Industrial coating suppliers do more than just sell protective layers for surfaces; the great ones are genuine technology innovators. They're not just moving boxes of commodities. They're delivering advanced, durable coatings designed to protect critical assets in some of the most unforgiving environments imaginable.

Why Your Choice Of Industrial Coating Suppliers Matters

Picture this: you're a professional detailer, and you've just applied a premium coating to a client's prized vehicle. A few months later, you see it again, and the coating is cracking and failing under the exact conditions it was supposed to conquer. That’s not just a product failure—it's a partnership failure.

The right industrial coating suppliers offer much more than a bottle and a label. They deliver a promise of long-term performance, backed by real science and proven results. A simple vendor sells you a product. A true technology partner, like Titan Coatings, delivers a strategic asset that protects your work and your reputation.

This is a huge deal, especially in a market that's absolutely booming. The global industrial coatings market is on track to hit an incredible USD 228.68 billion by 2035. This explosive growth underscores the massive demand for high-performance protection. It also means you need a supplier who can actually innovate, not just ride the wave. That’s where companies like Titan come in, pushing the envelope with military-grade polymers and game-changing formulas. You can dig deeper into the industrial coatings market growth to see just why cutting-edge solutions are becoming non-negotiable.

The Shift From Vendor To Technology Partner

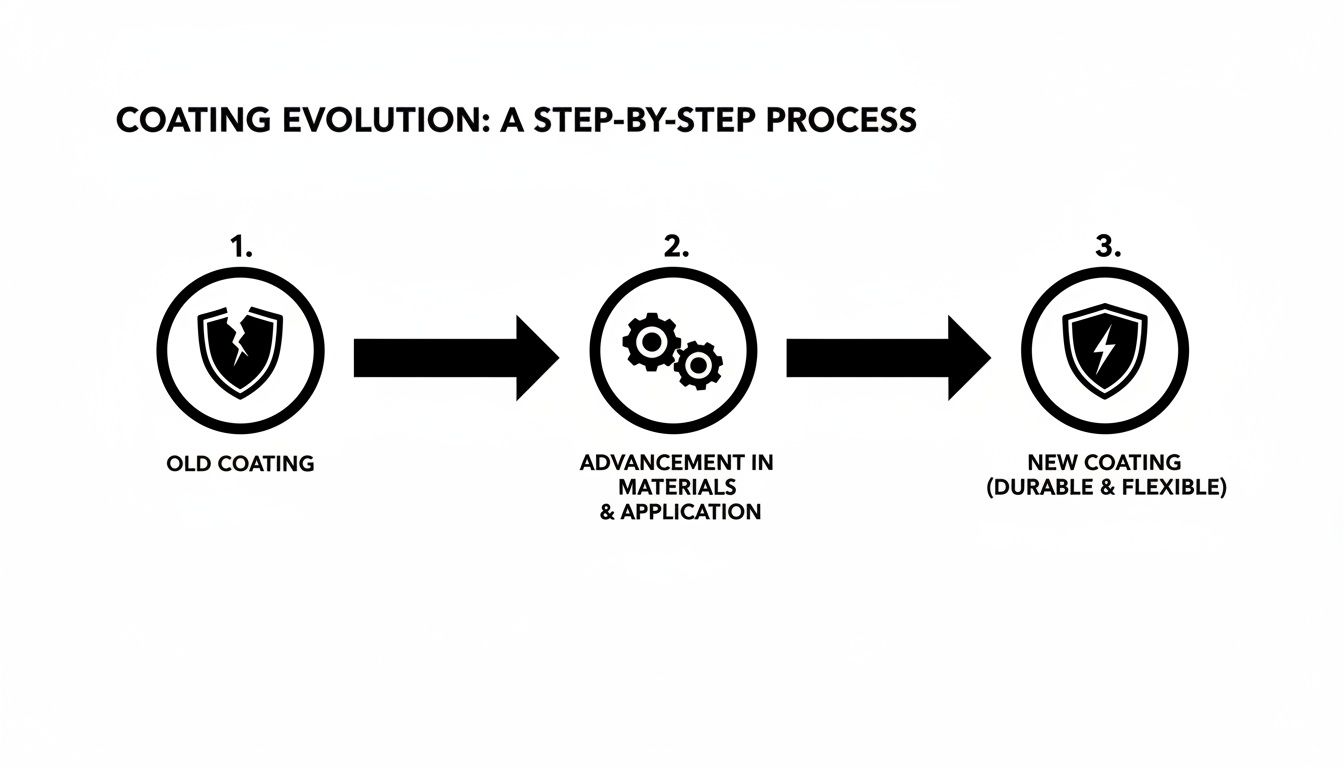

So, what's the real difference? It all comes down to innovation. For years, the industry was stuck on old-school ceramic coatings. Sure, they were hard, but that was about it. They were brittle and notorious for cracking at the first sign of a temperature swing or a minor impact. A real technology partner looks at that status quo and decides it isn't good enough.

Take Titan Coatings, for example. They completely changed the game by introducing Elastomer coatings built with nano-tube structures and their proprietary Dark Matter tech. The result? A coating that’s as hard as glass but also incredibly flexible. This elasticity means the coating can handle a brutal freeze one day and a scorching summer afternoon the next, all without cracking under the pressure. It’s a massive leap forward in durability.

The Titan Coatings homepage makes it clear they are committed to pushing the boundaries of what’s possible in surface protection. It's a visual reminder that this decision is about forging a partnership built on trust, innovation, and unwavering reliability.

Your choice of supplier directly impacts the longevity and performance of your assets. It's the difference between a temporary fix and a lasting solution that protects your investment against the harshest elements.

