So, you’re wondering how long it actually takes for a ceramic coating to cure. It’s a great question. While the surface might feel dry to the touch within a day, the reality is the coating needs anywhere from 1 to 3 weeks to achieve its full hardness and chemical resistance. Think of it less like paint drying and more like concrete setting; the real strength is built over time.

This journey is what ensures your vehicle gets that incredible, long-lasting protection you paid for.

Understanding the Complete Ceramic Coating Curing Timeline

You’ve just made a solid investment in your vehicle’s future, one that promises years of stunning gloss and ridiculously easy maintenance. But right after the installer hands you back the keys, the single most important phase begins: the cure.

Let’s be honest, we all get that itch to see the final results immediately. But patience during the curing process is the secret ingredient to a perfect, rock-hard finish that lasts.

The transformation from a freshly applied liquid to a hardened, molecularly-bonded shield doesn’t happen overnight. It progresses through distinct stages, each with its own rules.

The Initial Soft Cure

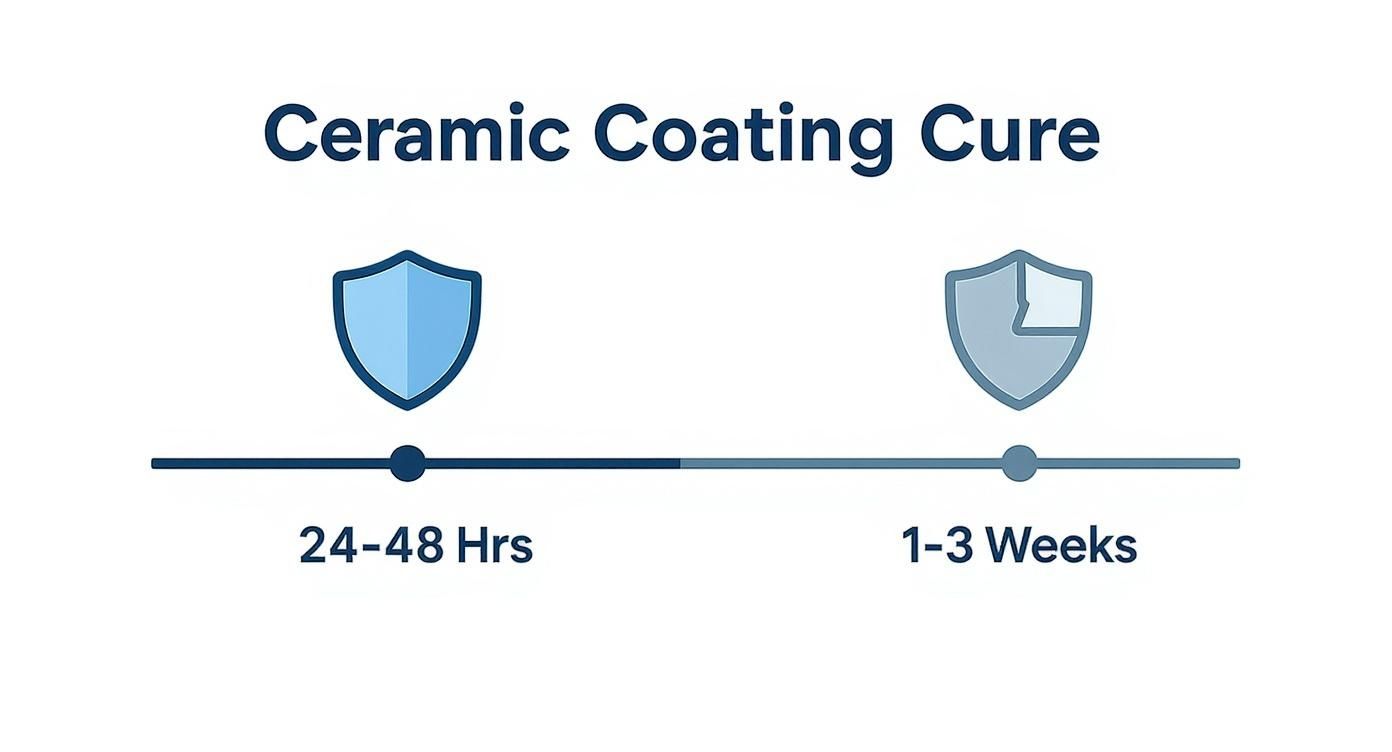

Right after application, the coating enters its most fragile state. These first 24 to 48 hours are absolutely critical. During this window, the carrier solvents are evaporating, leaving the nano-structure of the coating to begin its bonding process.

The surface will feel ‘tack-free’—meaning it’s dry to the touch—but it’s still incredibly soft and vulnerable. Something as simple as a fingerprint, a rogue rain shower, or a layer of dust can compromise the finish at this stage.

This is why professional detailers are so insistent about keeping the vehicle in a controlled, dry environment for the first day or two. It’s not just a suggestion; it’s a non-negotiable step for a flawless outcome.

The visual timeline below gives you a great snapshot of these key stages, from that initial soft shield to the final, fully hardened barrier.

As you can see, the initial hardening happens pretty fast, but achieving that full chemical bond and strength is a marathon, not a sprint.

