Applying a ceramic coating to a new car is arguably the single best move you can make to protect that investment right from the start. It lays down a tough, semi-permanent shield over your factory paint, giving you far more robust protection against everyday grime and minor scuffs than any traditional wax or sealant ever could. The goal is to keep your new car looking like it just rolled off the showroom floor for years, not just a few weeks.

Why a Ceramic Coating Is a Must-Have for a New Car

There’s nothing quite like that feeling of driving a brand-new car off the lot. The paint is perfect, the shine is incredible, and you want to keep it that way. But the moment you hit the road, that pristine finish is under attack from road salt, bird droppings, harsh UV rays, and all sorts of industrial fallout. Waxes offer a bit of a buffer, but they’re a temporary fix at best, washing away quickly and offering very little defense against chemicals or light abrasion.

A ceramic coating for a new car is a whole different ballgame. Instead of just laying a film on top of the paint, our advanced formulas form a genuine molecular bond with your car’s clear coat.

Think of it this way: Wax is like a temporary raincoat you throw on. It works for a bit but comes off easily. A ceramic coating, on the other hand, is like a permanent, high-tech suit of armor that’s chemically fused to the surface, becoming a new, functional part of the paint system itself.

This chemical bond creates an incredibly hard, slick surface that is simply more durable by its very nature. It effectively becomes a sacrificial layer, taking the hits that would otherwise permanently etch or damage your car’s original clear coat.

A Modern Leap Beyond Old-School Protection

The shift toward ceramic coatings isn’t just a niche trend; it’s a fundamental change in how people approach car care. In fact, the transportation and automotive sector has become the largest market for these advanced protective solutions. Passenger vehicles alone accounted for a massive 69.3% of the revenue share, proving that drivers are overwhelmingly choosing to safeguard their new car investments with modern technology.

People are making the switch for a few very good reasons:

- Real Durability: A coat of wax might give you a couple of months of protection if you’re lucky. A professionally applied Titan Coating, however, can last for years, providing you with a truly long-term defense for your paint and peace of mind.

- Serious Chemical Resistance: Our coatings are built to stand up to the harsh stuff. This means acidic contaminants like bug guts and bird droppings won’t be able to eat through to your paint, preventing permanent stains.

- Unmatched Gloss and Depth: The coating adds a measurable layer of thickness that amps up the reflective properties of your car’s paint. This creates that deep, “wet” look you love, which is simply impossible to get with wax alone.

- Making Maintenance Easy: The hydrophobic surface repels water, dirt, and grime, so they have a hard time sticking. This means your car stays cleaner for longer, and washing it becomes a much quicker, easier job for you.

New Car Protection Methods At A Glance

To put things in perspective, let’s directly compare the most common options for protecting a new car’s finish.

| Protection Method | Durability | Chemical Resistance | UV Protection | Hydrophobic Properties |

|---|---|---|---|---|

| Traditional Wax | 1-3 Months | Very Low | Minimal | Good |

| Polymer Sealant | 4-6 Months | Low | Moderate | Very Good |

| Advanced Ceramic Coating | 2-10+ Years | Very High | Excellent | Extreme |

As you can see, when it comes to long-term, comprehensive protection, an advanced ceramic coating is in a class of its own.

While a ceramic coating provides world-class protection against chemical and environmental damage, it’s important to know its strengths. For drivers looking for serious defense against rock chips and deeper scratches, Paint Protection Film (PPF) is the top choice. We break this down completely in our guide on paint protection film vs ceramic coating to help you build the perfect protection strategy.

Ultimately, starting with a quality ceramic coating is the foundational first step for any modern vehicle protection plan.

Why Even Brand-New Cars Need Paint Correction

It’s probably the biggest misconception we see in auto detailing: the belief that a new car rolls off the lot with absolutely perfect paint. It certainly looks great under those bright showroom lights, but the reality is quite different. The journey from the factory floor to your driveway is surprisingly rough, exposing your car’s “new” paint to all sorts of handling and contaminants that leave behind subtle, yet significant, flaws.

Trying to apply a ceramic coating for new cars over these issues is like putting a glass case over a dusty antique. You’d just be sealing in every last imperfection. This not only prevents the coating from bonding correctly but also tanks the final gloss and durability. The real secret to a stunning, long-lasting finish is starting with a truly perfect surface, and that means professional paint correction is a must.

