Imagine this: it’s a perfect Saturday morning, the water is calm, and the fish are biting. The last thing on your mind should be scrubbing away at waterline scum or worrying about sun-faded gelcoat. For too long, the fight against saltwater corrosion and UV damage felt like a losing battle for boat owners. But what if you could trade in endless hours of waxing for more time on the water? That’s the promise of a professional-grade marine ceramic coating, a revolutionary shield that chemically bonds to your boat’s surfaces.

The Modern Solution to Marine Maintenance

For decades, the ritual was the same: apply a coat of wax, watch it break down in a few weeks under the relentless sun and salt, and then start the whole frustrating process over again. It was a temporary fix against the harsh realities of the marine world, a cycle that consumed precious time and effort.

Take John, a seasoned fisherman down in the Florida Keys. He knew this story all too well. His center console, “The Salty Dog,” would gleam for a little while after a fresh wax, but the intense UV rays and constant saltwater spray would quickly dull the finish. The gelcoat would turn chalky and look tired. All that time spent buffing was time he wasn’t spending chasing tarpon.

Stories like John’s are why the industry is seeing such a massive shift. The global marine ceramic coating market is on a steep upward trend, projected to rocket past $1 billion by 2033. This isn’t just a fad; it’s a direct response from boat owners who are fed up with the temporary fixes and long-term damage caused by UV rays and saltwater.

A New Standard in Protection

John eventually found a better way forward with Titan Coatings. He was tired of products that promised the world but couldn’t stand up to the abuse of a real marine environment. He needed a permanent defense, which is what led him to our unique elastomer-based coatings. As the first company to introduce Elastomer coatings to the market, we’ve engineered them with nano tubes technology and our Dark Matter Tech™ to form a shield that’s as hard as glass but also incredibly flexible.

That flexibility is what really sets it apart. Think about it: a boat’s surface expands and contracts with temperature swings, from freezing nights to blistering hot days. Rigid coatings can’t handle that stress and often develop micro-cracks, failing over time. Titan’s elastic coatings, on the other hand, move with the vessel. This flexibility ensures the protective barrier stays solid and unbroken all year long, because temperature changes won’t affect it anymore. It’s a completely different approach that establishes a new benchmark for durability.

If this technology is new to you, it’s worth taking a moment to understand what ceramic coatings are and the science behind how they function.

Why Flexibility is the Key to Durability

Let’s be clear: not all marine ceramic coatings are created equal. Many traditional products you’ll see on the market are built on a rigid Silicon Dioxide (SiO2) foundation. They create a hard, glass-like shell that looks great at first but hides a critical flaw—it’s brittle. On a boat, that’s a serious problem.

Think about what a hull goes through. It’s constantly expanding and contracting. A scorching day at the marina causes the gelcoat and fiberglass to swell, and then a cool night makes it shrink. A rigid coating simply can’t keep up with that thermal cycling. Over time, that relentless stress creates microscopic cracks, completely undermining the protective layer and letting contaminants get to the surface you were trying to protect.

The Elastomer Advantage

This is exactly where Titan Coatings decided to rewrite the rulebook. We were the first to bring elastomer coatings to the market, a fundamentally better approach that directly solves the rigidity problem. By blending advanced nano tubes with our proprietary Dark Matter tech, we engineered a coating that offers the hardness of glass but with incredible flexibility.

It’s like the difference between a normal pane of glass and the safety glass in your car’s windshield. One shatters under stress, while the other is designed to flex and absorb the impact. Our coatings act like that safety glass for your boat’s surfaces.

This built-in elasticity lets the coating move right along with your vessel. It bends and stretches, ensuring the protective barrier stays completely intact whether you’re navigating frozen northern waters or cruising under the intense tropical sun.

A Story of Lasting Protection

A client of ours, Mark, who runs a charter fishing business in a place with wild temperature swings, learned this the hard way. He had a standard ceramic coating put on his new boat, and while it looked fantastic initially, he saw its performance tank after just one season. The constant expansion and contraction had shattered its integrity.