The Path to Full Hardness

Once you’re past that initial 48-hour window, the car is generally safe for some light, careful driving. But don’t be fooled—the real magic is still happening at a microscopic level. The coating is actively cross-linking, forming a tight, permanent bond with your car’s clear coat. This process can take anywhere from one to three weeks, depending on the specific coating and the environment it’s in.

It’s during this final curing period that the coating achieves its legendary properties: extreme hydrophobicity, slickness, and the ability to shrug off harsh chemicals and contaminants. Rushing this process is the single biggest mistake you can make.

For any car owner, understanding this timeline is key. A good detailer will walk you through it, explaining that every step is part of a meticulous system. If you’re a DIY enthusiast or just curious about the nitty-gritty, our guide on how to apply ceramic coating to a car offers a much deeper look into the professional process. Ultimately, that little bit of patience up front is what guarantees the coating performs as advertised for years to come.

Ceramic Coating Curing Stages At a Glance

To make this all a bit easier to digest, here’s a quick summary of the different curing phases. Think of it as your cheat sheet for what to expect and how to handle your vehicle for the best possible results.

| Curing Stage | Typical Duration | Vehicle Status | Key Precautions |

|---|---|---|---|

| Initial Flash-Off | 1-5 Minutes | Wet, Not Drivable | Do not touch. Coating is being leveled and wiped down. |

| Soft Cure | 24-48 Hours | Tack-Free, Indoor Only | No water contact. Avoid dust, pollen, and fingerprints. |

| Safe Handling | 48-72 Hours | Gentle Driving OK | Avoid washing, chemicals, and harsh weather if possible. |

| Full Cure | 1-3 Weeks | Fully Hardened | Vehicle is fully protected. Normal washing can resume. |

This table clearly lays out the journey from liquid to armor. Following these guidelines is the best way to protect your investment and ensure you get every bit of performance out of your new coating.

