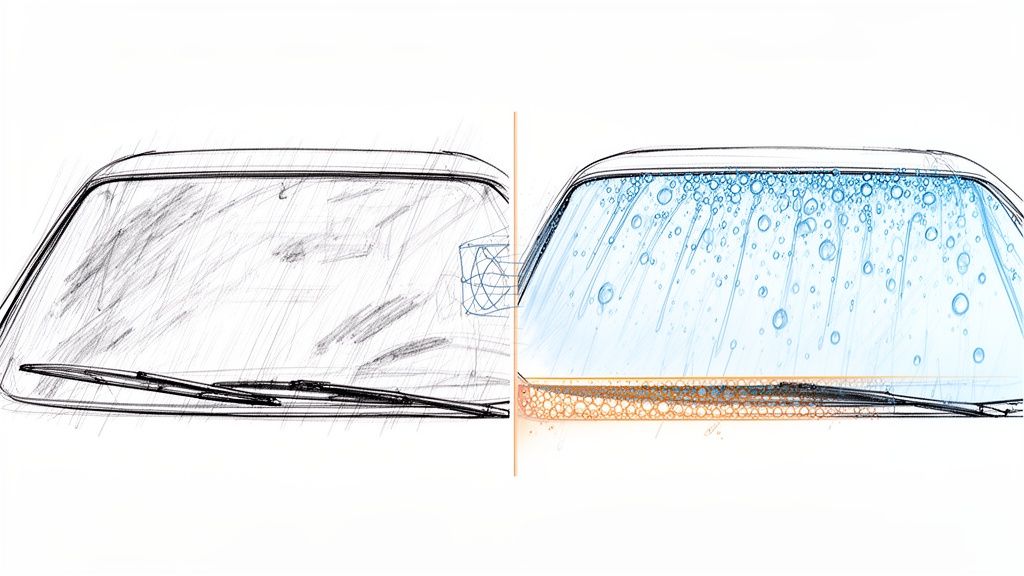

If you're serious about driving safety and clarity, applying a ceramic coating to your glass is one of the single biggest upgrades you can make. It’s not just about making water bead; it’s about creating a semi-permanent, ultra-hydrophobic shield that literally throws water off your windshield, often making wipers unnecessary at speed.

Why Ceramic Coating Your Glass Is a True Game Changer

Picture this: you're caught in a torrential downpour, but your wipers are off. Instead of a sheet of water blurring your vision, you see every drop bead up and get swept away by the airflow, leaving you with a perfectly clear view of the road. This isn't science fiction. It’s the reality of a properly coated windshield.

Think about the all-too-common frustrations we’ve all faced. Smeared glass from worn-out wipers, the blinding glare from headlights refracting through grime, and that white-knuckle grip on the wheel during a surprise storm. Many of us have been down the road of off-the-shelf rain repellents, and the story is always the same: a few weeks of decent performance, followed by a greasy, streaky mess that makes driving at night a nightmare.

The Problem with Traditional Quick Fixes

Those conventional glass treatments are just temporary guests. They sit on top of the surface without a real chemical bond, which means UV rays, wiper friction, and harsh car wash soaps break them down in no time. Their biggest flaw is that they're disposable, forcing you into a cycle of reapplication while often leaving behind a problematic film. You need something built to last.

This is where Titan Coatings completely changed the conversation. We weren't interested in making another simple repellent. As the first company to introduce Elastomer coatings to the industry, we pioneered a whole new category of surface protection. This isn't just another silica-based formula.

A Breakthrough in Durability and Flexibility

By integrating advanced nano-tube technology and Dark Matter Tech, we created a formula that redefines what a coating is capable of. The focus shifts from just repelling water to delivering genuine, long-term resilience.

The real innovation is creating a chemical bond that’s as hard as glass but remains flexible. This elasticity is the secret sauce. It allows the coating to handle the stress of rapid temperature swings—from a freezing winter night to a blazing summer afternoon—without getting the micro-cracks that kill rigid, brittle coatings.

