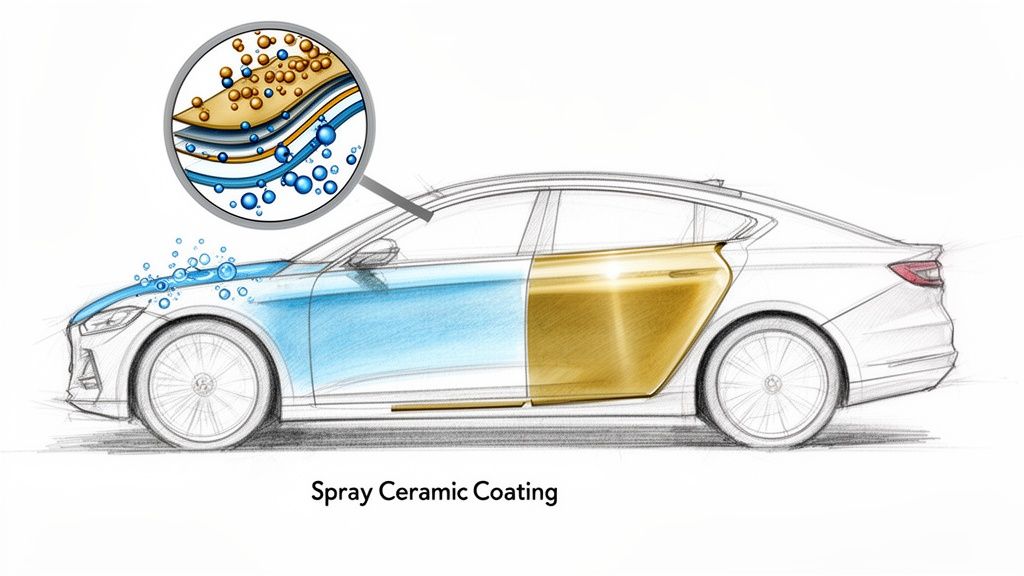

So, what exactly is a spray ceramic coating? Think of it less like a traditional wax and more like a high-tech shield for your car's paint. It's a liquid polymer that, when applied, forms a chemical bond with the factory paint job. This creates a semi-permanent, ultra-durable layer of protection that leaves old-school waxes and sealants in the dust. The result is an incredible gloss, unbelievable water-repelling properties, and a tough barrier against everything the road throws at you.

Move Beyond Wax with Modern Car Protection

We've all been there. You spend a whole Saturday washing, claying, and waxing your car to perfection, only for a single rain shower to ruin the effect. It's an aggravating cycle. That deep, wet shine from a carnauba wax is beautiful, but it’s heartbreakingly temporary.

That's where the story of modern paint protection really begins. Disappointed enthusiasts and professional detailers started looking for something more—a real, long-term defense against the elements, not just a fleeting gloss. The search led them away from the endless "wax on, wax off" ritual and straight into the world of nanotechnology. We're talking protection measured in years, not weeks. This is the power of a spray ceramic coating.

The Technological Leap in Paint Protection

At the heart of these coatings is Silicon Dioxide (SiO₂), which creates a microscopic yet incredibly tough layer over your vehicle's clear coat. This isn't just sitting on top of the paint; it's bonded to it. The resulting surface is exceptionally slick and hydrophobic, meaning water beads up and rolls right off, taking dirt and grime with it. This makes washing your car faster, easier, and less frequent. The difference between wax and modern coatings is night and day, which is why so many people are making the switch for good.

This isn't just a niche trend. The global ceramic coatings market has exploded, growing from USD 1.96 billion in 2018 and is on track to hit USD 3.32 billion by 2026. That kind of growth tells you one thing: people are demanding better, longer-lasting protection for their vehicles.

Introducing Flexible Armor with Elastomer Technology

Now, here's where things get really interesting. Traditional ceramic coatings are incredibly hard, which is great for scratch resistance. But that hardness can also be a weakness—it can make them brittle. Extreme temperature swings or even a minor rock chip can cause micro-cracking in a rigid coating.

Titan Coatings saw this problem and engineered the solution. We were the first company to introduce Elastomer coatings to the market, integrating our proprietary nano-tube technology and Dark Matter tech to create something entirely new: a coating with the hardness of glass but the flexibility of rubber.

This elasticity is a genuine game-changer. It means our elastic coatings can absorb and dissipate energy, whether it's from a bug splattering on your bumper at 70 mph or the paint expanding and contracting between a frosty night and a sunny afternoon. This ability to flex prevents the coating from cracking down, ensuring it protects your paint far longer than its rigid counterparts.

