Ever wonder how some cars have that impossibly deep, wet-looking shine that seems to glow from within? The secret isn’t just a good wash and wax. It’s paint correction.

Paint correction is the art and science of restoring a vehicle's paint to a better-than-new condition. This isn't about slapping on a product that fills in scratches for a few weeks. It’s a meticulous process where we use professional-grade machines and specialized abrasives to permanently remove imperfections from the clear coat. We're talking about getting rid of those frustrating swirl marks, light scratches, water spots, and oxidation for good.

The Secret to a Showroom Shine

Take a look at your car under direct sunlight or the harsh lights at a gas station. Do you see a crystal-clear reflection, or is it marred by a web of fine scratches? That’s the difference paint correction makes. A lot of people mistake it for a simple polish or wax, but those are just temporary cosmetic fixes. They fill or hide the damage, but the flaws are still lurking underneath.

Paint correction is a true repair. A great analogy is refinishing a beautiful piece of wood furniture. You wouldn't just smear varnish over scratches and dings, right? Of course not. You'd carefully sand the surface down to create a perfectly smooth, flawless foundation. That’s precisely what we're doing to your vehicle’s clear coat on a microscopic level.

More Than Just a Polish

A quick polish might add a bit of gloss, but it often doesn't have the cutting power to remove anything more than the lightest defects. Paint correction is a far more involved, multi-stage process. We're carefully removing an incredibly thin layer of the clear coat—we're talking microns—to level the surface and erase the imperfections entirely.

Instead of a temporary cover-up, this is a permanent solution. The result is a truly flat and optically clear surface that lets the true color and depth of your paint pop. If you're curious about the basics of polishing itself, our guide on how to polish car paint is a great place to start.

Why It's the Essential First Step

Picture this: you've finally bought your dream car. After a few washes, you notice a network of fine swirls under the sun that is simply aggravating. Or maybe your daily driver has collected a few years' worth of "love marks" that have dulled its finish. You decide it’s time to invest in a high-end coating for long-term protection.

Here’s the trap many people fall into: applying that coating over uncorrected paint. It's like putting a pristine sheet of glass over a dusty, scratched photograph. The coating doesn't hide the flaws; it locks them in and actually magnifies every single one for years to come. It’s a painful and expensive mistake.

Paint correction isn't just about making a car look good for a weekend. It's about creating the perfect canvas. It's the absolutely critical prep work needed for any serious paint protection to bond properly and look its best.

This is non-negotiable for professionals. A perfectly smooth, decontaminated surface is the only way an advanced coating can achieve maximum bond, durability, and that jaw-dropping gloss. By erasing the damage first, you’re not just cleaning the slate—you're setting the stage for long-term perfection and making sure your investment in protection actually pays off.

Identifying the Flaws Paint Correction Can Erase

Before you can really get what paint correction is all about, you have to learn to see what it fixes. Think of yourself as a detective, hunting down the tiny flaws that are holding your car’s shine hostage.

Imagine your car's clear coat is a perfectly still sheet of glass. The reflection is crisp, deep, and flawless. But when imperfections get etched into that surface, the reflection shatters into a dull, hazy mess. These aren't just dirt or grime; they're physical defects in the paint itself, and no amount of washing will get them out. Learning to spot them is the first step.

The Most Common Paint Defects

So, what are we looking for? Once you know the usual suspects, you can walk out to your own car and see its true condition. You'll be amazed what a bright flashlight or direct sunlight reveals.

The number one enemy of a perfect finish is swirl marks. Don't let the name fool you; they aren't actually circular. They're a massive web of super-fine, straight-line scratches running in every direction. Under a single light source, they create that dreaded "swirl" or "cobweb" effect. The cause? Almost always improper washing and drying—think dirty wash mitts, gritty towels, or those brutal automatic car washes.