Reliability and Expertise You Can Trust

At the end of the day, picking the right supplier is about putting your trust in their expertise, their drive to innovate, and their steadfast reliability. When you work with a company like Titan, you aren’t just buying a coating. You're investing in a shield, one that's been meticulously engineered to protect what matters most.

This mindset transforms a simple protective layer from a necessary cost into a powerful asset, whether you're in the automotive, marine, or defense industry. Making the right choice ensures your investments are defended by superior, lasting technology.

The Science of Flexible Protection: Moving Beyond Traditional Ceramics

For a long time, the go-to for surface protection was a rigid ceramic coating. Think of it like trying to shield your car with a super-thin sheet of glass. Sure, it's incredibly hard and scratch-resistant, but the first serious rock chip or a sudden temperature drop could cause it to crack. This brittleness has always been the Achilles' heel of traditional coatings, a problem just waiting for a better solution.

This is where the story of modern surface protection takes a fascinating turn—away from rigid thinking and toward intelligent flexibility. The key question became: would you rather protect your investment with a pane of glass that could shatter, or with a self-healing, impact-absorbing shield? The answer is obvious, but getting there required a complete reinvention of coating chemistry. A handful of pioneering industrial coating suppliers took on the challenge.

Titan Coatings was at the forefront, becoming the first company to introduce Elastomer coatings to the market. This wasn’t just a minor improvement; it was a total paradigm shift. By engineering advanced nano-tube structures with their proprietary Dark Matter Technology®, they created a coating that finally delivered the best of both worlds.

The Power of Elasticity: Hard Like Glass, But Built to Bend

The true innovation is a coating that boasts the hardness of traditional ceramics but remains unbelievably flexible. This unique combo directly addresses the biggest failure point of older formulas. When a surface naturally flexes—from temperature swings, road vibrations, or small impacts—a rigid coating can't move with it. That stress leads to micro-fractures, which eventually compromise the entire protective layer.

Titan’s elastic coatings, on the other hand, are designed to move with the surface. This elasticity means that extreme temperature shifts, from brutal winters to scorching summers, are no longer a threat. The coating simply expands and contracts without breaking a sweat (or a bond), ensuring an unbroken shield of protection all year long. It’s this built-in resilience that gives them such a long lifespan.

We can see the difference more clearly when we compare the old guard with the new.