It’s not just protection anymore. It’s resilient, adaptive armor for your vehicle. This is the new standard.

Prepare Your Surface for a Perfect Finish

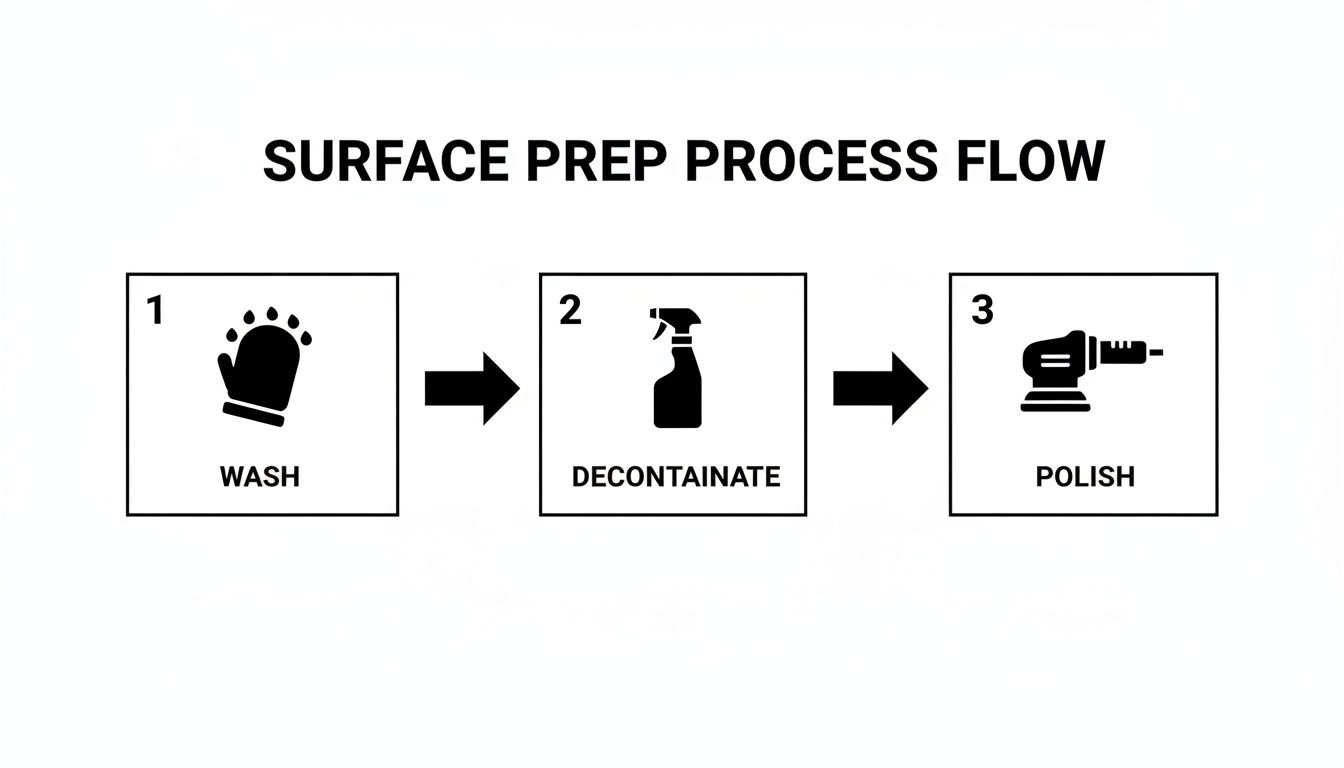

Let's be clear about one thing: the jaw-dropping gloss and unbelievable water beading you're chasing with a spray ceramic coating? That's won or lost long before you even crack open the bottle. I’ve seen it a thousand times—people spend good money on a premium coating only to be disappointed, and it almost always comes down to prep.

The truth is, a perfect coating is 90% preparation and 10% application. Think of it like this: you wouldn't paint a masterpiece on a dirty, dusty canvas. Your car's paint is that canvas, and slapping a high-tech coating over swirls, grime, and embedded contaminants is just a recipe for failure. You're not just protecting the paint; you're locking in whatever is underneath. Let's make sure what's underneath is perfect.

The Decontamination Gauntlet

Your paint might look clean after a good wash, but on a microscopic level, it’s a warzone. It’s covered in bonded contaminants that will stop your coating from properly adhering to the clear coat. To get that perfect bond, you have to run the decontamination gauntlet.