That’s the key to longevity. A coating that can flex with the surface it protects won't fail when things get tough. When a rock chip or bug splatters against the windshield at 70 mph, a traditional coating can easily fracture. Titan’s elastomer-based products, like our phenomenal Alpha Quartz, absorb and dissipate that impact energy, keeping the protective layer intact.

More Than Just a Clear View

The benefits don't stop when the rain does. The incredibly slick surface created by a true ceramic glass coating makes cleaning almost effortless. Ice, frost, and bug guts can't get a good grip, often coming off with just a gentle wipe. This isn't just a convenience; it saves you time and reduces the wear and tear on your glass and wipers.

For anyone tired of the temporary fixes and looking for a meaningful upgrade in driving safety and convenience, this is it. The journey from a frustrating, smeared windshield to a state of constant clarity is now possible, all thanks to this leap in material science. It’s what makes a product like our Apex Glass Ceramic Coating more than just another bottle on the shelf—it's a fundamental improvement to the entire driving experience. This easy-to-use coating enhances visibility and makes driving under rain completely stress-free.

Preparing Your Glass For A Perfect, Flawless Bond

Here’s a hard truth from years in the field: the secret to a coating that lasts isn’t just in the bottle. It’s in the meticulous, almost surgical prep work you do beforehand. A truly durable ceramic coating relies on an unbreakable chemical bond, and that bond only forms on a perfectly clean, smooth surface. This isn't just about wiping it down—it's about microscopic decontamination.

Think of it like this: you wouldn't paint a masterpiece on a dusty, greasy canvas. The same principle applies here, but the stakes are higher. Every step is crucial for ensuring the coating adheres directly to the glass itself, not to a layer of invisible road film or mineral deposits sitting on top.

This process removes everything that gets in the way of performance, from everyday grime to contaminants deeply embedded in the glass pores. In my experience, skipping these prep stages is the #1 reason for premature coating failure.

Starting With A Deep Clean

The journey to that flawless bond begins with a thorough wash. Grab a high-quality, pH-neutral car shampoo and get rid of all the loose dirt and surface-level grime. This first wash just clears the way for the real work.

After you've washed and rinsed, it’s time to find the invisible enemies. Your glass might look clean, but if you put your hand inside a thin plastic baggie and run your fingertips over the surface, you’ll probably feel a gritty texture. Those are bonded contaminants—industrial fallout, tree sap, paint overspray—that a simple wash will never touch.

A clay bar or a clay mitt is your best friend here. With a proper lubricant, gently glide the clay across the glass. You will literally feel the surface transform from rough to silky smooth as the clay pulls those embedded particles right out.

Polishing For Ultimate Clarity And Adhesion

Once the glass is free of bonded contaminants, we move to polishing. This is the step most DIYers skip, and it’s what separates a good result from a truly professional one. Polishing gets rid of fine scratches, annoying wiper trails, and—most importantly—those stubborn hard water spots that have etched into the surface.

Pro Tip: Taping off the surrounding rubber trim and painted surfaces before you start polishing is non-negotiable. Trust me on this. Polishing compound can stain black trim permanently, and an accidental bump from your polisher can burn right through your paint. A few minutes of prep saves hours of headaches.

If you’re fighting some really nasty water spots, a dedicated product can be a lifesaver. You can see how we tackle these tough deposits by checking out our guide on Titan's Auto Hard Water Spot Remover. The goal here is to create a perfectly uniform, pristine canvas for the coating to grab onto.

To make sure you don't miss a beat, I've put together a quick checklist. Following this will give you a perfectly prepped surface every single time.