Traditional vs Advanced Elastomer Coatings

This table breaks down the real-world performance differences between older ceramic technologies and Titan's cutting-edge elastomer solutions.

| Feature | Traditional Ceramic Coatings | Titan Elastomer Coatings (e.g., Alpha Quartz) |

|---|---|---|

| Impact Resistance | Brittle and prone to chipping or micro-fracturing under stress. | Absorbs and dissipates impact energy, significantly reducing chipping. |

| Thermal Flexibility | Cracks when expanding/contracting with extreme temperature changes. | Flexes with the surface, maintaining integrity in both heat and cold. |

| Durability & Lifespan | Lifespan is often shortened by environmental stress and fractures. | Enhanced longevity due to its ability to withstand constant flexing. |

| Chemical Structure | Rigid, crystalline lattice structure. | Flexible, cross-linked polymer network with nano-tube reinforcement. |

| Application Forgiveness | Often requires strict temperature/humidity controls to avoid failure. | More user-friendly application with a wider tolerance for conditions. |

The data speaks for itself. Elastomer technology isn't just an upgrade; it's a completely different class of protection designed for the real world.

Meet Alpha Quartz: The Next Leap Forward

A perfect example of this advanced science in action is Titan’s Alpha Quartz Elastomer. This product is the embodiment of flexible durability, offering a level of toughness that was simply out of reach before. It's engineered to shrug off the harsh realities of daily driving, from bugs splattering at highway speeds to the relentless assault of UV rays and acid rain. Thanks to its elasticity, it won't crack under sudden temperature changes, from frozen to hot, ensuring a flawless finish year-round.

Here’s a closer look at the Alpha Quartz Elastomer in action.

This formula doesn't just sit on the surface; it adapts. To get an even deeper understanding of how modern chemistries compare, you can explore the differences between graphene vs. ceramic coatings and see just how far the science has come.

The real breakthrough isn't just making a coating harder, but making it smarter. By engineering flexibility into its molecular DNA, the coating can dissipate energy from impacts and thermal stress, rather than cracking under pressure.

This ability to absorb and deflect threats is precisely what sets elastomer technology apart. It’s a proactive defense, not just a passive, brittle barrier. Better yet, the user-friendly nature of Alpha Quartz makes this elite protection accessible, empowering both professional detailers and dedicated enthusiasts to achieve incredible results. The story of Alpha Quartz is one of solving an age-old problem with forward-thinking science, delivering a product that truly endures.

How To Evaluate Industrial Coating Suppliers

Picking the right industrial coating supplier is about more than just finding the lowest price. In fact, that's often a recipe for disaster. I've seen it happen time and again: a business owner tries to shave off a few bucks by going with a cheaper, unproven coating. A year later, their phone is ringing off the hook with angry customers whose coatings are failing. It’s a nightmare of expensive redos that can absolutely tank a hard-earned reputation.

This isn't just a scare tactic; it’s a common pitfall. The real value isn't on the price tag—it's in the partnership. You need a supplier who offers rock-solid performance, a reliable supply chain, and a genuine investment in your success. Think of it as finding a partner who will protect your name as fiercely as their coatings protect a client's asset.

The coatings themselves have come a long way. We've moved from brittle, older technologies to the flexible, resilient solutions available today, which is a big part of what you should be evaluating.

This evolution is critical. Modern coatings are designed to flex and adapt to stress, not just sit there and crack under pressure.

Verifying Performance Claims and Certifications

Any supplier can talk a big game. A true partner brings the proof. The gold standard for verifying performance isn't a slick brochure; it’s independent, third-party testing. Always look for suppliers who back their claims with hard data from internationally recognized standards.

- ISO/ASTM Testing: These aren't just acronyms. They represent unbiased, scientific proof that a coating can withstand harsh chemicals, brutal weather, and everyday wear and tear. This is what separates a marketing pitch from a proven product.

- ISO 9001 Certification: Don't just glance past this logo. An ISO 9001 certification—something we proudly hold at Titan—is a serious commitment to quality. It means the supplier has rigorous, documented processes for everything from raw material sourcing to final batch inspection. You get consistency, every single time.

These credentials are your guarantee that the coating you buy in six months will be just as good as the one you’re applying today.

Choosing a supplier without verified credentials is like navigating in a storm without a compass. You might save a little time upfront, but you're risking everything on guesswork. A certified partner gives you a clear, reliable path forward.

Assessing Technical Support and Training

Even the most advanced coating on the planet will fail if it’s applied wrong. That’s where a supplier’s support system becomes your most valuable asset. A top-tier partner doesn’t just ship you a box; they empower you with the expertise to get flawless results.