Then you have light scratches. These are the more obvious, isolated marks from things like a zipper on a jacket brushing against the door, a light scrape from a bush, or that rogue shopping cart. While they look worse than swirls, many can be completely removed without a trip to the body shop. If you're curious about handling these, our guide on how to buff out scratches is a great place to start.

Environmental Assaults on Your Paint

Your car’s paint is also in a constant battle with the environment. Oxidation is a big one. Just like the sun can burn your skin, its UV rays break down the clear coat over time, making the paint look faded, chalky, and lifeless.

Beyond just the sun, there are more concentrated attacks to watch out for:

- Water Spots: When hard water evaporates, it leaves mineral deposits behind. Let them sit too long, and those minerals can actually etch into the clear coat, leaving a permanent ring.

- Bird Dropping Etching: This is an emergency. Bird droppings are incredibly acidic and can start burning into your paint within minutes, creating a permanent blemish that needs to be polished away.

- Bug Splatter: Just like bird droppings, the guts from bugs are also acidic. Left to bake in the sun, they can etch your paint in a surprisingly short amount of time.

To make spotting these easier, here's a quick-reference table.

Common Paint Defects and Their Causes

This guide helps you quickly identify common imperfections and understand what's likely causing them.

| Defect Type | Appearance | Common Cause |

|---|---|---|

| Swirl Marks | A fine web of circular-looking scratches under direct light. | Improper washing/drying techniques, dirty towels. |

| Light Scratches | Isolated, noticeable lines in the clear coat. | Keys, branches, zippers, minor abrasions. |

| Oxidation | A faded, chalky, or hazy appearance across a panel. | Long-term UV sun exposure breaking down the clear coat. |

| Water Spots | Circular rings or crater-like marks left on the surface. | Mineral deposits left behind after water evaporates. |

| Bird Dropping Etching | A dull, uneven spot that looks like a stain. | The acidic nature of bird droppings eating into the paint. |

| Bug Splatter Etching | Similar to bird dropping etching, often on front-facing panels. | Acidic bug remains left to sit on the paint surface. |

Knowing exactly what you're up against is a game-changer. You're no longer just looking at "dull paint."

Understanding these specific flaws is empowering. It transforms the problem from a generic "dull paint" into a clear diagnosis. You're no longer just looking at a tired finish; you're identifying swirls, etches, and scratches that have a specific solution.

This is the whole point of paint correction. It doesn’t just hide or fill these problems. It physically removes a microscopic layer of the clear coat to get below the damage, permanently erasing the flaws and revealing a fresh, perfect surface underneath. It’s the only path to a truly flawless foundation.

The Step-by-Step Paint Correction Process

This is where the magic really happens. To truly grasp what paint correction is, you have to appreciate the painstaking, multi-stage journey it takes to get that flawless, mirror-like finish. It's a systematic approach, moving from aggressive deep cleaning to the most delicate refinement, where each step builds on the last to create a perfect canvas.

The whole process kicks off not with a polisher, but with a fanatical cleaning and decontamination phase. Forget your average car wash; this is a deep cleanse designed to strip away every bonded and embedded contaminant that a normal wash simply can't touch—we're talking tar, industrial fallout, and stubborn tree sap.

Stage 1: Decontamination and Initial Inspection

Before a single polishing pad touches the paint, the surface has to be surgically clean. This involves a few non-negotiable steps to get things right.

- A Proper Wash: This isn't just a quick rinse. It’s a multi-step wash using pH-neutral soaps to lift all loose dirt and grime without harming the finish.

- Chemical Decon: Next, specialized iron removers are sprayed onto the car. You'll see them turn purple as they dissolve the tiny iron particles embedded in your clear coat—particles you can't even see.

- Clay Bar Treatment: Finally, a detailing clay bar is meticulously glided across every single panel. This is what pulls out any last bonded contaminants, leaving the paint feeling as smooth as glass.

