answers

Choosing between graphene and ceramic coatings can feel complex. Let’s cut through the noise and tackle the questions we hear most often, so you can make the right call for your vehicle.

Is Graphene Coating Really Better Than Ceramic?

It’s less about “better” and more about which technology best fits your needs. Graphene-infused coatings do have an edge in a few key areas, particularly in resisting water spots and dissipating heat, which can boost longevity in harsh climates. But a top-tier ceramic coating is still a fantastic, proven performer.

Honestly, the real debate often comes down to your local environment and how much you want to invest.

That said, if you’re looking for what’s truly next-level, our Elastomer coatings are in a class of their own. They offer the intense hardness of glass but with a flexibility neither ceramic nor graphene can match.

How Long Do Graphene and Ceramic Coatings Last?

With proper care, you can expect a professional ceramic coating to last anywhere from 2-5 years. Graphene coatings often push that window further, with many promising 5-7 years of protection.

Our Elastomer coatings were engineered to outlast both. Their unique, flexible structure allows them to expand and contract with temperature swings, preventing the micro-cracking that degrades other coatings over time. That’s why we confidently warranty Titan Coatings’ Elastomer products like Vulcan TX155 for up to 8 years—it’s a testament to their incredible resilience.

Can I Apply These Coatings Myself at Home?

You can, and many enthusiasts do. DIY versions of both ceramic and graphene coatings are widely available. However, a word of caution: the results live and die by the prep work. Achieving a flawless, long-lasting bond requires a perfectly decontaminated and corrected paint surface, a skill that professional detailers spend years perfecting.

All of our professional-grade products, including the entire Titan Coatings lineup, are exclusively for our network of certified installers. This isn’t about being difficult; it’s about guaranteeing performance. An expert application ensures the coating works exactly as engineered and is backed by our full warranty, protecting your investment and giving you total peace of mind.

Ready to step up to the next generation of paint protection? Titan Coatings developed Elastomer technology to create a shield that’s not just tough, but flexible and resilient.

Experience the unparalleled durability and dripping-wet gloss of Titan Vulcan TX155. Find out more and locate a certified installer at the Titan Coatings Shop.

0 Comments