The Environmental Factors That Control Curing Speed

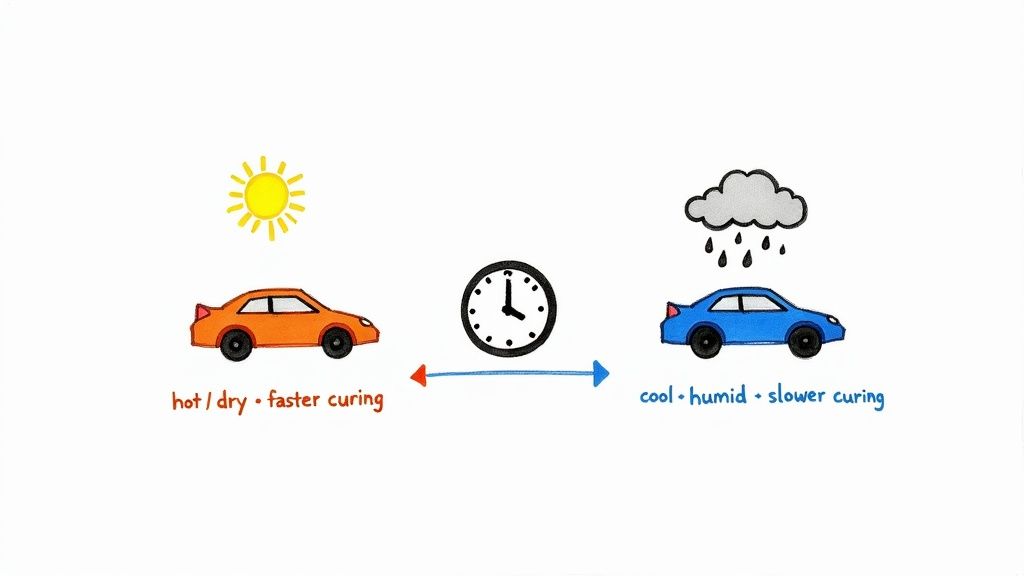

Ever wonder why a ceramic coating applied in Miami might cure faster than the exact same one in Seattle? The secret isn’t in the bottle—it’s in the air. The environment plays a massive role in how quickly and effectively a coating cures, acting like an invisible director guiding the whole process.

Think of it like baking a cake. If the oven is too cool, the batter never sets properly. Too hot, and the outside burns while the inside is still raw. A ceramic coating is no different; it needs the right conditions to cross-link correctly and form that tough, lasting bond with your vehicle’s paint.

The Power of Temperature

Temperature is probably the biggest driver in the curing equation. Warmer air gives the chemical reactions within the coating a serious energy boost, helping the solvents flash off faster and encouraging the molecules to link up quickly. It’s the reason a detailer in sunny, dry Arizona almost always sees a faster cure than someone working in damp, cool Portland.

Most coatings have an ideal application and curing window, typically somewhere between 10°C and 30°C (50°F to 86°F). In this sweet spot, the hardening process is predictable and steady. But once temperatures drop below that range, the cure time can stretch out dramatically, sometimes taking two or even three times longer to reach the same level of hardness.

The Role of Humidity

Humidity, or the amount of moisture in the air, is the other half of the puzzle. A little bit of moisture is actually necessary to kick off the chemical reaction. The problem is when there’s too much. High humidity puts the brakes on the evaporation of the coating’s carrier solvents.

When those solvents get trapped and can’t escape the surface, the whole curing timeline gets thrown off. This can leave you with a softer, less resilient finish that’s a magnet for contamination in those critical early hours.

This is exactly why pro installers are so obsessed with controlling their environment. They aren’t just wiping a product on; they’re managing a complex chemical reaction right there on the paint. For a coating to live up to its potential, you have to respect these factors. The goal is always a stable, controlled setting that lets the coating cure perfectly, creating that durable, glass-like shield. Interestingly, the same environmental factors, like UV, that affect curing also damage paint, which is why finding the best UV protection for car paint is so critical for keeping a car looking its best.

How Titan Coatings Redefine Durability and Curing

Let’s be honest, not all coatings are created equal. While many promise a hard shell of protection, the technology humming beneath the surface makes all the difference in how long that protection actually lasts and performs. The real magic isn’t just about being hard; it’s about intelligent engineering that works with your vehicle, not against it.

Alex’s detailer, a pro who’s seen it all, put it perfectly when he explained why he chose Titan. “Think of a modern skyscraper,” he said. “It’s built to be unbelievably strong, but its true genius is that it’s also engineered to flex during an earthquake. That flexibility is what keeps it from crumbling.”