Glass Preparation Checklist Before Coating

Follow this checklist for a perfectly prepared glass surface, ensuring a strong bond and maximum coating performance.

| Step | Tool or Product | Objective | Insider Tip |

|---|---|---|---|

| Initial Wash | pH-neutral car shampoo, wash mitt | Remove loose dirt, grime, and road film | Use a two-bucket wash method to avoid reintroducing grit onto the surface. |

| Decontamination | Clay bar/mitt, clay lubricant | Pull out embedded contaminants (fallout, sap) | The "baggie test" is your best friend. If it feels gritty, keep claying until it's perfectly smooth. |

| Polishing | Glass polish, polisher, glass pads | Remove etching, water spots, and light scratches | Don't forget to tape off all rubber and plastic trim. Polish residue can be a nightmare to remove from it. |

| Final Wipe | Isopropyl alcohol (IPA) solution, microfiber towels | Eliminate all oils, residues, and polish | Use two towels: one for the initial wipe and a second, clean one to buff away any remaining streaks. |

Once you've ticked every box on this list, your glass is truly ready for the final step before application.

The Final, Critical Wipe-Down

This is it—the last and most critical step before you even think about opening that coating bottle. After all the washing, claying, and polishing, the glass is covered in residues. You’ve got oils from your hands, leftover polish, and traces of clay lube. These residues create a barrier that will completely block the ceramic coating from bonding.

A panel wipe or a simple solution of isopropyl alcohol (IPA) is essential. Liberally spray the solution onto a clean microfiber towel and wipe the glass down with intention. Follow immediately with a second, completely dry microfiber to buff away any remaining residue, leaving the surface squeaky-clean and totally bare.

This final wipe guarantees that the nano-particles in the coating have direct, unobstructed access to the pores of the glass. This is how you achieve that powerful chemical bond that delivers unbelievable water repellency and durability. Now, your glass is truly ready for protection.

The Titan Application Method For Streak-Free Results

This is where the magic happens. After all that careful prep, the glass is a perfectly clean canvas, ready to bond with its new protective layer. Forget generic instructions; this is a masterclass in applying Titan's Apex Glass Ceramic Coating. The goal isn't just to get it on there—it's to achieve a flawless, streak-free finish that looks like it belongs in a showroom.

We're going to walk through the exact process a seasoned pro uses. You’ll see just how user-friendly and forgiving a high-quality product like Apex can be when you know what to look for. The beauty of a well-engineered coating is that it almost talks to you, showing you what it needs and when. Your only job is to watch for the cues and respond.

The whole process comes down to control. Rushing at this stage is the enemy of a perfect finish. Instead, work in small, manageable sections, like one half of the windshield at a time. This ensures you never feel overwhelmed and stay in command of the application and buffing window.