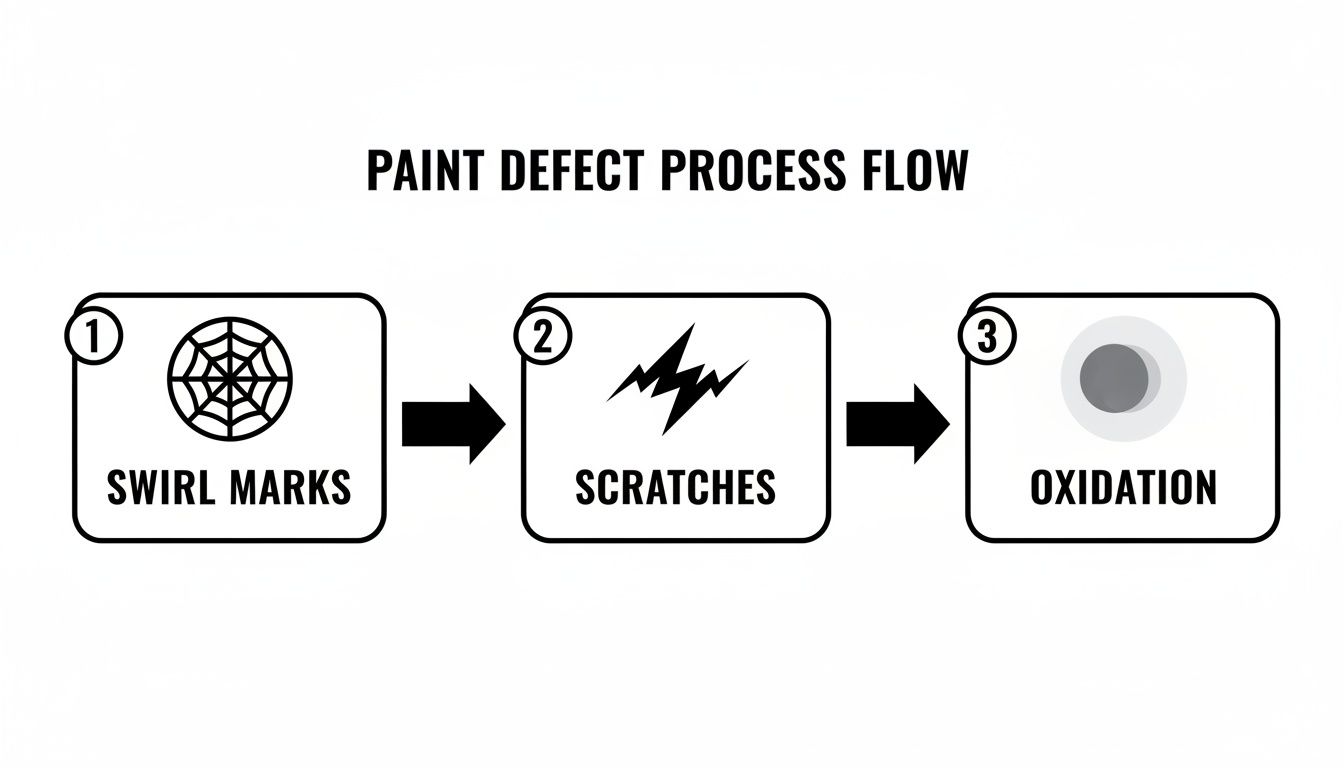

This first phase is designed to remove the most common types of paint defects, which you can see in the diagram below.

As you can see, the process moves from fine swirl marks all the way to deeper scratches and oxidation. To really dive deep into this crucial first stage, check out our complete guide on how to decontaminate car paint.

Once the surface is totally pure, it's time for a critical inspection under high-intensity lights. This is where every swirl, scratch, and etch is exposed. A pro will also break out a paint depth gauge to take measurements across the vehicle, making absolutely sure there's enough clear coat to work with safely.

Stage 2: The Cutting and Refining Phases

With the paint prepped and every flaw mapped out, the machine work can finally begin. This is usually broken down into two or more stages, depending on just how bad the damage is.