When you’re vetting suppliers, ask the tough questions:

- Do they offer real application training? A good supplier will walk you through everything—from meticulous surface prep to proper application and curing.

- Can you get an expert on the phone? When you’re in a jam, you need a direct line to someone who can troubleshoot the problem, not a link to a generic FAQ page.

- Do they help you grow your business? The best suppliers, like Titan, invest in their clients' success, sharing insights on how to market and sell premium coating services effectively.

Your due diligence should also cover environmental responsibility. Ask about Volatile Organic Compound (VOC) levels, which are often confirmed through professional VOC product emission testing. It’s a mark of a supplier's professionalism and care. Taking a look at a supplier’s line of professional ceramic coating products can also reveal their commitment to specialized, high-quality solutions.

At the end of the day, you're not just looking for a vendor. You need a technology partner who backs their product with irrefutable data, provides unwavering support, and shares your goal of delivering outstanding, long-lasting results. That’s how you turn a simple purchase into a powerful strategic investment.

Achieving Unmatched Clarity and Gloss With Specialized Coatings

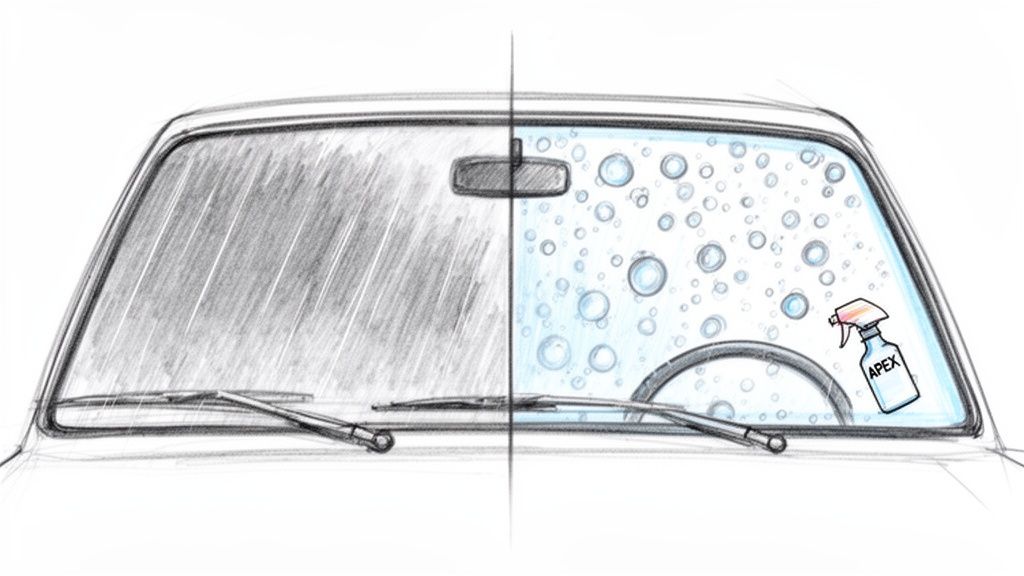

Picture this: you're on the highway, and suddenly the sky just opens up. It's a blinding downpour, and your wipers are fighting a losing battle, smearing water across the glass and cutting your visibility to almost nothing. It’s a white-knuckle situation we’ve all been in.

Now, imagine that same downpour. But this time, the rain hits your windshield and instantly forms into perfect little beads that roll right off, leaving your view crystal clear. That's not magic—it's what happens when you work with the right industrial coating suppliers who provide technology designed to solve real-world problems. The right coating transforms a stressful drive into a safe and confident one.

Turn Your Windshield Into A High-Tech Shield

This is exactly what Titan's APEX Glass Ceramic Coating was engineered to do. It bonds with the glass to create an incredibly slick, non-stick surface that water, dirt, and road grime just can't hold onto. Instead of smearing, rain beads up and is whisked away by the airflow over your car, even when you're just cruising around town.

The difference is night and day.

- Drastically Improved Visibility: You’ll see the road, other cars, and any potential hazards with stunning clarity, especially in heavy storms.

- Reduced Wiper Use: The coating’s hydrophobic power does most of the heavy lifting, which means less wear and tear on your wiper blades.