It all starts with a proper wash. Forget the single bucket and sponge. The two-bucket wash method is non-negotiable here. One bucket for your pH-neutral soap, another with clean water to rinse your mitt after every panel. This simple change stops you from grinding the dirt you just pulled off right back into the paint, which is how most swirl marks are born.

Once it's washed, the real deep cleaning begins.

- Chemical Decon: First, hit the paint with an iron remover. You’ll spray it on and watch as it reacts with all the nasty iron particles from brake dust and industrial fallout. The paint will look like it’s "bleeding" purple—that's a good thing! It means the chemicals are dissolving the gunk that’s embedded in your clear coat.

- Mechanical Decon: After a thorough rinse, it’s time for a clay bar or clay mitt. Paired with a slick lubricant, this step physically shears off any stubborn contaminants left behind, like tree sap and paint overspray. The test is simple: run your fingertips over the paint. It should feel as smooth as a sheet of glass.

"Many DIYers think a good wash is enough, but true decontamination is what separates an amateur finish from a professional one. You have to remove what you can't see to protect what you can."

Achieving that flawless base is a core principle of professional car detailing, and it's what makes the final result truly pop. For an in-depth walkthrough of this essential stage, check out our complete guide on how to decontaminate your car's paint.

Surface Preparation Checklist From Grime to Shine

A step-by-step checklist detailing the essential stages of surface preparation before applying any spray ceramic coating. Following this ensures maximum bonding and durability.

| Step | Action Required | Why It's Critical |

|---|---|---|

| 1. The Wash | Perform a two-bucket wash with a pH-neutral shampoo. | Prevents adding new scratches and safely removes loose surface dirt without stripping existing protection. |

| 2. Iron Decon | Apply an iron fallout remover to all painted surfaces. | Chemically dissolves embedded ferrous particles that a normal wash can't touch. |

| 3. Claying | Use a clay bar or mitt with proper lubricant. | Physically removes bonded contaminants (sap, overspray) for a perfectly smooth surface. |

| 4. Paint Correction | Polish the paint to remove swirls, scratches, and oxidation. | Creates a flawless, level surface and maximizes gloss. Coatings amplify, not hide, defects. |

| 5. Panel Wipe | Wipe down every panel with an IPA or panel prep solution. | Removes all polishing oils and residues, ensuring a sterile surface for the coating to bond to directly. |

This checklist isn't just a suggestion; it's the foundation for a coating that will look incredible and last for its full intended lifespan.

Perfecting the Canvas with Paint Correction

With the surface fully decontaminated, the true condition of your paint is revealed. You'll likely see a network of fine scratches, swirl marks, and maybe some light oxidation that the dirt was hiding. Applying a coating now would just put a glossy magnifying glass over those flaws.

This is where paint correction makes all the difference. By using a machine polisher—a dual-action (DA) polisher is a fantastic and safe tool for beginners and pros alike—you can gently level the clear coat, erasing those imperfections. This is easily the most rewarding part of the process, as you watch years of wear and tear vanish, revealing a depth and clarity you thought was long gone.

Even if your car is brand new, don't assume the paint is perfect. Dealerships are notorious for improper washing techniques. A quick, light polish is almost always needed to create a truly flawless foundation.

The Final and Most Critical Wipe-Down

You're so close. The paint is washed, decontaminated, and polished to a mirror shine. But there’s one last, absolutely crucial step: the panel wipe.

Every touch, every bit of polishing oil, every trace of residue creates a barrier between the clear coat and your ceramic coating. A panel wipe, usually a specific formula or a simple mix of Isopropyl Alcohol (IPA) and water, strips everything away.

Mist it onto a panel, wipe it away with a fresh, clean microfiber towel, and you’re left with a surgically clean surface. This is the pristine canvas your spray ceramic coating needs to form a strong, permanent molecular bond. Don't ever skip this. Seriously. Your coating's life depends on it.

Mastering the Art of Application

Now for the best part. Your surface is perfectly prepped, and the real transformation is about to begin. This is where all that meticulous cleaning and polishing pays off, creating that deep, durable gloss that makes heads turn. Applying a spray ceramic coating isn't rocket science, but it absolutely demands focus and a bit of finesse. Get this right, and you'll be rewarded with a finish that looks like it just rolled out of a high-end detail shop.