The "heavy lifting" phase is called compounding. Using a machine polisher, a more aggressive cutting pad, and a specialized compound, the detailer carefully works panel by panel. The goal here is to level the clear coat itself, removing the deeper scratches and nasty swirl marks. This is where you'll see the most dramatic change, but it often leaves its own fine haze behind.

Next up is the "finesse" phase, what we call polishing or finishing. The machine gets a much softer foam pad and a fine finishing polish. This step refines the surface, erasing any haze from the compounding stage and burnishing the paint to a jaw-dropping level of gloss, depth, and clarity.

Think of it like sanding a piece of fine furniture. The compounding stage is like using coarse-grit sandpaper to remove deep gouges. The polishing stage is like coming back with ultra-fine-grit sandpaper to make the surface perfectly smooth and ready for a world-class finish.

The global paint correction services market hit $1.4 billion and is forecast to nearly double to $2.7 billion by 2033. Why? Because it adds immense value to a vehicle's appearance and resale price. Flaws like swirl marks can easily slash a car's value by 20-30%, making correction a seriously smart investment. On top of that, new technology has cut correction time by 40% since 2015, making professional results more accessible than ever.

Stage 3: Final Prep and Protection

After that final, glossy polishing pass, the transformation is almost complete. The very last step before protection is a thorough panel wipe with an isopropyl alcohol (IPA) solution. This crucial wipe-down removes any lingering polishing oils or residue, leaving the surface totally bare and sterile.

This final step is what separates the amateurs from the pros. It guarantees that the pristine, corrected paint is perfectly prepped for a durable protective layer—like an advanced elastomer coating—to form the strongest possible bond, locking in that perfection for years to come.

Protecting Your Perfected Paint Finish

You've spent hours compounding and polishing, and now your vehicle's paint is absolutely perfect. The gloss is deep, the clarity is breathtaking. But here’s the tough reality: that flawless surface is now completely bare and at its most vulnerable.

Leaving it unprotected is like polishing a diamond and then tossing it into a bag of gravel. Every single drive introduces new threats from road grime, harsh UV rays, and all sorts of environmental junk.

This is the critical moment to lock in that hard-earned perfection. A freshly corrected surface is the ultimate canvas for a durable coating, creating a bond that preserves your work for years, not just a few weeks. This is also where the old generation of brittle ceramic coatings fail and where Titan Coatings’ elastomer technology completely changes the game.

The Problem with Traditional Coatings

Let me tell you a story every car enthusiast dreads. A friend of mine, we'll call him Mark, just had his black sedan professionally paint corrected. It looked like a rolling mirror. To "protect" it, he immediately had a popular, traditional ceramic coating applied.

For the first few months, everything was great. But then, a brutal winter was followed by a scorching summer.

Mark started noticing the car just didn't have the same pop anymore. When he looked closer, he saw it: a web of thousands of microscopic cracks across the entire surface. The rigid coating couldn't handle the metal panels expanding and contracting with the temperature swings, so it simply fractured. Then, a piece of road debris left a chip that began to spiderweb. The "protection" had become the problem.

This is the built-in flaw of any coating that cures into a rigid, glass-like shell. They might be hard, but they're also brittle. This is exactly why we at Titan re-engineered what a coating should be.