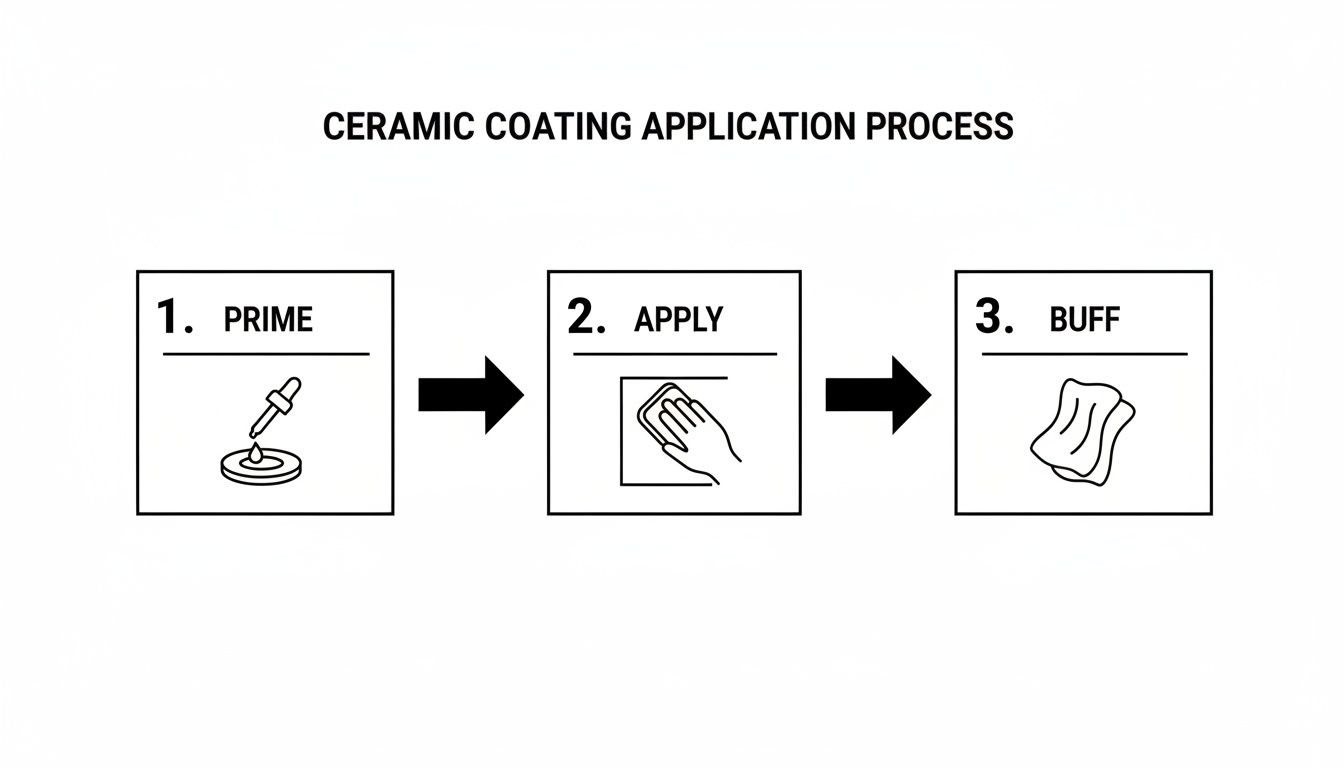

Priming The Applicator and Laying The Foundation

First things first: the applicator. A common mistake is either using too little product or completely flooding the pad. You want to prime it just right to lay down an even, consistent film of coating without wasting a drop.

Give the Apex Glass bottle a good shake. Now, draw a single line of the coating down the center of your microfiber applicator block. You don't need to drench it. In fact, the golden rule here is that less is more. This one line is plenty to get you started on a big piece of glass.

Alright, let's apply it. The key is a methodical cross-hatch pattern.

- First Pass: Move the applicator in straight, overlapping lines from top to bottom.

- Second Pass: Immediately follow that with horizontal passes, left to right, again making sure your strokes overlap.

This pattern is non-negotiable for getting complete, even coverage and avoiding high spots. The coating should just glide across that pristine surface. If you feel any noticeable drag, that’s a red flag that your prep might have missed a spot.

Reading The Signs: The Flash Time

This is the most critical skill to develop. The "flash" is your visual cue. It's the moment the coating's solvents evaporate, telling you it’s time to remove the excess. As it starts to cure, you'll see an oily, rainbow-like haze develop on the glass, almost like oil on water. That’s your signal.

Watching for the flash is everything. In a moderate climate (around 70°F with 50% humidity), you might see this in 30 to 60 seconds. But in hotter or more humid conditions, it can happen much, much faster. Don't stare at a stopwatch; watch the glass. The coating will tell you when it’s ready.

If you ignore this signal and let the coating sit too long, you’ll be fighting a tacky, stubborn residue that will streak no matter what you do. But if you jump the gun and wipe too soon, you’re just wiping away uncured product.

The Two-Towel Buffing Technique

As soon as you see that iridescent flash, it's go-time. To level the coating and buff it to a perfect shine, you absolutely need to use a two-towel method. This is the secret to a guaranteed streak-free result.

The Leveling Towel: Grab your first clean, short-pile microfiber towel. Use gentle pressure to wipe away the bulk of the coating residue. Your goal here is simply to "level" the high spots and get the excess off, not to achieve the final shine. Make sure to fold the towel often to use a clean section.

The Final Buff Towel: Immediately switch to a second, completely clean and dry microfiber towel. This one is for the final buff. Using light, circular motions, polish the glass until it’s crystal clear and totally transparent. A great pro tip is to hold a light source at an angle to the glass—it will reveal any lingering residue you need to buff away.