For this walkthrough, we'll be using Titan's Ultra Ceramic Spray as our go-to example. Its formula is a sweet spot for both seasoned pros and dedicated weekend warriors, delivering killer results without the unforgiving nature of some professional-grade coatings. It's incredibly easy to install with great results, making it perfect for your first dive into ceramic protection.

This visual guide lays out the critical prep work into three main stages: the wash, the decontamination, and the polish.

Stick to this workflow, and you're building the perfect foundation. A pristine surface is non-negotiable if you want the coating to bond properly and unleash its full protective power.

Setting the Stage for a Flawless Finish

Your environment is just as crucial as your technique. Let me be blunt: trying to apply a coating in direct sunlight or on a hot panel is a recipe for disaster. You’ll end up with a streaky, blotchy mess that’s a nightmare to fix. The heat drastically speeds up the "flash time"—that small window where the solvents evaporate—leaving behind a tacky residue that won't buff off cleanly.

Always work in the shade, preferably inside a garage with good lighting. The surface should be cool to the touch. If you have to work outside, aim for the early morning or late evening when the sun is low and the metal has had a chance to cool down.

Before you start, get your tools lined up and ready to go:

- The Coating: Your bottle of spray ceramic.

- Microfiber Towels: You'll need at least two, but honestly, having a small stack is better. Make sure they are high-quality, plush, and perfectly clean. Designate one for spreading (the "applicator") and the other for buffing (the "leveler").

- Good Lighting: A headlamp or a portable LED work light is your best friend here. It’s the only way to spot high spots and ensure you’ve buffed every inch to perfection.

The Application Technique: A Detailer's Hard-Won Lesson

The core of the technique is simple: work in small, manageable sections. A rookie mistake I see all the time is trying to coat an entire hood or door in one go. This almost always leads to the product drying before you can properly level it.

I remember a conversation with a pro detailer, Alex, who learned this the hard way on a big, black SUV. Feeling confident, he misted the entire hood. By the time he spread the product and reached for his buffing towel, one side had already flashed and started to set up. He told me he spent the next hour frantically trying to polish it off, his arm screaming, vowing never to make that mistake again.

The rule of thumb is simple and non-negotiable: Never apply more product than you can spread and buff off within 30-60 seconds. For just about everyone, this means working in a 2×2 foot section at a time.

Here’s the simple, effective process Alex now swears by:

- Lightly mist the coating onto your small working area. Two or three sprays are typically all you need.

- Immediately take your first microfiber and gently spread the product. Use an overlapping cross-hatch pattern (up-and-down, then side-to-side) to get even coverage.

- Don’t hesitate. Grab your second, clean microfiber towel and immediately buff the area to a brilliant gloss, making sure to remove all residue. Keep flipping the towel to a fresh, dry side.

After buffing, use your light and inspect the panel from several angles. You're hunting for "high spots"—any dark, oily-looking patches where the coating wasn't fully leveled. If you catch one right away, a quick buff will usually take care of it. If you waited a little too long, a tiny extra mist of product can re-liquefy the area, letting you buff it away cleanly. For a deeper dive, check out our guide on the process of applying a ceramic coating to your car.

The technology driving these sprays has its roots in serious industrial applications. Back in 2018, thermal spray technology was the undisputed king in the ceramic coatings world, dominating over a third of the high-performance market. For us in the detailing world, this translates to spray coatings with incredible adhesion and durability. As the wider thermal spray market is projected to reach USD 11.77 billion by 2026, we get to benefit from products that deliver that streak-free, glossy finish we're all after.

By respecting the flash time, working methodically, and using the right tools, you can nail that coveted, glass-like finish every single time.

Protecting Your Vehicle Beyond the Paint

A flawless, protected finish is fantastic, but true vehicle preservation doesn't stop where the paint does. Your glass, wheels, and trim are under constant assault from the same harsh elements. This is where you go from a good detail to a great one—by adopting a holistic protection strategy that covers the entire vehicle. The benefits go way beyond just looking good.

Let's talk about a real-world scenario. A client of mine, Sarah, is a daily commuter who used to absolutely dread driving in the rain. Her wipers would just smear everything around, water would sheet across the glass, and visibility during downpours was a genuine safety hazard. She just figured that squinting through a blurry windshield on a dark, wet highway was part of driving.

Transforming Your Drive with Hydrophobic Glass

Everything changed for Sarah once we applied a specialized ceramic glass coating. After a quick, straightforward application of a product like Titan's APEX Glass Coating, her entire driving experience was transformed. The coating created an intensely hydrophobic surface on her windshield, forcing rainwater into perfect, tiny beads that would literally fly off the glass as soon as she hit about 40 mph.