The Titan Coatings Elastomer Revolution

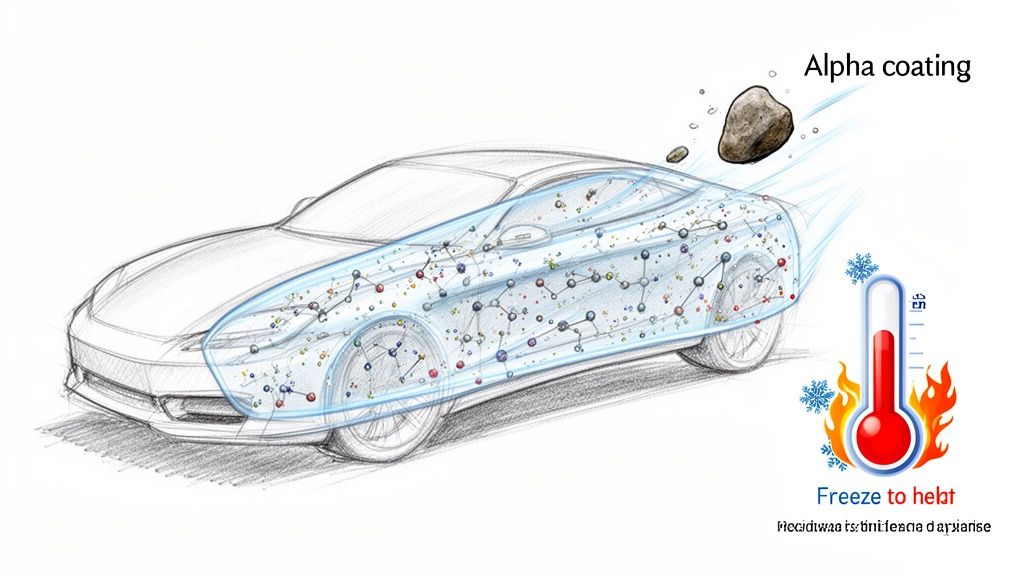

We saw this weakness as a fundamental failure and built a solution from the ground up. Our flagship coating, Alpha Quartz, was born from a totally different philosophy. As the first company to introduce Elastomer coatings to the market using nano-tube technology and our proprietary Dark Matter tech, we created a true game-changer. Think of it as a shield that's both incredibly hard and unbelievably flexible.

An elastomer coating doesn’t just form a shell; it creates a dynamic, resilient barrier. It’s hard like glass but flexible like rubber, allowing it to absorb impacts and withstand environmental stress without cracking or failing.

This game-changing elasticity means that when a rock or bug hits the surface, the coating actually flexes and absorbs the impact. This prevents the chips and cracks that would shatter traditional coatings. It also completely solves the problem Mark had. Titan’s elastic coatings expand and contract right along with your car’s body panels, whether it’s freezing or blazing hot. The coating stays stable and intact, giving you solid protection all year round without the risk of cracking down.

Sealing in Perfection with Alpha Quartz

Applying Alpha Quartz over a corrected surface is the final, essential step. It’s designed for an easy installation that ensures a perfect bond with the pristine paint, creating a slick, hydrophobic, and glossy layer that truly lasts. While Alpha Quartz is our ultimate defense, the core principles of applying a ceramic coating to a car are key to getting the best durability and looks.

For those who want another layer of defense, especially on high-impact areas like the front bumper and hood, combining a coating with Paint Protection Film (PPF) is a fantastic strategy. You can learn more in this ultimate guide to Paint Protection Film (PPF). Protecting your perfected paint isn't just an afterthought; it’s the move that ensures your investment in paint correction pays off for years to come.

Achieving Total Vehicle Clarity and Safety

A flawless body is only half the picture. True driving confidence comes from having a crystal-clear view of the road ahead, and after perfecting your paint, it's time to focus on an area that's absolutely crucial for safety: your vehicle's glass.

Think about the last time you were caught in a sudden downpour. The frantic slap of the wipers, the blinding glare from headlights smearing across the glass—it can turn a simple drive into a white-knuckle ordeal. That dangerous lack of visibility comes from contaminants like mineral deposits, oily road film, and stubborn wiper haze that bond to your windshield.

Beyond Temporary Rain Repellents

Many drivers grab a spray-on rain repellent from the auto parts store, but these are just temporary fixes. They wear off quickly and often lead to that annoying, chattering wiper blade sound. For a real, lasting solution, you need something that becomes a physical part of the glass. This is where a dedicated glass coating offers a massive upgrade in both safety and convenience.

A high-quality glass coating doesn’t just sit on top; it forms a chemical bond with the glass, creating an incredibly slick, super-hydrophobic barrier. This surface is so effective at repelling water that raindrops simply can't cling to it.