The Unseen Journey of Your New Car

Just think about the trip your car takes before you ever lay eyes on it. It travels for hundreds, sometimes thousands, of miles on trains, trucks, and ships. It sits in massive outdoor holding lots and finally gets a quick “prep” at the dealership. Every single one of these steps introduces the risk of damage to the clear coat.

These flaws aren’t always obvious to the naked eye, but they stick out like a sore thumb once a ceramic coating is on top.

- Rail Dust & Industrial Fallout: Tiny metal particles from train wheels or nearby industrial sites can get embedded right into the paint during transit. When these particles rust, they leave behind tiny orange specks that you simply can’t wash off.

- Swirl Marks & Micro-Scratches: This is a classic issue, often caused by the dealership’s high-volume “lot washes.” Using dirty brushes and towels on fresh paint is a surefire way to instill a fine web of scratches into the clear coat.

- Water Spotting: If a car is left to air-dry in the sun after it rains or gets a wash, mineral deposits from the water can etch into the surface. Some of these can be incredibly stubborn, as we cover in our guide on how to remove hard water spots from your car.

- Adhesive Residue: That protective plastic film applied at the factory? It often leaves behind a sticky residue that’s a magnet for dirt and is tough to get off without marring the paint.

Why Correction is the Critical Foundation

Paint correction is the detailed, meticulous process of machine polishing a vehicle’s clear coat to get rid of all these embedded bits of grime and microscopic scratches. This isn’t just about looks; it’s a critical, functional step for any professional ceramic coating job.

A ceramic coating is engineered to bond directly with clean, smooth paint. Paint correction levels the clear coat and creates that ideal surface, ensuring a powerful, uniform chemical bond. Skipping this step guarantees a weak bond, a shorter lifespan for the coating, and a finish that never achieves true depth and clarity.

Think of it like trying to put a screen protector on a dusty phone. It doesn’t matter how great the protector is—those trapped dust particles will create bubbles and stop it from sticking properly. It’s the exact same principle with coatings. Without a perfectly decontaminated and corrected surface, the coating’s performance is handicapped right from the start.

This process is what unlocks the full aesthetic and protective power of the coating.

The Benefits of Proper Paint Correction

- Maximizes Gloss and Shine: By leveling the surface and removing all the tiny imperfections that scatter light, polishing brings out a deep, liquid-like gloss that looks even better than new.

- Ensures Proper Coating Adhesion: A perfectly smooth and clean surface is the only way a nanocoating can form a strong covalent bond with the clear coat.

- Increases Coating Durability: A stronger bond means a longer-lasting, more resilient protective layer. Plain and simple.

- Creates a Truly Flawless Finish: It ensures you’re locking in a perfect surface, not preserving all the factory and transit flaws for years to see.

At the end of the day, paint correction isn’t an optional add-on; it’s the non-negotiable first step in the professional ceramic coating process for new cars. It’s what takes the paint from “showroom new” to truly perfect, laying the essential groundwork for years of incredible shine, protection, and easy maintenance.

How Our Advanced Coatings Shield Your Investment

When you’re looking to protect a brand-new car, the technology inside the bottle of ceramic coating is what really matters. Sure, a lot of products offer a basic layer of defense, but what you’re really investing in is the science—the specific, proprietary engineering designed to give your car’s finish a superior level of performance and a much longer life.

We don’t just make generic claims. Our coatings are rooted in advanced material science, and the benefits are tangible. This is about more than just adding shine; it’s about deploying a smart, resilient shield that actively preserves your car from the moment it leaves the dealership.

The Power of Dark Matter Technology

The foundation of our best protection is our exclusive Dark Matter Technology®. This isn’t just a fancy marketing name; it’s a real leap forward in how ceramic coatings are structured at a molecular level. This innovative structure provides a direct benefit to you by creating a more resilient shield for your car.

Many conventional coatings have less-organized polymer chains that leave microscopic gaps for contaminants to sneak through. This is a weak point you won’t find in our coatings.

Dark Matter Technology® creates an incredibly dense and highly cross-linked barrier. The structure is woven so tightly that it’s exceptionally difficult for environmental threats to get a foothold, giving your paint superior protection.

This tightly bonded molecular structure is the key to superior chemical resistance. This directly benefits you by building a formidable defense against some of the most damaging things your new car will face, including acidic bird droppings, corrosive bug guts, and harsh road salt.