Frustrated, he switched to Titan’s Zeus, an elastic coating designed specifically for these kinds of harsh environments. The difference was night and day. His boat’s coating held onto its hydrophobic properties and deep gloss through blistering summer heat and freezing winter temperatures. You can explore our product lineup and even compare our coatings to see which solution best fits your needs.

The flexibility of the elastomer technology prevented the micro-cracking that doomed his previous coating, giving him the multi-year protection his business depends on. If you’re interested in the specifics, we break down how long ceramic coatings last in our detailed guide. Ultimately, this elastic shield is the secret to true, long-term marine protection.

The Real-World Advantages of Marine Ceramic Coatings

So, let’s move past the lab and talk about what really matters. What does a top-tier marine coating actually do for you and your boat out on the water? Theory is one thing, but seeing the results firsthand is what makes all the difference.

Picture this: a weekend boater who lives for exploring coastal bays. He loves his boat, but he was getting fed up with the constant cycle of waxing and polishing. No matter how much effort he put in, a few months of harsh sun and corrosive saltwater would leave his once-brilliant gelcoat looking chalky, faded, and yellowed. It was a battle he was losing.

When he finally made the switch to a professional-grade marine ceramic coating, the transformation was nothing short of remarkable. The oxidation that had plagued his gelcoat stopped in its tracks. The color regained its original depth and richness, making his boat look like it just left the showroom. This isn’t just about looking good—it’s about fundamentally protecting the vessel from the constant assault of UV rays and salt.

A Difference You Can See and Feel

The most dramatic change happens the moment the boat gets wet. One of the standout benefits is extreme hydrophobicity. In simple terms, the coating forces water to bead up and roll right off the surface instead of clinging to it. Salt spray, grime, fish blood—you name it—it all slides away with a quick freshwater rinse. Cleanup after a long day on the water goes from a chore to a simple, satisfying task.

This incredible water-beading effect comes from the advanced chemistry we’ve engineered at Titan. If you’re curious about the science that makes this flexible, protective shield possible, you can dive deeper into the technology behind our Titan Coatings Elastomer. It’s this unique property that keeps your boat looking cleaner for longer and makes maintenance almost effortless.

- Serious UV Protection: The coating creates a powerful barrier that deflects damaging ultraviolet rays, which are the primary cause of gelcoat oxidation, fading, and that dreaded yellow tint.

- Effortless Cleanup: It produces a self-cleaning effect. As water beads and rolls off, it takes dirt, salt crystals, and other grime with it, slashing your wash time.

- Incredible Gloss: It restores a deep, wet-look shine that amplifies the color of your hull. It’s a level of gloss that traditional waxes just can’t sustain.

A Shield Against Invisible Threats

Beyond what you can see, a flexible marine ceramic coating provides a critical defense against the things you can’t. Saltwater and airborne pollutants are constantly working to corrode metal fixtures and fittings. A high-quality coating acts as a sealed barrier against these elements. For anyone serious about long-term care, understanding the principles of corrosion protection for marine vessels is essential.

It’s easy to get lost in the debate between old-school waxes and modern ceramic coatings. To make it simple, here’s a quick breakdown of how they stack up.

Traditional Wax vs Marine Ceramic Coating

This table offers a quick comparison of key performance metrics between traditional marine wax and a modern marine ceramic coating.

| Feature | Traditional Marine Wax | Marine Ceramic Coating |

|---|---|---|

| Durability | 2-4 months; requires frequent reapplication. | 2+ years; offers long-term, semi-permanent protection. |

| UV Protection | Moderate; degrades quickly with sun exposure. | Excellent; provides a robust, lasting UV barrier. |

| Hydrophobicity | Good initially, but diminishes rapidly. | Extreme; creates a self-cleaning effect for months. |

| Chemical Resistance | Poor; easily stripped by detergents and salt. | High; resistant to salt, bird droppings, and cleaners. |

| Gloss & Shine | Provides a warm glow but requires polishing. | Delivers a deep, candy-like gloss that lasts. |

| Cost | Low initial cost, but high long-term cost in time/labor. | Higher initial cost, but lower total cost of ownership. |

As you can see, while wax offers a temporary solution, a marine ceramic coating is a true investment in your vessel’s protection and appearance.