The Problem with Brittle Protection

Most traditional ceramic coatings are a lot like a simple pane of glass. Sure, they’re extremely hard—which is great for fending off light scratches—but they’re also rigid and brittle. Your car’s body panels are constantly expanding in the summer heat and contracting in the freezing cold. For a rigid coating, this is a recipe for disaster.

Over time, this constant thermal stress leads to micro-cracks. They’re invisible at first, but they weaken the coating from the inside out, slowly destroying the very shield you paid to have installed.

The Titan Advantage: Elasticity Meets Strength

This is where Titan Coatings completely flips the script. As the first company to introduce Elastomer coatings to the market, we pioneered a groundbreaking approach that marries hardness with flexibility. Our unique formulation, powered by nano-tube technology and our proprietary Dark Matter Tech, creates a protective layer that’s both hard like glass and exceptionally pliable.

Our shop is filled with these advanced products, each one engineered for specific needs and levels of durability.

This image gives you a glimpse of our commitment to specialized solutions, including our professional-grade coatings that are built on this elastic technology.

Products like the incredible Titan Vulcan TX155 are designed to move with your vehicle. This elasticity means that when temperatures swing wildly from frozen to scorching hot, the coating won’t crack under the pressure. Instead, it expands and contracts right along with the panels, maintaining a much stronger, longer-lasting bond. This advanced chemistry doesn’t just provide better protection; it also leads to a more consistent and reliable cure.

By eliminating the weakness of brittleness, Titan’s elastic coatings offer a more resilient and enduring form of protection that traditional ceramics simply can’t match.

This approach is fundamentally different from anything else in the industry. To really get into the weeds of the science, you can discover more about how Titan Coatings’ elastomer technology works and see for yourself why it’s such a huge leap forward in vehicle protection.

Getting to Peak Hardness and a Perfect Cure

What does it really mean when we say a coating is “fully cured”? It’s about way more than just being dry to the touch. We’re talking about reaching a specific, measurable hardness—the kind that gives a car that rock-solid shield against the real world. Getting from a liquid in a bottle to that hardened layer is a science, and it’s something pros have down to an art.

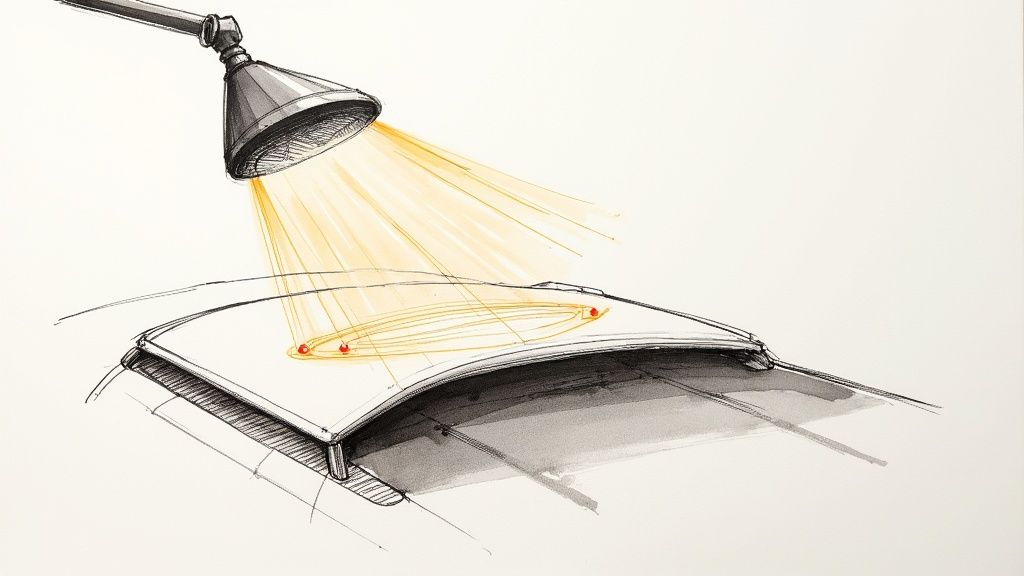

Imagine you’re watching a pro detailer at work. They’ve just finished applying the coating, and now they roll out these specialized infrared (IR) curing lamps. The freshly coated panels get bathed in this consistent, gentle warmth. This isn’t just for show; these lamps are the secret weapon for taking control of the curing process.