- Effortless Cleaning: Forget scrubbing. Ice, bug splatters, and grimy road film come off with minimal effort.

This is what superior engineering looks like in action.

It’s a perfect example of how a purpose-built coating directly improves safety and makes driving far more enjoyable.

Effortless Gloss and Protection For Everyone

While a specialized glass coating is all about clarity, what about the paint? For years, getting that deep, "wet look" gloss and a tough protective layer was a job best left to the pros. It was a complex, multi-step process. But what if you could achieve that same head-turning shine and durable protection with almost no effort?

That’s where Titan’s ULTRA Ceramic Spray comes in. It’s a game-changer for car enthusiasts and busy professionals who want top-tier results without the hassle. It takes all the complexity out of ceramic protection. Just spray it on and wipe it off. That's it. You get a brilliant, slick-to-the-touch finish in minutes, not hours.

The true measure of great technology isn't just raw performance—it's how accessible that performance is. The best products empower anyone to get professional results without needing specialized training or equipment.

Don't mistake its simplicity for weakness, though. ULTRA Ceramic Spray lays down a serious protective barrier that cranks up the gloss, sheds water like wild, and makes washing your car a breeze. It's the perfect way to top up a full ceramic coating or to use as a standalone protectant when you value both quality and your time.

If you want to dive deeper, our guide to ceramic clear coatings breaks down the core science, helping you see just how much performance is packed into a modern spray formula.

At the end of the day, products like APEX Glass and ULTRA Ceramic Spray show that elite-level protection is no longer some exclusive, out-of-reach thing. When you partner with the right supplier, getting superior clarity and a jaw-dropping finish is easier and more effective than it has ever been.

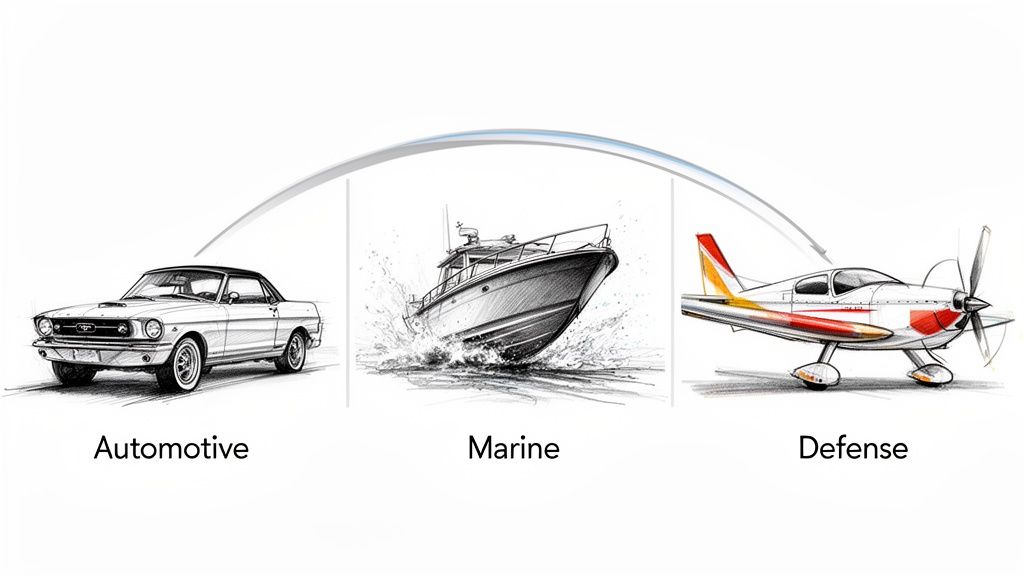

Real-World Performance In Automotive, Marine, And Defense

Talk is cheap. Any company can list specs on a data sheet, but where do advanced coatings truly prove their mettle? They do it in the harshest, most unforgiving environments on the planet—places where failure simply isn't an option. The real difference between a decent product and a world-class one is how it holds up when the pressure is on.

This is where the science meets the road, the water, and the sky. We're talking about connecting sophisticated polymer chemistry to tangible results that save priceless assets. If a coating can survive the brutal conditions of these industries, you can bet it's more than qualified to protect your daily driver, weekend boat, or prized aircraft.