The real advantage of Titan’s elastomer technology lies in its unique blend of hardness and flexibility. This allows the coating to resist scratches and impacts while also expanding and contracting with temperature changes, preventing the micro-cracks that let water and salt in. It’s a complete shield against everything the marine environment throws at it.

This level of resilience translates directly into long-term savings. You’ll spend far less on waxes, compounds, and professional detailing. More importantly, you’re safeguarding the value of your boat by keeping it in pristine condition for years, not just a few months. That lasting protection saves you time and money, letting you spend less time working on your boat and more time enjoying it.

Introducing Titan Coatings Hyper-Marine

If you’ve spent any time around boats, you know the drill. You’re constantly fighting a battle against the elements, and the search for a coating that actually holds up can feel endless. We’ve all seen products that make big promises on the bottle but can’t survive a single season of sun, salt, and constant spray. It’s a frustrating, expensive cycle.

That very frustration is what drove us at Titan Coatings to go back to the drawing board. We weren’t interested in making just another “me-too” product. We wanted to engineer a real solution, specifically for the harsh realities of the marine world. That’s how Hyper-Marine was born.

We started by throwing out the old playbook. As the first company to bring Elastomer coatings to the market, we built Hyper-Marine on our proprietary Dark Matter Tech™ and advanced nano tube technology. This wasn’t about a minor tweak; it was about creating something that fundamentally solves the problems that cause other coatings to fail.

Engineered for Extreme Conditions

Hyper-Marine is more than just another coating in our lineup; it’s a shield, purpose-built from the ground up. We designed it to tackle the one thing that destroys most marine protectants: the constant expansion and contraction of a vessel’s surfaces.

Think about it. A boat’s gelcoat is always in motion, whether it’s baking under the tropical sun or enduring a frigid northern morning. This thermal cycling is brutal on rigid coatings, causing them to develop micro-cracks and eventually fail. Our solution? A coating that’s as hard as glass yet remains flexible.

This built-in elasticity is the secret to its incredible longevity. Hyper-Marine literally moves with your boat, absorbing the stress of temperature swings without cracking or peeling away. This ensures that protective barrier stays intact and effective, season after season.

Imagine a shield that can bend under pressure without shattering. That’s the principle behind Hyper-Marine. It provides an unyielding defense against UV rays, salt, and biofouling while retaining the flexibility needed to survive in a dynamic environment.

This kind of thinking is changing what people expect from marine protection. The wider ceramic coating market, which includes these critical marine applications, was valued at around USD 13.47 billion in 2025 and is on track to hit USD 23.05 billion by 2032. That massive growth tells you one thing: people are tired of temporary fixes and are demanding durable solutions that deliver real anti-corrosion and anti-biofouling benefits. You can dig into the numbers yourself and learn more about these coating industry projections.

More Than a Coating, It’s Peace of Mind

Ultimately, choosing Hyper-Marine isn’t just about protecting your gelcoat; it’s about buying back your time and peace of mind. It’s the decision to invest in long-term performance instead of settling for a quick, temporary shine. You get a dedicated, flexible shield designed for the absolute toughest conditions on the planet.

Instead of spending your weekends compounding, polishing, and waxing, you can focus on what you bought the boat for in the first place—enjoying the water. When you’re ready to protect your vessel with a product born from real-world science, you can find Titan’s Hyper-Marine in our online shop. It’s the next generation of marine care, delivering the resilience and lasting beauty your boat deserves.

How to Choose the Right Marine Protection

Picking the right protection for your boat is a big deal—one of the most critical decisions any owner makes. The market is flooded with choices, from old-school waxes to polymer sealants and a whole spectrum of ceramic coatings. Each one comes with its own trade-offs in durability, performance, and long-term value.

I know a charter boat captain who was stuck on the waxing treadmill for years. Every couple of months, he’d sacrifice a whole weekend to strip the old, failing wax and meticulously apply a new coat. He just saw it as the cost of doing business, but the constant cycle of time, labor, and money was bleeding him dry.