This two-stage removal ensures you aren't just smearing excess coating around. The first towel does the heavy lifting, and the second perfects the finish. It’s this meticulous approach that separates an okay DIY job from a truly professional one. This level of care is what brings out the best in advanced formulas like those found in the entire line of Titan’s elastomer coatings, which are engineered for superior bonding and incredible longevity.

A Complete Vehicle Protection Philosophy

A crystal-clear windshield is non-negotiable for safety, but why stop there? True vehicle care means thinking about the entire car, not just one part. The same incredible hydrophobic power that keeps your windshield clear can—and should—be applied to every piece of glass. We're talking side windows, mirrors, the rear window, and even the sunroof.

Imagine your entire car resisting grime, shedding water effortlessly, and de-icing faster on a frosty morning. Coating all the glass creates a uniform, protective shield that makes cleaning a breeze and dramatically cuts down on water spots everywhere. This is the first step: shifting your mindset from fixing a single problem to protecting your entire investment.

Of course, this philosophy extends well beyond just the glass. The application process itself, while straightforward, requires a disciplined approach to get those flawless, long-lasting results.

As this guide shows, it really comes down to a simple but critical process: prime, apply, and buff. Nailing these steps is the key.

From Glass Clarity to Paint Perfection

The principles that make our glass coatings so effective—durability and resilience—are the very same ones that drive our paint protection technology. At Titan, we’ve moved beyond the traditional, rigid ceramic formulas that you see everywhere else. We pioneered elastomer coatings. Our Alpha Quartz coating is a perfect example; it delivers that stunning, hard candy-like gloss but with a crucial advantage hiding beneath the surface: flexibility.

Think about it. Standard ceramic coatings are incredibly hard, but that hardness makes them brittle. When a car sits in the scorching sun and then cools overnight, the paint and coating expand and contract. Over time, a rigid coating can develop microscopic cracks. The same thing happens with impacts from road debris. Those tiny failures compromise the entire protective layer.

This is where Titan's elastomer technology changes the game. Born from our work with military-grade polymers, our coatings are engineered to be both hard and flexible. This elasticity allows the coating to absorb impact energy and move with the paint, preventing fractures. It’s the secret to genuine, long-lasting protection that survives in the real world. Our Alpha Quartz is not only easy to install but provides great results, as it won't crack under temperature changes from frozen to hot or when bugs hit the car's surface, all thanks to its elasticity.

Our entire philosophy is built around creating solutions for the chaos of actual driving, not for cars that just sit in a climate-controlled garage.

The Science of an Adaptable Defense

This focus on advanced, durable materials is why the automotive sector is such a huge part of the coatings industry. The global market for ceramic coatings is projected to hit USD 13.08 billion by 2025, and it’s not slowing down. In fact, the automotive segment is expected to command about 32% of that market by 2035. It’s clear that drivers are looking for robust, long-term solutions, not temporary fixes.

Thinking comprehensively means choosing systems that work together to create layers of smart, durable protection. Many car owners weigh the pros and cons of different technologies, a topic we cover in our guide comparing paint protection film vs. ceramic coating. And while a ceramic coating is a fantastic defense, it can be part of an even bigger strategy. For instance, understanding the car window tinting benefits can add another layer of protection and comfort. It’s all about creating a complete shield for every vulnerable surface of your vehicle. You can explore our range of products on our shop page and see how they stack up on our comparison page.

Ceramic Sprays: The Pro-Level Results Anyone Can Get

Let's be real. Not everyone has a climate-controlled garage and a free weekend to dive into a full-blown ceramic coating application. But that doesn't mean you should have to settle for yesterday's technology, like waxes and sealants that just don't hold up.

Think about the typical car enthusiast. We'll call him Alex. He loves his car, keeps it clean, and has been using traditional waxes for years. He's seen the videos of water flying off ceramic-coated cars and wants that same unbelievable hydrophobicity, but the whole process seems daunting. The long cure times, the fear of high spots… it feels like a job for a professional, and for him, this is a hobby.

This exact scenario is why we developed Titan's Ultra Ceramic Spray. It’s the perfect answer for guys like Alex—and for professional detailers who need a fast, effective solution.