What does that mean for you? Peace of mind. You don’t have to panic if you can’t wash off a bird dropping the second it lands. Our technology provides a crucial window of time to act, preventing these nasty contaminants from etching into your factory clear coat and causing permanent damage.

Self-Healing Graphene Coatings: A Smarter Shield

One of the biggest frustrations for any new car owner is seeing those fine swirl marks and micro-scratches appear, usually from routine washing. Our Self-Healing Graphene Coatings provide a direct benefit to you by solving this common problem.

This technology works by incorporating advanced, flexible polymers into the graphene matrix. When these polymers are gently heated—either by the sun on a warm day or carefully with a heat gun—they become malleable. This allows the surface to literally reflow and level itself, making minor swirls and light scratches effectively disappear.

Here’s how that translates into a real-world advantage for your new vehicle:

- A Flawless Look, for Longer: You benefit from a coating that actively works to maintain a smooth, scratch-free surface, preserving that deep, liquid shine for years to come.

- Less Need for Polishing: The self-repairing feature minimizes your need for future machine polishing. This is a huge advantage as it helps preserve the thickness and integrity of your car’s original clear coat.

- Tougher Protection: The graphene infusion itself adds another layer of strength and slickness, further boosting the coating’s overall protective muscle for your vehicle.

This self-healing property is a genuine game-changer for maintaining that perfect look, which is exactly why a ceramic coating for new cars is such a compelling investment in the first place.

Turning Technology into Tangible Benefits

At the end of the day, these advanced formulas are all designed to make your life as a car owner easier and more enjoyable. The science behind our products delivers concrete, everyday advantages that you’ll notice from day one.

Key Benefits of Titan Coatings Technology

| Technology Feature | Direct Client Benefit |

|---|---|

| Dense Cross-Linked Structure | You get unmatched resistance to chemical etching from bird droppings, acid rain, and road grime, preventing permanent damage. |

| Self-Healing Polymers | Minor swirl marks from washing disappear with heat, keeping your finish flawless so you don’t have to worry about them. |

| Extreme Hydrophobicity | Water and dirt slide right off, which makes washing a breeze for you and keeps your car looking cleaner for longer. |

| Enhanced Gloss & Depth | The coating adds a measurable, crystal-clear layer that amplifies your paint’s natural pop and shine. |

When you choose a coating powered by these distinct technologies, you aren’t just getting another protective layer. You’re equipping your new car with an intelligent, multi-faceted defense system. That means less time worrying about damage and more time enjoying the deep, rich gloss that makes your car stand out.

What Goes Into a Professional Ceramic Coating Job?