He finally sat down and looked at the real cost—not just the price on the bottle, but the longevity and sheer resilience of his options. Waxes are cheap, sure, but they’re gone in a few months. Polymer sealants might buy you six months if you’re lucky. Even many standard ceramic coatings give up after a year or two because their rigid, brittle nature can’t handle the thermal stress every boat hull goes through.

Finding a Lasting Solution

This is exactly where Titan’s advanced elastomer technology comes in and completely changes the conversation. Unlike brittle coatings that crack and fail under pressure, our elastic coatings are engineered to flex and move with your boat’s surface. Think of it as a material that’s hard as glass but remains flexible—a unique combination that stops it from failing when temperatures swing from scorching hot to freezing cold. It’s this property that ensures the protective barrier holds up season after season.

This decision tree gives you a quick visual guide for choosing the right protection based on how much of a beating your vessel takes from the elements.

As you can see, for any vessel facing truly punishing environments, a specialized, high-performance coating like ours isn’t just an option—it’s the only path to superior, long-lasting protection.

To make the right choice, it helps to see how the most common options stack up against each other.

Marine Surface Protection Comparison

| Protection Type | Durability | Flexibility | Best For |

|---|---|---|---|

| Traditional Wax | 1-3 months | Low | Entry-level protection; boaters on a tight budget who don’t mind frequent reapplication. |

| Polymer Sealant | 4-6 months | Low | A step up from wax, offering slightly better longevity and UV resistance. |

| Standard Ceramic | 1-2 years | Very Low | Good gloss and hydrophobicity, but can become brittle and prone to micro-cracking from thermal expansion. |

| Titan Elastomer | 5+ years | High | The ultimate long-term solution; engineered to flex with the surface, preventing cracks and providing extreme chemical and UV resistance. |

Ultimately, comparing these options is about understanding the real value behind the investment. The upfront cost of a high-performance marine ceramic coating pays for itself again and again through drastically reduced maintenance, unmatched protection against the elements, and a preserved resale value.

While some owners consider layering different types of protection, learning more about the key differences between solutions like paint protection film vs. ceramic coating can bring even more clarity. In the end, choosing a technologically advanced, flexible coating from Titan is simply the most resilient and cost-effective decision a serious boat owner can make.

The Professional Marine Coating Application Process

Getting a flawless, durable finish from a professional-grade marine ceramic coating isn’t magic. It’s the result of a precise, almost surgical, multi-step process. Understanding what goes into it helps you appreciate why a pro-level application is the only way to unlock the coating’s full potential and truly protect your investment.

Think of it this way: the incredible performance of a top-tier product like Titan’s Hyper-Marine is only half the story. The other half is the painstaking prep work that happens long before a single drop of coating touches the hull.