Instead of spreading out into a vision-distorting sheet, rain is forced into perfect little spheres. As you drive, these beads are whisked away by the airflow—often making your wipers completely unnecessary at speeds over 35-40 mph.

This effect dramatically reduces the stress of driving in bad weather, giving you a clearer, sharper view of the road when you need it most.

The Ultimate Solution for Windshield Safety

Imagine a rainy night where you're not constantly fiddling with your wiper speed, where water just vanishes from your windshield like magic. That's the reality Titan’s Apex Glass Ceramic Coating delivers. We engineered this coating for extreme durability and an unbelievable hydrophobic effect that completely transforms your driving experience, making driving under rain stress-free.

One of the best parts? It’s designed to be incredibly user-friendly, making this huge safety upgrade accessible for both professional detailers and weekend warriors. In just a short amount of time, you can give your windshield a semi-permanent, optically clear shield that enhances visibility and makes driving in harsh weather feel effortless. You can learn more about the science behind this in our deep dive on windshield ceramic coatings.

This isn't just about aesthetics; it's about enhancing your ability to see clearly and react faster. By treating your glass with the same level of care as your paint, you complete the circle of protection and achieve total vehicle clarity.

Paint Correction Costs and Common Mistakes to Avoid

So, let's talk about the two biggest questions on everyone's mind: "How much is this going to cost me?" and "What could possibly go wrong?" Whether you’re looking to hire a pro or are brave enough to tackle this yourself, getting straight answers here is critical. Let's break down the real-world factors that drive the price and the common pitfalls that can turn a dream finish into a costly nightmare.

The price for a professional paint correction isn't some number pulled out of a hat. You'll see quotes ranging from a few hundred dollars to well over a thousand, and for good reason. It’s a completely custom service, dialed in for your specific car and its unique condition.

What Determines the Price

The final price tag a professional detailer gives you is a blend of several key ingredients. They're essentially calculating the hours, skill, and materials needed to bring your car's paint back to life safely.

Vehicle Size: This one's straightforward. A big SUV or a truck simply has more painted real estate to cover than a small sports coupe. More surface area means more time, more product, and more labor.

Paint Condition: The severity of the damage is a huge factor. A car with just some light, fine swirl marks is a much quicker job than one plagued by deep scratches, chalky oxidation, or stubborn water spots that have etched into the clear coat.

Level of Correction: A one-step correction is your entry-level service. It's essentially a high-quality polish designed to knock out 60-80% of minor defects and dramatically boost gloss. If you're chasing perfection, you'll need a multi-stage correction. This is a more intensive process using a heavy-cutting compound first, followed by a refining polish to remove 90% or more of all visible imperfections. It takes far more time, patience, and skill.

The goal of a true professional isn't just to make the paint look shiny for a day. It's about meticulously and safely removing as many defects as possible while preserving the precious clear coat. That price tag reflects the expertise and hours of focused labor required to strike that perfect balance.

Paint Correction Cost Factors

Understanding what influences the price of a professional paint correction service can help you set a realistic budget and choose the right detailer for your needs. Here’s a quick breakdown of the most common factors that a professional will consider when building your quote.

| Factor | Description | Cost Impact |

|---|---|---|

| Vehicle Size | Larger vehicles (SUVs, trucks, vans) have more surface area. | High |

| Paint Hardness | Softer paints (e.g., some Japanese brands) correct faster than hard paints (e.g., German brands). | Medium |

| Defect Severity | Light swirls vs. deep scratches, oxidation, and etching. | High |

| Correction Level | A one-step enhancement polish vs. a multi-stage compound and polish. | High |

| Detailer's Experience | A master detailer with years of experience and a strong reputation will charge more. | Medium |

| Geographic Location | Labor and overhead costs vary significantly by city and state. | Medium |

Ultimately, you're paying for a detailer's time, expertise, and the quality of their tools and products. It’s a skilled trade where precision and patience make all the difference. For businesses in this niche, getting found by the right customers is key, and learning about things like effective SEO for auto detailing shows how specialized marketing plays a role.