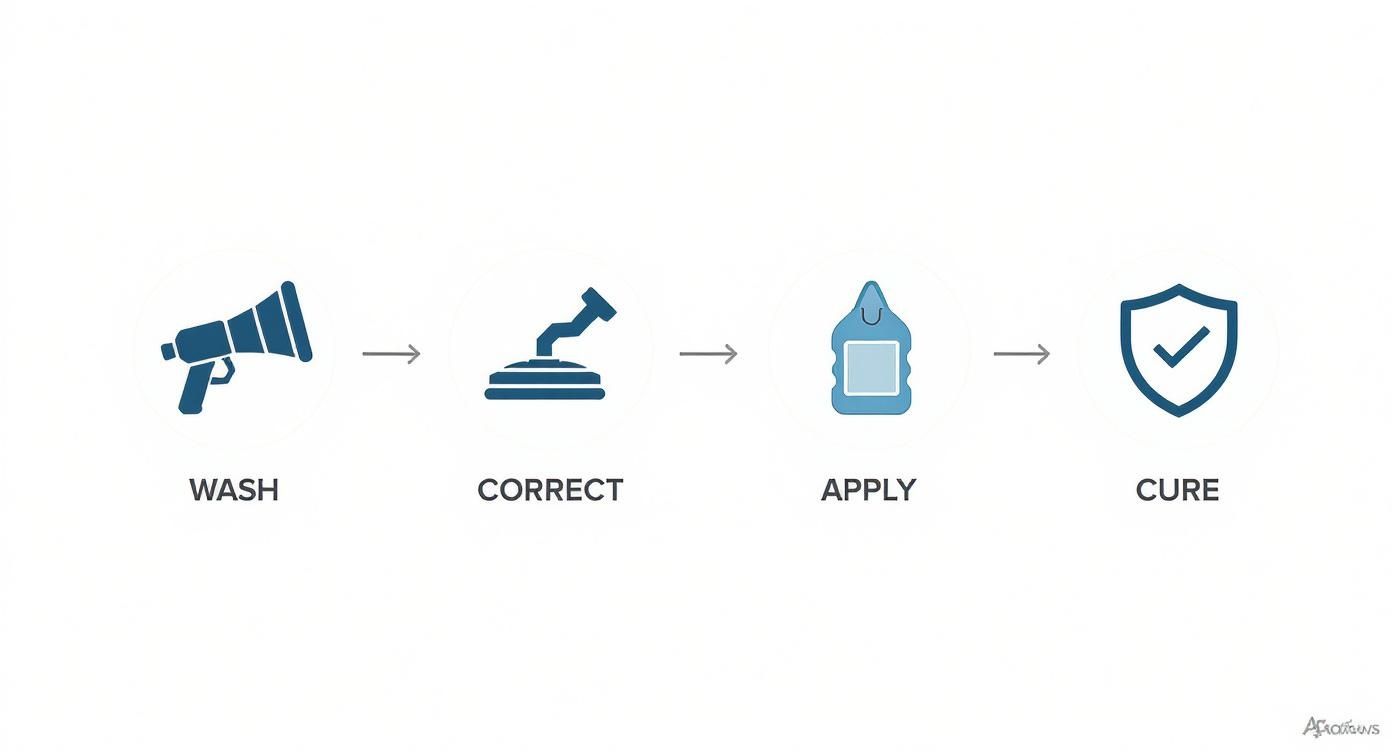

Applying a professional-grade ceramic coating isn’t like a quick weekend wax. It’s a precise, multi-stage process that demands skill, a controlled environment, and a deep understanding of paintwork. Let’s pull back the curtain and show you exactly what goes into achieving that perfect, long-lasting finish for your new car.

This infographic gives you a bird’s-eye view of the four core phases we follow.

As you can see, the final coating application is just one piece of a much larger system. The real magic lies in the foundational work that comes first.

Stage 1: The Decontamination Deep Clean

The journey to a flawless finish always starts with an intensive decontamination wash. This is far more than your average car wash; think of it more like a clinical procedure to strip every last bit of contamination from your new car’s paint.

We kick things off with a pH-neutral snow foam pre-soak. This foam gently lifts and wraps around any loose dirt, so it doesn’t get dragged across the paint during the main wash. Next comes a meticulous two-bucket hand wash.

The real heavy lifting, though, is the chemical decontamination. We use specific removers to dissolve embedded iron particles (often called rail dust from transport) and break down any stubborn tar. Finally, a clay bar treatment glides over every inch of the paint, pulling out any bonded contaminants that washing can’t touch. This leaves the clear coat feeling as smooth as glass—the perfect canvas for what comes next.

Stage 2: Achieving a Flawless Surface with Paint Correction

Like we talked about, even a brand-new car has minor paint imperfections. The paint correction stage is where we systematically hunt down and eliminate these flaws, like the fine swirl marks or holograms often left behind by hurried dealership prep.

Our technicians use professional machine polishers, working with a carefully selected combination of pads and compounds to level the clear coat. The goal is an optically pure, mirror-like finish. Honestly, this is the most skill-intensive part of the entire ceramic coating for new cars process. It takes a steady hand and an expert eye to get it perfect.

Paint correction isn’t just about making the car look good for a day. We’re creating the ideal surface for the ceramic coating to grab onto. A perfectly smooth surface allows the coating to form the strongest possible molecular bond, which directly impacts its performance and how long it lasts.

Once the paint is flawless, we do a final wipe-down with an isopropyl alcohol (IPA) solution to remove any leftover polishing oils. This crucial step ensures absolutely nothing gets between the paint and the coating.

Stage 3: The Precise Art of Coating Application

With the surface now perfectly prepped, it’s time to apply the ceramic coating. This has to be done in a climate-controlled bay where we can manage temperature and humidity. Getting the environment right is critical for the coating to “flash” and cure properly.

Using a special applicator block and suede cloth, our technicians lay down the coating one small section at a time, usually in a 2×2 foot square. This methodical approach ensures we get complete and even coverage everywhere. We watch carefully for the “flash” time—that’s the point where the carrier solvents evaporate—before gently leveling the residue and buffing the panel to reveal an incredibly slick, glossy surface.

The coating itself is obviously a huge part of the equation. We depend on our own lineup of professional ceramic coating products, each one engineered for superior hardness, gloss, and durability to meet different protection goals.