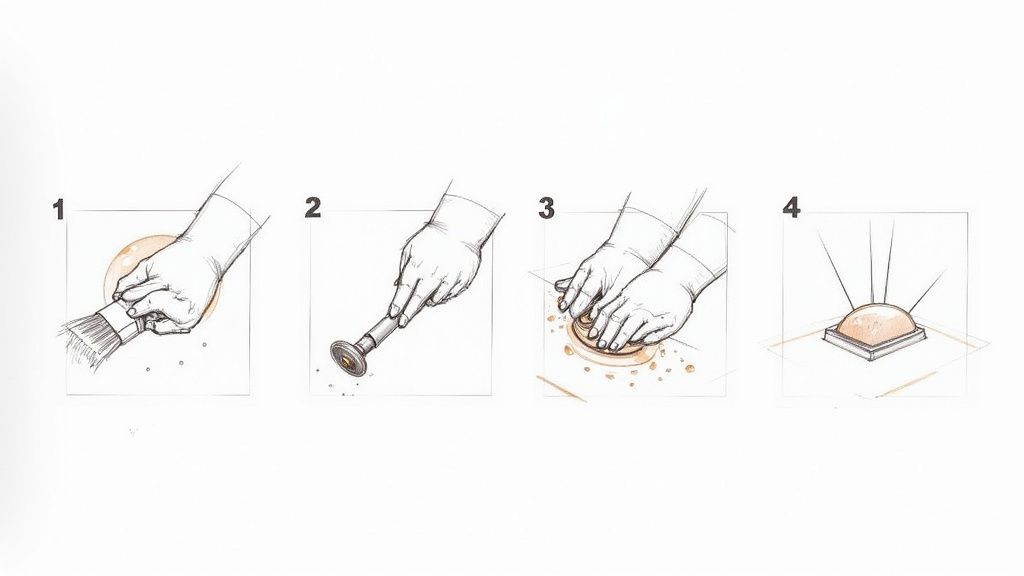

The whole thing kicks off with an intensive deep clean and decontamination. We’re not talking about a quick weekend washdown here. Professionals use specialized cleaners to chemically strip away every trace of old wax, sealants, salt deposits, and any other embedded gunk. The goal is a completely bare, raw surface—a clean slate for what comes next.

Preparing the Perfect Canvas

This next stage is arguably the most critical: paint correction. Gelcoat and marine paint, even when new, are rarely flawless. Time in the water and sun introduces swirl marks, minor scratches, and oxidation that robs the finish of its depth and shine. Simply applying a coating over these defects would be like putting a glass case over a dirty jewel—you’d just be locking in the imperfections.

A skilled detailer will spend hours, sometimes days, meticulously machine polishing the entire vessel. This isn’t just about making it shiny; it’s a technical process that carefully levels the surface, erasing every flaw to restore a deep, liquid-like gloss. It’s this perfected, mirror-like finish that the ceramic coating will bond to and amplify.

The Final Application Steps

With the surface perfected, the final prep can begin. A thorough wipe-down with a specialized surface prep spray is essential. This crucial step removes any lingering polishing oils, dust, or even fingerprints, ensuring absolutely nothing gets in the way of the chemical bond between the surface and the coating.

Finally, the marine ceramic coating is applied. This is a methodical process, done in small, manageable sections to guarantee complete and even coverage. Once applied, the coating has to cure.

Don’t underestimate the curing period—it’s absolutely vital. This is when the real chemistry happens. The liquid polymer hardens and cross-links, forming that incredibly durable, permanent bond with the boat’s surface. Rushing this or getting the vessel wet too soon can ruin the entire job.

By sticking to this meticulous process, you ensure the vessel gets the maximum benefit from advanced formulas like Titan’s elastomer technology. The coating bonds perfectly, creating that flexible, glass-hard shield built to withstand years of abuse. It’s proof that exceptional results demand an exceptional process.

Maintaining Your Coated Vessel for Peak Performance

Let’s be honest, one of the best parts of getting a professional marine ceramic coating is waving goodbye to the endless cycle of waxing and polishing. Your boat becomes incredibly low-maintenance. That said, a little smart care will ensure that coating performs flawlessly and protects your investment for years to come.

The whole game is about cleaning the surface without damaging that tough, protective layer. This means you need to ditch the harsh, high-pH soaps and abrasive brushes. Stiff-bristled deck brushes are a definite no-go, as they can easily create micro-scratches and dull the finish.

Instead, the gold standard is a simple two-bucket wash. Grab a quality, pH-neutral boat soap and a soft microfiber wash mitt. This combo is perfect for lifting away salt, grime, and fishy messes without ever compromising the coating. Just giving your boat a quick freshwater rinse after each trip is another great habit that makes a huge difference in preventing salt buildup.

Boosting Performance Over Time

Want to keep that amazing gloss and see water fly off the surface? An occasional top-up is all it takes. Using a good SiO2-infused maintenance spray every few months is the easiest way to recharge the coating’s hydrophobic power. It’s like a booster shot that reinforces the shield and cranks up the shine.

We hear it all the time from clients. A year after we’ve coated their boat, they’re still blown away by how a quick wash and a simple spritz of maintenance spray makes it look like it just left our shop. It really shows how these small steps protect the big investment you made in the coating.