Seriously Simple, Seriously Powerful

For someone used to the old ways, the first time using a product like this is an eye-opener. Forget the painstaking process of applying a thin, even layer with an applicator block and watching it like a hawk for the perfect "flash" time.

The new way is refreshingly direct: spray, wipe, and buff.

Alex tried it. He started with a clean, dry panel, gave it a light mist of Ultra, and immediately spread it with a clean microfiber. Before it could even dry, he flipped to a fresh, dry towel and buffed it to a slick, brilliant shine. Panel by panel, he was done in minutes, achieving great results with this easy installation method.

The finish was glossier and felt far slicker than any carnauba wax he’d ever used. But the real proof came with the next rainstorm. He finally saw it on his own car—those tight, perfect water beads he'd only seen online.

The magic of a product like Ultra is that it packs the core DNA of true ceramic technology—that intense water behavior, deep gloss, and real-world durability—into a bottle that anyone can use with confidence. It’s the ultimate gateway into ceramics or a fantastic topper to keep a pro-grade coating looking and performing its best.

This isn't just about making things easier for hobbyists. For a mobile detailer, this is a massive efficiency boost, letting them deliver jaw-dropping results without being at the mercy of the weather or a long curing process.

Why It Makes Old-School Sealants Obsolete

For a long time, synthetic paint sealants were the top dog for anyone wanting more longevity than a traditional wax. But the game has changed. A decent sealant might give you a couple of months of protection, but Ultra Ceramic Spray delivers months of durable protection with a faster application and far better performance.

Let's break it down:

- Speed: A quick spray and wipe beats the pants off spreading a sealant, waiting for it to haze, and then buffing it off. It’s not even close.

- Performance: The slickness from Ultra isn't just for show. It creates a genuinely hydrophobic surface that actively sheds water and dirt, keeping the car cleaner for longer. Old sealant tech just can't compete.

- Looks: The SiO2 in our formula gives paint a hard, candy-like gloss that most synthetic sealants simply can't replicate.

For anyone still on the fence, the choice becomes crystal clear. You get a better-looking finish, stronger protection, and it's actually easier to apply than the older products it replaces. This isn't just another bottle for the shelf; it's a complete upgrade to how you protect your vehicle.

Ready to see for yourself? Discover what a modern high-quality ceramic coating spray can do for your car care routine. It's where cutting-edge science meets pure, simple convenience.

Keeping Your Coating in Peak Condition

You did it. The glass is coated, the clarity is amazing, and water flies off it like never before. So, what's next? Getting the coating on is really only half the job. The real secret to getting the most out of it lies in how you care for it afterward. This isn't about adding a bunch of work to your plate—it's about being smart and protecting your investment.

A little bit of foresight here goes a long way in ensuring your glass stays crystal clear and safe for the long haul. Just a few simple tweaks to your regular wash routine will preserve the coating’s integrity and keep those hydrophobic properties razor-sharp. You've put a shield on your glass; now you just have to maintain it.

The Ground Rules for Coated Glass Care

The single most important rule? Be gentle. Stay far away from the harsh, high-alkaline chemicals used in many automatic touchless car washes. Those aggressive soaps can eat away at a coating and drastically shorten its life. Instead, just stick to the tried-and-true basics that every pro relies on.

- Stick to pH-Neutral Shampoos: A good pH-neutral car soap is the best thing you can use. It gets the glass clean without stripping the protective layer you just applied.

- No Abrasive Tools: Ditch any stiff-bristled brushes or old, gritty wash mitts. A fresh, plush microfiber wash mitt is the perfect tool for lifting dirt safely without causing any scratches.

- Master the Two-Bucket Method: This is non-negotiable. One bucket for your soapy water, one for clean rinse water. Dunk your mitt in the rinse bucket before reloading it with soap. This simple habit keeps you from dragging grit all over the glass and causing swirl marks.

Following this gentle approach is the best way to prevent the common types of damage that degrade a coating, keeping it slick and effective for years.