Stage 4: Curing for Maximum Performance

The final step is arguably the most important for the coating’s long-term survival: the cure. Right after application, the coating is still chemically active, hardening and cross-linking with the vehicle’s clear coat. To get this just right, we often use infrared (IR) curing lamps to gently accelerate the process, applying controlled heat to each panel.

This IR-assisted curing solidifies the coating into its final, glass-like state, locking in the gloss, chemical resistance, and water-beading properties from the get-go. After this, the vehicle needs to stay dry and clean for at least 24-48 hours while the cure fully completes. It takes a little patience, but the result is a durable, protective shield that will keep your new car looking incredible for years.

Keeping Your Ceramic Coated Car Looking Its Best

Let’s be clear: one of the best things about ceramic coating a new car is how ridiculously easy it makes cleaning. That slick, hydrophobic surface means dirt and road grime have a tough time sticking around. But “low-maintenance” isn’t the same as “no-maintenance.” To keep that coating working hard for years to come, you’ll need a simple, safe wash routine.

Proper care is all about protecting your investment. It preserves the coating’s defensive layer and makes sure that deep, wet-looking gloss stays front and center. The great news? It doesn’t take much—just the right approach and the right products.

The Do’s of Ceramic Coating Maintenance

The golden rule here is simple: be gentle. Your coating is incredibly tough, but it’s not made of diamonds. The whole point is to get rid of contaminants without accidentally creating swirl marks or harming that protective layer.

- Stick to the Two-Bucket Wash Method: This is non-negotiable for safe car washing. You’ll have one bucket with your car shampoo and another with plain water for rinsing. Wash one panel, then rinse your wash mitt thoroughly in the clean water before dipping it back in the soap. This tiny step is your best defense against dragging grit across the paint, which is how most swirl marks are born.

- Use a pH-Neutral Shampoo: Aggressive, high-alkaline, or acidic soaps are the enemy of a ceramic coating. They can slowly eat away at the surface. A good, pH-neutral car shampoo is designed to lift dirt without stripping your protection, keeping the coating healthy and the water beading like crazy.

- Dry with a Plush Microfiber Towel: Letting your car air-dry, especially in the sun, is a recipe for ugly water spots from mineral deposits. Instead, grab a high-quality, ultra-soft microfiber drying towel. Gently pat the panels dry or use a light drag-and-dry technique. No aggressive rubbing needed.

What to Avoid with a Coated Vehicle

Knowing what not to do is just as important as knowing what you should. A few common mistakes can seriously handicap your coating’s performance, so it’s best to avoid them entirely.

The single biggest threat to any ceramic coating is abrasion. Automated car washes with their giant, spinning brushes are public enemy number one. Those brushes are loaded with dirt from every car that went before you, and they will absolutely inflict micro-scratches, dull the finish, and damage the coating.

This is exactly why hand-washing is the only way to go. You should also stay away from abrasive polishes, compounds, or any old-school carnauba waxes. These products weren’t made to play nice with a ceramic surface and can clog the pores of the coating, killing its hydrophobic properties.

Boosting Performance with Maintenance Sprays

Want to keep your coating performing like it was just applied? A dedicated maintenance spray, used every few months, is the perfect tool for the job. These products are specifically formulated to refresh and rejuvenate the coating’s surface.

Think of it as a booster shot for your paint protection. These sprays lay down a fresh, slick layer that amps up the water-beading and adds a noticeable pop of gloss. Our maintenance products are built on Dark Matter Technology® principles, so they bond seamlessly with the existing coating to extend its life and performance. It’s a simple step that takes maybe ten minutes after a wash but makes a massive difference in long-term durability.

It’s no secret that people are catching on to long-term paint protection. In fact, the global ceramic coating market, valued at USD 12.15 billion, is expected to skyrocket to USD 25.60 billion by 2034. This explosion in growth shows just how much new car owners want to simplify maintenance and protect their vehicle’s value. You can read more about the rising trends in the ceramic coating market. By following these straightforward maintenance tips, you’re making sure your investment stays right at the front of that trend.

Answering Your Toughest Ceramic Coating Questions

It’s completely normal to have a few questions before you decide to invest in a professional ceramic coating, even after you understand the benefits. To help you feel confident about protecting your new car, we’ve gathered the most common questions we get from owners and provided some straight, honest answers.

Will A Ceramic Coating Stop All Scratches And Rock Chips?