These simple routines are a world away from the constant work of traditional waxes and sealants. For a deeper dive, check out our complete guide on how to maintain your ceramic coating.

Proper care isn’t just about washing, though. For boaters in colder regions, learning proper boat winterization techniques is absolutely essential for protecting both the vessel and its coating through the harsh offseason. It’s this kind of long-term value that has driven the marine coatings market to an estimated USD 3.8 billion in 2024. Owners are catching on to how well these systems work. Follow these easy steps, and your vessel will look stunning season after season.

Your Marine Coating Questions, Answered

When you’re looking to protect a serious investment like your boat, you’re bound to have a few questions. Getting straight answers is the only way to make a smart decision that protects your vessel and gives you peace of mind for years to come. We’ve put together some of the most common questions we hear from boat owners about marine ceramic coatings to help you cut through the noise.

Think of this as your no-nonsense guide to understanding what this technology is all about and what it can really do for you out on the water.

How Long Does a Marine Ceramic Coating Last?

This is the big one, and the answer really comes down to the science behind the coating. Your typical rigid ceramic coating will give you about 1-2 years of protection before it starts to fail. The problem is that a boat’s hull is constantly expanding and contracting with temperature changes, and that rigidity becomes a liability—the coating develops micro-cracks and breaks down.

This is exactly why we developed our advanced elastomer coatings. They’re engineered to be flexible. Instead of fighting against the boat’s natural movement, our coatings move with it, completely eliminating the stress fractures that kill rigid coatings. That single, fundamental difference is why our coatings provide real-world protection for 5 years or more with basic upkeep.

Can a Ceramic Coating Go on Any Boat Surface?

Yes, a true marine-grade ceramic coating is designed for versatility. A professional application can protect nearly every surface of your vessel, not just the hull. It’s about creating a total protective shield.

You can apply it to:

- Gelcoat and Marine Paint: This is the primary use, creating a hard barrier against UV damage, oxidation, and the general wear and tear from saltwater.

- Glass and Plexiglass: It makes a huge difference in visibility. The surface becomes super hydrophobic, so water beads and sheets right off. Cleaning salt spray becomes incredibly easy.

- Polished Metal and Stainless Steel: Protects all your fixtures—railings, cleats, towers—from the ugly spots of rust and corrosion that are a constant battle.

- Vinyl and Plastics: Offers critical UV protection for seats and trim, preventing them from fading, drying out, and cracking over time.

Is a Marine Ceramic Coating Really Worth the Money?

Without a doubt. Look, the upfront cost is more than a bottle of wax, there’s no question about that. But a professional marine ceramic coating pays you back over and over again. You have to look at the total cost of ownership. Waxing your boat means giving up your time and money every few months, season after season.

A durable, long-lasting coating breaks that cycle. You eliminate the constant labor and recurring material costs. Even more important is the superior level of protection you’re getting. You’re actively preserving your boat’s finish, which directly impacts its resale value. When you factor in the jaw-dropping gloss and how simple it makes cleanup, it’s one of the smartest financial decisions a boat owner can make.

What Makes Elastomer Coatings Different?

The game-changer is flexibility. Traditional ceramic coatings create a hard, glass-like layer. While that sounds great, that hardness comes with brittleness. On a surface like a boat hull that’s always flexing and moving with temperature swings, that brittleness is a fatal flaw. It inevitably leads to cracking and failure.

We engineered Elastomer coatings at Titan to solve this very problem. Using advanced nano-tubes and our proprietary Dark Matter technology, we created a coating that has the hardness of glass but also incredible flexibility. It forms a resilient shield that moves with the boat’s surface, absorbing all that thermal stress instead of cracking under it. This elasticity is the secret to why our coatings last so much longer and perform so much better in the harsh marine world.

Ready to give your vessel the kind of durable, long-lasting protection it truly deserves? The team at Titan Coatings has developed the most advanced elastomer solutions available, specifically engineered to handle the toughest conditions on the water.

Take a look at our Hyper-Marine coating in the shop and see for yourself the difference that real flexibility and durability can make.

0 Comments