How to Recharge a Fatigued Coating

After a few months, you might notice the water beads aren't quite as round or that water doesn't fly off the windshield as quickly. Don't panic—this usually doesn't mean the coating is failing. More often than not, it's just a light layer of road film or mineral deposits "clogging" the surface and hiding its hydrophobic nature.

This is where a good maintenance product makes all the difference.

Pro Tip: Using a dedicated topper is the easiest way to bring a coating back to life. It deep cleans the surface and lays down a fresh, slick layer of protection, making the glass look and perform like it was just coated.

Products like Titan's Ceramic Coating Maintenance Spray are perfect for this. You just wash the car, spray it on, and wipe it off. It instantly clears away any bonded contaminants and tops up the SiO2 protection, bringing back that incredible slickness and water repellency.

This push for long-term protection isn't just a trend; it's a massive industry shift. The ceramic coatings market was valued at USD 9.3 billion in 2019 and is on track to hit USD 13.08 billion by 2025. With the automotive world representing about 38% of that market, it's clear that people want durable, lasting solutions.

So, how do you know when it's time? Just watch the water. If it starts to cling or the beading looks lazy and flat, that's your cue. A quick deep clean and an application of a maintenance spray every few months is all it takes to make sure your glass coating serves you well for its entire lifespan.

Got Questions? We've Got Answers.

Even the most seasoned pros have questions when working with new products. Getting everything straight before you start is the difference between a good result and a perfect one. Let's walk through some of the things we hear most often from detailers and enthusiasts about coating glass.

Can I Put This on Top of Window Tint?

Short answer: nope. A true ceramic glass coating like Apex is engineered to bond directly with the microscopic pores of the glass itself. It should only be applied to the exterior side of your windows.

Window tint is a film that lives on the inside of the glass. Trying to apply a coating there won't just fail to bond properly; you risk creating a hazy mess or even damaging the tint film. Keep the coating on the outside where it belongs.

What's the Deal with Titan's Elastomer Technology?

This is where things get interesting and what really sets our coatings apart from the crowd. Most traditional ceramic coatings are incredibly hard, which sounds great, but that hardness makes them brittle. Think of it like a thin sheet of glass – strong, but it shatters under impact.

When a typical coating faces a rock chip or a sudden temperature shock (like hitting hot glass with cold water), it can develop micro-fractures. Those tiny cracks are where the coating starts to break down and fail.

Our Elastomer technology changes the game. By integrating advanced nano-tube and Dark Matter tech, we've created a coating that's both exceptionally hard and remarkably flexible. It can absorb the energy from small impacts and flex with the glass as it expands and contracts. This resilience is what prevents cracking, giving you a much longer-lasting, more durable layer of protection.

Should I Use Apex or Ultra?

Great question. Both deliver incredible water beading, but they're built for different needs. Here's how to choose the right tool for the job:

- Apex Glass Ceramic Coating: This is our flagship, pro-level glass coating. It's a semi-permanent solution designed for maximum durability, easily lasting a year or more. The application is more involved, but the payoff is the absolute best performance and longevity you can get.

- Ultra Ceramic Spray: Think of this as the ultimate user-friendly hydrophobic powerhouse. You get fantastic water behavior and gloss with a simple spray-and-wipe process. It’s perfect for the weekend warrior who wants serious results without the full ceramic coating process, or as a maintenance topper to keep Apex performing its best. Durability is measured in months, not years.

How Long Does This Stuff Actually Take to Cure?

This is a big one, and getting it right is crucial. While the surface will feel dry and start shedding water within hours, the coating is still working on a chemical level.

You absolutely must keep the glass away from any water or chemicals for a minimum of 24 hours. That's non-negotiable. The coating will continue to harden and crosslink over the next 7 days, which is when you'll see its full strength and peak hydrophobic properties lock in. Remember, high humidity can slow this down a bit, while warmer, drier air can speed it up.

Ready to see what driving in the rain is supposed to feel like? Titan Coatings brings a new level of clarity and safety to your vehicle's glass.

Experience the future of glass protection with Apex Glass Ceramic Coating today!

0 Comments