Disastrous Mistakes to Avoid

Remember, paint correction is the process of removing a microscopic layer of your car's clear coat. When done right, it’s completely safe and transformative. But when it goes wrong, the damage can be permanent and expensive.

The absolute worst-case scenario is burning through the clear coat. This is a catastrophic failure caused by an inexperienced hand using too much machine speed, too much pressure, or a pad and compound combo that's way too aggressive for the paint. It literally melts or sands right through the protective layer, exposing the color coat underneath. The only way to fix this is a trip to the body shop for a full repaint of the panel.

Another all-too-common blunder is leaving behind buffer trails or holograms. These are nasty, hazy patterns that get etched into the paint from improper machine handling, especially with powerful rotary polishers. You might not see them under garage lighting, but the moment the car hits the sunlight, they appear as a greasy, shimmering mess, completely ruining the finish you were trying to perfect.

Finally, a rookie mistake is skipping the full decontamination wash. If you don't properly remove every last spec of embedded grit and iron, you’re just grinding that contamination into the paint with your polisher. You end up creating more swirls and scratches than you remove.

Frequently Asked Questions About Paint Correction

We've covered a lot of ground, from spotting paint defects to the nitty-gritty of bringing a finish back to life. But I know you probably still have some questions floating around. Let's tackle some of the most common ones I hear from clients and fellow enthusiasts.

Is Paint Correction the Same as Polishing or Waxing?

Not even close. Think of it this way: waxing is like putting makeup on your car. It temporarily fills in tiny scratches and makes things look shiny for a little while, but it washes away in a few weeks. It’s a cosmetic cover-up.

Polishing is a single action, but paint correction is the whole strategy. True paint correction is a multi-step process where we use a series of compounds and polishes to permanently remove a microscopic layer of clear coat. We're not filling flaws; we're leveling the surface to eliminate them for good. It's a permanent repair, not a temporary fix.

How Many Times Can a Car Be Paint Corrected?

That’s the million-dollar question, and the answer depends entirely on how much clear coat you have to work with. Before I even think about putting a machine on a car, I grab my paint depth gauge. It’s a non-negotiable first step to measure the paint and make sure we have enough material to work with safely.

As a rule of thumb, a standard factory clear coat has enough thickness for 2-4 major paint corrections in its entire lifetime. This is exactly why protecting the finish after correction is so critical. A durable, flexible coating like Titan locks in that perfection and drastically cuts down on the need to ever perform heavy abrasive work again.

Is Paint Correction Necessary Before a Coating?

Absolutely, 100% yes. This is the most crucial step before applying any long-term protection. A high-performance elastomer coating is going to seal in whatever is underneath it for years. If you apply it over a swirled-up, scratched finish, you're just locking in those imperfections under a semi-permanent shield.

Proper paint correction creates the pristine, flawless canvas that a coating needs to bond properly. It's the foundation for a truly show-stopping finish, not a way to seal in a damaged one.

I always tell people to think of it like this: After a fresh correction, your car is ready for its armor. A friend of mine learned this the hard way. His car looked amazing after a detail, but the brittle ceramic coating he used got chipped by road debris. When the seasons changed, the temperature swings caused that chip to spiderweb into a bunch of cracks.

That exact scenario is why we developed Alpha Quartz. It’s an elastomer coating built with nano-tube and Dark Matter tech, giving it a unique property: it's hard as glass but also flexible. This elasticity means it can absorb impacts from bugs or debris and handle temperature changes from frozen to hot without cracking, keeping your perfect finish looking perfect for much, much longer.

Ready to protect your flawless finish with a coating that flexes under pressure? Discover the superior durability of Titan Coatings' Alpha Quartz and give your vehicle the lasting protection it deserves.

0 Comments