The results were immediate and frankly, unbelievable for her. Her wiper usage dropped dramatically, visibility improved so much that rainy drives were no longer stressful, and the glass stayed cleaner for way longer. This is a perfect example of how a ceramic coating designed for a specific job delivers profound safety benefits, turning a dreaded task into a non-issue.

The core principle behind a quality glass coating is creating a surface so slick and repellent that water and dirt simply can't cling to it. This not only enhances safety but also makes cleaning off ice, bugs, and grime significantly easier.

This technology isn't some niche gimmick; it's part of a massive shift in how we care for vehicles. Spray ceramic coatings are projected to snag a 32% market share in ceramics by 2035, driven by their proven longevity, UV shielding, and powerful hydrophobic magic. It's all about delivering real-world results for drivers like Sarah.

Extending Protection to Wheels and Trim

The same principles that keep your windshield clear can—and should—be applied to other vulnerable areas, especially your wheels. Wheels get bombarded with highly corrosive brake dust—those tiny, hot, metallic particles that embed into the finish and cause permanent pitting and damage over time.

A dedicated ceramic wheel coating creates a hard, slick barrier that prevents this brake dust from bonding to the surface. Cleaning becomes remarkably simple. Often, a quick blast from a pressure washer is all it takes to wash away grime that would have previously required harsh chemicals and intense scrubbing.

This comprehensive approach is key. When you protect every surface, you're not just making a vehicle look better—you're preserving its value and making your life easier. While a paint coating provides the main shield, it's the specialized coatings that complete the armor.

Take Titan's elastomer technology, for example. It brings a unique flexibility to paint protection. A product like our Alpha Quartz is a revolutionary elastomer coating that is easy to install with great results. It's designed to be hard like glass yet flexible enough that it won't crack under temperature changes between frozen and hot or when bugs hit the car's surface due to its elasticity. This ensures the protection lasts longer because it can adapt to real-world stress without failing. It’s this combination of broad-spectrum and specialized protection that truly defines modern vehicle care.

Choosing the Right Armor for Your Car

Walking down the detailing aisle or browsing online, it's easy to get lost. Every bottle promises a mirror shine and unbeatable protection. So, how do you cut through the noise and find what your car actually needs? The reality is, the right choice boils down to your goals, your experience, and the science behind the product.

Most off-the-shelf spray ceramics offer a quick hit of gloss, and that's great for a weekend touch-up. But for genuine, lasting defense, you need something more substantial. Think of it as the difference between a light rain jacket and a full suit of armor. One handles a drizzle; the other is built for a battle.

The Power of Elasticity in Paint Protection

Here’s a dirty little secret about many traditional ceramic coatings: they’re rigid. That impressive hardness rating they advertise can also be their biggest weakness. Your car's body panels are constantly expanding and contracting with temperature changes, from a scorching summer day to a frigid winter night.

A brittle coating can't handle that movement. It develops tiny micro-fractures, invisible at first, that compromise the entire protective layer. Add in a rock chip or even a bug hitting the bumper at 70 mph, and you’ve got a stress point that can lead to failure.

This is exactly why Titan Coatings decided to rewrite the rulebook. We were the first to bring elastomer coatings to the market, built on our exclusive nano-tube and Dark Matter technologies. Our coatings are engineered from the ground up to be different.

Imagine a protective layer that’s as hard as 9H glass but flexes like rubber. That’s the core principle of our elastic coatings. This unique flexibility allows the coating to absorb and dissipate energy from impacts and adapt to temperature fluctuations without cracking. It’s a smarter, more durable form of armor.

This advanced chemistry is what puts a product like our Alpha Quartz in a league of its own. It’s not just a hard shell sitting on your paint; it's a dynamic shield that moves with your vehicle, guaranteeing protection that stands up to the real world.

Finding Your Perfect Match: A Titan Coatings Comparison

So, what’s right for you? Are you looking for a user-friendly spray that delivers incredible results, or do you need the absolute pinnacle of professional-grade, long-term protection? Let’s break down the options to find your perfect match, and you can see a full breakdown on our comparison page.

We've designed our product line to meet you where you are. Whether you're a seasoned pro or a dedicated enthusiast, there's a Titan coating that fits your needs. The key is understanding how each one performs.