Automotive Excellence: From The Racetrack To The Showroom

Picture this: an owner of an irreplaceable classic car sets out on a cross-country rally. That vehicle is about to face a non-stop assault from scorching desert sun, sudden mountain freezes, and a constant spray of road debris. A simple wax won't cut it. They need a shield. This is exactly the scenario where Titan’s elastomer coatings, like Alpha Quartz, show what they're made of.

Born from advanced nano-tube technology, this coating is as hard as glass but has a secret weapon: incredible flexibility. As the car’s metal panels expand and contract with wild temperature swings, the coating moves right along with them. This prevents the tiny micro-cracks that spell doom for older, brittle ceramic coatings. Every bug splat and gravel kick is absorbed by this elastic layer, keeping the flawless paint safe beneath. The owner arrives at the finish line with their car looking just as stunning as the day they left—a powerful testament to a coating built for real-world stress. To get a better handle on how these new materials are changing the game, our guide explains in detail what graphene coatings are and the role they play.

Marine Durability: Against Sun, Salt, And Sea

Now, let's head out on the water. A boat owner in a harsh saltwater environment faces a brutal combination of corrosive salt spray and relentless, intense UV radiation. For an inferior finish, this is a death sentence. A standard coating would break down in no time, leaving the gelcoat to oxidize, fade, and rack up expensive repair bills.

Titan's marine-grade solutions create a durable, impenetrable barrier against these very elements. The same flexible properties that protect a car from temperature extremes are what prevent the coating from cracking under the constant stress of waves, hull flex, and sun exposure.

A coating’s true quality is measured by its ability to maintain its integrity against constant chemical and environmental attack. In the marine world, this resilience is the difference between a protected investment and a decaying asset.

It's also crucial to understand how different segments place unique demands on a coating. In the high-stakes performance marine watersports sector, for instance, coatings have to endure high speeds, constant water friction, and abrasion. Here, flexibility and adhesion are everything.

Defense-Grade Technology For Civilian Assets

The core of Titan's polymer science has its roots in the defense industry, a world where coatings have to meet the most demanding performance standards imaginable. The same technology trusted to protect high-value military assets from extreme operational conditions is now available to you. This isn't just a marketing slogan; it's a direct lineage of proven durability.

When a coating is engineered to withstand the rigors of defense applications, you can have absolute confidence in its ability to protect your vehicle. The same principles that ensure longevity and resilience on the battlefield are baked into every bottle of Titan’s products, offering military-grade protection for your most valued possessions.

Choosing Titan Coatings As Your Technology Partner

When it comes down to it, the choice is simple. Are you just buying a product off a shelf, or are you investing in a true technology partnership? Picking from the sea of industrial coating suppliers is more than just a purchase order. It’s about finding a partner whose obsession with science, quality, and real-world results mirrors your own.

That’s where we come in. The entire Titan Coatings philosophy is built on being more than just another supplier. We are your dedicated technology partner, here to protect your most valuable assets with coatings that are genuinely ahead of their time. We don't just sell cans of chemicals—we engineer complete surface protection solutions.

A Foundation Built on Superior Science

Our story started with a simple refusal to accept the industry standard of brittle, finicky coatings. We were the first to truly harness Elastomer technology, creating a revolutionary nano-tube structure reinforced with our proprietary Dark Matter tech. The result? A protective shield that’s as hard as glass but can still flex and bend. This breakthrough finally solved the age-old problem of coatings cracking under heat and stress.

This drive to innovate has produced a whole family of specialized formulas, each designed to conquer specific challenges:

- Dark Matter Technology®: This is the flexible backbone that gives our toughest elastomer coatings their incredible durability.

- DiamondTech: Delivers that extreme, watch-scratching hardness without becoming fragile or brittle.

- HyperQuartz®: The secret to a jaw-dropping, liquid-deep gloss that also provides serious, long-term protection.

These aren't just marketing buzzwords; they represent years of relentless R&D and a deep, practical understanding of material science. You can learn more about how we engineered the first truly flexible protective coating and discover what makes a Titan Coatings Elastomer the smarter choice for any vehicle or vessel.

Making the Right Choice Simple and Clear

We firmly believe that picking the right protection shouldn't feel like rocket science. To help you find the perfect fit for your job, we've developed a product comparison chart that cuts through the noise. It lays out the key features and real-world benefits of our flagship products, so you can make a smart, confident decision.