This is easily the question we hear most, and it’s important to set the right expectations. A top-tier ceramic coating, especially one powered by our Dark Matter Technology®, adds a substantial layer of hardness to your paint. This benefits you by brilliantly resisting the fine swirl marks and light scratches that inevitably happen during regular washing.

But let’s be clear: a coating isn’t a suit of invincible armor. It’s a sacrificial layer designed to take the hit so your paint doesn’t have to. It won’t stop a deep, intentional key scratch, and it won’t repel a rock flying at you on the highway.

Think of a ceramic coating like the high-end, scratch-resistant crystal on a luxury watch. It keeps the face looking perfect through daily wear and tear, but a sharp, direct impact can still cause damage. For genuine impact defense against rock chips, Paint Protection Film (PPF) is the real champion.

For the absolute best protection, many owners go for a “best of both worlds” approach. They have a professional install PPF on high-impact zones—like the front bumper, hood, and mirrors—and then layer a ceramic coating over the entire vehicle. This combo gives you incredible chemical resistance, that signature gloss, and true peace of mind against road debris.

How Long Does A Professional Ceramic Coating Really Last?

Durability is a huge deal, and there’s a massive gap between what you can buy off the shelf and a professional-grade system. A DIY spray might give you a few months to maybe a year of performance. In contrast, our professional Titan Coatings are engineered for the long haul, with certified options lasting anywhere from 3 years to over 10 years.

The actual lifespan of your coating really boils down to three things:

- The Coating Itself: Our formulas are designed to create a permanent, covalent bond with your car’s clear coat. With the right care, our premier coatings can honestly last the lifetime of the car.

- The Prep Work: We can’t stress this enough—the prep is everything. Flawless paint correction and surface preparation are non-negotiable for creating the strongest possible bond and unlocking the coating’s full potential.

- Ongoing Maintenance: A safe washing routine is your best friend. Simple, regular hand washing with a pH-neutral soap is all it takes to maintain the coating’s protective qualities and insane water-beading.

Should I Let The Dealership Apply A Ceramic Coating?

It might sound convenient to have the dealership handle it, but this is almost always a bad deal. The coatings offered at dealerships usually come with some serious downsides that just aren’t worth the price tag.

For starters, they often use cheaper, private-label products that simply can’t compete with the performance and durability of a true professional-grade coating. Even more critical is the application process. Dealership staff rarely have the specialized training, let alone the time, for the meticulous paint correction a brand-new car needs.

Dealerships work on volume. Their “detailer” is often given just a few hours to prep and coat an entire car, which is nowhere near enough time to do the job correctly. They end up rushing, which means they’re often sealing in the very same factory defects and transit marks you wanted to get rid of. A dedicated professional detailer, on the other hand, will invest days—not hours—to make sure your car’s finish is absolutely perfect before a single drop of coating is applied. Choosing a certified installer is an investment in genuine expertise, superior technology, and a result that speaks for itself.

Can I Just Apply A Professional Coating Myself?

There’s a world of difference in the chemistry and skill required to apply a consumer-grade product versus one of our professional-only coatings. The DIY products you see in auto parts stores are designed to be user-friendly, but that forgiveness comes at the expense of performance and longevity.

Our professional coatings contain a much higher concentration of active ingredients like silica dioxide (SiO₂) and our own proprietary polymers. This is what makes them so tough, but it also makes them incredibly unforgiving to apply. They demand a controlled environment with specific temperature and humidity levels to cure properly.

Trying to apply a pro-level product without the right training is a recipe for disaster. We’ve seen it all:

- High Spots: These are dark, streaky patches of unevenly applied coating that weren’t leveled correctly. Once cured, they are extremely difficult to fix.

- Premature Flashing: In the wrong conditions, the coating can start to cure almost instantly, making it impossible to level out and buff to a smooth, uniform finish.

- Poor Bonding: Without perfect surface prep, the coating simply won’t stick correctly, leading to it failing way ahead of schedule.

For a new car, investing in a professional application is the only way to guarantee the flawless finish and long-term protection you’re paying for. It ensures the advanced technology in the bottle is matched by the skill of the person applying it.

Your new vehicle is a major investment, and it deserves the most advanced protection you can give it. At Titan Coatings, we engineer military-grade formulas to provide a superior shield, ensuring your car stays looking incredible for years to come.

Explore our world-class ceramic coatings and find a certified installer near you.

0 Comments