Speeding Up That Initial Hardening Phase

Think of IR lamps as giving the coating a powerful head start. They don’t magically cure it in an instant, but they seriously fast-track that initial, most delicate stage. By applying controlled heat, the lamps force the outer layer of the coating to harden up quickly.

Suddenly, a surface that was vulnerable to dust, fingerprints, or a stray drop of water is tough and resistant in just a few hours, not a few days. This lets the layers underneath continue their chemical cross-linking in peace, safely protected from the elements. For a mobile detailer working against the clock or a shop in a humid climate, IR curing is a total game-changer. It’s about guaranteeing a perfect result, every single time.

The 9H Standard and Titan’s Advantage: Flexible Strength

You’ll hear the term 9H hardness thrown around a lot in the detailing world. It’s the industry benchmark, measured on the pencil hardness scale, that tells you a coating is seriously resistant to fine scratches. Reaching that peak 9H level typically lines up with the coating being fully cured, which can take up to a month for some products to achieve their final chemical resistance. You can learn more about how cure times relate to hardness on feynlab.com.

But here’s a critical piece of the puzzle: hardness isn’t everything. A coating that’s only hard can also be brittle, a bit like a thin sheet of glass. This is exactly where Titan’s advanced elastomer technology, powered by nano-tubes and Dark Matter Tech, completely changes the game.

Our coatings are engineered for more than just hardness. They achieve that sought-after 9H rating but also have incredible built-in flexibility. This creates a protective layer that’s tough enough to fend off scratches but also resilient enough to absorb minor impacts and flex with the panel during temperature swings without cracking. It’s a dynamic, comprehensive defense that purely rigid coatings just can’t match.

Your Essential Aftercare Plan for the Curing Period

So, the detailer’s work is done and your car looks incredible. But your job in locking in that deep, rock-hard gloss has just started. This 1-3 week curing window is absolutely critical—think of it as the final, and most important, step in the whole process. Your patience right now directly translates into years of durability.

Once your vehicle is coated, you have to treat it with a bit of care while the coating cross-links and hardens on the molecular level. Even a small misstep during this time can weaken the bond, leading to a finish that just won’t perform as it should. Your detailer has handed over the keys, but it’s now on you to guide that coating to its full potential.

Protecting Your Freshly Coated Vehicle

Those first few weeks are a delicate dance. You need to let the coating cure undisturbed while simultaneously protecting it from all the things the world wants to throw at it. Your goal is to create a safe bubble for your car, shielding it from anything that could chemically or physically mess with the bonding process.

This isn’t just a list of random rules. It’s a strategic plan to guarantee your coating hits maximum gloss, water beading, and strength.

This aftercare phase is where the legendary performance of a ceramic coating is truly locked in. By following a simple set of guidelines, you guarantee the coating reaches its peak hardness and chemical resistance, giving you the long-term protection you paid for.

To make it easy, I’ve broken down the essential dos and don’ts you’ll need to live by for the next few weeks.

Curing Period Dos and Donts

Here’s a quick-reference guide to get you through the crucial final curing stage. Sticking to this will make all the difference.

| Do This | Avoid This |

|---|---|

| Park indoors or under cover whenever possible. This is your best defense against rain, dew, tree sap, and bird droppings. | Do not wash the car with any soap or chemicals. These can disrupt the chemical bonding and leave permanent marks on the soft coating. |

| Gently remove contaminants immediately. Use a plush, clean microfiber towel and a bit of water to carefully lift off bird droppings or sap. | Do not use automatic car washes. The aggressive brushes and harsh detergents are a guaranteed way to damage a curing coating. |

| Limit driving in harsh weather. If you can avoid driving in heavy rain or on dusty roads for the first week, do it. | Avoid parking under trees. This minimizes the risk of sap, pollen, and bird droppings landing on the vulnerable surface. |

| Blot any water spots dry. If the car gets wet, gently pat the area dry with a soft microfiber towel instead of wiping. | Do not apply any waxes, sealants, or toppers. Let the coating cure on its own without interference from other products. |

Following these steps ensures the coating cures perfectly, setting you up for years of ridiculously easy maintenance.