Titan Coatings Product Comparison

This table breaks down our leading spray and elastomer coatings, helping you decide which armor is right for your vehicle.

| Feature | Ultra Ceramic Spray | Alpha Quartz (Elastomer) | APEX Glass Coating |

|---|---|---|---|

| Technology | SiO2 Hybrid Ceramic | Elastomer with Nano-Tubes & Dark Matter Tech | Graphene-Oxide & SiO2 Hybrid |

| Ease of Use | Very High (DIY Friendly) | Moderate (Prosumer/Professional) | High (DIY Friendly) |

| Durability | Up to 1 Year+ | Multi-Year Protection | Up to 2 Years+ |

| Key Benefit | Quick application, fantastic gloss | Extreme durability & flexibility | Unmatched hydrophobic properties |

| Best For | DIY enthusiasts, coating toppers | Professionals demanding maximum longevity | Windshields and all exterior glass |

As you can see, the choice between an easy-to-use spray and a professional-grade coating often comes down to longevity and the specific technology you need. It’s a key consideration when weighing paint protection film vs ceramic coating as well.

Ultimately, choosing the right coating means aligning the product’s strengths with your expectations. Whether you want the simple brilliance of Ultra Ceramic Spray or the flexible fortitude of Alpha Quartz, you're investing in technology designed to keep your vehicle looking its best for years to come.

Frequently Asked Questions About Ceramic Coatings

No matter how thorough a guide is, questions always come up. That’s perfectly normal, especially when you're working with something as precise as vehicle protection. Let's dig into some of the most common questions we hear from both weekend warriors and seasoned pros to clear the air.

How Long Does a Spray Ceramic Coating Really Last?

This is the big one, and the honest-to-God answer is: it depends. The real-world lifespan of any spray ceramic coating boils down to three key things: the quality of the product you choose, how well you prepped the surface, and the way you maintain it afterward.

Your basic, off-the-shelf spray might give you a few months of decent water beading. But then you have advanced formulas, like Titan's Ultra Ceramic Spray, which are engineered for up to a year of solid protection, sometimes even more. If you're chasing serious, long-term durability, you’d step up to a professional-grade elastomer coating. A product like Titan's Alpha Quartz is built to last for years, largely because its unique, flexible nano-tube technology resists the kind of environmental damage and micro-cracking that kills traditional rigid ceramics.

Can I Apply a Coating Over Existing Wax or Sealant?

Let me be crystal clear: absolutely not. This is probably the single biggest mistake you can make, and it’s a surefire way to make your coating fail almost instantly. A ceramic coating needs to form a powerful, semi-permanent bond directly with your vehicle's clear coat on a molecular level.

Think of it this way: any layer of old wax, sealant, or even leftover polishing oil creates a barrier. The coating has nothing to anchor to. Instead of grabbing onto the paint, it's just sitting on a slick, unstable surface. You’ll be lucky to get a few days out of it. Always, always do a full decontamination and a final IPA (isopropyl alcohol) wipe-down to get the surface surgically clean.

What Is the Difference Between a Spray and a Professional Coating?

The main distinctions come down to the concentration of the good stuff (like Silicon Dioxide, or SiO₂) and the core chemistry behind the formula.

- Spray Coatings: Products like Titan's Ultra are designed to be user-friendly. They have a lower concentration of solids, which makes the application process much more forgiving for a DIYer working in their garage.

- Professional Coatings: These are a whole different beast. Elastomer-based coatings like Titan’s Alpha Quartz have a much higher concentration of active ingredients, giving you a harder, more chemically resistant, and longer-lasting shield. The game-changer with Titan's elastomer tech is the flexibility. It's not rigid, so it can better absorb impacts and handle extreme temperature swings that would stress a normal ceramic.

How Do I Maintain My Car After Applying a Ceramic Coating?

Good maintenance is what keeps the coating performing at its peak for years. The best part? A properly coated car is ridiculously easy to take care of.

Stick to a pH-neutral car shampoo for every wash. Stay away from harsh, high-alkaline chemicals and—please—avoid those automatic car washes with their paint-destroying brushes. The two-bucket wash method is your best friend for keeping the finish swirl-free. The slickness from a coating like Titan’s Alpha Quartz gives it incredible self-cleaning properties, meaning dirt and grime slide right off with very little effort. Your wash process becomes faster, safer, and a lot more satisfying.

At Titan Coatings, we don’t just make products that create a temporary shine; we engineer lasting armor for your vehicle. It’s time you saw what our advanced elastomer technology can really do.

Ready to give your vehicle the flexible, long-lasting protection it deserves? Explore our Alpha Quartz elastomer coating today!

0 Comments