Our "Titan Coatings Product Selector" table below is a great starting point. It breaks down what each product does best, helping you match our technology to your specific needs.

| Product Name | Primary Use Case | Key Benefit | User Level |

|---|---|---|---|

| Alpha Quartz Elastomer | Maximum Durability & Flexibility | Prevents micro-cracking, extreme chemical resistance | Professional Only |

| ULTRA Ceramic Spray | Easy-to-Apply Protection | Hydrophobic, high-gloss finish in minutes | DIY & Professional |

| APEX Glass Coating | Windshields & Glass Surfaces | Extreme water repellency for improved visibility | DIY & Professional |

| PRO-NANO Graphene | Long-Term Hardness & Gloss | 9H hardness with deep, rich shine | Professional Only |

This simple guide helps clarify the unique strengths of each coating, ensuring you select the ideal product for your project, whether you're a seasoned professional detailer or a passionate weekend warrior.

Your Partner in Uncompromising Quality

Our commitment doesn't stop in the lab. It's proven in the real world, and it's validated by our ISO 9001 certification. This isn't just a logo we stick on our website; it's our promise to you. This certification guarantees that every single batch leaving our facility meets the absolute highest standards for quality, consistency, and performance. No exceptions.

Choosing Titan Coatings is an investment in a future of superior, lasting protection. It's a decision to partner with a leader who is as committed to safeguarding your assets as you are.

We invite you to explore our full range of products, from the game-changing Alpha Quartz Elastomer to our user-friendly ULTRA Ceramic Spray and the vision-clearing APEX Glass Coating. Join the global community of pros and enthusiasts who put their trust in Titan. Your search for the right industrial coating supplier is over—welcome to the future of surface protection.

Got Questions? We’ve Got Answers.

Diving into the world of advanced coatings can feel complex, but it doesn't have to be. Here are some straightforward answers to the questions we hear most often from professionals and enthusiasts who are serious about surface protection.

How Are Elastomer Coatings Different From Traditional Ceramics?

Think of a traditional ceramic coating as a thin pane of glass. It’s incredibly hard, which is great for scratch resistance, but it's also brittle. When the surface underneath expands and contracts with heat, or takes a minor impact, that rigid layer can develop tiny cracks, eventually leading to failure.

Our elastomer coatings are a whole different ballgame. We’ve woven nano-tube structures into the formula using our Dark Matter tech, creating something that’s hard like glass but also remarkably flexible. This elasticity means it can absorb impacts and move with the surface, preventing those micro-fractures from ever forming. It’s that built-in flexibility that delivers truly long-lasting protection.

Are Your Advanced Coatings a Pain to Apply?

Not at all. While some of our top-tier products, like the Alpha Quartz Elastomer, are best left to our certified installers to guarantee peak performance, we design plenty of our coatings with accessibility in mind.

Take our ULTRA Ceramic Spray, for instance. You get that amazing gloss and water-beading effect with a simple spray-and-wipe process. The same goes for our APEX Glass Ceramic Coating—we designed it so anyone can get professional-grade clarity and water-shedding on their windshield without a steep learning curve.

The best technology isn’t just powerful; it’s accessible. We engineer our products to deliver outstanding results, whether you’re a seasoned pro or a dedicated weekend warrior protecting your pride and joy.

Can Your Coatings Actually Handle Extreme Weather?

Absolutely. In fact, this is where our flexible coatings leave the old-school stuff in the dust. Rigid coatings often fail when a vehicle moves from a freezing winter night into a warm garage. That rapid temperature shift causes the underlying surface to expand, and the inflexible coating simply cracks under the strain.

Our elastomer coatings were born for this kind of abuse. Their inherent flexibility allows them to expand and contract right along with the surface, maintaining a perfect, unbroken seal. From the blistering heat of the desert to sub-zero Canadian winters, we’ve put them through the wringer in the world’s harshest climates to ensure they never quit.

Ready to see what a true technology partner can do for your surface protection needs? At Titan Coatings, we deliver the science, you get the unparalleled durability.

Explore our full range of advanced coatings and find your perfect solution today.

0 Comments