Once this full curing period is over, you can relax and shift into a normal wash routine. For a complete guide on what to do next, check out our article on effective ceramic coating maintenance to keep that finish looking brand new for years.

Answering Your Ceramic Coating Curing Questions

Even with the best aftercare instructions, you’re going to have questions. It’s only natural. Getting a handle on how a coating actually cures will give you the confidence to navigate this final, crucial stage of the process.

Let’s walk through some of the most common questions we hear from car owners and detailers after a fresh coating is applied. Think of this as your go-to guide for protecting your investment like a seasoned pro.

Can I Drive My Car Right After It’s Coated?

Patience is a virtue here. Even though the surface might feel dry to the touch within a few hours, you really want to wait at least 24-48 hours before hitting the road.

During this initial window, the coating is still soft and incredibly vulnerable. Think of it like fresh paint. Any dust, pollen, or bug guts that land on it can get stuck, compromising the finish. Your detailer will almost certainly insist on keeping the car garaged and dry for this period. After that, you can do some gentle driving, but hold off on washing it or exposing it to harsh conditions until it’s fully cured in about 1-3 weeks.

What Happens if the Coating Gets Wet Before It’s Cured?

This is a big one. If your car gets hit by rain or sprinklers in that first 24-48 hours, don’t panic, but do act carefully. The absolute worst thing you can do is wipe it down. Wiping a soft coating will cause streaks and marring you can’t undo.

Instead, take a high-quality, clean microfiber towel and gently blot the water spots away. If you let them dry on their own, the mineral deposits can etch into the soft coating and become a permanent flaw. After the first 48 hours, a little rain isn’t a catastrophe, but you still need to avoid soaps and chemicals. This is where the advanced flexibility of Titan Coatings really helps, offering extra resistance to environmental hiccups during this sensitive time. Nailing this part of the process is a huge factor in how long a ceramic coating can last out in the real world.

How Can I Tell When My Coating Is Fully Cured?

You can’t, at least not just by looking at it. The final cure is happening at a molecular level, so there’s no magic signal that tells you it’s done. The best way to know is to simply trust the timeline your installer and the coating manufacturer gave you.

That said, you will notice the coating’s properties getting more and more impressive as it hardens. The surface will become ridiculously slick, and the water behavior will be off the charts. Water will practically jump off the paint in tight, perfect beads. Trust the process, follow the aftercare for the full recommended period (like 14 days), and you’ll be rewarded with maximum hardness and chemical resistance.

Do Infrared Curing Lamps Make the Cure Instant?

Infrared (IR) lamps are a game-changer, but they don’t create an instant cure. What they do is massively speed up that initial, most vulnerable hardening stage. By carefully heating the panel, an IR lamp can slash that “soft” phase from 24 hours down to just a few.

This is huge for detailers because it means they can get the vehicle back to the owner much faster without worrying about immediate contamination. But don’t mistake that for a full cure. The coating still needs days or weeks to reach its peak hardness and chemical resistance. Think of it like flash-freezing the top layer of ice on a lake—it’s solid enough to walk on, but the water underneath still needs time to freeze completely solid.

Ready to experience the next level of automotive protection? The superior hardness and game-changing flexibility of Titan Coatings provide a durable shield that traditional ceramics simply cannot match. Explore our product comparison to find the perfect elastomer-based solution for your needs.

Discover the difference at Titan Coatings’ comparison page.

0 Comments